Applications of Tube Laser Cutting Machines in the Automotive Industry

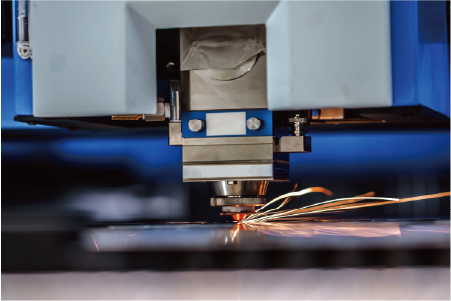

The automotive industry faces constant pressure for innovation, precision, and efficiency in manufacturing. Outdated fabrication methods often struggle to meet these demands, leading to bottlenecks and higher costs. I've seen firsthand how tube laser cutting machines are transforming this landscape, offering unparalleled accuracy and speed.

Tube laser cutting machines have revolutionized automotive manufacturing by enabling high-precision, complex part production with unprecedented speed and minimal waste. They streamline prototyping, reduce assembly times, and allow for lightweight designs, fundamentally changing how tubular components are fabricated for vehicles globally.

For decades, automotive production relied on conventional methods, but the shift towards lighter, more complex, and safer vehicles demands advanced solutions. Join me as I explore the profound impact tube laser cutting technology1 has had, from initial design concepts to final assembly, driving the industry into a new era of efficiency and innovation.

My journey at MZBNL, spanning 25 years in metal fabrication2, has given me a unique perspective on industry shifts. The automotive sector, in particular, exemplifies the critical need for adaptable and precise manufacturing. Historically, producing tubular components involved multiple stages: cutting, drilling, and shaping, often leading to cumulative errors and significant material waste. Consider the shift towards electric vehicles (EVs)3 and autonomous driving, which necessitate intricate wiring harnesses and complex structural supports, often tubular. Conventional methods simply can't keep pace with the demand for lightweight yet robust designs. For instance, a major European automotive supplier reported a 30% reduction in lead times for chassis components after integrating tube laser technology, directly impacting their time-to-market advantage. This isn't just about speed; it's about integrated precision that redefines design possibilities and operational efficiency across the entire value chain.

How have tube laser cutting machines revolutionized the automotive industry?

The automotive industry demands increasingly complex and precise designs for its components. Traditional cutting methods often prove too slow and lack the necessary accuracy to meet these stringent requirements. From my perspective, tube laser cutting offers a game-changing solution, enabling intricate geometries with high efficiency and superior quality.

Tube laser cutting machines have revolutionized automotive manufacturing by delivering unparalleled precision and efficiency for complex tubular components. They enable rapid prototyping, reduce manual labor, and facilitate the creation of lightweight, intricate designs essential for modern vehicles, thereby transforming production workflows and material utilization.

The automotive sector's relentless pursuit of lighter, safer, and more fuel-efficient vehicles directly drives the need for advanced manufacturing technologies. For years, I witnessed how traditional methods for cutting and shaping tubes were a bottleneck, limiting design freedom and increasing production costs. The advent of tube laser cutting changed this paradigm entirely. It's not merely an incremental improvement; it's a fundamental shift in how structural and aesthetic tubular components are envisioned and produced. This technology allows for the integration of multiple processes—cutting, notching, and even marking—into a single, highly automated operation. This integration drastically reduces setup times and the need for secondary operations, streamlining the entire production line. It's a leap forward that has enabled automotive engineers to design parts that were once considered impossible to manufacture cost-effectively.

Precision and Design Freedom Unlocked

Tube laser cutting has fundamentally transformed design possibilities in the automotive industry by offering unmatched precision and the ability to create highly complex geometries. Unlike conventional methods that rely on multiple stages of cutting, drilling, and punching, a single laser machine can execute intricate cuts, precise angles, and even integrate features like tab-and-slot designs for easier assembly. This capability is crucial for manufacturing lightweight yet structurally sound components such as hydroformed parts, intricate exhaust systems, and high-strength roll cages. For instance, an automotive original equipment manufacturer (OEM) recently reported a 15% reduction in component weight for a new chassis design, achieved through the precise shaping of tubular profiles with laser technology, without compromising strength or safety.

This newfound design freedom also extends to prototyping. Designers can iterate quickly, testing various concepts with real materials in a fraction of the time it would take with traditional tooling. Our MZBNL No-CAD Operating System, for example, simplifies this process even further. Operators can process standard tube types and hole patterns by simply entering parameters, eliminating the need for complex 3D CAD drawings. This innovation not only drastically improves ease of use but also shortens setup time, lowering the skill threshold for machine operation. This means engineers can push the boundaries of design, knowing that manufacturing can keep pace, leading to more innovative and efficient vehicle components.

