CO2 Laser vs. Fiber Laser: Main Differences in Cutting Capability, Cost, and Applications

Choosing the wrong laser technology wastes capital and hurts your production schedule. The debate is complex. I will give you a clear, data-backed guide to make the right decision.

Fiber lasers are best for cutting thin, reflective metals like stainless steel and aluminum with high speed and low operating costs. CO2 lasers excel at cutting thick non-metals like wood and acrylic, providing a superior, smoother edge finish on these materials and thick steel plates.

As the General Manager of MZBNL, I've helped over 4,000 clients navigate this exact choice. The decision between CO2 and fiber laser technology isn't about which is "better" overall, but which is right for your specific application, budget, and future growth. Let's break down the key differences so you can invest with confidence.

What are the fundamental differences between CO2 and fiber lasers?

Technical jargon is confusing and unhelpful. You just need to understand how each machine works to see its strengths. I will explain the core difference in simple terms.

CO2 lasers create a light beam by exciting a gas mixture with electricity, using mirrors to direct it. Fiber lasers use solid-state diodes to energize a fiber optic cable, creating a more focused and intense beam.

To dive deeper, the technology behind the beam generation is what defines each machine's capabilities. I've seen these technologies evolve since we founded MZBNL in 2010, and understanding the "how" is crucial.

The CO2 Laser Generation Process

A CO2 laser is a gas laser. It uses a sealed tube filled with a gas mixture, primarily carbon dioxide, nitrogen, and helium. When electricity passes through this tube, the gas molecules get excited and produce photons—light. This light bounces between mirrors at either end of the tube, amplifying it into a powerful beam. This beam has a longer wavelength (around 10.6 micrometers), which is excellent for absorption by organic materials like wood, acrylic, and leather. It's a mature, reliable technology that we've implemented for many clients in furniture and display rack manufacturing.

