Complete Buyer’s Guide to Tube Laser Cutting Machines

Finding the right tube laser cutting machine can be daunting amidst countless options. Are you struggling to pinpoint what truly matters for your production needs? I understand this challenge, and that’s why I've put together this comprehensive guide to help you navigate the complexities and make an informed investment.

A tube laser cutting machine utilizes a focused laser beam to precisely cut and shape metal tubes,offering superior accuracy, speed, and automation over traditional methods. When buying one, key considerations include power, automation features, software integration, and after-sales support to ensure optimal production efficiency.

For decades, I've seen firsthand how the right machinery transforms businesses, and the wrong one can stifle growth. This guide isn't just about specifications; it’s about empowering you to make a strategic decision that will elevate your operational efficiency, reduce costs, and unlock new possibilities for your fabrication business. Let’s dive deeper into what makes a true difference.

In today's competitive manufacturing landscape, investing in a tube laser cutting machine is no longer a luxury but a necessity for many metal fabrication businesses aiming for precision, speed, and automation. From my perspective, having been in this industry for 25 years, I've observed a significant shift1 where companies are moving away from manual and less efficient methods towards integrated, smart solutions. This isn't just about cutting metal; it's about optimizing workflow, minimizing waste, and reducing the skill threshold for operators, fundamentally changing how production lines operate. Consider a client like Ahmed Al-Farsi, an owner of a mid-sized metal fabrication business in the UAE. He continually seeks automated solutions to upgrade his production efficiency, especially for architectural metalwork and vehicle parts. His challenges, such as reliance on skilled CAD operators and high operator turnover, are common across the industry. This guide aims to address these critical pain points by offering insights gleaned from thousands of successful client integrations and real-world application data, providing a robust framework for critical evaluation and selection.

Introduction to tube laser cutting technology and its evolution

Are your current metal tube fabrication methods holding you back from achieving precision and speed? Traditional cutting techniques often result in material waste, slow turnaround times, and high labor costs. Discover how tube laser cutting technology emerged as a game-changer, revolutionizing metal processing and boosting efficiency.

Tube laser cutting technology precisely cuts various metal tubes using a high-powered laser beam, offering unparalleled accuracy and intricate design capabilities. Its evolution from basic CO2 lasers to advanced fiber optic systems has dramatically improved speed, efficiency, and automation in modern manufacturing environments, enabling complex geometries.

I’ve personally witnessed the profound transformation in metal fabrication over the past quarter-century. When I started MZBNL, manual cutting and punching were the norms, often leading to inconsistencies and bottlenecks. The shift to laser technology marked a pivotal moment, enabling industries to achieve levels of precision and automation previously unimaginable. This evolution isn't just about new machines; it's about a fundamental change in how we conceive and execute metalwork, pushing boundaries in design, efficiency, and material utilization. Understanding this journey helps you appreciate the capabilities of today's advanced systems and how they can specifically address your production challenges, much like how we've helped over 4000 enterprise clients globally.

Early Stages of Metal Fabrication and Their Limitations

Before the advent of advanced laser technology, metal tube fabrication relied heavily on traditional methods such as sawing, drilling, punching, and milling. These processes, while fundamental, presented significant limitations in terms of precision, speed, and design complexity. Manual operations often led to variations in cut quality, increased material waste due to less efficient nesting, and required extensive post-processing like deburring and grinding.

The inherent labor intensity of these methods also meant higher operational costs and a greater reliance on highly skilled operators. For instance, achieving intricate patterns or sharp angles on tubes was either impossible or prohibitively expensive and time-consuming. This created a bottleneck for industries requiring high volumes of precise components, such as furniture manufacturing or automotive parts, where consistency and rapid production cycles are paramount.

Furthermore, traditional methods were often limited in the types of materials they could efficiently process and the thickness ranges they could handle without specialized tooling. Each new design or material often necessitated significant setup changes and tool purchases, adding to both lead times and overall manufacturing expenses, which stifled innovation in product design.

The Dawn of Laser Technology in Tube Processing

The introduction of laser technology into metal processing marked a significant leap forward, initially with CO2 lasers and later with the more energy-efficient and faster fiber lasers. This innovation allowed for non-contact cutting, eliminating tool wear and distortion, and enabling exceptionally high precision and repeatability. Suddenly, complex geometries, small holes, and sharp contours on tubes became achievable with unprecedented accuracy.

