How to Evaluate Quality in a Metal Tube Cutting Machine

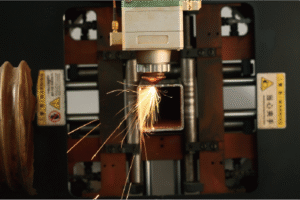

Are you struggling to discern true quality in a metal tube cutting machine? The market is flooded with options, but a wrong choice can cripple your productivity and profits. I'll guide you through the essential criteria to ensure your next investment is a resounding success.

Evaluating quality in a metal tube cutting machine involves assessing several critical factors: material and component integrity, cutting precision, operational efficiency, user-friendliness, and robust after-sales support. A high-quality machine ensures longevity, minimal downtime, and consistent output, directly impacting your overall business profitability.

I know firsthand how critical a reliable tube cutting machine is for businesses like yours. Investing in quality isn't just about the initial purchase price; it's about securing future productivity, reducing operational headaches, and ultimately, boosting your bottom line. Let's delve deeper into what truly defines excellence in this essential industrial equipment.

When assessing a metal tube cutting machine, the temptation often lies in focusing solely on peak laser power or advertised cutting speeds. However, a truly holistic evaluation demands a critical examination of its long-term viability, something I've learned over 25 years in this industry. Consider the hidden costs associated with a seemingly cheaper machine: frequent breakdowns, high operator skill requirements, and significant material waste. For instance, many fabricators initially choose lower-cost options only to face recurring issues that severely impact project deadlines and profitability. Ahmed Al-Farsi, a client from the UAE, shared how his previous machines, while affordable, required constant maintenance and skilled CAD operators, leading to substantial downtime and retraining burdens. This highlights the dialectical tension between upfront cost and long-term operational efficiency. True quality isn't just about what a machine can do, but what it consistently delivers under demanding industrial conditions, integrating innovations that simplify operations and maximize material utilization, a philosophy we champion at MZBNL.

What are the key features of a high-quality metal tube cutting machine?

Are you seeking to unlock peak efficiency in your metal fabrication? Many believe higher power equals higher quality, but the truth is more nuanced. Discover the core features that truly define a superior tube cutting machine, ensuring your investment delivers consistent, high-precision results for years.

Key features of a high-quality metal tube cutting machine include robust structural integrity, advanced laser technology, intuitive control systems, high-precision motion components, and efficient material handling. Innovations like automated loading, intelligent software, and optimized waste reduction mechanisms further distinguish top-tier machines by enhancing productivity and lowering operational costs.

For professionals like Ahmed Al-Farsi, who are constantly pushing the boundaries of architectural metalwork and vehicle parts, identifying these core features isn't just an academic exercise; it's a strategic imperative. The ability of a machine to integrate seamlessly into existing workflows, reduce manual labor, and minimize material waste directly translates into tangible profit margins. I've seen countless times how a machine that boasts high-speed cutting on paper can fall short in real-world applications due to a clunky interface or excessive material scrap. My experience with MZBNL has shown me that true quality emerges from a synergistic blend of cutting-edge technology and thoughtful, user-centric design. This holistic approach ensures that every component, from the laser source to the software interface, contributes to a machine that doesn't just cut, but optimizes your entire production process, setting you apart in a competitive market.

Understanding the definitive features of a high-quality metal tube cutting machine goes beyond simply reviewing its specifications; it involves appreciating how integrated innovations translate into real-world operational benefits and significant cost savings. Over my 25 years in this industry, I've seen countless machines enter the market, but only those truly focused on user experience and efficiency stand the test of time. It's about designing a system where every element contributes to a more productive, more profitable outcome for the end user.

Integrated Smart Automation & User Experience

The paradigm shift in industrial automation is undeniably towards systems that are not only powerful but also intuitively smart and user-friendly. Traditionally, the operation of complex laser tube cutting machines demanded highly skilled CAD operators who had to return to design offices for even minor drawing modifications. This created a significant bottleneck, causing delays and increasing the cost of production due to skilled labor requirements and inefficiencies in the design-to-production workflow.