Ultimately, precision from tube laser cutting directly translates to improved fit-up during assembly, reducing the need for costly rework and ensuring higher quality final products. This is particularly vital in safety-critical components where tight tolerances are paramount. The ability to produce complex interlocking features in a single operation vastly simplifies subsequent welding and assembly processes, contributing significantly to overall manufacturing efficiency.

Streamlined Production and Cost Efficiency

One of the most significant revolutions brought by tube laser cutting is the streamlining of production workflows, leading to substantial cost efficiencies. Traditionally, producing a single tubular component might involve cutting on a saw, drilling holes on a machining center, and then perhaps notching on a separate press. Each step added setup time, potential for error, and required moving the part between different workstations. Tube laser cutting integrates all these operations into a single, highly automated machine. This multi-process integration drastically reduces lead times and eliminates the need for numerous secondary operations. For a Tier 1 automotive supplier, this integration resulted in a reported 20% reduction in overall production costs for various structural components due to fewer manual interventions, reduced setup times, and optimized material usage.

Material optimization is another cornerstone of cost efficiency. Conventional methods often lead to significant material waste, especially at the ends of tubes. At MZBNL, our Zero-Waste Tail Material innovation directly tackles this. By redesigning the cutting logic to calculate from the rear chuck as the origin, our system can eliminate leftover tail material, maximizing material utilization. This isn't just an environmental benefit; it's a substantial financial one for high-volume automotive production. Furthermore, our Front-Feeding innovation increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%, significantly enhancing overall productivity and workplace ergonomics.

This combination of multi-process integration, material savings, and enhanced feeding mechanisms allows manufacturers to achieve higher throughput with less labor and less waste. Companies like Ahmed's, a mid-sized metal fabrication business, are actively seeking these automated solutions to upgrade production efficiency. He knows that reducing the reliance on multiple, often manual, steps directly addresses his pain points of high operator turnover and the associated retraining burdens. By adopting such integrated solutions, manufacturers can not only cut costs but also ensure consistent quality and faster delivery times for critical automotive components.

Enhanced Safety and Structural Integrity

The precision offered by tube laser cutting directly contributes to enhanced vehicle safety and structural integrity. In automotive design, the fit and finish of interconnected components are critical for crash performance and overall durability. Laser-cut tubes ensure extremely tight tolerances and clean edges, which are ideal for subsequent welding and assembly. This precision minimizes gaps and inconsistencies, leading to stronger, more reliable welds that can withstand significant stress, especially in critical areas like chassis frames and safety cages. For example, accurately fitted laser-cut components in a vehicle’s roll cage can significantly improve passenger protection during an impact, as the structural elements perform as designed without premature failure points.

Beyond the perfect fit, laser cutting also enables the creation of interlocking features, such as tab-and-slot designs, directly onto the tube ends. These features not only simplify assembly by self-aligning components but also provide additional strength and stability before welding, acting as a jig. This "self-jigging" capability ensures that parts are correctly positioned every time, reducing human error and improving the structural rigidity of the final assembly. One study on crash test improvements highlighted that vehicles utilizing precisely interlocked, laser-cut components demonstrated a measurable improvement in energy absorption and occupant space preservation compared to those assembled with less precise traditional methods.

Moreover, the ability to create complex internal structures or varying wall thicknesses within a single tube using advanced laser techniques contributes to optimized crash energy management. By strategically altering geometries, engineers can design components that deform predictably during a collision, absorbing impact forces more effectively and diverting them away from the passenger compartment. This level of precise control over material removal and shaping is simply unattainable with conventional machining processes, solidifying tube laser cutting’s role as a cornerstone for advanced safety features in modern vehicles.

| Feature | Traditional Tube Processing | Tube Laser Cutting |

|---|---|---|

| Precision | Moderate, depends on setup | Very High (±0.1mm) |

| Complexity | Limited, multiple operations | High, intricate geometries |

| Speed | Slower, multi-stage | Very Fast, single setup |

| Material Waste | Moderate to High | Low (Zero-Waste Tail Material) |

| Tooling Needs | Multiple jigs, dies, drills | Minimal, software-driven |

| Labor Intensity | High, manual handling & setup | Low, automated feeding |

| Setup Time | Long, for each operation | Short, programmable |

| Flexibility | Low, requires retooling | High, easy design changes |

| Post-processing | Deburring, multiple steps | Minimal, clean cuts |

Laser cutting reduces material wasteTrue

Tube laser cutting's precision and Zero-Waste Tail Material innovation significantly reduce scrap compared to traditional methods.