At MZBNL, our 25 years of experience in metal fabrication have shown us that laser technology fundamentally changed the equation. Industries could now produce parts with tight tolerances, reducing the need for secondary operations and accelerating the overall production cycle. The ability to cut a wide range of materials and thicknesses with a single machine also brought immense flexibility to manufacturing lines.

This shift was a game-changer for businesses like Ahmed Al-Farsi's, who continually seeks to upgrade production efficiency. Laser cutting addressed the pain points of skilled labor dependency and the need for greater automation. By integrating laser technology, his company could move beyond the limitations of older machinery, allowing for more intricate architectural metalwork and vehicle parts, which are key areas of his business expansion.

Evolution Towards Smart & Integrated Systems

The evolution of tube laser cutting machines has progressed far beyond mere cutting capabilities, moving towards fully integrated, smart, and digitalized systems. Modern machines, like those developed by MZBNL2, now incorporate features such as automatic loading and unloading, robotic integration, and advanced software that optimize nesting and minimize waste. This level of automation significantly reduces human intervention, leading to higher throughput and lower operational costs.

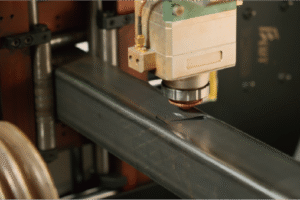

Multi-process integration is another critical advancement. For example, our Automatic Punching & Cutting Integrated Machine allows for a seamless workflow where cutting and punching operations are performed in a single setup, eliminating the need to transfer workpieces between different machines. This not only saves time but also improves accuracy by reducing potential errors from multiple handling stages. Such integrated solutions are vital for businesses like Ahmed's, who prioritize turnkey solutions that are easy to install and operate.

The drive towards Industry 4.0 has also led to the incorporation of IoT and AI, enabling real-time monitoring, predictive maintenance, and remote diagnostics. This proactive approach to machine management minimizes downtime and ensures continuous operation, enhancing overall productivity and reliability. As a high-tech enterprise with 30+ patents, MZBNL is at the forefront of this digital transformation, delivering smart and digitalized systems that offer both high-speed and high-precision cutting, truly reflecting the cutting edge of laser technology's evolution.

| Feature | Traditional Cutting (Saw/Drill/Punch) | Tube Laser Cutting (Modern) |

|---|---|---|

| Precision | Moderate to Low | Very High |

| Speed | Slow to Moderate | Very High |

| Design Complexity | Limited | High (Intricate Geometries) |

| Tooling Required | High (Multiple tools for different shapes) | Minimal (Focusing lens) |

| Material Waste | High | Low (Optimized Nesting) |

| Post-processing | Often Required (Deburring) | Minimal/None |

| Automation Level | Low to Moderate | High to Fully Automated |

Fiber lasers improve efficiencyTrue

Fiber laser systems offer greater energy efficiency and faster cutting speeds compared to older CO2 laser technology.

Traditional methods are more preciseFalse

Laser cutting provides significantly higher precision than sawing or drilling, with tolerances up to ±0.1mm.

The current market landscape for tube laser cutting machines

Feeling overwhelmed by the vast array of tube laser cutting machines available today? The market is dynamic, filled with diverse technologies and competitive pricing, making selection complex. Let's demystify the current landscape and help you identify the key trends and players shaping this essential industry.

The current market for tube laser cutting machines is characterized by robust growth, driven by increasing demand for automation, precision, and efficiency across manufacturing sectors. Fiber laser technology dominates due to its speed and versatility, with a competitive landscape featuring innovations in software, IoT integration, and customized solutions from global suppliers.

From my perspective at MZBNL3, having navigated this market for over two decades, I’ve seen it evolve from a niche segment to a globally competitive arena. What was once a simple transaction has become a strategic investment, where understanding market drivers and regional nuances is as crucial as the machine's technical specifications. Businesses like Ahmed Al-Farsi’s in the UAE are not just looking for a machine; they are seeking a partnership that can provide turnkey solutions, proven technology, and reliable support across international borders. This segment will explore the forces shaping this landscape, helping you appreciate the strategic positioning of various manufacturers and the factors that influence purchasing decisions for discerning buyers worldwide.

