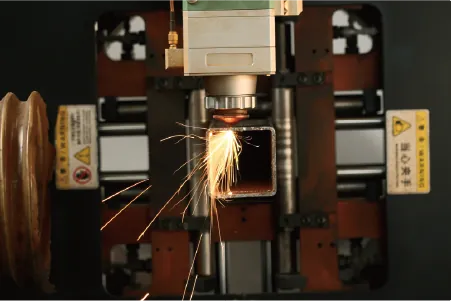

Can a Small Tube Laser Cutter Deliver High-Precision Results? Yes, with This Technology.

Struggling with precision on a small budget? Complex machines require skilled operators you can't find. Our technology delivers high-precision results without the high-cost expertise.

Yes, a small tube laser cutter can absolutely deliver high-precision results, often achieving tolerances of ±0.05mm. This is made possible by integrating a stable machine structure, a quality laser source, and advanced, simplified software that removes the need for extensive operator training.

As the General Manager of MZBNL, I have spoken with thousands of business owners. A common myth I hear is that true precision is only possible with massive, expensive machinery. This is no longer true. The technology has evolved, and I want to show you how smaller, more accessible machines are now leading the charge in precision manufacturing. Let's explore how this is possible.

What are the capabilities of small tube laser cutters in precision cutting?

Need intricate cuts but think your shop is too small? Traditional methods are slow and inaccurate. Small laser cutters now offer the power of large machines in a compact footprint.

Small tube laser cutters are capable of executing complex geometries, holes, and notches with high repeatability. They can process materials like stainless steel and aluminum with minimal thermal distortion, achieving a level of detail previously reserved for larger, more expensive equipment.

To dive deeper, the capabilities are not just about making a clean cut. It's about consistently producing complex parts that fit together perfectly, every single time. Since 2010, we've equipped over 4,000 clients, from furniture makers to automotive parts suppliers, with this technology. They are now able to perform tasks that were once outsourced or impossible for them.

Key Precision Capabilities:

- Complex Pattern Cutting: This includes cutting fish-mouth arcs, slots, and intricate patterns on round, square, or rectangular tubes. For a client in the sanitary ware industry, this meant creating perfect joints for their faucet designs, reducing assembly time by 40%.

- High Repeatability: Our machines can produce thousands of identical parts with a tolerance of just ±0.05mm. This is critical for industries like automotive manufacturing where every component must meet strict quality standards.

- Minimal Heat-Affected Zone (HAZ): The focused laser beam minimizes heat damage to the surrounding material. This preserves the structural integrity of the metal, which is crucial for load-bearing components in fitness equipment or institutional furniture.

- Material Versatility: Our small cutters are not limited to one type of metal. They effectively process stainless steel, carbon steel, aluminum, and brass, giving our clients the flexibility to take on diverse projects without needing multiple machines.

How does the technology behind small tube laser cutters achieve high precision?

Worried new tech is too complex for your team? The learning curve for advanced machinery can halt production. We designed a system that anyone can master in a day.

High precision is achieved through a combination of a rigid machine frame, high-quality laser sources, and intelligent software. At MZBNL, our key innovation is the No-CAD System, which bypasses complex programming and allows operators to achieve precision with minimal training.

To dive deeper, the real breakthrough isn't just in the hardware, but in making the technology accessible. For years, the industry believed that to get high precision, you needed an operator with years of CAD/CAM software experience. We saw this as a major bottleneck for small and medium-sized enterprises (SMEs). So, we challenged that assumption. The result was our patented No-CAD System, which is central to our machines.

The MZBNL No-CAD Advantage

Instead of a multi-step, highly technical process, we simplified it. Our system democratizes precision manufacturing. It allows a business owner to hire for attitude and work ethic, not for a rare and expensive software skillset. We've seen it time and again: a new operator, who has never touched a laser cutter before, is producing perfect, high-precision parts by the end of their first day. This is a fundamental shift from weeks of training. This innovation is driven by market pressure for cost-effective agility. It empowers SMEs to compete in high-stakes industries like automotive parts and medical equipment manufacturing, leveling the playing field. Precision is no longer exclusive to large-scale operations.

What factors influence the precision of small tube laser cutters?

Getting inconsistent results from your cutting process? Variations in material and machine setup cause costly errors. Understanding these factors is key to maintaining quality control and profitability.

Key factors include the machine's mechanical stability, the quality of the laser beam, the focus position, cutting speed, and assist gas pressure. Even environmental factors like workshop temperature and floor vibration can affect the final precision of the cut.

To dive deeper, achieving consistent precision is about controlling variables. I remember visiting a client's workshop where they were struggling with accuracy. Their machine was top-of-the-line, but it was placed on an uneven floor next to a heavy stamping press. The vibrations were throwing off the cuts by a fraction of a millimeter—enough to ruin the job. We helped them build a simple, isolated concrete pad for the machine, and the problem vanished. It’s not always about the machine itself, but the entire operating environment.

