Is laser cutting faster and more precise than CNC machining?

Struggling with slow production and costly errors? Every wasted minute and piece of scrap material hurts your bottom line. Modern laser cutting offers a clear, more efficient path forward.

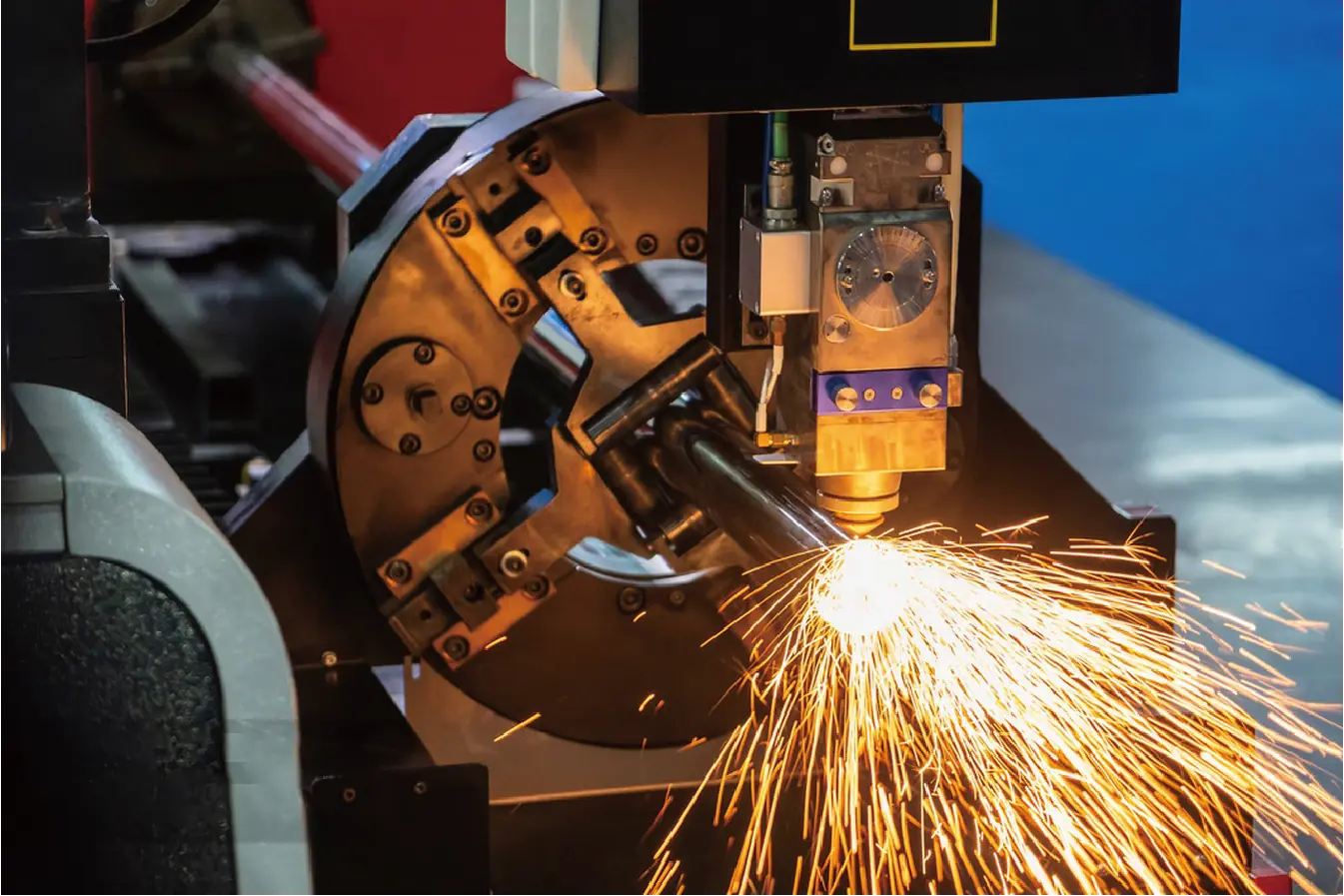

Yes, for many applications, modern laser cutting is significantly faster and more precise than traditional CNC machining. Innovations like our No-CAD systems at MZBNL drastically reduce programming and setup times, boosting throughput while minimizing material waste and operator error.