Key Market Drivers and Growth Segments

The global market for tube laser cutting machines is primarily driven by several powerful forces, including the accelerating demand for automation, the increasing complexity of product designs, and the pervasive push towards Industry 4.04. Industries such as automotive, furniture, construction, and medical equipment are consistently seeking higher precision and greater efficiency in their fabrication processes. My experience with MZBNL's diverse clientele, ranging from metal pipe processing factories to electrical appliance manufacturers, confirms this trend; businesses are rapidly adopting advanced machinery to reduce labor costs, enhance output quality, and meet tighter production deadlines.

A significant driver is the rising cost of skilled labor and the simultaneous need for consistent, high-quality output. Automated tube laser systems directly address this by minimizing manual intervention and reducing the dependency on highly trained operators—a pain point I’ve heard from clients like Ahmed, who faces challenges with skilled CAD operators and high operator turnover. Furthermore, the ability of these machines to handle a variety of materials, including stainless steel, carbon steel, and aluminum, broadens their applicability across multiple industrial segments, fueling demand for versatile solutions.

Moreover, the increasing emphasis on customized solutions and just-in-time manufacturing models is propelling the market forward. Companies no longer produce homogenous batches but require flexible machines that can switch between different product specifications quickly and efficiently. This aligns perfectly with MZBNL's focus on offering cost-effective customized solutions, allowing our clients to adapt swiftly to market demands and maintain a competitive edge.

Regional Market Dynamics and Competitive Landscape

The global tube laser cutting machine market exhibits distinct regional dynamics, with key manufacturing hubs in China, Germany, and Turkey playing significant roles—locations that Ahmed Al-Farsi frequently considers for his sourcing. China, my home base, has emerged as a dominant force, offering a wide range of machines that blend advanced technology with competitive pricing, making it a preferred sourcing location for many international buyers. MZBNL, with its integrated R&D, manufacturing, and sales, stands as a testament to China's capabilities in delivering high-tech solutions.

European manufacturers, particularly from Germany, are renowned for their robust engineering, precision, and long-term reliability, though often at a higher price point. Turkish suppliers also provide competitive options, balancing quality with cost-effectiveness. What I've observed is that buyers like Ahmed, who prioritize a high cost-performance ratio and proven technology with global references, often evaluate suppliers from all these regions before making a decision. Our extensive network, with main export countries spanning Southeast Asia, the Middle East, Europe, and North America, positions MZBNL as a truly global player capable of meeting diverse regional needs.

The competitive landscape is fierce, with established players and innovative newcomers constantly pushing the boundaries of technology. Success in this market hinges not only on machine performance but also on a strong brand reputation, comprehensive after-sales service, and the ability to offer tailored solutions. MZBNL's 25 years of experience, coupled with 30+ patents and over 4000 global enterprise clients, underscore our commitment to technological innovation and reliable support in this competitive environment.

Emerging Trends: AI, IoT, and Customization

The future of the tube laser cutting machine market is undeniably linked to the integration of Artificial Intelligence (AI) and the Internet of Things (IoT). These technologies are transforming machines into smart, interconnected systems that can self-diagnose, optimize production parameters, and even anticipate maintenance needs. At MZBNL, our smart and digitalized systems are designed precisely with these advancements in mind, offering features that enhance predictive maintenance and real-time operational insights, crucial for minimizing downtime.

AI-driven software is becoming increasingly sophisticated, enabling faster and more accurate part programming, improved nesting algorithms to maximize material utilization, and automated quality control. This level of intelligence reduces the reliance on manual programming and operator expertise, addressing pain points like the need for skilled CAD operators, which Ahmed experienced with previous machines. The No-CAD System Innovation pioneered by BNL exemplifies this trend, allowing operators to process standard tube types and hole patterns by simply entering parameters, drastically cutting down on setup time and skill requirements.