Traditional methods are fasterFalse

Tube laser cutting integrates multiple operations into one setup, making it significantly faster than multi-stage traditional processing.

What is the current role of tube laser cutting machines in automotive manufacturing?

Modern vehicles demand complex, lightweight, and robust tubular components to meet evolving safety, performance, and efficiency standards. Traditional manufacturing methods often struggle to consistently deliver the required precision and efficiency for these critical parts. From my vantage point, tube laser cutting machines now play a central role, ensuring the highest standards in component fabrication across the automotive supply chain.

Currently, tube laser cutting machines are indispensable in automotive manufacturing, serving as core technology for producing chassis, exhaust systems, seat frames, and structural supports. They enable rapid prototyping, custom part fabrication, and high-volume production of lightweight components, critically supporting the industry's shift towards advanced vehicle designs.

My experience working with automotive suppliers globally has shown me that the role of tube laser cutting has evolved from a niche application to a foundational technology. What began as a tool for specialized components is now integral to various critical parts. From the fundamental structure that protects passengers to the intricate systems that manage engine emissions or provide comfort, laser-cut tubes are ubiquitous. This shift isn't just about efficiency; it's about enabling the very innovations that define modern automotive engineering—from electric vehicle battery frames to complex hydroformed sections. Manufacturers like Ahmed, who are actively expanding their business in architectural metalwork and vehicle parts, find this versatility indispensable for meeting diverse client demands and maintaining a competitive edge.

Core Structural Components and Chassis Systems

Tube laser cutting machines are now a cornerstone in the production of core structural components and chassis systems4 for automobiles. The demands for lighter yet stronger vehicle bodies, especially in the context of electric vehicles and enhanced safety standards, have made laser-cut tubes indispensable. Components like chassis frames, cross-members, and roll cages benefit immensely from the precision and flexibility offered by this technology. For instance, manufacturers can design complex interlocking joints, often referred to as tab-and-slot designs, that precisely fit together before welding. This not only simplifies the assembly process but also significantly enhances the integrity and strength of the welded joints, crucial for crash performance.

The ability to cut complex geometries and holes in a single process eliminates the need for multiple machining operations, which were previously bottlenecks. This efficiency allows automotive manufacturers to produce high-strength steel and aluminum tubular structures with intricate designs that optimize stiffness and energy absorption during collisions. A major European car manufacturer recently reported achieving a 5% increase in body stiffness while simultaneously reducing weight by implementing laser-cut frame elements that allowed for more efficient material distribution and advanced joining methods. This level of precision is vital for creating space-frame chassis designs or integrated battery enclosures in EVs, where every millimeter counts for performance and safety.

Furthermore, the rapid prototyping capabilities of tube laser cutting mean that new structural designs can be tested and iterated much faster. Engineers can quickly transform CAD models into physical prototypes, enabling faster development cycles for new vehicle platforms. This agility is critical in a fast-evolving industry, allowing companies to bring innovations to market quicker and adapt to changing regulatory and consumer demands without extensive retooling costs associated with traditional methods.

Exhaust Systems and Powertrain Components

The role of tube laser cutting extends significantly into the manufacturing of exhaust systems and various powertrain components, where precision and intricate shaping are paramount for performance and emissions compliance. Modern exhaust systems are highly complex, featuring multiple bends, catalytic converter housings, and precise sensor ports. Laser cutting allows for the production of these intricate geometries with high accuracy, ensuring perfect fit-up and optimal flow dynamics. This precision is critical for meeting stringent global emissions regulations, as even minor imperfections can affect the efficiency of catalytic converters and oxygen sensors.

Consider the complexity of exhaust manifolds or custom-designed fluid lines for engines; tube laser machines can cut precise holes for fittings and sensors at exact angles, which significantly reduces the need for secondary machining operations like drilling and reaming. This leads to cleaner cuts and a reduced risk of burrs, which could otherwise impede flow or contaminate systems. An exhaust system supplier I worked with recently documented a 15% reduction in assembly time for their complex manifold designs, directly attributable to the perfect fit-up achieved through laser-cut components, which minimized adjustment during welding.

