Why a Metal Tube Laser Cutter is a Game-Changer for Production

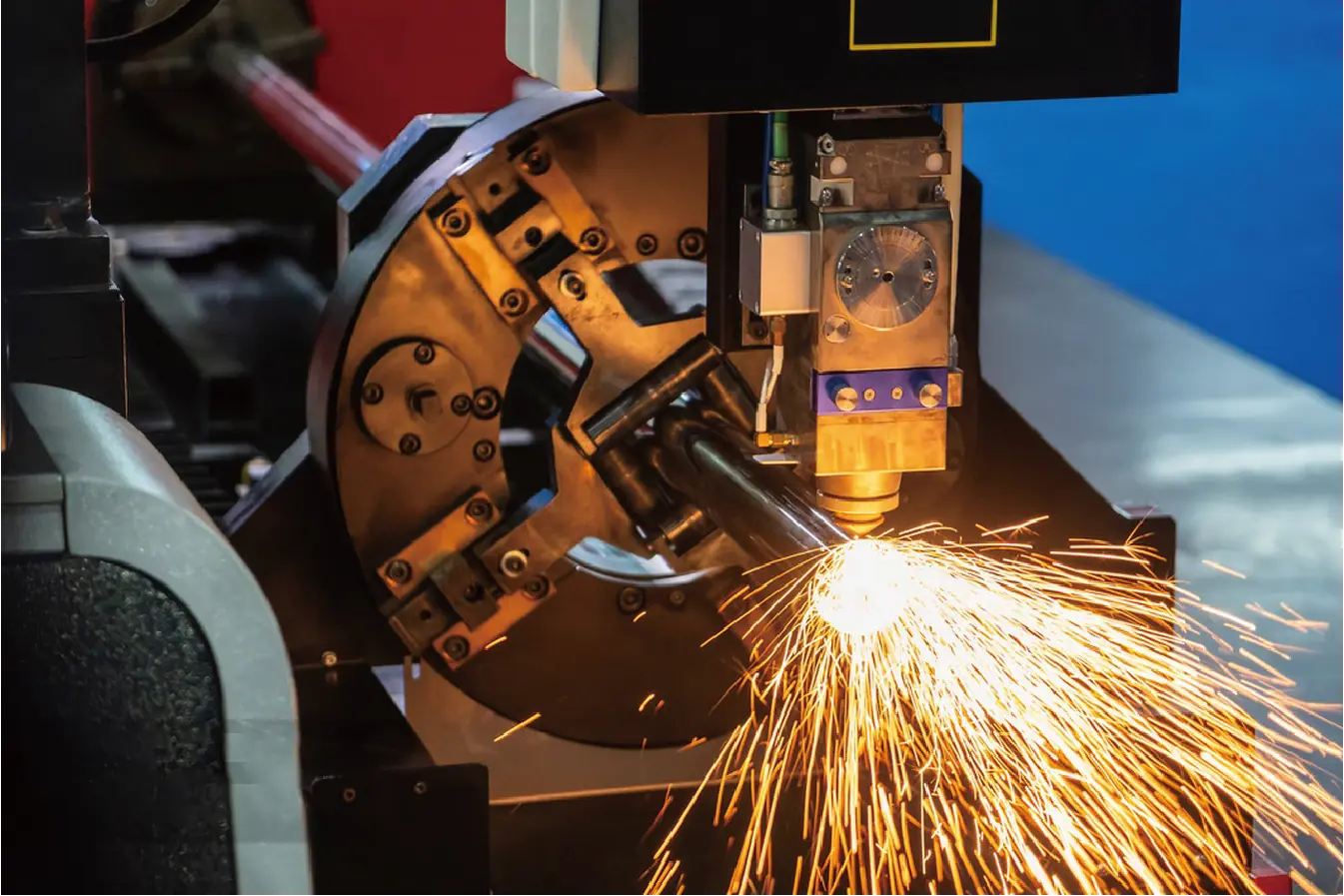

Slow, manual processing hurts your business. You lose time, waste materials, and fall behind competitors. A metal tube laser cutter solves this by automating production for maximum efficiency.

A metal tube laser cutter is a game-changer because it combines multiple steps like cutting, drilling, and shaping into one automated process. This technology boosts production speed, improves accuracy, cuts down material waste, and lowers labor costs, giving manufacturers a powerful competitive edge.

For years, I have seen factories struggle with old methods. They work hard but cannot keep up with modern demands. The switch to laser technology is not just an upgrade; it is a complete transformation of how work gets done. Let's explore why this change is so important for today's manufacturers.

What is the traditional approach to metal tube processing?

Traditional tube processing involves many separate steps. This multi-stage process is slow and often leads to errors. Understanding these old methods shows why new technology is so necessary.

The traditional approach uses several different machines and a lot of manual labor. It includes sawing tubes to length, drilling holes with a press, and milling complex shapes. Each step requires a separate setup and operator, making the process slow, expensive, and less precise.

In my experience visiting factories across the globe, the traditional workshop setup is easy to spot. You see a long line of machines, each performing a single task. First, an operator takes a long metal tube to a sawing machine to cut it to the required length. Then, another person moves that cut piece to a drill press to make holes. If the design needs a slot or a specific shape, it goes to a milling machine. Every time the tube is moved, it has to be clamped and aligned perfectly. This introduces many chances for human error. A small mistake at one station can ruin the entire piece, wasting both material and time. We saw clients struggling with this for years. They needed multiple skilled operators just to manage this slow, step-by-step workflow. The process was a major bottleneck that limited their production capacity and made it very difficult to compete on price or speed.

