How to choose CNC laser cutting systems?

Choosing a new CNC laser cutter is a major decision. A wrong move costs you money and time. But the right choice can transform your entire production line.

The best way to choose a CNC laser cutting system is to first define your specific material and production needs. Then, evaluate systems based on total cost of ownership, software simplicity, and automation capabilities, not just the initial price. Finally, confirm the manufacturer offers reliable, long-term support.

I’ve spent over a decade in this industry, and I’ve seen firsthand how a single machine can make or break a business. This decision is about more than just technology; it’s about your future profitability and competitive edge. So, let’s walk through the process step-by-step to ensure you make an informed choice that pays dividends for years to come.

How can you identify the specific needs of your manufacturing process?

You need to upgrade, but the options are overwhelming. This uncertainty leads to delays or bad investments. The first step is to clearly map your exact production requirements.

To identify your needs, analyze the types of materials you process, their maximum thickness, the precision required, and your daily production volume. This foundational step ensures you don't overspend on unnecessary features or under-equip your team for future growth.

To dive deeper, you must look beyond your current projects and consider your goals for the next five years. Many plant managers I speak with focus only on the immediate job, but the real value comes from investing in a system that can grow with you. At MZBNL, we always start by asking about the business, not just the machine.

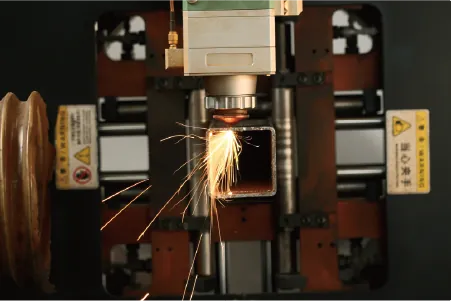

Assess Your Materials and Workflow

First, list every material you cut—stainless steel, aluminum, copper—and note the thickest gauge for each. This will determine the laser power you need. But don't stop there. Think about your entire workflow. Where are the bottlenecks? I remember a client in the furniture industry who was fixated on cutting speed. After visiting his plant, I saw the real problem was the time it took his engineers to create CAD drawings for custom orders. His true need wasn't a faster laser; it was a simpler process.

Define Your Operational Pains

Are high labor costs a problem? Is finding skilled operators difficult? Is material waste eating into your profits? Be honest about these challenges. These are not just operational headaches; they are key criteria for your new machine. A system that solves these core business problems will deliver a much higher return on investment.