As the General Manager of MZBNL, I've spent over a decade helping businesses solve their biggest production challenges. The debate between laser cutting and CNC machining comes up often. While both have their place, the advancements in laser technology have changed the game completely. Let's break down the real-world differences so you can make the best decision for your factory floor.

What are the speed and precision capabilities of laser cutting?

Do you need perfect cuts, executed quickly? Traditional methods are often slow and can be imprecise, leading to expensive rework and delays. Laser cutting delivers unmatched speed and accuracy for today's complex jobs.

Modern laser cutters achieve incredible speeds and maintain tolerances within micrometers. Our systems at MZBNL enhance this with features like front-feeding and zero-waste technology. This means faster throughput and higher quality parts, directly improving your production line's output.

When we talk about speed and precision, we are talking about the core of manufacturing efficiency. I’ve seen factories transform their entire workflow by adopting the right technology. Laser cutting operates on a principle of focused light, which means there is no physical tool wear or contact with the material. This alone eliminates a host of variables that can affect precision in mechanical cutting.

The No-CAD Revolution

One of the biggest bottlenecks I used to see with advanced machinery was the programming. You needed a highly skilled engineer to translate a design into machine code. So, we developed our No-CAD system. Instead of complex programming, an operator can simply input the desired parameters directly into the machine. This innovation has single-handedly reduced operator training time from weeks to a single day. Think about what that means for labor costs and operational flexibility.

Maximizing Throughput and Material

Our technology is designed to solve real-world production pains. Here’s how we boost speed and precision:

- Front-Feeding Systems: These automated systems reduce manual loading times between jobs, keeping the machine running continuously and maximizing output.

- Zero-Waste Technology: Advanced software optimizes cutting paths to use nearly every square inch of material. I spoke with a client in the automotive parts sector who reduced their material waste by 18% in the first quarter after installing our machine. That’s a direct impact on the bottom line.

- High-Powered Lasers: The sheer power of modern lasers allows for cutting speeds that were unimaginable a decade ago, without sacrificing the quality of the cut edge.

How does CNC machining compare in terms of speed and precision?

CNC machining is a trusted, powerful method. But its long setup times, physical tool wear, and programming complexity can slow you down. Understanding its limitations helps reveal where laser cutting truly excels.

CNC machining is highly precise but generally slower for intricate, 2D work due to physical tool contact, necessary tool changes, and longer programming cycles. It excels with thick materials and 3D shaping, but for tubes and sheets, laser cutting is significantly faster.

I have great respect for CNC technology. For creating complex three-dimensional parts or working with very thick blocks of metal, it is often the best choice. The process involves a rotating cutting tool that physically removes material. This subtractive method is incredibly precise. But, this physical contact is also its main limitation when speed is the priority.

The Time Factor in CNC

The operational timeline for a CNC job is often longer than for a laser cutter. First, a skilled programmer must create a detailed toolpath using CAM software[^1]. This can be time-consuming. Next, the operator sets up the machine, which includes securing the workpiece and loading the correct cutting tools. For complex jobs, the machine may need to perform multiple tool changes, each one adding to the total cycle time. Because tools physically wear down, they must be monitored and replaced to maintain precision, adding another layer of operational oversight.

A Head-to-Head Comparison

Here is a simple breakdown of how these two technologies stack up in key areas:

| Feature | Laser Cutting (MZBNL) | Traditional CNC Machining |

|---|---|---|

| Setup Time | Very fast, especially with No-CAD parameter input. | Moderate to long, requires CAM programming. |

| Operator Skill | Low; training can be completed in a single day. | High; requires skilled programmers and machinists. |

| Speed on Tubes | Extremely fast, non-contact cutting. | Slower due to physical tool paths and rotation. |

| Material Waste | Minimal, with zero-waste optimization. | Higher, due to tool path and fixture requirements. |

| Tooling | No physical tool wear or changes. | Tools wear and require replacement. |

What factors influence the speed and precision of both laser cutting and CNC machining?

Your production results can vary. Not understanding why can lead to poor investment decisions and inconsistent quality. Knowing the key variables empowers you to optimize your entire process effectively.

For both methods, material type and thickness are crucial. Laser cutting speed is affected by laser power and assist gas type. CNC machining speed depends on tool sharpness, spindle speed, and feed rate. Operator skill remains a universal factor for both technologies.

You can have the best machine in the world, but if you don't account for the variables, you won't get optimal results. It's my job to help our clients understand these factors so they can maximize their investment. Both laser and CNC performance are deeply tied to a few core elements.