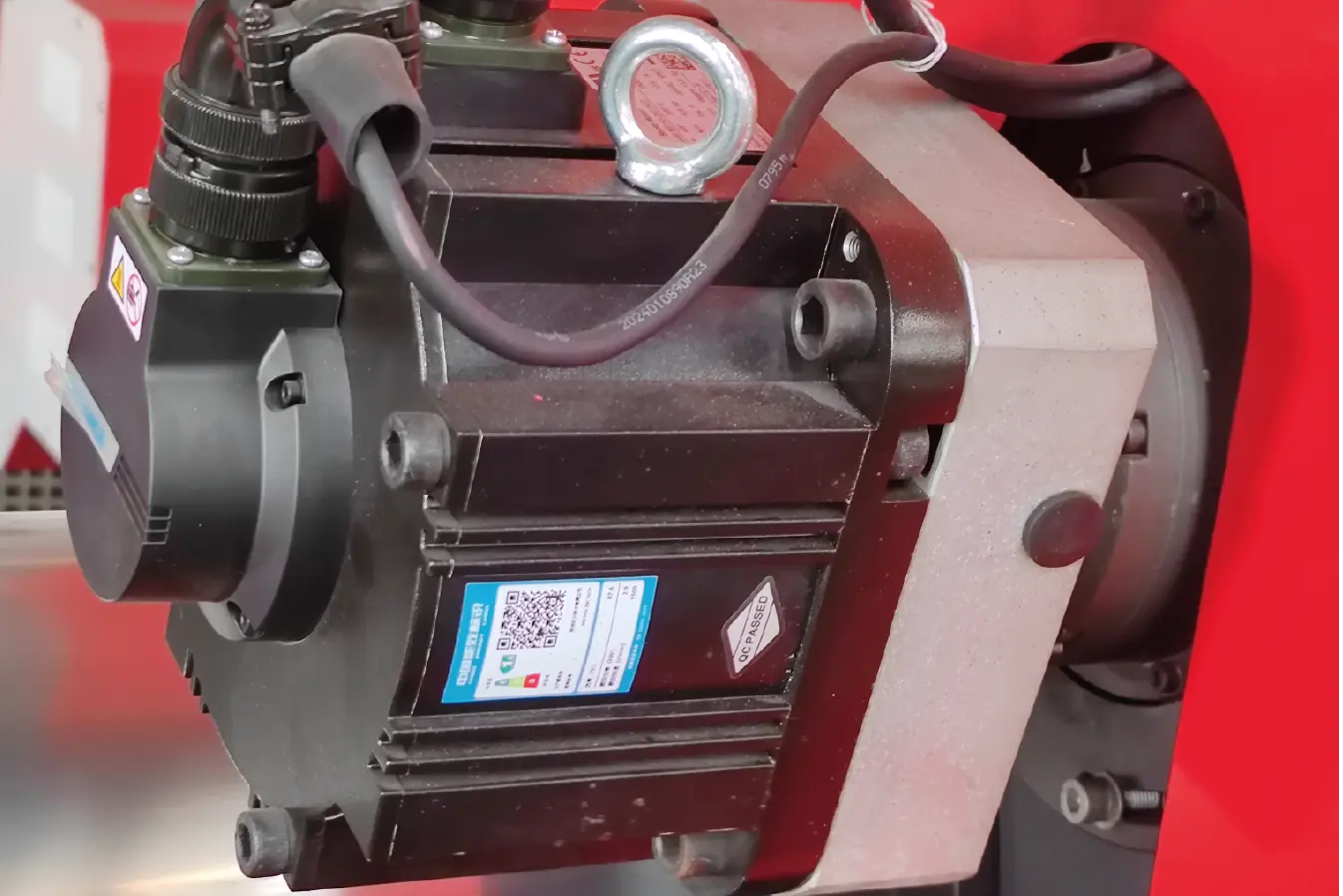

The Fiber Laser Generation Process

A fiber laser is a solid-state laser[^1]. Instead of gas and mirrors, it uses banks of semiconductor diodes as a light source. This light is channeled into a special fiber optic cable that is "doped" with rare-earth elements[^2]. These elements absorb the diode light and re-emit it as an extremely intense, straight, and focused laser beam. Its shorter wavelength (around 1.06 micrometers) is absorbed about 10 times more effectively by metals than a CO2 beam. This is why it has become the dominant technology for metal processing.

How do CO2 and fiber lasers compare in terms of cutting capability?

Raw power on a spec sheet doesn't tell the whole story. You need the right tool for your specific materials. Matching the laser's capability to your product is the key to efficiency.

Fiber lasers cut thin metals like stainless steel up to five times faster than CO2 lasers. However, CO2 lasers produce a smoother, burr-free edge on thick steel plates and are unmatched for cutting non-metal materials.

To dive deeper, let's look at speed, precision, and material finish. Your choice here directly impacts your production output and the amount of secondary finishing work required. I remember a client in the automotive parts industry who switched to one of our fiber laser tube cutters. Their cycle time per part dropped by 60% overnight simply because the technology was a better match for their thin-walled steel tubes.

Speed and Precision

For metals under 5mm thick, there is no contest. A fiber laser is significantly faster. Its intense, focused beam melts and vaporizes metal very quickly. This high speed is critical in high-volume industries like automotive components and electronics, where every second counts. The smaller spot size also allows for incredibly fine details and intricate patterns with high precision.

Material Versatility and Edge Quality

This is where the CO2 laser holds its ground. Because of its longer wavelength, it produces a much smoother, shinier, and burr-free edge on steel plates thicker than 20mm. For businesses cutting thick plate, the quality of a CO2 cut often reduces the need for secondary grinding or finishing. And for non-metals, CO2 is the only choice. It cuts wood, acrylic, plastic, and leather cleanly, whereas a fiber laser's wavelength would simply reflect off or poorly process these materials.

| Feature | Fiber Laser | CO2 Laser |

|---|---|---|

| Primary Strength | Speed on thin metal | Edge quality on thick metal & non-metals |

| Thin Metal (<5mm) | Very High Speed | Moderate Speed |

| Thick Metal (>20mm) | Fast, but rougher edge | Slower, but very smooth edge |

| Non-Metals | Not suitable | Excellent |

| Reflective Metals | Excellent (e.g., brass, copper) | Poor / Risky |

What are the cost implications of using CO2 versus fiber lasers?

The initial purchase price is misleading. The total cost of ownership is what truly determines your return on investment. We must look at the complete financial picture, not just the invoice.

Fiber lasers typically have a higher initial purchase price but much lower operating costs due to high electrical efficiency and minimal maintenance. CO2 lasers are cheaper to buy but cost more to run over time.

To dive deeper, we advise all our clients to analyze both capital expenditure (CapEx)[^3] and operating expenditure (OpEx)[^4]. A machine that is cheap to buy can quickly become expensive if it consumes a lot of power and requires constant service.

Initial Investment (CapEx)

Generally, a CO2 laser machine has a lower upfront cost than a fiber laser of comparable power. This can make it an attractive option for companies with limited initial capital or for shops that specialize in non-metal applications where fiber isn't an option.