How has the demand for precision and efficiency evolved in metal processing?

Customers want better products, and they want them faster. Old, slow methods simply cannot meet these new expectations. The industry now demands a level of quality that only modern technology can deliver.

The demand in metal processing has shifted from basic parts to highly precise and complex components delivered on tight deadlines. Industries like automotive, medical, and furniture require perfect finishes and tight tolerances, making older, manual methods inefficient and obsolete in a competitive global market.

I remember talking to a client in the medical equipment business. They told me that twenty years ago, a simple metal frame was good enough. Today, that same frame must be perfect. The holes must be in the exact right spot, the cuts must be clean with no sharp edges, and every single piece must be identical to the last. This is what we mean by "tight tolerances." It means there is almost no room for error. In the automotive industry, parts have to fit together perfectly for safety and performance. In high-end furniture, the look and feel depend on flawless metalwork. This evolution is driven by global competition. If your factory cannot deliver high-quality parts quickly, your customer will find someone else who can. At MZBNL, we saw this change happening and knew that we had to build machines that could meet these new, higher standards of precision and efficiency.

What are the main challenges faced by manufacturers without laser cutting technology?

Factories using old methods face high costs and slow output. This directly hurts their profits and stops them from growing. Identifying these challenges shows why upgrading is essential for survival.

Manufacturers without laser cutters face high labor costs, significant material waste from mistakes and tail ends, and long production times. They struggle with inconsistent quality and find it hard to produce complex designs, which limits their market competitiveness and profitability in a fast-paced environment.

When we talk to manufacturers who haven't upgraded, they consistently tell us about the same core problems. These issues create a ceiling on their growth and profitability, and they can be broken down into a few key areas.

High Labor Costs and Skill Gaps

Traditional processing requires a team of skilled workers. You need one person for the saw, another for the drill, and maybe a third for the milling machine. Finding and retaining these skilled operators is expensive and difficult. If one key person leaves, production can stop completely. This reliance on a large, skilled workforce drives up costs and creates a lot of operational risk for the business.

Significant Material Waste

With old methods, waste is a huge problem. Every cut with a saw blade turns a small amount of metal into dust. More importantly, the way tubes are held often leaves a small piece at the end, known as tail material, that cannot be used. This adds up to a lot of wasted metal and lost money over time. We designed our MZBNL machines to solve this with our Zero-Waste Tail Material innovation, which often reduces this waste to zero.

Production Bottlenecks

Moving a tube from one machine to another creates a bottleneck. Each transfer takes time and manual effort. The entire production line can only move as fast as its slowest step. This makes it impossible to achieve the fast turnaround times that modern customers demand.

How does a metal tube laser cutter address these production challenges?

These production challenges can feel overwhelming. They cost your business time and money every single day. A laser cutter offers a single, powerful solution to all these problems.

A metal tube laser cutter solves these challenges by combining multiple jobs into one automated process. It cuts, drills, and shapes with incredible precision. This greatly reduces the need for labor, minimizes material waste, and speeds up production, directly fixing issues of inefficiency and high cost.

At MZBNL, we designed our machines to directly target the biggest pain points in the industry. We didn't just want to make a faster machine; we wanted to make the entire manufacturing process smarter and simpler for the user.

Simplifying Operations with a No-CAD System

One of the biggest barriers to new technology is complexity. Traditionally, operating a CNC machine required an engineer who could create complex CAD drawings. This meant long training periods, often 15 days or more. We changed that with our No-CAD System. Instead of drawing, the operator just enters the required parameters, like length and hole diameter. This innovation reduces the training time to just one day. It means almost anyone can learn to operate our machines quickly, which solves the skilled labor shortage.

Boosting Efficiency with Front-Feeding

Loading long, heavy tubes into a machine is slow and hard work. Most machines load from the side or rear, which is inefficient. Our unique Front-Feeding Innovation automates this process. It increases feeding efficiency by about 40% and reduces the physical labor for the operator by about 40%. The machine does the heavy lifting, so the operator can focus on production.

Maximizing Material Use with Zero-Waste Logic

As I mentioned, wasted tail material is a major cost. We solved this with our Zero-Waste Tail Material innovation. By redesigning the cutting logic, our machine can use nearly the entire tube. This boosts material utilization and directly translates to cost savings on every job. It’s a simple change in logic that has a huge impact on our customers' bottom line.

What are the future implications of adopting laser cutting technology in manufacturing?

The future of manufacturing can seem uncertain. Falling behind the technology curve is a major risk for any business. Adopting laser technology is not just an upgrade; it's future-proofing your operations.

The future implication is a move toward "smart manufacturing." Adopting laser cutting technology allows for more automation, data integration, and design flexibility. It positions companies to be more agile, competitive, and sustainable, ready to meet the demands of future markets and complex supply chains.

Adopting a machine like an MZBNL laser tube cutter is the first

Conclusion

A metal tube laser cutter isn't just another machine; it's a strategic investment in efficiency, quality, and future growth. It solves core manufacturing challenges by reducing waste, simplifying operations, and delivering the precision your customers demand, making your business more competitive and profitable.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.