MZBNL recognized this critical industry pain point and pioneered and perfected its revolutionary No-CAD Operating System. This innovation empowers operators to process standard tube types and hole patterns simply by entering parameters directly into the machine interface, entirely eliminating the need for complex 3D CAD drawings. This dramatically simplifies the operational process, making advanced laser cutting technology accessible to a broader range of personnel.

The impact of such user-centric design is profound. We've seen operator training times reduce from an industry average of 15 days at the equipment factory to just 1 day of on-site training. This reduction directly addresses issues like high operator turnover, which Ahmed Al-Farsi previously faced, where constant retraining became a significant burden. By lowering the skill threshold and enhancing ease of use, MZBNL’s machines foster greater operational autonomy and significantly cut down on labor-related overheads, making the entire production cycle far more agile and responsive.

Material Handling Efficiency & Ergonomics

Beyond the cutting process itself, the efficiency of material loading and unloading profoundly impacts overall productivity and operator well-being. Many conventional laser cutting machines still rely on manual side or rear loading mechanisms, which are labor-intensive, time-consuming, and often ergonomically challenging for operators. This method is prone to errors and can significantly slow down throughput, especially in high-volume production environments.

Recognizing this inefficiency, MZBNL introduced an optimized front-feeding mechanism. This innovative design automatically pulls the tube in from the front of the machine, streamlining the entire loading process. The direct result is a remarkable increase in feeding efficiency by approximately 40%. This isn't just a theoretical number; it translates into more tubes processed per hour, directly boosting the machine's effective utilization rate.

Furthermore, this front-feeding innovation significantly reduces operator labor intensity by approximately 40%. This improvement goes beyond mere numbers; it addresses critical ergonomic concerns in the workplace, reducing physical strain on operators and contributing to a safer, more sustainable work environment. For businesses like Ahmed Al-Farsi's, focused on automating existing manual workflows, such an innovation is key to achieving higher overall productivity without overburdening their workforce, ensuring continuous and efficient operation.

Waste Minimization & Resource Optimization

One of the often-overlooked yet substantial costs in metal fabrication is material waste, particularly the "tail material" left over at the end of a cutting process. Conventional laser cutting systems typically start cutting from the tube head, and when the process concludes, a section of the tube remains unusable at the tail end. Over time, especially with high-volume production, this accumulated scrap material can represent a significant financial loss.

BNL critically redesigned the cutting logic to tackle this problem head-on, focusing on maximizing material utilization. Our system now calculates from the rear chuck as the origin, fundamentally altering the cutting sequence. This intelligent approach allows the system to efficiently manage the remaining tube length, eliminating leftover tail material as long as the remaining section is smaller than the product length. This is a game-changer for cost-efficiency.

This "zero-waste tail material" design is a testament to our commitment to resource optimization and client profitability. By minimizing scrap, businesses not only save on raw material costs but also contribute to more sustainable manufacturing practices. The direct financial impact can be substantial, especially when processing expensive alloys or in operations with high material throughput. Below is a comparison illustrating how BNL's innovations address common industry challenges.

| Feature | Traditional System | BNL Innovation | Impact on Business |

|---|---|---|---|

| CAD Dependency | High, skilled operators needed | Low, parameter-based | Reduced training (15 days -> 1 day), lower skill threshold, faster setup, less reliance on specialized personnel. |

| Material Feeding | Manual, side/rear loading | Automated, front-feeding | 40% efficiency increase, 40% labor reduction, improved ergonomics, higher throughput. |

| Tail Material | Significant waste generated | Near-zero waste | Maximized material utilization, significant cost savings on raw materials, increased sustainability. |

Cutting precision impacts profitabilityTrue

High-precision cutting reduces material waste and rework, directly improving profit margins.

Higher power always means better qualityFalse

Quality depends on multiple integrated factors like precision components and software, not just laser power.

How do build materials affect the performance of cutting machines?

Ever wondered why some cutting machines perform flawlessly for years while others falter? The secret often lies in their foundational elements. Ignoring the quality of build materials can lead to costly breakdowns and inconsistent results. Let's uncover how robust construction dictates long-term performance.