Furthermore, the demand for highly customized solutions continues to shape the market. Manufacturers are not just selling machines; they are selling integrated systems that fit seamlessly into a client's existing workflow and can be adapted for future needs. This includes multi-process integration and the ability to provide bespoke configurations. Ahmed’s preference for turnkey solutions and his interest in customization is a perfect example of this market trend. Companies that can offer robust, adaptable machines, coupled with strong post-sales training and support, like MZBNL, are best positioned to thrive in this evolving market.

| Market Trend | Impact on Buyers | How MZBNL Addresses It |

|---|---|---|

| Automation Demand | Seek machines reducing labor, increasing output. | High-speed, high-precision, automatic feeding (Front-Feeding). |

| Industry 4.0 / IoT | Desire for smart, interconnected, data-driven systems. | Smart and digitalized systems, remote diagnostics capability. |

| Ease of Use | Need for simpler operation, less skilled labor. | No-CAD System Innovation (1-day training). |

| Cost Efficiency | Focus on material savings, lower operating costs. | Zero-Waste Tail Material Innovation, multi-process integration. |

| Customization | Require tailored solutions for specific needs. | Cost-effective customized solutions. |

Fiber lasers dominate the marketTrue

Fiber laser technology leads due to its superior speed and versatility in tube cutting applications.

China is the only manufacturing hubFalse

While China is dominant, Germany and Turkey also serve as important manufacturing hubs for tube lasers.

Common challenges buyers face when selecting a tube laser machine

Are you struggling to choose the right tube laser cutting machine amidst confusing technical jargon and varying promises? Many buyers face common hurdles, from understanding complex specifications to ensuring reliable after-sales support. Let's pinpoint these challenges to help you make a confident, well-informed decision.

Buyers of tube laser cutting machines frequently encounter challenges such as deciphering complex technical specifications, accurately assessing the true cost of ownership beyond the initial price, and verifying the reliability and availability of after-sales service. Additionally, integrating new machinery with existing workflows and operator skill sets often poses a significant hurdle.

Through my interactions with thousands of clients over 25 years, I’ve recognized a recurring pattern of pain points buyers experience. It's not just about the machine's capabilities; it's about the entire ecosystem surrounding the purchase. For example, Ahmed Al-Farsi, my typical customer, frequently voiced concerns about the need for skilled CAD operators and high operator turnover—a clear indicator of the challenges related to ease of use and training. He also highlighted the lack of local service support5 and long machine lead times from some suppliers. Addressing these common pitfalls proactively is essential for a successful investment, and I believe understanding them is the first step towards a truly effective solution.

Navigating Technical Specifications and Performance Metrics

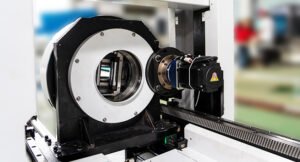

One of the most significant challenges buyers face is sifting through the myriad of technical specifications and performance metrics6. Terms like laser power (watts), cutting speed (m/min), positional accuracy (mm), and repeatability can be overwhelming, and it's easy to get lost in the details without understanding their practical implications for your specific operations. A higher wattage, for instance, might seem appealing, but it may be overkill for your typical material thickness, leading to unnecessary upfront costs and higher energy consumption.

Understanding how these metrics translate into real-world productivity is crucial. For a company like Ahmed's, which primarily processes metal pipes for architectural and automotive parts, the focus should be on the machine's ability to handle various tube sizes and shapes efficiently, along with its cutting precision for complex designs. My advice to clients is always to consider their primary materials, maximum tube dimensions, and desired daily output before fixating on headline figures. We, at MZBNL, prioritize helping clients match our machines' capabilities, such as high-speed and high-precision cutting7, with their specific production needs to ensure optimal performance.

Furthermore, integrating new machinery with existing workflows and operator skill sets presents a significant hurdle. Many traditional systems require extensive CAD/CAM knowledge, leading to a reliance on highly skilled operators—a pain point Ahmed experienced. This reliance can result in increased training burdens and production delays when skilled personnel are unavailable. This is precisely why MZBNL innovated the No-CAD Operating System, simplifying operations significantly and reducing the required training time from 15 days at the factory to just 1 day of on-site training, directly addressing the operator turnover challenge.

