Buying Guides & Selection Tips

How to choose CNC laser cutting systems?

Selecting a CNC laser cutting system is a critical decision that impacts your production efficiency and profitability. The process involves understanding your specific material and production needs, evaluating systems based on total cost of ownership rather than initial price, and ensuring the manufacturer provides reliable, long-term support. Key considerations include assessing the materials you process, required precision, and production volume to avoid unnecessary features. Additionally, evaluate different systems for their automation capabilities and software simplicity. MZBNL’s innovative features like No-CAD interface and zero-waste cutting help reduce operational costs and streamline processes, offering a competitive edge….

4 Types of Laser Cutters You Need to Know (and Their Pros and Cons)

Understanding the four main types of laser cutters—CO2, Fiber, Nd:YAG, and Diode—is crucial for making an informed investment. CO2 lasers are versatile for non-metals, Fiber lasers excel in metal cutting, Nd:YAG lasers are powerful for thick materials, and Diode lasers are compact and energy-efficient for engraving. Each type offers unique advantages and trade-offs, impacting efficiency, cost, and material capabilities. Choosing the right laser cutter depends on your specific industrial needs, primary materials, and long-term business goals, providing a strategic advantage in production efficiency and cost management….

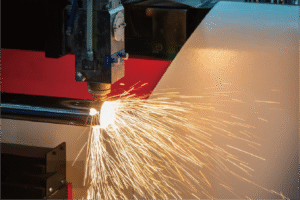

CO2 Laser vs. Fiber Laser Cutting: A Selection Guide (Comparing Efficiency, Cost, and Maintenance)

Selecting the right laser cutter is crucial for maximizing efficiency and minimizing costs. Fiber lasers offer higher efficiency, lower operating costs, and reduced maintenance, making them ideal for high-throughput industries. CO2 lasers, while effective for thicker materials, come with higher energy consumption and upkeep. The choice between the two depends on specific material requirements and production goals. Fiber lasers excel in cutting thin metals with speed and cost-effectiveness, while CO2 lasers are better for very thick materials and non-metals. Understanding these differences helps manufacturers make strategic investments that enhance profitability and competitive edge….

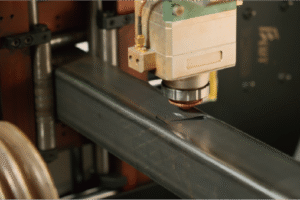

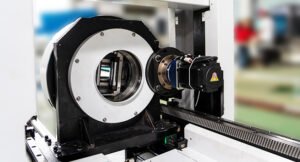

7 Tips to Choose Best Fiber Laser Cutting Machines

Selecting the right fiber laser cutting machine is crucial for enhancing factory efficiency and profitability. Key factors include evaluating specific power needs, precision, material compatibility, and operational costs. Prioritize machines with user-friendly software and robust after-sales support to ensure minimal downtime and fast ROI. Understanding the core components like the laser source, cutting head, and machine bed is essential. Match machine power to your primary cutting materials to avoid unnecessary costs. Opt for versatile machines to handle various metals, ensuring your business can seize new opportunities efficiently….

Fiber Laser Power Selection Guide for Manufacturers

Choosing the right fiber laser power is crucial for manufacturers to optimize efficiency and cost-effectiveness. Key factors include material type, thickness, and desired cutting speed. Beyond raw power, consider operational simplicity and material-saving features to maximize ROI. Common mistakes include over-specifying power and neglecting future needs. A balanced approach, focusing on total value rather than just cutting speed, ensures long-term profitability. This comprehensive guide provides a step-by-step process to assess specific needs, avoiding costly errors and making informed, data-driven decisions….

Comparing Metal Tube Cutting Machines: Which Method Fits Your Budget?

Are you struggling to select the perfect metal tube cutting method within your budget? I understand that a wrong choice can lead…

Tube Laser Cutting Machines: 5 Essential Questions You Need to Know

Are you facing production bottlenecks or struggling with rising material costs in your metal fabrication business? Many manufacturers grapple with outdated methods,…

Complete Buyer’s Guide to Tube Laser Cutting Machines

Finding the right tube laser cutting machine can be daunting amidst countless options. Are you struggling to pinpoint what truly matters for…

What to Look for in a High-Performance Tube Laser Cutting Machine

Are you struggling to keep up with the demands of modern metal fabrication1? The right tube laser cutting machine can revolutionize your…

Top 5 Questions to Ask Before Buying a Tube Laser Cutting Machine

Considering a tube laser cutting machine can feel overwhelming, but making the right choice is crucial for your business’s future. Skip the…