Laser Intelligence Simplified

Since 2010, we've turned breakthrough ideas into everyday productivity for 4,000+ manufacturers worldwide.

Our Story – Milestones Timeline

From pioneering semi-automatic technologies to leading the way in intelligent laser processing, discover the key moments that shaped Mingzhou Intelligent Equipment into a global leader in tube processing innovation.

Company founded in Foshan, China – First hydraulic punching machine launched

Our founders leveraged 25+ years of metal tube processing expertise to develop a semi-automatic hydraulic punching machine with ±0.1mm accuracy and 3000 holes/day capacity — tripling traditional efficiency.

Automation Era Begins – First and second-generation CNC lines introduced

We launched our first fully automatic CNC punching line, integrating feeding, positioning, and punching. By 2015, our second-generation line with smart inspection boosted output by 80%, achieving 120 pcs/hour.

Product Diversification & Intelligent Integration

Introduced specialized CNC machines, smart loading systems, and multi-line automation—recognized as a High-Tech and "Specialized & Innovative" Enterprise.

Laser Breakthrough – Launched "Drawing-Free" Smart Laser Cutting Machine

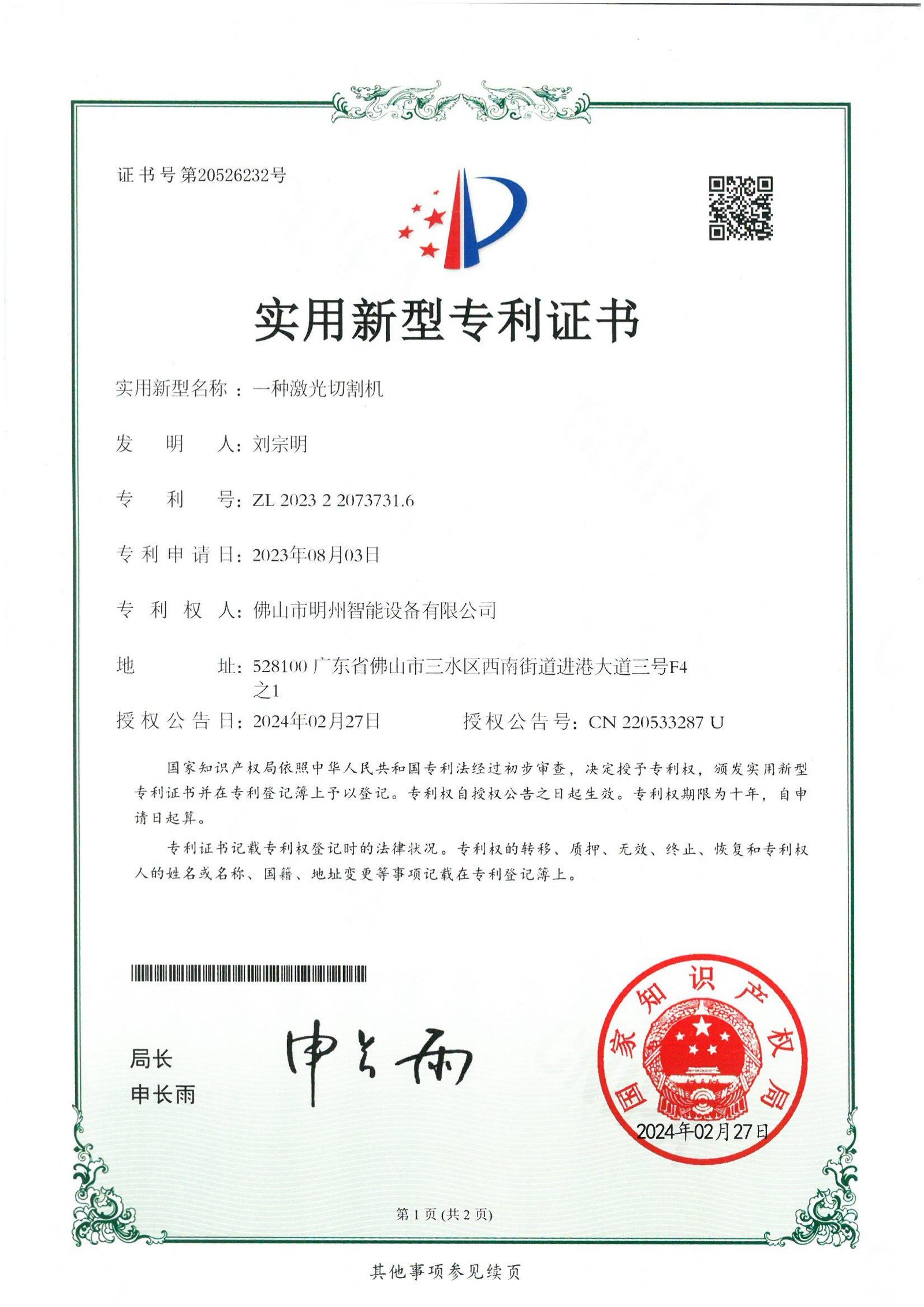

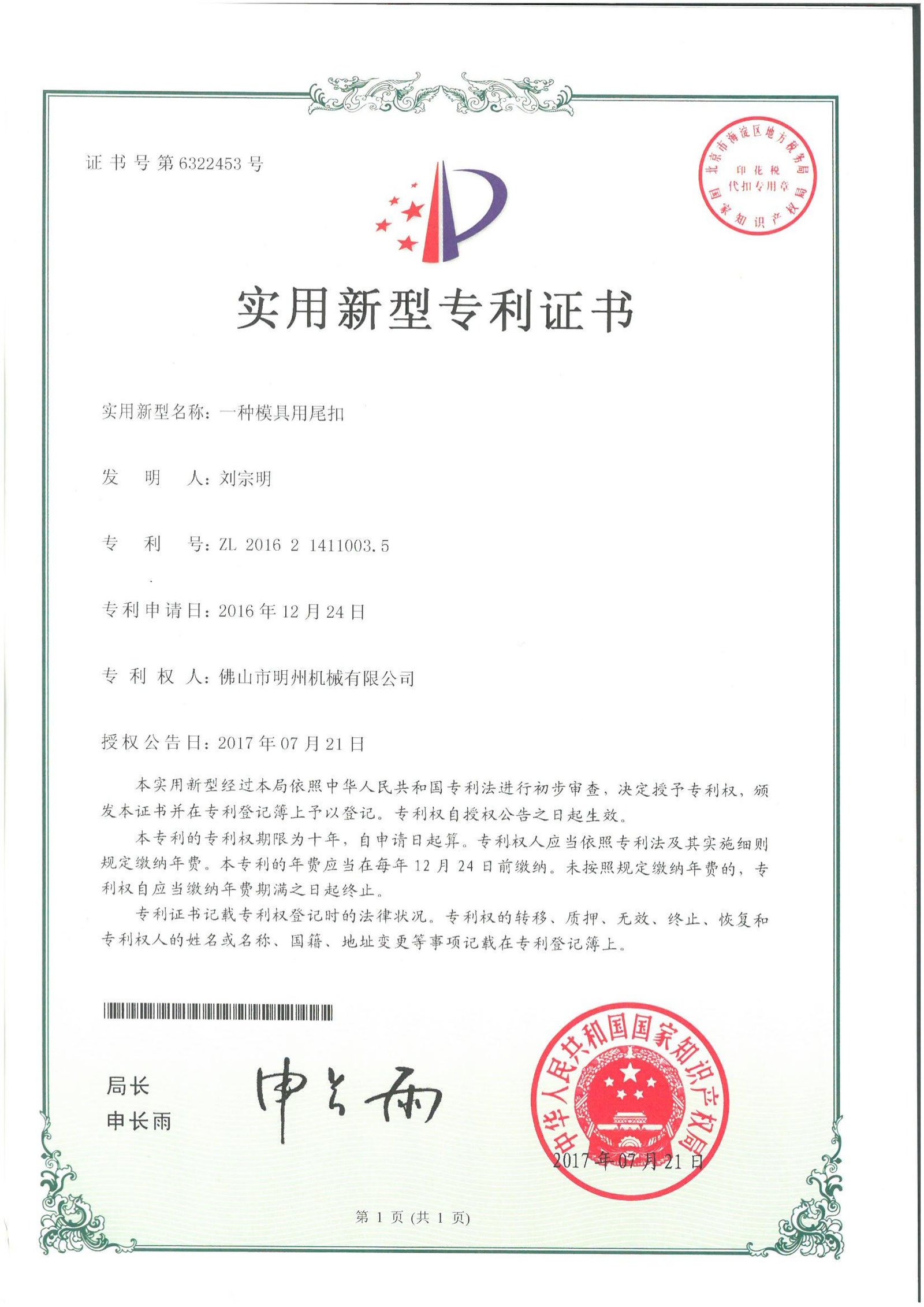

Entering the laser processing field, we introduced a patented machine featuring visual positioning and smart programming — no CAD skills required. Over 30 patents granted, including multi-chuck synchronization.