Operating Costs (OpEx)

This is where the fiber laser provides a powerful long-term advantage.

- Energy Efficiency: A fiber laser is dramatically more efficient. Its "wall-plug efficiency[^5]" (the ability to convert electrical power into laser power) can be over 30%. A CO2 laser is typically under 10% efficient. This means a 4kW fiber laser can consume the same or less electricity as a 2kW CO2 laser, leading to huge savings on your monthly power bill.

- Maintenance: Fiber lasers are solid-state and have no moving parts or mirrors in the laser source. The laser-generating diodes have a lifespan of over 100,000 hours. CO2 lasers require regular maintenance, including cleaning and aligning mirrors, servicing turbines, and replacing optics, which means more downtime and service costs.

- Consumables: CO2 lasers require a constant supply of laser gas (the CO2, N2, He mixture) to operate. Fiber lasers have no such requirement.

In which applications do CO2 and fiber lasers excel?

You know your industry's needs better than anyone. But which technology is built to serve those needs best? Let's match the machine to the mission for maximum productivity.

Fiber lasers dominate high-volume metal processing for industries like automotive, electronics, and our specialty at MZBNL, metal tube cutting. CO2 lasers are the standard for signage, architectural models, and custom wood or plastic fabrication.

To dive deeper, the global market clearly shows where each technology provides the most value. As the demand for efficiency grows, manufacturers are specializing their equipment. At MZBNL, we see this every day. A furniture maker might need both technologies: a fiber laser for their steel frames and a CO2 laser for cutting wooden tabletops and acrylic panels.

Where Fiber Lasers Shine:

- Automotive & Motorcycle Parts: High-speed cutting of frames, exhausts, and components.

- Metal Tube Processing: Our focus at MZBNL. Fiber is perfect for cutting tubes for furniture, fitness equipment, and facility structures with speed and precision.

- Sheet Metal Fabrication: Cutting panels for enclosures, cabinets, and appliances.

- Electronics: Precision cutting of small, thin metal components and casings.

- Highly Reflective Metals: Cutting brass, copper, and aluminum, which can damage a CO2 laser.

Core Strengths of CO2 Lasers:

- Architectural & Display Manufacturing: Cutting thick acrylic for signs, wood for models, and panels for display racks.

- Furniture & Woodworking: Intricate designs in wood, MDF, and other non-metals.

- Packaging: Die-board cutting and scoring of cardboard.

- Plastics Fabrication: Creating custom parts from a wide range of plastics.

- Engraving: Deep and clean engraving on wood, glass, stone, and acrylic.

What recommendations can I make when choosing between CO2 and fiber lasers?

Making the final choice is a major strategic decision. You need a clear framework, not a sales pitch. I will give you my straightforward advice based on two decades of experience.

Choose a fiber laser if you primarily cut metal under 20mm thick, value production speed, and want the lowest possible operating cost. Choose a CO2 laser if you cut a diverse range of non-metals or require the absolute best edge quality on thick steel.

To dive deeper, the best decision comes from looking inward at your business first. At MZBNL, my first question to a new client is always, "What are you making today, and what do you want to be making in five years?" The answer tells me everything I need to know to guide them properly.

First, Analyze Your Material Mix

List every material you cut and its thickness. If your list is 90% metal, especially under 20mm, a fiber laser is almost certainly your best bet. If your list is a mix of thick steel and a wide variety of plastics and woods, a CO2 laser offers the versatility you need. Don't buy a machine for the 5% of jobs you might do; buy it for the 95% of work that pays the bills.

Second, Evaluate Your Production Goals

Is your business model based on high-volume, low-margin parts? If so, the speed and low operating cost of a fiber laser are critical for your profitability. Is your model based on high-margin, custom, or specialty work where a perfect finish is non-negotiable? The superior edge quality of a CO2 laser on thick plate or its unique ability to process non-metals might be your key competitive advantage.

Third, Future-Proof Your Investment

The market is clear: fiber lasers are proliferating for metalwork, but the demand for CO2 lasers remains strong for their unique capabilities. The future of manufacturing will focus on customized solutions. Your decision today should reflect your growth strategy. Investing in the right technology is about securing your competitive edge for years to come.

Conclusion

The choice between fiber and CO2 is a strategic one. It depends entirely on your primary materials, production speed requirements, and long-term operating budget. Fiber lasers offer unmatched speed and efficiency for metals, while CO2 lasers provide critical versatility for non-metals and superior edge quality on thick plate.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.