The True Cost of Ownership: Beyond the Sticker Price

While the initial purchase price is a critical factor, savvy buyers must look beyond it to understand the true cost of ownership8 (TCO) over the machine's lifespan. This includes not only the capital expenditure but also operational costs, maintenance expenses, and the cost of spare parts and consumables. Some machines might appear cheaper upfront but come with significantly higher long-term running costs due to energy inefficiency, expensive proprietary parts, or frequent breakdowns.

Ahmed Al-Farsi, for example, values a high cost-performance ratio over a low price, indicating his understanding of TCO. He knows that a machine that is cheaper to buy but unreliable or costly to maintain will erode profits over time. Factors such as power consumption, the cost of laser gases (if applicable), and the expected lifespan of critical components like the laser source and cutting heads must be thoroughly investigated. I always advise my clients to request detailed breakdowns of estimated annual operating costs and maintenance schedules.

Moreover, the availability and pricing of spare parts are critical. Some suppliers may offer low initial machine prices but then charge exorbitant amounts for replacement parts, or worse, have long lead times for essential components, leading to prolonged downtime. MZBNL ensures transparency in spare parts availability and pricing, coupled with remote diagnostics capabilities, to minimize any such hidden costs and support continuous operation, providing peace of mind for our global clientele.

Ensuring Reliable After-Sales Service and Support

Perhaps the most critical, yet often overlooked, aspect of a machine purchase is the quality and accessibility of after-sales service and support9. A high-tech machine, regardless of its features, is only as good as the support system behind it. Buyers frequently face challenges with unresponsive support, lack of local service presence, and insufficient training, leading to frustration and significant production losses. Ahmed's previous experience with suppliers lacking local service support underscores this very real concern.

When considering a supplier, it’s imperative to inquire about their service network, response times, and the availability of technical experts. Does the supplier offer comprehensive installation and commissioning services? What kind of ongoing training is provided for operators and maintenance staff? MZBNL, for instance, not only provides thorough post-sales training but also focuses on building a robust global distributor network to ensure local agent presence and prompt support in main export countries like the Middle East.

Furthermore, the ability to provide remote diagnostics and quick troubleshooting is invaluable in minimizing downtime. A machine breakdown can halt an entire production line, making swift and effective support paramount. My team and I are committed to ensuring our clients have access to reliable assistance, whether through our easily maintainable machines, detailed operator training, or a responsive support team that understands the urgency of production continuity. Prioritizing suppliers with proven technology and global references, as Ahmed does, typically correlates with better after-sales service.

| Challenge | Buyer Pain Point | MZBNL's Solution / How We Help |

|---|---|---|

| Complex Technical Specs | Difficulty understanding relevance for specific needs. | Personalized consultations, matching product features (e.g., high-precision) to client requirements. |

| High Operator Skill Requirement | High turnover, extensive training burden. | No-CAD System Innovation: reduces training to 1 day on-site. |

| Hidden Costs of Ownership | Unforeseen expenses (maintenance, parts, energy). | Transparent cost-performance ratio, durable design, spare parts availability, energy efficiency. |

| Lack of Local Service Support | Prolonged downtime, unreliable assistance. | Global distributor network, remote diagnostics, easy to maintain design. |

| Long Machine Lead Times | Delays in project delivery. | Efficient manufacturing processes, established supply chain. |

Higher wattage isn't always betterTrue

A higher wattage laser may be unnecessary for typical material thicknesses, leading to higher costs without added benefit.

Initial price reflects total costFalse

The true cost of ownership includes operational, maintenance, and spare parts costs beyond the initial purchase price.

Effective strategies for evaluating and choosing the right machine

Are you struggling to confidently select the ideal tube laser cutting machine10 for your business? The process can be complex, but with the right strategies, you can navigate the options effectively. Discover how to define your needs, prioritize key features, and conduct thorough due diligence to ensure a successful investment.

Effective strategies for choosing a tube laser cutting machine involve precisely defining production needs, prioritizing innovative features like automation and intuitive software, and conducting thorough due diligence on potential suppliers. Buyers should focus on long-term value, comprehensive after-sales support, and proven technology to ensure the machine meets both current demands and future growth.