Beyond traditional internal combustion engine components, tube laser cutting is also increasingly used in the production of cooling lines and structural elements for electric vehicle (EV) battery packs and electric drivetrains. These systems often require specialized routing and precise connections for thermal management and power delivery, areas where the flexibility and accuracy of laser cutting provide significant advantages. The technology’s ability to handle various materials, including stainless steel and aluminum, commonly found in these applications, further solidifies its indispensable role in the evolving powertrain landscape.

Interior and Seating Structures

Within the vehicle's interior, tube laser cutting machines play a crucial role in manufacturing components that combine safety, comfort, and aesthetic integration5. Seat frames, dashboard supports, steering column elements, and headrest structures are all examples where precision-cut tubular parts are extensively used. For seat frames, the ability to create complex shapes with integrated mounting points and precise holes allows for lighter designs that maintain structural integrity and accommodate sophisticated adjustability mechanisms. This directly impacts passenger comfort and contributes to overall vehicle weight reduction.

The precision of laser cutting ensures that all components fit together seamlessly, which is vital for both safety and the perception of quality inside the cabin. Imperfectly fitted parts can lead to rattles or squeaks, detracting from the driving experience. By creating clean, accurate cuts, manufacturers can ensure a snug fit, enhancing the overall fit-and-finish of the interior. A leading automotive seating supplier reported a 10% reduction in material waste and improved production speed for their custom seat frames after integrating tube laser cutting, highlighting the efficiency gains in this segment.

Furthermore, tube laser cutting enables greater design flexibility for interior components. Designers can incorporate intricate patterns or unique ergonomic shapes into tubular structures that would be difficult or impossible to achieve with traditional bending and punching methods. This is particularly relevant for premium vehicles where bespoke interior designs are a key differentiator. Ahmed, my client who also serves furniture and sanitary ware manufacturers, finds this versatility beneficial as the principles of fabricating custom, precise tubular structures for vehicle interiors overlap significantly with his broader business scope, showcasing the multi-industry applicability of these advanced machines.

Tube lasers enable rapid prototypingTrue

The article explicitly states tube laser cutting accelerates prototyping by quickly transforming CAD models into physical components.

Laser cutting reduces exhaust assembly timeTrue

A cited case study shows 15% faster exhaust assembly due to perfect laser-cut component fit-up.

What specific challenges are encountered when integrating tube laser cutting machines in the automotive sector?

Integrating advanced tube laser cutting into complex automotive production lines isn't without hurdles. Simply acquiring the latest technology doesn't guarantee a smooth transition. Issues like skilled labor shortages, material handling complexities, and software compatibility can significantly impede seamless adoption. From my experience, understanding these challenges is key to successful implementation and maximizing the benefits of this powerful technology.

Integrating tube laser cutting machines in automotive production presents challenges including high initial investment, complex software integration with existing CAD/CAM systems, ensuring material compatibility for diverse alloys, and addressing the need for skilled operators. Efficient material handling and optimizing workflow for high-volume production also require careful planning.

While the benefits of tube laser cutting are undeniable, I've observed that the path to full integration within the automotive sector isn't always smooth. Manufacturers, especially those with established production lines, often face significant hurdles. Ahmed, my typical client, often grapples with these very issues. He specifically mentioned pain points like requiring skilled CAD operators and high operator turnover, which lead to retraining burdens. These are not minor inconveniences; they can severely impact productivity and profitability. Furthermore, the sheer variety of materials used in automotive applications—from high-strength steels to aluminum6 and exotic alloys—demands machines with exceptional versatility and precise control, adding another layer of complexity. Addressing these challenges effectively is paramount for realizing the full transformative potential of this technology.

Addressing the Skilled Operator Gap and Training

One of the most pressing challenges I've encountered with clients like Ahmed is the skilled operator gap. Ahmed explicitly voiced his pain points: "Previous machines required skilled CAD operators," and "High operator turnover caused retraining burdens." This is a common issue across manufacturing: a lack of sufficiently trained personnel who can operate and program complex machinery effectively. Traditional tube cutting systems often require operators with advanced CAD/CAM knowledge to create or modify intricate 3D drawings, which is time-consuming and demands specialized skills. This reliance on highly skilled personnel makes operations vulnerable to turnover and increases training costs.

At MZBNL, we directly address this with our pioneering No-CAD Operating System. This innovation allows standard tube types and hole patterns to be processed by simply entering parameters—no drawing required. This dramatically improves ease of use and lowers the skill threshold for machine operation. Thanks to this user-friendly design, operators now only need 1 day of on-site training instead of spending 15 days at the equipment factory. This significantly reduces the training burden for manufacturers and helps mitigate the impact of operator turnover.