The build materials of a metal tube cutting machine, including the machine frame, gantry, and critical components, directly influence its stability, vibration dampening, and overall longevity. High-quality, precision-machined materials ensure superior rigidity and thermal stability, crucial for maintaining cutting accuracy and resisting deformation under continuous operation and environmental stresses.

Just as a building's foundation determines its stability, the raw materials and craftsmanship behind a laser tube cutting machine1 dictate its performance ceiling and operational lifespan. I've witnessed countless situations where factories, seeking short-term savings, opted for machines constructed with inferior materials, only to face premature wear, misalignment issues, and frequent maintenance. This directly impacts their profitability through increased downtime and reduced output quality. When I discuss solutions with clients like Ahmed Al-Farsi, whose business demands consistent, high-volume production of precision parts, I always emphasize that a machine's robust build is not an optional luxury but a fundamental requirement. It ensures that the cutting accuracy you achieve on day one is maintained years down the line, safeguarding your investment and reputation.

The performance of a metal tube cutting machine is inextricably linked to the quality and suitability of its build materials. It's a critical aspect that often gets overlooked in favor of flashier features, yet it dictates the machine's long-term reliability, precision, and overall operational efficiency. My experience with MZBNL, a company with 25 years in metal fabrication, has consistently shown that investing in superior materials upfront pays dividends in sustained performance and reduced maintenance costs. The choice of materials profoundly influences the machine's ability to withstand continuous operation, absorb vibrations, and maintain dimensional stability under varying conditions.

Frame Rigidity and Vibration Dampening

The core of any high-precision machine tool is its frame, and in a metal tube cutting machine, rigidity is paramount. A machine frame constructed from high-grade, heavy-duty steel or cast iron, meticulously welded and stress-relieved, provides the essential foundation for stability. Inferior frames, often made from thinner, less robust materials, are prone to vibrations during high-speed cutting. These vibrations are not merely an annoyance; they directly compromise cut quality, leading to rough edges, inaccurate dimensions, and increased post-processing requirements.

Effective vibration dampening is also critical for prolonging the life of sensitive components like the laser head and motion system. High-quality machines incorporate design elements and material choices that absorb kinetic energy, preventing it from transferring into the cutting zone. This ensures the laser beam maintains its precise focus and path, even during dynamic movements. For example, a machine with a well-engineered, massive bed will exhibit far less deflection and resonance compared to a lighter, less robust alternative2, directly contributing to consistent cutting accuracy over thousands of hours of operation.

Moreover, the long-term structural integrity of the frame ensures that the machine's calibration remains stable. Over time, constant stress and vibrations can cause wear and misalignment in poorly constructed frames, leading to a gradual degradation of cutting precision. By investing in a machine with a superior, rigidly built frame, businesses like Ahmed Al-Farsi’s can be confident that their investment will continue to deliver repeatable, high-quality results for years, minimizing the need for costly recalibrations and repairs.

Component Material Selection and Precision Manufacturing

While the frame provides the macro stability, the quality of materials used for critical moving components directly impacts the micro-precision and longevity of the machine. Elements such as linear guides, gears, servo motors, and especially the chucks that hold the tube, must be manufactured from materials with exceptional durability, wear resistance, and dimensional stability. Using top-tier components from reputable suppliers (e.g., Japanese or German linear guides and bearings) is a hallmark of a high-quality machine.

Precision manufacturing processes are equally vital. Components like gears and rack-and-pinion systems must be ground to extremely tight tolerances to ensure smooth, backlash-free motion. Heat treatment processes, such as hardening and tempering, enhance the strength and wear resistance of these parts, preventing premature failure under continuous high-speed operation. For instance, the chucks used in MZBNL's machines are designed with high gripping force and concentricity, often made from durable, precisely machined alloys3, to ensure the tube is held securely and rotates without slippage or eccentricity, which is crucial for maintaining cutting accuracy on cylindrical surfaces.