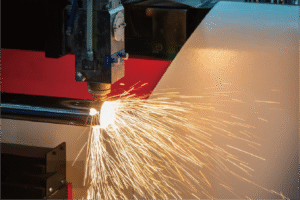

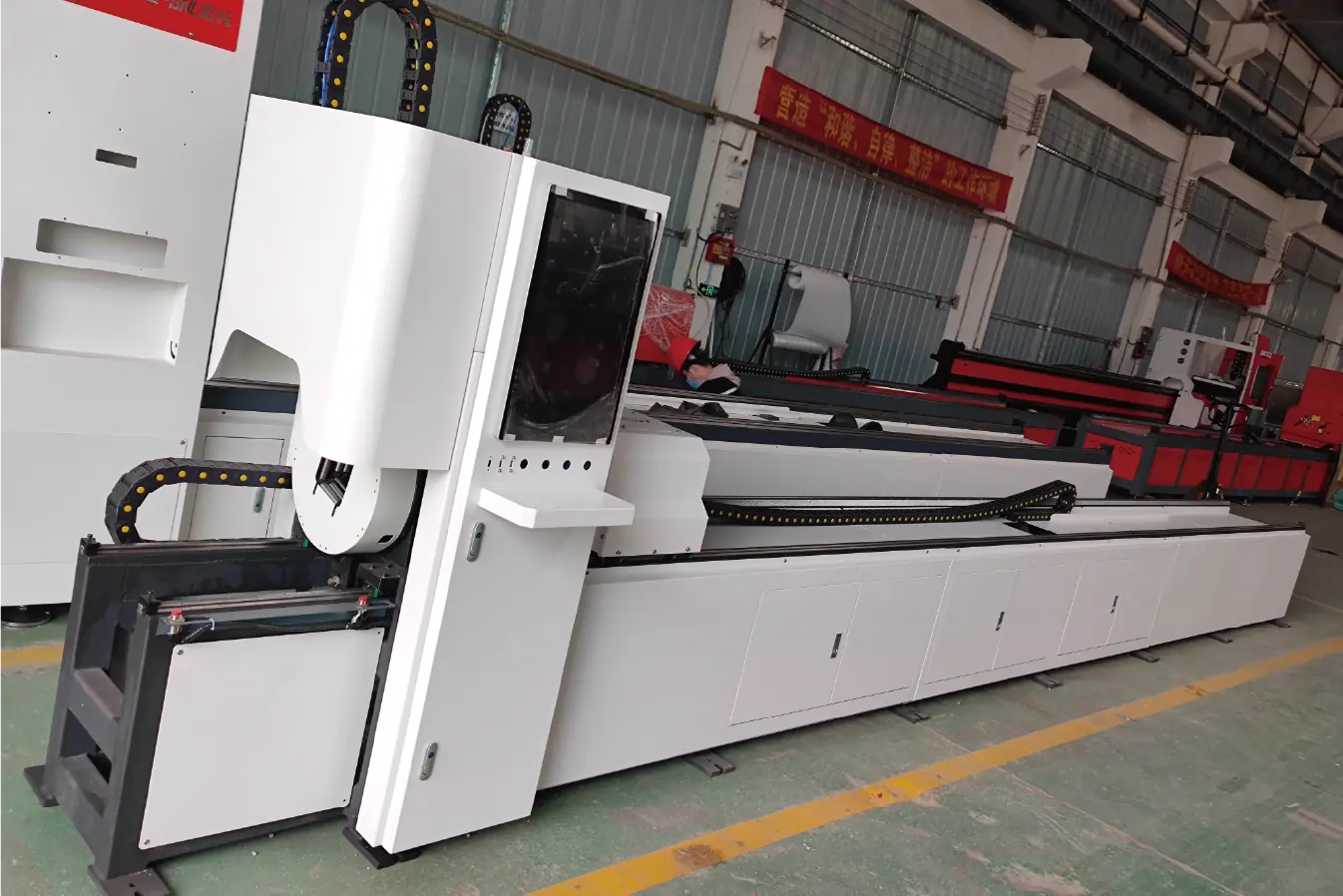

How should you evaluate different types of CNC laser cutting systems?

Fiber laser, CO2 laser, automation features... the jargon is confusing. Choosing the wrong type of system can lead to poor performance and wasted material. We can clarify the key differences.

Evaluate systems by comparing the laser source, automation features, and software usability. Our MZBNL systems, for example, feature a No-CAD interface that eliminates the need for complex drawing skills, drastically simplifying operations and reducing training time.

Diving deeper, the choice is not just about the laser itself, but the entire ecosystem around it. The industry is moving rapidly toward intelligence and automation. A machine that only cuts metal is no longer enough. You need a system that streamlines your entire production from design to finished part.

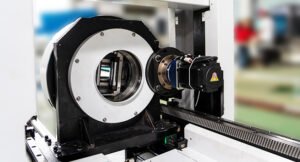

The Power of Simplified Software

The biggest hidden cost in manufacturing is often complexity. We recognized this early on. That's why we developed our No-CAD system. It allows an operator to program a complex cut directly on the machine without ever touching CAD software. This single innovation reduces the skill threshold so dramatically that we can train a new operator in a single day, not weeks. For our clients in automotive parts manufacturing, this has been a game-changer for addressing the skilled labor shortage.

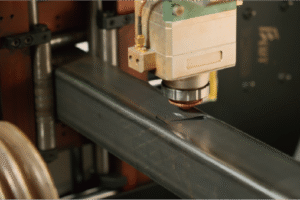

Efficiency-Boosting Hardware

Look for features that reduce manual intervention and maximize uptime. Here are a few things we've engineered into our machines to solve common problems:

- Front-End Feeding: This allows for continuous operation, minimizing downtime between material loads.

- Zero-Waste Cutting: Our intelligent software optimizes cutting paths to ensure virtually no material is wasted, directly impacting your bottom line.

- Automated Unloading: This separates finished parts from scrap, reducing manual labor and preparing parts for the next stage of production.

These features are what separate a modern, intelligent system from an outdated one.