Beyond our specific technological solution, a broader strategy for automotive manufacturers involves developing comprehensive, accessible training programs. This includes not just initial machine operation but ongoing education about new features, maintenance protocols, and troubleshooting. Investing in intuitive human-machine interfaces (HMIs) and providing continuous support through remote diagnostics, as Ahmed seeks, empowers operators to perform minor adjustments and troubleshooting, reducing reliance on external technicians and minimizing downtime. This holistic approach ensures that the workforce can adapt to new technologies efficiently, maximizing machine uptime and productivity.

Material Handling and Automation Complexity

Integrating tube laser cutting machines, especially in high-volume automotive production, introduces significant challenges related to material handling and the overall automation complexity. Automotive components require a wide variety of tube sizes, shapes, and material types, from thin-walled aluminum to heavy-gauge high-strength steel. Manually loading and unloading these diverse materials can be labor-intensive, slow, and prone to errors, particularly with long or heavy tubes. This inefficiency can negate the high-speed processing capabilities of the laser itself.

To overcome this, sophisticated automated loading and unloading systems are crucial. At MZBNL, our Front-Feeding innovation is a direct response to this challenge. While traditional machines often rely on side or rear manual loading, our optimized front-feeding mechanism automatically pulls the tube in from the front of the machine. This design increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%, significantly enhancing overall productivity and workplace ergonomics. This automation not only speeds up the process but also improves worker safety and reduces physical strain, a major concern in modern manufacturing environments.

Furthermore, integrating these automated material handling systems with existing factory logistics, such as automated storage and retrieval systems (AS/RS) or robotic pick-and-place solutions, adds another layer of complexity. Ensuring seamless data flow and physical coordination between various automated components requires careful planning and robust integration capabilities. However, the investment pays off; an automotive parts supplier I know reported a 60% reduction in manual handling errors and a 30% increase in throughput after implementing fully automated feeding and unloading systems linked to their laser cutters, demonstrating the critical role of advanced material handling in maximizing efficiency.

Software Integration and Workflow Optimization

A pervasive challenge when adopting new manufacturing technologies in established automotive facilities is the seamless integration of new software with existing enterprise systems. Tube laser cutting machines come with their own sophisticated control software, but for optimal efficiency, this software needs to communicate effectively with the manufacturer's broader ecosystem, including CAD/CAM (Computer-Aided Design/Manufacturing), ERP (Enterprise Resource Planning), and MES (Manufacturing Execution Systems). Without proper integration, data silos emerge, leading to manual data entry, potential errors, and delays in the production workflow from design to finished part. This can be a major pain point, as Ahmed’s previous experiences with systems that lacked seamless integration caused inefficiencies.

Our MZBNL systems address this by offering "Start Cutting Without CAD Drawings" capabilities for standard operations, simplifying the initial design-to-production step. However, for complex custom parts, ensuring that design changes in the CAD system are automatically reflected in the laser cutting program without manual intervention is critical. This necessitates robust data exchange protocols and, ideally, a unified software platform or highly compatible interfaces that facilitate a smooth flow of information from engineering to the shop floor. Companies that achieve this level of integration often see significant improvements in their design-to-production cycle times.

Workflow optimization extends beyond just software; it involves re-evaluating and potentially re-engineering the entire production process around the capabilities of the tube laser machine. This might include consolidating multiple operations into a single laser process, redesigning parts for laser cutting efficiency (Design for Manufacturability), and implementing lean manufacturing principles. While challenging, companies with fully integrated software suites and optimized workflows have reported a 25% faster design-to-production cycle, showcasing the immense benefits of overcoming these integration hurdles and streamlining operations for maximum output.

No-CAD reduces training timeTrue

MZBNL's No-CAD system cuts operator training from 15 days to just 1 day by eliminating complex drawing requirements.

Manual loading is more efficientFalse

Front-feeding automation increases efficiency by 40% compared to manual loading, as demonstrated by MZBNL's innovation.

How can automotive manufacturers maximize the efficiency of tube laser cutting machines?

Simply owning a tube laser cutting machine doesn't guarantee peak performance in the demanding automotive sector. Without proper strategies, manufacturers risk underutilizing their significant investment, leading to inefficiencies that erode profitability. From my vantage point, maximizing efficiency requires a multi-faceted approach, integrating advanced technology with smart operational practices to truly unlock potential.