The choice of materials also affects the machine’s ability to maintain its precision over thousands of hours. Components made from materials susceptible to creep, fatigue, or excessive wear will gradually lose their accuracy, leading to inconsistent cut quality and increased maintenance. A quality manufacturer meticulously selects materials based on their specific functional requirements, ensuring each part contributes to the overall robust and reliable performance of the machine.

Thermal Stability and Environmental Resilience

Industrial environments, especially in regions like the Middle East where Ahmed Al-Farsi operates, can present significant temperature fluctuations. These thermal changes can cause expansion and contraction in machine components, directly impacting dimensional accuracy. A high-quality metal tube cutting machine must be designed with thermal stability in mind, using materials with low coefficients of thermal expansion where precision is critical, or incorporating effective thermal management systems.

Effective cooling systems are essential for maintaining the operational stability of the laser source, optics, and critical electronic components. High-performance water chillers ensure the laser source operates within its optimal temperature range, preventing beam quality degradation and ensuring consistent cutting power. Additionally, well-designed air conditioning or cooling systems for the control cabinet protect sensitive electronics from overheating, which can lead to system errors or component failure.

Furthermore, the machine's design and material selection must consider its resilience to the specific operating environment. Factors like dust, humidity, and temperature extremes can accelerate wear or compromise electronic systems if not adequately addressed through sealed enclosures, filtration systems, and robust material finishes. By prioritizing materials and designs that ensure thermal stability and environmental resilience, a high-quality machine guarantees consistent performance even during long production runs and under challenging external conditions, safeguarding both the machine's longevity and the quality of its output.

Frame rigidity affects cut qualityTrue

A rigid frame minimizes vibrations that cause rough edges and dimensional inaccuracies during cutting.

All metals expand equally when heatedFalse

Different metals have unique coefficients of thermal expansion, which is why precision machines use materials with low thermal expansion properties.

What role does precision play in determining the quality of tube cutting machines?

Are your cut parts consistently failing quality checks? Imprecise cuts can lead to costly rework and material waste. The cornerstone of a high-quality metal tube cutting machine lies in its unwavering precision. Let's explore why every micron matters for your bottom line.

Precision is paramount in a tube cutting machine, directly impacting cut quality, material utilization, and part fitment. It encompasses accuracy in motion control systems, laser focus, and repeatable positioning. High precision ensures minimal kerf loss, tight tolerances and consistent part geometries, which are critical for seamless downstream assembly and reduced scrap rates.

In the world of metal fabrication, where components often need to fit together flawlessly for complex assemblies like vehicle parts or architectural structures, precision isn't just a desirable trait; it's a non-negotiable standard. I've seen how even slight deviations in cut dimensions can cascade into significant issues, leading to wasted materials, rejections, and delayed project deliveries—a nightmare for any business owner. For clients like Ahmed Al-Farsi, whose contract-based fabrication services rely heavily on delivering finished parts to demanding OEMs and builders, consistently high precision is the bedrock of his reputation and profitability. At MZBNL, we understand that our machines aren't just cutting metal; they're crafting components that define the quality of our clients' end products. This commitment to micron-level accuracy drives our R&D and manufacturing processes, ensuring every cut meets the most stringent industry benchmarks.

Precision stands as the fundamental pillar of quality in a metal tube cutting machine, influencing every aspect of its performance from the microscopic kerf width to the macroscopic fit of assembled components. In an industry where tolerances are increasingly tight and material costs are significant, the ability of a machine to consistently deliver highly accurate and repeatable cuts is paramount. My 25 years in metal fabrication have taught me that a machine’s true value isn't just in its speed, but in its ability to produce perfect parts consistently, minimizing rework and maximizing material utilization. This directly translates into competitive advantage and profitability for businesses.

Motion Control and Positional Accuracy

The bedrock of precision in any CNC machine, including tube cutting systems, lies in its motion control system. This system dictates how accurately the laser head and tube move relative to each other, ensuring that the programmed cutting path is followed with unwavering fidelity. High-quality machines employ advanced servo motors coupled with high-resolution linear encoders4. These encoders provide precise, real-time feedback on the exact position of the cutting head, allowing the control algorithms to make instant, minute adjustments, thus eliminating errors caused by mechanical play or dynamic forces.