For over two decades, I've guided countless clients through the often-complex journey of selecting the right metal fabrication machinery. What I've learned is that the most successful investments stem not from chasing the lowest price, but from a methodical approach that aligns technology with business objectives. Take Ahmed Al-Farsi, my typical customer: he isn't just looking for a machine; he’s looking for a turnkey solution that's easy to install and operate, offers a high cost-performance ratio, and comes with strong post-sales training and support. His preferences perfectly illustrate the strategic mindset required. This section will walk you through the precise steps I recommend for evaluating and choosing a machine that truly enhances your operations, just as MZBNL11 has helped over 4000 global enterprise clients.

Defining Your Specific Production Needs and Volume

The first and most critical step in choosing the right tube laser cutting machine is to meticulously define your specific production needs. Without a clear understanding of what you need the machine to do, you risk over-investing in unnecessary features or, conversely, acquiring a machine that falls short of your operational demands. Begin by identifying the types of materials you will primarily process (e.g., carbon steel, stainless steel, aluminum), their thickness ranges, and the maximum and minimum tube diameters and lengths you typically work with.

Beyond material specifications, consider the complexity of the parts you intend to produce. Do you require intricate cuts, small holes, or highly precise angles? Will the machine need to handle various tube shapes beyond standard rounds and squares, such as rectangular, oval, or open profiles? Understanding these details is paramount. For Ahmed, who expands his business in architectural metalwork and vehicle parts, his needs include precise cutting for complex geometries and efficient processing of various tube profiles.

Finally, accurately estimate your required production volume and desired throughput. This will inform the necessary cutting speed, automation level, and overall machine capacity. A mid-sized business planning significant automation, like Ahmed's 100+ staff operation planning to automate existing manual workflows, would prioritize machines with automatic feeding and robust performance to ensure consistent high-volume output. Clearly defining these needs provides a foundational blueprint for your selection process.

Prioritizing Key Features and Innovations

Once your production needs are clear, the next step is to prioritize the machine features and innovations that offer the most value for your specific operations. While many features exist, focusing on those that directly address your pain points and enhance efficiency will yield the best return on investment. For me, having pioneered significant advancements at MZBNL, I always emphasize innovations that simplify operations and maximize material utilization.

One such critical innovation is the No-CAD Operating System, which MZBNL pioneered. This system allows operators to process standard tube types and hole patterns by simply entering parameters, eliminating the need for complex 3D drawings. This directly addresses Ahmed's pain point of needing skilled CAD operators and reduces operator training from 15 days to just 1 day on-site. Another vital feature is the Front-Feeding mechanism, which enhances feeding efficiency by about 40% and reduces operator labor intensity by approximately 40% compared to traditional side or rear loading. This directly impacts productivity and workplace ergonomics.

Furthermore, consider systems that maximize material utilization. Our Zero-Waste Tail Material Innovation, for instance, redesigns the cutting logic to eliminate leftover tail material, significantly boosting cutting efficiency and material savings. Features like multi-process integration (e.g., automatic punching & cutting integrated machine) also streamline workflows. Prioritizing these smart, digitalized, and easy-to-operate features ensures your investment aligns with modern manufacturing demands and future growth, delivering genuine cost-effectiveness.

Due Diligence: Supplier Vetting and Site Visits

Selecting the right machine is inseparable from selecting the right supplier. Thorough due diligence is paramount to ensuring you partner with a reliable and reputable manufacturer. Start by evaluating the supplier’s track record, experience, and certifications. MZBNL, for example, boasts 25 years of experience in metal fabrication, holds 30+ patents, and serves over 4000 global enterprise clients, providing a strong testament to our established expertise and reliability.

Beyond reputation, investigate their R&D capabilities and commitment to innovation. A high-tech enterprise that continually invests in research and development is more likely to provide cutting-edge solutions and adapt to future market demands. Reviewing their global references and client testimonials, as Ahmed prefers, can provide invaluable insights into their product performance and after-sales support quality. Ask for case studies, especially from businesses similar to yours or in your region.