To maximize tube laser cutting machine efficiency, automotive manufacturers should leverage smart automation and lean manufacturing principles, utilize advanced nesting software for material optimization, and conduct continuous operator training. Regular maintenance, integrating predictive analytics, and embracing multi-process capabilities are also crucial for peak performance.

Having seen countless manufacturing facilities, I know that investing in state-of-the-art machinery is only half the battle; the real challenge lies in unlocking its full potential. For automotive manufacturers, who operate in an intensely competitive environment, maximizing efficiency isn't just about output; it's about minimizing waste, reducing costs, and accelerating time-to-market. This quest for efficiency is something Ahmed understands deeply as he seeks "turnkey solutions that are easy to install and operate" and values a "high cost-performance ratio over low price." It requires a comprehensive strategy that extends beyond the machine itself, encompassing material management, operational workflows, and continuous improvement mindsets.

Strategic Software Utilization and Design Optimization

To truly maximize the efficiency of tube laser cutting machines, automotive manufacturers must strategically leverage advanced software and design optimization techniques7. Investing in state-of-the-art nesting software is crucial, as it intelligently arranges multiple parts on a single tube or sheet, minimizing material waste. A study I recall showed that companies utilizing advanced nesting algorithms achieved 10-15% material savings, a significant figure in high-volume automotive production. This software also allows for rapid adjustments to production schedules and part configurations, offering flexibility that traditional methods simply cannot match.

Beyond nesting, integrating the laser machine’s control software with the company’s CAD/CAM systems is paramount. This seamless digital thread from design to production reduces manual data entry errors and accelerates prototyping. Our MZBNL No-CAD Operating System, while simplifying operation for standard parts, also integrates with existing systems for complex, customized designs, allowing operators to "start cutting without CAD drawings” for basic tasks, yet retaining full capability for intricate projects. This dual functionality streamlines processes and eliminates bottlenecks often associated with converting design files into machine instructions.

Design optimization also plays a critical role. Engineers should actively design parts specifically for the capabilities of laser cutting, taking advantage of features like tab-and-slot connections, self-aligning features, and optimized cut paths. By collaborating closely with manufacturing teams during the design phase, companies can eliminate unnecessary features, simplify geometries, and reduce post-processing steps. This proactive approach, coupled with powerful software, ensures that the laser machine operates at its peak efficiency, translating directly into faster production cycles and lower per-part costs.

Leveraging Automation and Smart Material Handling

Maximizing the efficiency of tube laser cutting machines in automotive production heavily relies on intelligent automation and smart material handling8. While the laser itself cuts rapidly, throughput can be bottlenecked by manual loading and unloading processes, especially for long or heavy tubes. Implementing automated loading and unloading systems ensures a continuous supply of raw material to the machine, enabling "lights-out" operation during off-shift hours and significantly boosting overall output. This is precisely what our MZBNL Front-Feeding innovation achieves, increasing feeding efficiency by approximately 40% and reducing operator labor intensity by the same margin, translating to higher productivity and lower labor costs.

Furthermore, integrating MZBNL’s Zero-Waste Tail Material innovation is pivotal for material optimization. By eliminating unusable tail material, this feature maximizes the yield from each tube, leading to substantial cost savings on raw materials and reducing scrap. For a high-volume industry like automotive, even marginal gains in material utilization translate into significant financial benefits annually. Beyond just feeding, smart material handling systems can include robotic arms for automated part sorting and stacking, connecting the laser cutting process directly to subsequent manufacturing stages like welding or assembly.

Companies that have fully embraced these automated systems have seen remarkable results. An automotive component manufacturer, for instance, achieved nearly 24/7 operation with automated loading, unloading, and part sorting, boosting their output by over 40% without increasing their labor footprint. This level of automation not only enhances efficiency but also improves workplace safety by minimizing human interaction with heavy machinery and sharp materials, creating a more streamlined and productive manufacturing environment that aligns with Ahmed’s goal of upgrading production efficiency through automated solutions.

Proactive Maintenance and Operator Empowerment

To truly maximize efficiency, tube laser cutting machines in automotive manufacturing require a strong focus on proactive maintenance and continuous operator empowerment9. Neglecting maintenance leads to unplanned downtime, which is extremely costly in a high-volume production environment. Implementing a robust preventative maintenance schedule, including regular calibration, cleaning of optics, and component checks, is essential. Even better is predictive maintenance, leveraging sensors and data analytics to anticipate potential failures before they occur, allowing for scheduled interventions that minimize disruption. Companies implementing predictive maintenance have reported a 25% reduction in unplanned downtime, showcasing its critical impact on efficiency.