Positional accuracy and repeatability are two critical metrics. Positional accuracy refers to how close the actual position of the cutting head is to its commanded position, while repeatability measures how consistently the machine can return to a specific point. For intricate tube designs with multiple holes or complex contours, superior motion control ensures that each feature is cut in precisely the correct location and orientation. A machine boasting sub-micron positional accuracy, for example, can produce parts that fit together seamlessly without the need for manual alignment or grinding, significantly reducing assembly time and costs in downstream processes.

Furthermore, sophisticated control algorithms are designed to compensate for dynamic forces that arise during rapid acceleration, deceleration, or changes in cutting direction. This dynamic compensation ensures that accuracy is maintained even at high cutting speeds, preventing issues like "corner lag" or "overshoot" that can compromise the geometric integrity of the cut part. Businesses producing parts for the automotive or architectural sectors, like Ahmed Al-Farsi’s, where precise fitment is crucial for structural integrity and aesthetic appeal, rely heavily on such high levels of motion control precision.

Laser Beam Quality and Focus Control

Beyond mechanical precision, the quality of the laser beam5 itself and the machine's ability to precisely control its focus are equally vital for superior cut quality. A high-quality fiber laser source produces a stable beam with minimal divergence, allowing for a very small and consistent focal spot size on the material surface. A smaller, more concentrated spot delivers higher power density, resulting in a cleaner, narrower kerf (the width of the cut) and smoother cut edges with minimal dross.

Advanced machines incorporate sophisticated auto-focusing systems. These systems dynamically adjust the laser focus based on the material thickness, type, and even variations in the tube's geometry. This ensures that the laser beam remains optimally focused at the cutting front throughout the entire process, regardless of slight variations in the tube's surface or changes in cutting parameters. Without precise focus control, the laser beam can defocus, leading to wider, inconsistent cuts, increased heat affected zones (HAZ), and a greater need for post-processing operations like deburring or grinding.

The implications of superior beam quality and focus control are direct: reduced material waste due to narrower kerf widths, faster cutting speeds because less energy is wasted, and significantly improved edge quality that often eliminates the need for secondary finishing operations. This not only enhances the aesthetic and functional quality of the finished parts but also streamlines the entire production workflow, leading to substantial savings in labor and consumables.

Chuck System and Material Support Precision

Even with excellent motion control and laser quality, precision can be compromised if the tube itself is not held and supported accurately throughout the cutting process. The chuck system, responsible for clamping and rotating the tube, must offer high gripping force, exceptional concentricity, and minimal runout to prevent tube slippage or eccentric rotation. High-quality pneumatic or electric chucks, often featuring multiple jaws and synchronized movements, ensure the tube remains perfectly centered and stable, especially during high-speed rotation.

For long or heavy tubes, proper material support systems are indispensable. Sagging or vibration of unsupported tube lengths can lead to significant inaccuracies along the cut profile. Advanced machines incorporate automated follow-up supports that move synchronously with the cutting head, providing continuous support and preventing deflection. This is particularly crucial for thin-walled tubes or those with complex geometries, where even minor sagging can distort the cut.

Furthermore, multi-chuck systems can enhance precision by providing additional clamping points, minimizing vibration and improving stability for very long tubes or when processing close to the tail end. The synergy between a robust chuck system, precise material supports, and the machine's overall motion control ensures that the tube maintains its perfect position relative to the laser, guaranteeing consistent precision from the first cut to the last. This comprehensive approach to precision, encompassing every aspect of material handling and cutting mechanics, is what truly sets a high-quality metal tube cutting machine apart.

Precision reduces material wasteTrue

High precision cutting minimizes kerf width and scrap rates, directly improving material utilization.

Laser focus doesn't affect cut qualityFalse

Precise laser focus control is critical for maintaining optimal power density and achieving clean cuts with minimal dross.

How can maintenance and ease of use influence a machine's overall quality?