Wherever possible, arrange a site visit to the supplier’s factory or a demonstration at a client facility. This allows you to observe the manufacturing quality, see the machine in operation, and interact directly with technical and support staff. For international buyers like Ahmed, virtual demonstrations and detailed video tours can serve as valuable alternatives. Such visits provide a deeper understanding of the supplier's commitment to quality, service, and innovation, ensuring that the machine you choose is backed by a solid and trustworthy partner.

| Evaluation Area | Key Questions to Ask | MZBNL's Strong Points |

|---|---|---|

| Production Needs | What materials, dimensions, and volumes do you handle most? | Versatile machines for various materials/sizes; high speed for volume. |

| Feature Priority | Which innovations directly solve your pain points (e.g., CAD)? | No-CAD System, Front-Feeding, Zero-Waste Tail Material Innovations. |

| Supplier Reputation | How long have they been in business? What are their global references? | 25 years experience, 4000+ global clients, 30+ patents. |

| After-Sales Support | What training, service network, and spare parts support is offered? | Comprehensive training (1-day), global distributor network, remote diagnostics. |

| Cost-Performance | Beyond price, what is the TCO? What are the long-term savings? | Cost-effective customized solutions, material savings, reduced labor. |

Material specifications are crucialTrue

Defining material types and thickness ranges is essential for selecting the right tube laser cutting machine.

Price should be the main factorFalse

While important, price shouldn't be the primary consideration - long-term value and features matter more.

Innovative solutions and features to consider for advanced needs

Are you looking to push the boundaries of your metal fabrication capabilities and embrace the future of manufacturing? Beyond standard features, advanced tube laser cutting machines offer revolutionary innovations that can unlock unprecedented levels of efficiency and precision. Let's explore the cutting-edge solutions designed for tomorrow’s demands.

Advanced tube laser cutting machines incorporate innovative solutions like intuitive No-CAD operating systems, automated material handling with front-feeding mechanisms, and zero-waste tail material designs. These features significantly enhance operational efficiency, reduce labor intensity, minimize material waste, and integrate smart manufacturing principles for unparalleled productivity and cost savings.

Having spent 25 years in this industry, constantly pushing the envelope of what's possible, I've seen how incremental improvements give way to truly transformative innovations. For forward-thinking clients like Ahmed Al-Farsi, who are always looking to upgrade production efficiency and are even considering becoming a regional distributor, these advanced features are not just nice-to-haves; they are critical differentiators. They represent the next level of automation and profitability, solving persistent pain points and opening doors to new business models. Let me share some of the groundbreaking solutions MZBNL has pioneered, which I believe are essential considerations for any business aiming for peak performance and future relevance.

The Power of No-CAD Systems for Streamlined Operations

One of the most significant advancements in tube laser cutting technology is the development of No-CAD operating systems. Traditionally, operators had to create or modify complex 3D drawings using CAD software, which often meant returning to the design office, leading to significant inefficiencies and time consumption. This complex workflow was a major pain point for many manufacturers, including Ahmed, who highlighted the burden of requiring skilled CAD operators and dealing with high operator turnover.

MZBNL recognized this critical bottleneck and pioneered a perfected No-CAD Operating System for laser tube cutting machines. With this innovation, standard tube types and hole patterns can now be processed simply by entering parameters—no drawing required. This dramatically simplifies the operator's role, making the machine accessible to a broader range of personnel and drastically shortening setup times. It transforms what was once a 15-day training period at the equipment factory into just 1 day of on-site training.

This user-friendly design reduces the skill threshold for machine operation, which directly addresses the issue of operator turnover and the associated retraining burdens. By streamlining the programming process12, businesses can achieve faster production cycles, minimize human error, and reduce dependency on a specialized workforce. It’s a game-changer for operations seeking to maximize efficiency and achieve a quicker return on investment, aligning perfectly with Ahmed’s preference for turnkey solutions that are easy to install and operate.

Maximizing Efficiency with Automated Feeding and Zero-Waste Systems

Beyond just cutting, the efficiency of a tube laser machine is profoundly impacted by its material handling capabilities and its ability to minimize waste. Traditional machines often rely on manual loading from the side or rear, which is labor-intensive and inefficient. Recognizing this, MZBNL introduced an optimized Front-Feeding mechanism that automatically pulls the tube in from the front of the machine.

This innovative design significantly boosts feeding efficiency by approximately 40% and simultaneously reduces operator labor intensity by around 40%. For a busy fabrication business, this translates directly into higher overall productivity and improved workplace ergonomics, as operators spend less time and effort on material handling. It’s a practical solution that tackles the daily grind of production, leading to tangible improvements in output and employee well-being.