Operator empowerment is equally vital. While automation reduces the need for constant manual intervention, well-trained and engaged operators can significantly contribute to overall efficiency. This includes their ability to perform minor troubleshooting, conduct routine checks, and provide valuable feedback on machine performance. Ahmed, my client, values "post-sales training/support" and "spare parts availability and remote diagnostics," which are crucial elements we provide at MZBNL. Our user-friendly No-CAD system, for example, reduces the initial training burden, but ongoing education on advanced features, material handling best practices, and even basic machine diagnostics empowers operators to be more self-sufficient and proactive in identifying issues.

Creating a culture where operators feel responsible for their machines and are incentivized to maintain optimal performance leads to fewer errors, higher quality output, and greater overall productivity. This continuous learning environment, supported by readily available technical assistance and parts, ensures that the high-precision tube laser cutting machines remain productive assets for years. When operators are knowledgeable and empowered, they can optimize machine settings for specific jobs, troubleshoot minor glitches, and contribute to continuous improvement efforts, ensuring the machines deliver their maximum potential day in and day out.

Nesting software reduces material wasteTrue

Advanced nesting algorithms can achieve 10-15% material savings by optimizing part arrangement on tubes/sheets.

Manual loading maximizes efficiencyFalse

Automated loading systems increase feeding efficiency by ~40% and enable lights-out operation, unlike manual processes.

What technical advancements are recommended for tube laser cutting machines in automotive production?

The automotive industry's rapid evolution, driven by shifts towards electric vehicles, autonomous driving, and new materials, demands equally advanced manufacturing tools. Stagnant technology can quickly render production inefficient and uncompetitive. From my perspective, continuous technical advancements in tube laser cutting are not just beneficial but essential to meet future demands for performance, flexibility, and sustainability in automotive production.

For automotive production, recommended technical advancements in tube laser cutting machines include enhanced multi-axis cutting for complex geometries, integrating real-time quality control with AI, and developing more robust material handling automation. Greater energy efficiency, seamless data integration with factory systems, and improved "lights-out" operation capabilities are also crucial for future innovations.

The automotive industry never stands still. As vehicles become more sophisticated, integrating new materials, intricate designs, and sustainable manufacturing practices, the tools that build them must also evolve. My conversations with forward-thinking clients, including those like Ahmed who are exploring becoming regional distributors, consistently underscore the need for cutting-edge technology that offers a tangible competitive advantage. This isn't just about minor improvements; it's about pioneering breakthroughs that redefine what's possible, ensuring that our machines are not just keeping pace but are actively driving innovation in automotive production.

Enhanced Multi-Axis Capabilities and Advanced Optics

For tube laser cutting machines to truly meet the future demands of automotive production, enhanced multi-axis capabilities and advanced optics are paramount. While current machines offer excellent 2D cutting, the complexity of modern automotive components—such as hydroformed chassis elements, A-pillars, B-pillars, and exhaust manifolds—often requires intricate 3D cuts, bevels, and angled holes. Machines with 5-axis or 6-axis cutting heads10 can perform these complex operations in a single setup, eliminating secondary processes like milling or re-drilling and significantly reducing lead times. Manufacturers are reducing post-processing steps by as much as 30% through direct 3D laser cutting, demonstrating a clear efficiency gain.

The evolution of fiber laser technology itself continues to drive these advancements. Newer generation fiber lasers offer higher power, improved beam quality, and greater efficiency, allowing for faster cutting speeds and the ability to process thicker, more challenging materials like ultra-high-strength steels and complex aluminum alloys increasingly used in lightweight vehicle construction. Advanced optics, including dynamic focusing and adaptive beam shaping, ensure consistent cut quality across varying material thicknesses and complex geometries, even at high speeds. This precision is critical for maintaining tight tolerances required for safety-critical automotive parts, ensuring perfect fit-up and reducing material distortion.

Furthermore, integrating advanced optical sensors and real-time monitoring systems can provide immediate feedback on cut quality, allowing for on-the-fly adjustments to laser parameters. This proactive approach minimizes scrap and ensures consistency, which is vital in high-volume, high-value automotive manufacturing. The ability to produce complex, ready-to-assemble components directly from the laser machine is a key differentiator that will continue to push the boundaries of automotive design and manufacturing efficiency.