Is your production line constantly halted by complex maintenance or tricky operations? A truly high-quality machine isn't just powerful; it's user-friendly and easily maintained. Ignoring these aspects can lead to crippling downtime and inflated operating costs. Let's explore their critical impact.

Ease of use and streamlined maintenance significantly impact a metal tube cutting machine's overall quality by reducing downtime, minimizing operator error, and lowering total cost of ownership. Intuitive interfaces, simplified troubleshooting, and accessible components contribute to higher operational efficiency and prolonged machine lifespan, empowering consistent, uninterrupted production.

I often tell my clients that the most advanced machine is only as good as its usability and maintainability. In my 25 years in this industry, I've seen brilliant engineering undermined by overly complex interfaces or components that are a nightmare to service. This leads directly to operator frustration, increased errors, and prolonged production halts, eroding profitability. Ahmed Al-Farsi's experience6 perfectly illustrates this: his previous machines required skilled CAD operators, and equipment from some suppliers lacked local service support, creating significant pain points. At MZBNL, our design philosophy prioritizes not just cutting-edge performance but also a seamless user experience and straightforward maintenance protocols. We believe that empowering operators and simplifying upkeep are fundamental pillars of true machine quality, ensuring that our clients' operations run smoothly day in and day out, maximizing their return on investment.

The true quality of a metal tube cutting machine is not solely defined by its raw cutting power or precision, but profoundly by its ease of use and maintainability. In a fast-paced manufacturing environment, complex operations and difficult maintenance procedures can quickly negate any initial performance advantages, leading to frustrating downtime, increased labor costs, and operational inefficiencies. My experience has shown that machines designed with the user and service technician in mind ultimately deliver a much higher return on investment over their lifespan. They empower operators, minimize errors, and ensure that the production line remains active and profitable.

Intuitive Operation & Training Efficiency

A truly high-quality metal tube cutting machine prioritizes the operator experience, transforming complex processes into intuitive actions. The traditional reliance on highly skilled CAD operators, who needed extensive training and often had to bounce between design offices and the factory floor to make adjustments, created a significant bottleneck for many businesses. This complexity led to increased training burdens and higher susceptibility to human error, particularly with high operator turnover.

MZBNL7 directly addressed this challenge with its pioneering No-CAD Operating System. This innovation allows operators to process standard tube types and hole patterns by simply inputting parameters directly into the machine's interface, completely bypassing the need for intricate 3D CAD drawings. This simplification drastically flattens the learning curve, transforming what once required weeks of specialized training into a process that can be mastered in a single day of on-site instruction. For clients like Ahmed Al-Farsi, who previously struggled with high operator turnover and the associated retraining costs, this feature directly solves a major pain point.

The impact of such user-friendly design extends beyond just training time. It reduces operator fatigue, minimizes the likelihood of errors, and allows for greater flexibility in workforce deployment. By making advanced laser cutting accessible to a wider pool of skilled labor, businesses can achieve higher operational efficiency and maintain consistent production output, even as their team evolves. An intuitive machine is not just a convenience; it's a strategic advantage that enhances productivity and reduces operational friction.

Streamlined Maintenance & Diagnostics

Even the most robust machine requires periodic maintenance. The quality of a machine can be significantly judged by how easily and quickly routine maintenance tasks can be performed, and how effectively issues can be diagnosed and resolved. Machines designed with accessible components, clear labeling, and modular construction greatly simplify these processes, minimizing downtime. Complex, hard-to-reach parts or proprietary systems that require specialized tools can significantly inflate maintenance costs and extend repair times.

High-quality machines integrate sophisticated diagnostic capabilities, often with remote access features. For instance, MZBNL's machines are equipped with advanced remote diagnostics, allowing our support team to connect to the machine remotely, identify issues, and often guide the client's technicians through troubleshooting steps without the need for an immediate on-site visit. This significantly reduces response times and the costs associated with technician travel, a crucial benefit for international clients like Ahmed Al-Farsi, whose sourcing key points include remote diagnostics and local agent presence.