Key Variables for Laser Cutting

With laser cutting, the process is a thermal one. So, the material's properties are critical.

- Material Type: Reflective materials like aluminum or copper can be more challenging and may require a higher-power laser. The material's thermal conductivity also plays a role.

- Material Thickness: This is the most significant factor. Thicker materials require more power and a slower cutting speed to ensure a clean cut all the way through.

- Laser Power: A higher-wattage laser can cut thicker materials faster.

- Assist Gas: The type of gas used (like oxygen or nitrogen) and its pressure can dramatically affect the cut quality and speed.

At MZBNL, we design our machines to simplify these choices. Our control systems have built-in libraries with optimized settings for common materials and thicknesses, reducing the guesswork for the operator.

Key Variables for CNC Machining

For CNC, the process is mechanical. The factors are different.

- Material Hardness: Harder materials require slower feed rates and tougher cutting tools.

- Tool Selection: The geometry, material, and coating of the cutting tool must be matched to the job. A dull tool will ruin precision.

- Spindle Speed & Feed Rate: These must be perfectly balanced. Too fast, and you risk breaking the tool; too slow, and you waste time.

In what scenarios is laser cutting the preferred choice over CNC machining?

You must use the right tool for the job. Choosing the wrong one costs you time, money, and quality. For many modern manufacturing needs, laser cutting is the clear winner for specific applications.

Laser cutting is the ideal choice for intricate patterns, thin-to-medium thickness materials, and high-volume production of complex parts. It excels in industries like furniture, automotive, and sanitary ware manufacturing where speed, precision on tubes, and minimal waste are critical.

Over the years, I've seen clear patterns emerge. Certain industries and applications benefit immensely from the switch to laser cutting. If your work involves complex shapes on metal tubes or sheets, laser cutting should be your first consideration. The technology allows for a level of design freedom that is difficult or time-consuming to achieve with CNC.

I remember a client in the institutional furniture business. They were struggling to produce a new line of desks with complex, curved metal tube legs. Their CNC process was slow and resulted in a high rejection rate. After we installed one of our automatic laser tube cutters, their production time for each frame dropped by 60%. More importantly, their precision was so consistent that their assembly process became faster as well. This is a perfect example of how the right technology creates positive ripple effects throughout the entire production chain.

Laser cutting is the preferred method when:

- Speed is Critical: For high-volume orders with tight deadlines.

- Designs are Intricate: Cutting sharp corners, small holes, or detailed patterns.

- Material is Tube or Sheet Metal: Especially for materials up to medium thickness.

- Minimal Heat Distortion is Needed: The heat-affected zone[^2] from a laser is very small.

- Operational Simplicity is a Goal: Reducing the need for highly skilled programmers and operators.

What are the recommendations for choosing between laser cutting and CNC machining based on project requirements?

You need to make a smart capital investment. The wrong choice can lock you into an inefficient process for years. A simple framework can guide your decision to the most profitable outcome.

Choose laser cutting for speed, intricate designs on tubes and thin sheets, and operational simplicity. Choose CNC for 3D shapes and very thick, hard materials. Analyze your primary materials, part complexity, and production volume to find the best solution.

The final decision comes down to a clear-eyed assessment of your specific needs. There is no single machine that is perfect for everything. As a partner to our clients, my goal is to provide clarity, not just sell a machine. So, let's make this simple. Ask yourself these questions about the majority of the jobs you run.

When to Choose Laser Cutting

This is your best bet if your answers align with these points:

- Your primary material is metal tubes or sheets.

- You need to cut complex, 2D shapes.

- Production speed and high volume are top priorities.

- You want to minimize material waste.

- You need to reduce reliance on highly-skilled, hard-to-find programmers.

I believe that for a huge segment of the manufacturing world, especially in furniture, automotive parts, and general metal processing, laser cutting offers an undeniable competitive advantage. It aligns perfectly with the modern need for agile, sustainable, and cost-effective production.

When to Stick with CNC Machining

CNC remains the undisputed champion in these areas:

- You need to create 3D parts with features like pockets, threads, and chamfers.

- You regularly work with very thick blocks of metal or other hard materials.

- Your production volume is low, and jobs are highly varied (prototyping).

Conclusion

Laser cutting, powered by modern innovations, offers a powerful advantage in speed and precision for many manufacturing applications. It simplifies operations, reduces waste, and delivers a strong ROI. This technology is redefining what is possible on the modern factory floor and providing a clear path to profitability.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.