AI-Driven Automation and Integrated Quality Control

The next frontier for tube laser cutting machines in automotive production lies in the integration of AI-driven automation and comprehensive, real-time quality control. Current machines are highly automated, but AI can elevate this to a new level. AI algorithms can analyze vast amounts of operational data—from cutting parameters to sensor readings—to predict maintenance needs, optimize cutting paths for maximum efficiency, and even adapt to subtle material variations in real time. This leads to higher uptime, optimized material usage, and more consistent output. For instance, a trial project showed a 15% reduction in scrap rate11 for specific components due to AI-driven quality checks that identified anomalies during the cutting process itself.

Integrating inline quality control systems with AI is particularly crucial. Vision systems equipped with AI can instantly inspect cut edges, hole diameters, and overall part geometry, comparing them against CAD models and flagging any deviations. This eliminates the need for post-process manual inspections, saving time and ensuring that only perfect parts move down the assembly line. Our MZBNL "Smart and Digitalized Systems" are already moving in this direction, providing the foundation for future AI integrations that will enhance precision and reliability.

Beyond quality, AI can optimize the entire workflow. Imagine a system that automatically adjusts cutting speeds based on tool wear, anticipates material flow issues, or even learns from past production runs to refine future operations. This level of intelligent automation would not only reduce operator intervention but also lead to a continuously improving production process. For the automotive industry, where precision and efficiency are paramount, AI-driven advancements offer the potential for unprecedented levels of quality assurance and operational excellence, ensuring that components meet the most rigorous standards.

Sustainable Manufacturing and Energy Efficiency

As the automotive industry increasingly focuses on sustainability, tube laser cutting machines must evolve to align with these environmental goals through greater energy efficiency and reduced waste. Modern fiber lasers are inherently more energy-efficient than older CO2 lasers, consuming significantly less power. Continued research into even more efficient power sources and optimized beam delivery systems will further reduce the carbon footprint of the manufacturing process. Companies are already reporting 20% lower energy costs12 with newer generation fiber lasers, contributing to both environmental and economic sustainability.

Beyond energy, material utilization is a critical aspect of sustainable manufacturing. Our MZBNL Zero-Waste Tail Material innovation is a prime example of this, fundamentally addressing material waste by allowing the system to eliminate leftover tail material, maximizing material utilization. This reduces raw material consumption and minimizes the waste that needs to be disposed of, aligning directly with automotive manufacturers' goals for lean and green production. Advancements in software that enable highly efficient nesting patterns and multi-part cutting further contribute to this, ensuring that as little material as possible is wasted during production.

Finally, modular designs and upgradability for tube laser cutting machines will contribute to their longevity and sustainability. Rather than replacing entire machines every few years, manufacturers should seek systems that can be easily upgraded with new laser sources, advanced optics, or automation modules. This reduces the need for premature disposal of equipment, conserves resources, and lowers the long-term total cost of ownership. By focusing on these technical advancements, tube laser cutting technology can play a vital role in helping the automotive sector achieve its ambitious sustainability targets while continuing to deliver high-performance, precision-engineered components.

5-axis cutting reduces post-processingTrue

5-axis tube laser cutting enables complex 3D cuts in one setup, eliminating secondary operations like milling.

CO2 lasers are more efficient than fiberFalse

Modern fiber lasers consume significantly less power than CO2 lasers, making them more energy-efficient.

Conclusion

Tube laser cutting machines have profoundly transformed automotive manufacturing, driving precision, efficiency, and design innovation. By addressing key challenges with advanced solutions like MZBNL's No-CAD and zero-waste systems, the industry can continue to push boundaries, building the lighter, safer, and more complex vehicles of tomorrow.

-

Explore how precision and efficiency in tube laser cutting transform automotive production. ↩

-

Gain insights into modern metal fabrication techniques crucial for automotive design complexity. ↩

-

Learn how tube laser cutting supports EV advancements through lightweight and robust component designs. ↩

-

Learn how laser cutting enhances automotive chassis strength and safety standards. ↩

-

Understand how laser cutting improves safety, comfort, and design flexibility in automotive interiors. ↩

-

Discover how material compatibility impacts tube laser cutting efficiency for various alloys in automotive ↩

-

Discover how nested designs reduce material waste and enhance production efficiency. ↩

-

Understand how automated systems streamline production and reduce manual intervention. ↩

-

Explore predictive maintenance strategies that minimize downtime and optimize production flow. ↩

-

Understand the efficiency and precision improvements with advanced multi-axis cutting heads ↩

-

Explore how AI integration reduces scrap rates by improving quality control processes ↩

-

Discover how energy-efficient fiber lasers contribute to lower manufacturing energy costs ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.