Complementing this, the Zero-Waste Tail Material Innovation is another groundbreaking feature. Conventional laser cutting systems typically generate unusable tail material at the end of the process because they start cutting from the tube head. BNL redesigned the cutting logic to calculate from the rear chuck as the origin, allowing the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This intelligent design maximizes material utilization13, reduces scrap, and further boosts cutting efficiency, contributing significantly to cost savings and environmental sustainability.

Embracing Smart Manufacturing and IoT Integration

The future of metal fabrication lies in smart manufacturing, where machines are interconnected, data-driven, and capable of optimizing their own performance. For businesses with advanced needs, integrating IoT and smart systems into their tube laser cutting machines offers unparalleled advantages in terms of monitoring, control, and predictive maintenance. MZBNL's machines are designed with these smart capabilities, allowing for real-time data collection and remote diagnostics.

This level of connectivity means that machine performance can be monitored from anywhere, identifying potential issues before they lead to costly downtime. For a global enterprise, or a client like Ahmed who values remote diagnostics and spare parts availability, this capability ensures continuous operation and minimizes disruptions. It also supports better decision-making by providing insights into production bottlenecks, material usage, and machine health, enabling continuous improvement.

Moreover, the integration of smart systems extends to software that optimizes nesting, production scheduling, and even material inventory management, creating a truly digitalized and efficient workflow. This holistic approach to automation is what positions MZBNL as a leader in the industry, offering not just machines but comprehensive system solutions. For Ahmed, who is considering becoming a regional distributor and is interested in co-branding or exclusive distribution rights, these advanced features and the underlying technological leadership represent a compelling value proposition that goes beyond a single machine purchase, paving the way for long-term partnership and mutual growth.

| MZBNL Innovation | Traditional Method | Key Benefit for Buyer | Impact on Ahmed's Business |

|---|---|---|---|

| No-CAD System Innovation | Manual CAD drawing | Reduces setup time, lowers skill threshold (1-day training). | Solves skilled CAD operator pain, reduces retraining burden. |

| Front-Feeding Innovation | Side/Rear manual loading | 40% increase in feeding efficiency, 40% less labor. | Boosts overall productivity, improves workplace ergonomics. |

| Zero-Waste Tail Material | Unusable tail material | Maximizes material utilization, boosts cutting efficiency. | Reduces material costs, increases profitability. |

| Smart/Digitalized Systems | Limited data, manual monitoring | Real-time insights, remote diagnostics, predictive maintenance. | Ensures continuous operation, supports long-term growth. |

No-CAD systems reduce training timeTrue

No-CAD systems eliminate complex CAD drawings, reducing operator training from 15 days to just 1 day.

Front-feeding increases labor intensityFalse

Front-feeding mechanisms actually reduce labor intensity by 40% compared to manual side/rear loading.

Conclusion

Choosing the right tube laser cutting machine requires a deep understanding of your needs, a careful evaluation of innovative features, and thorough supplier due diligence. By prioritizing smart solutions, such as MZBNL's No-CAD, Front-Feeding, and Zero-Waste innovations, you can secure a machine that not only meets current demands but also propels your business into a more efficient, automated, and profitable future.

-

Discover the benefits of smart, integrated systems in modern metal fabrication. ↩

-

Find out about the smart integration and automation features of MZBNL's cutting machines. ↩

-

Learn about MZBNL's impact and offerings in the laser cutting industry. ↩

-

Understand how Industry 4.0 integrates with modern cutting technologies. ↩

-

Learn how local service support mitigates downtime, ensuring smooth machine operation. ↩

-

Understand how laser power, speed, and accuracy impact machine performance. ↩

-

Explore the significance of cutting precision for complex designs. ↩

-

Discover factors affecting TCO, such as energy efficiency and maintenance costs. ↩

-

Ensure reliable assistance to minimize downtime and optimize machine operation. ↩

-

Learn effective strategies for selecting the best laser cutting machine ↩

-

Discover the comprehensive support provided by MZBNL to ensure a successful investment ↩

-

Understand how it speeds up production and reduces errors. ↩

-

Discover cost-saving and sustainability benefits from material efficiency. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.