Furthermore, the availability of spare parts and comprehensive service manuals is a critical indicator of a supplier's commitment to long-term quality. A machine might be excellent, but if replacement parts are scarce or delivery times are prohibitive, downtime becomes a costly reality. By ensuring readily available spares and clear maintenance protocols, manufacturers like MZBNL ensure that their machines not only perform well but also remain operational and efficient throughout their extensive service life, effectively addressing Ahmed's concern for spare parts availability and reliable service support.

Safety Features & Ergonomic Design

Operator safety and comfort are integral components of a machine's overall quality and directly influence its long-term operational efficiency. A well-designed machine incorporates comprehensive safety features that protect operators from potential hazards, while ergonomic considerations reduce physical strain and fatigue, leading to higher productivity and fewer workplace accidents. Ignoring these aspects can lead to costly injuries, legal liabilities, and decreased morale.

High-quality metal tube cutting machines are typically equipped with advanced safety features such as fully enclosed cutting areas to contain laser radiation and debris, interlocks that prevent operation when protective covers are open, emergency stop buttons strategically placed, and light curtains that halt machine movement if an operator enters a restricted zone. These features are not mere add-ons; they are fundamental design elements that demonstrate a manufacturer's commitment to operator well-being and regulatory compliance.

Beyond safety, ergonomic design enhances daily operations. MZBNL's innovative Front-Feeding system, for example, not only boosts feeding efficiency by approximately 40% but also significantly reduces operator labor intensity by the same margin. This translates into less physical exertion for workers, reducing the risk of musculoskeletal injuries and allowing operators to maintain higher levels of productivity and focus throughout their shifts. An ergonomically designed machine fosters a safer, more comfortable, and ultimately more productive working environment, ensuring that the machine is not just technically superior but also a positive asset to the entire fabrication team.

Ease of use reduces training timeTrue

Intuitive interfaces like MZBNL's No-CAD system can reduce operator training from weeks to just one day.

Remote diagnostics increase downtimeFalse

Remote diagnostics actually reduce downtime by enabling faster troubleshooting without on-site visits.

What recommendations exist for professionals choosing a metal tube cutting machine?

Overwhelmed by the options for a new tube cutting machine? A critical investment demands a strategic approach. Avoiding common pitfalls and making an informed decision can revolutionize your production. Let's outline the definitive steps to select the perfect machine for your business.

Professionals choosing a metal tube cutting machine should prioritize robust build quality, advanced automation (like No-CAD), proven cutting precision, and comprehensive after-sales support. Evaluating the supplier's experience, global presence, and customization capabilities alongside the machine's ease of use and long-term maintainability is crucial for a successful, profitable investment.

Having guided countless clients, from startups to large enterprises, through the complex process of selecting the right metal fabrication equipment, I've distilled the myriad considerations into a set of actionable recommendations. It's not merely about comparing technical specifications on a brochure; it's about understanding your long-term operational needs, anticipating future growth, and partnering with a supplier who truly grasps your unique challenges. For someone like Ahmed Al-Farsi, who considers turnkey solutions and values high cost-performance alongside strong post-sales training and support, these recommendations are directly aligned with his critical sourcing key points. My aim is to empower you to make a decision that transcends the immediate purchase, fostering a lasting partnership and an investment that truly elevates your business.

Choosing a metal tube cutting machine is a significant capital investment that can profoundly impact a business's productivity, profitability, and competitive edge for years to come. In my 25 years of experience at MZBNL, I've observed that the most successful investments stem from a methodical approach that goes beyond superficial features. It requires a critical evaluation of a company's specific needs, the supplier's true capabilities, and a thorough understanding of the machine's total cost of ownership8. These three pillars form the foundation for making an informed decision that ensures long-term value and sustained operational excellence.

Define Your Specific Needs & Future Growth

Before even looking at machine specifications, the first critical step for any professional is to conduct a meticulous assessment of their current and projected operational needs. This involves clarifying several key parameters: What types of materials will you predominantly cut (e.g., carbon steel, stainless steel, aluminum, brass, copper)? What are the required tube dimensions—diameters, lengths, and wall thicknesses? What level of cutting speed and precision is necessary for your end products? These factors directly dictate the appropriate laser power, machine size, and motion system requirements.