What cost implications and budget constraints should you consider?

The initial price tag on a new machine can be intimidating. But hidden operational costs can make a "cheaper" machine far more expensive over its lifetime. We believe in looking at the total cost.

Consider the total cost of ownership (TCO), not just the purchase price. This includes operational costs, material utilization, labor expenses, and maintenance. A system with zero-waste cutting and one-day operator training delivers a much faster ROI.

When you dive deeper into the numbers, the most expensive machine is often the one that sits idle or requires a highly paid specialist to run. As a General Manager, I am always focused on ROI. The true value of a machine is measured by how quickly it pays for itself and starts generating profit. That’s why we design our systems to attack the biggest hidden costs in production.

A Clear Comparison

Let's look at how a modern system stacks up against a standard one. The initial investment might be different, but the long-term value is what matters.

| Cost Factor | Standard CNC Machine | MZBNL Intelligent System |

|---|---|---|

| Operator Training | 2-3 Weeks | 1 Day |

| Material Waste | 5-10% | <1% (Zero-Waste Tech) |

| CAD Specialist | Required | Not Required (No-CAD) |

| Setup Time | High | Minimal |

As you can see, the savings in labor, training, and materials quickly compound. A machine that saves you money every single day delivers a powerful and rapid return on your investment. This is how you strengthen your competitive advantage in a tough market.

Why is it crucial to assess manufacturer support and maintenance?

Your new machine is down. Production has stopped, and you're losing money every hour. The manufacturer is unresponsive. This is a common and costly nightmare that we work hard to prevent.

Assess manufacturer support by checking their response times, parts availability, and training programs. Reliable after-sales service is not a bonus; it is an essential part of your investment to maintain uptime and ensure long-term profitability.

To dive deeper, you must understand that when you buy a machine, you are also entering a long-term relationship with the manufacturer. At MZBNL, we don't just sell machines; we build partnerships. We are an ISO-certified company, and our commitment to quality extends from our factory floor to your facility. We know that our success is directly tied to our clients' ability to run productively and profitably.

What to Look For in a Partner

I once got a call from a client in a remote area whose machine went down on a Friday afternoon before a critical deadline. Our team worked through the weekend to diagnose the issue remotely and shipped the necessary part overnight. The client was back up and running by Monday morning. That is the level of commitment you should expect.

Key Support Pillars

- Comprehensive Training: Does the manufacturer provide hands-on training that empowers your team to operate and maintain the machine confidently?

- Global Parts Network: How quickly can they get you spare parts, no matter where you are located? Downtime is expensive, and waiting for parts is unacceptable.

- Responsive Technical Team: Can you get a knowledgeable expert on the phone quickly to help you troubleshoot a problem?

A manufacturer who invests in these areas is a partner who is invested in your success.

How do you make an informed decision using performance metrics and reviews?

You have all the data, but you're still uncertain. Making the final call is stressful. Using a final checklist can provide the clarity you need to make a confident decision.

Make your final decision by comparing performance metrics like cutting speed and precision. But more importantly, validate these claims with real-world case studies and testimonials. The best indicator of future success is a manufacturer's proven track record with businesses like yours.

Diving deeper, the numbers on a specification sheet only tell part of the story. The most important metric is proven success in the field. With over 30 patents and more than 4,000 clients globally, we have built our reputation on delivering tangible results. I always encourage potential clients to look beyond the brochure and ask for real proof.

Ask for a Demonstration

The best way to evaluate a machine is to see it in action, cutting your own parts from your own designs. This removes all doubt and shows you exactly what the machine can do for your specific application. A confident manufacturer will always be happy to provide this.

Talk to Existing Customers

Ask for references from companies in your industry. Are they happy with the machine's performance? What has their experience been with the support team? Hearing directly from a fellow plant manager is often the most valuable insight you can get. We are proud of the relationships we have built in sectors from sanitary ware manufacturing to institutional facility equipment, and we believe our clients' success speaks for itself. Your goal is to find a system that not only meets your technical needs but also comes from a partner you can trust for years to come.

Conclusion

Choosing a CNC laser cutter is a major strategic decision. By focusing on your true needs, total cost of ownership, and manufacturer support, you invest in more than a machine. You invest in higher efficiency, reduced costs, and a long-term competitive advantage for your business.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.