Revolutionized Material Feeding – Front-Pull Automatic Loading

Our next-gen loading system outperformed traditional rear-feeding:30% increase in loading speed 40% reduction in operator workload Single-machine capacity exceeded 600 tubes/day

Breakthrough in Scrap Reduction – Tail-End Optimization

We pioneered the "Rear-Chuck Origin Algorithm", reducing tail scrap from the industry average of 150mm to just 40mm — a major leap in cost-efficiency.

Achieved True Zero-Waste Cutting

Our patented Zero-Tail Cutting System features:Innovative front-chuck clamping desig,Realized true zero-tail processing,First adopted in:Elevator rail production,Medical tube manufacturing,Automotive exhaust pipe systems

Our Mission

Make advanced laser tube-cutting simple, smart, and sustainable for every factory.

Our Vision

To be the world's most trusted partner in intelligent tube-processing — powering a greener industrial future.

Innovation Driven

Cutting-edge technology for modern manufacturing

Global Reach

Serving factories worldwide with excellence

Sustainability Focus

Building a greener industrial tomorrow

Core Innovations

No-CAD Quick Start

Start cutting in minutes — import common profiles directly, no drawing needed.

Front-Feeding Speed

Servo-driven loading reaches 1.5 G; keep materials — and profits — moving fast.

Zero-Waste Tail Cutting

Leave tailings under 45 mm (or 0 mm with BL/NYL models) to maximise yield and sustainability.

Featured Videos

Discover our latest innovations and solutions through these featured video presentations

Product Innovation Showcase

Explore our cutting-edge solutions and technological advancements

Industry Applications

See how our solutions transform industrial processes and workflows

Customer Success Stories

Learn from real-world implementations and customer experiences

Our Company Qualification

Product Line Snapshot

Choose the perfect series for your manufacturing needs — from flagship performance to smart entry-level solutions

B-Series

Models: BL · B(Y)

Flagship performance, zero or ultra-short tail.

Typical Applications

- Automotive chassis

- Heavy fitness frames

N-Series

Models: NYL · NY · N

Best balance of cost & capability.

Typical Applications

- Furniture tubing

- Construction rails

M-Series

Models: M(Y)

Smart entry-level for growing factories.

Typical Applications

- Metal racks

- Light fixtures

Ultimate Flexibility

Every series supports manual, semi-automatic, or fully automatic loading — choose the flexibility you need today and upgrade tomorrow.

Industries We Empower

From furniture and fitness to automotive and construction, our machines cut the tubes that build modern life.

Furniture & Home

Precision cutting for modern furniture frames, home décor, and interior design elements.

Construction & Railings

Heavy-duty tube cutting for structural frameworks, safety railings, and architectural components.

Automotive & Motorcycle Parts

High-precision cutting for exhaust systems, chassis components, and performance parts.

Fitness Equipment

Durable tube cutting for gym equipment frames, exercise machines, and sports apparatus.

Ready to revolutionize your industry with precision tube cutting?

Sustainability & ESG Impact

Driving environmental responsibility through innovative manufacturing solutions

Zero-Tail Innovation

Each zero-tail cut saves up to 1 kg of steel per tube. Our precision manufacturing technology eliminates waste at the source, creating measurable environmental impact.

"In 2024 alone, our clients kept 12,000 tonnes of metal out of landfills — the CO₂ equivalent of planting 600,000 trees."

Environmental

Social

Governance

Process Innovation

- Zero-waste cutting technology reduces material consumption

- Energy-efficient manufacturing processes

- Circular economy principles in production

Future Commitments

- Carbon neutral operations by 2030

- 100% renewable energy adoption

- Supply chain sustainability certification

Leadership & Team

Driven by innovation and backed by decades of expertise in laser technology

Eric Liu

Leading the company with unparalleled expertise and a vision for cutting-edge laser technology solutions

R&D Team

of total staff dedicated to R&D

Relentless in innovation, our R&D team drives breakthrough technologies and next-generation laser solutions

Global Service Team

Our global service team provides round-the-clock multilingual support, ensuring seamless customer experience worldwide

Our Team by Numbers

Ready to unlock smarter, faster, greener tube processing?

Talk to our specialists or book a virtual demo today.