Here are the main factors you need to control:

| Factor Category | Specific Elements | Why It Matters for Precision |

|---|---|---|

| Machine Hardware | Frame Rigidity, Servo Motors, Guide Rails | A stable, heavy-duty frame resists vibration. High-quality motors and rails ensure the cutting head moves exactly where the software tells it to go. |

| Laser & Optics | Laser Source Quality, Lens Condition, Nozzle Centering | A stable laser beam and clean, properly focused optics are essential for a clean, narrow kerf (the width of the cut). |

| Process Parameters | Cutting Speed, Laser Power, Gas Pressure | These must be perfectly matched to the material type and thickness. Incorrect parameters can lead to dross, wide kerfs, or incomplete cuts. |

| Operating Environment | Floor Stability, Ambient Temperature, Debris | Vibrations can cause inaccuracies. Temperature fluctuations can affect machine calibration. Dust and debris can contaminate the optics. |

Understanding and managing these elements is the foundation of a reliable, high-precision cutting operation.

What measures can enhance the precision of small tube laser cutters?

Want to push your machine's accuracy even further? Standard settings are good, but optimal performance requires fine-tuning. We have built-in measures to help you achieve peak precision.

To enhance precision, use high-purity assist gas, regularly calibrate the machine, and maintain the optics. Implementing a robust quality control process and utilizing advanced software for automatic edge detection and centering can significantly improve accuracy and repeatability.

To dive deeper, a great machine is just the starting point. Think of it like a race car. It has incredible potential, but it needs a skilled team and regular tuning to win. The same is true for your laser cutter. At MZBNL, we build features into our machines and software to make this "tuning" process as simple as possible. We focus on empowering the operator to get the best possible result without needing an engineering degree.

Practical Steps for Enhanced Precision:

- Implement a Regular Maintenance Checklist: This is non-negotiable. We provide our clients with a simple daily and weekly checklist.

- Daily: Check and clean the protective lens and nozzle.

- Weekly: Verify nozzle calibration and check the water chiller's temperature and fluid level.

- Monthly: Clean dust screens and inspect guide rails.

- Utilize Software Automation: Our No-CAD system includes features like automatic tube centering. Before the first cut, the machine uses sensors to find the exact center and orientation of the tube, compensating for any slight imperfections in the material. This automated step removes a major source of human error.

- Focus on Operator Knowledge: While our system is simple, a knowledgeable operator is an asset. We encourage operators to understand how different materials react. For instance, knowing that stainless steel requires higher gas pressure than carbon steel helps them use the pre-loaded parameters more effectively and troubleshoot any minor issues on the fly.

What are the best practices for operating small tube laser cutters to ensure precision?

Afraid of operational errors wasting expensive material? Improper machine use leads to scrap and lost time. Following simple best practices ensures every cut is perfect and profitable.

Best practices include performing a daily pre-operation check, using correct parameters for each material, and keeping the work area clean. Securely clamping the tube and running a test cut on scrap material before a production run are crucial steps for consistent precision.

To dive deeper, profitability in manufacturing is a game of inches—or in this case, millimeters. Every piece of scrap material is lost profit. Over my career, I've seen that the most profitable shops are not necessarily the ones with the newest machines, but the ones with the best processes. A disciplined approach to operation pays for itself almost immediately. We've designed our operational workflow to be as foolproof as possible, embedding these best practices directly into the machine's interface.

A Simple Workflow for Precision:

- Pre-Shift Inspection: Before powering on, the operator should do a quick visual check. Is the machine clean? Are there any obstructions? Is the assist gas tank full? This takes 60 seconds but can prevent hours of downtime.

- Load Program & Verify: With our system, this is as simple as selecting a pre-saved drawing from the touchscreen. The operator can see a 3D model of the finished part and confirm it's the correct job.

- Secure the Material: The operator loads the tube into the automatic chucks. Our pneumatic chucks self-center and apply the correct clamping force, which is critical for holding the tube securely without deforming it.

- Run a Test Cut: Before starting a large batch, always run the program on a small offcut. This allows the operator to measure the part and confirm that the dimensions are perfect before committing hundreds of feet of material.

- Monitor the First Production Piece: Watch the first full part as it's being cut. Listen to the machine and look at the quality of the cut. This final check ensures everything is running smoothly.

Conclusion

A small tube laser cutter can deliver exceptional precision. This is possible with modern technology that combines a rigid design with intelligent, user-friendly software like our No-CAD system. This innovation removes the barriers of high cost and complexity, empowering more businesses to compete and win.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.