Furthermore, it's crucial to consider your business's future growth trajectory. Will your production volume increase? Do you anticipate diversifying into new product lines or materials? For clients like Ahmed Al-Farsi, who actively expands his business in architectural metalwork and vehicle parts supply, choosing a versatile machine or one with modular upgrade paths can be a strategic advantage, accommodating future demands without requiring an entirely new investment. A critical aspect here is evaluating how seamlessly the new machine can integrate into your existing factory layout and automation plans. Prioritizing a "turnkey solution," as Ahmed does, can simplify installation and commissioning, making the transition smoother and more cost-effective in the long run by reducing complex integrations.

A clear understanding of your unique requirements and future ambitions allows you to filter out unsuitable options and focus on machines that truly align with your strategic objectives. This initial self-assessment prevents over- or under-investing and ensures the chosen machine is a perfect fit for your operational realities.

Evaluate Supplier Credentials & Support Ecosystem

The quality of a metal tube cutting machine is intrinsically linked to the credibility and support infrastructure of its manufacturer. It's not enough to buy a machine; you're entering a long-term partnership with its supplier. Therefore, a thorough evaluation of the supplier's credentials9 is non-negotiable. Look for manufacturers with a proven track record, extensive industry experience, and a strong commitment to research and development. For instance, MZBNL's 25 years of experience in metal fabrication, coupled with over 30 patents and a client base of 4000+ global enterprises, speaks volumes about our established expertise and innovative capabilities.

Beyond historical performance, assess the supplier's R&D model. Companies that integrate R&D, manufacturing, sales, and service, like MZBNL, often offer more cohesive product development and comprehensive support. This integrated approach ensures that customer feedback directly influences product improvements and that service teams have in-depth knowledge of the machines. For international clients like Ahmed Al-Farsi, who values robust after-sales service, training support, spare parts availability, and local agent presence, a strong global presence is vital. MZBNL's extensive network across Southeast Asia, the Middle East, Europe, and North America ensures prompt service and readily available spare parts, minimizing potential downtime for our clients.

Critically analyze the pitfalls of choosing suppliers with limited support. A machine, no matter how advanced, will eventually require maintenance or troubleshooting. Suppliers lacking a robust service network, remote diagnostics capabilities, or readily available spare parts can lead to significant and costly operational disruptions. Ahmed’s consideration of becoming a regional distributor for MZBNL if the machine performs well and support is reliable further underscores the profound importance of a strong, trustworthy supplier partnership that extends beyond the initial sale.

Prioritize Total Cost of Ownership (TCO) Over Initial Price

One of the most common pitfalls in capital equipment procurement is focusing solely on the initial purchase price. While attractive, a lower upfront cost often masks higher long-term operational expenses. Professionals must adopt a Total Cost of Ownership (TCO) perspective, which accounts for all costs incurred over the machine’s lifespan. TCO includes not just the purchase price but also energy consumption, consumable parts (e.g., nozzles, lenses, gases), maintenance costs, labor efficiency, and perhaps most critically, material waste.

A seemingly cheaper machine might have higher energy consumption, less efficient cutting, or generate excessive tail material waste, which quickly erodes any initial savings. For example, without innovations like MZBNL’s Zero-Waste Tail Material system, accumulated scrap can amount to substantial financial losses over time. Similarly, a machine lacking user-friendly interfaces or robust automation, like our No-CAD system, can incur higher labor costs due to the need for more skilled operators or longer training periods. Ahmed Al-Farsi's preference for a "high cost-performance ratio over low price" perfectly aligns with this TCO philosophy; he understands that long-term savings from reduced material waste, lower labor requirements, and minimal downtime far outweigh a slightly higher initial investment.

Ultimately, a high-quality machine, while potentially having a higher initial price point, delivers a lower TCO through superior energy efficiency, reduced material consumption, minimal maintenance requirements, and higher overall productivity. By comprehensively evaluating these factors, businesses can make a strategic investment that maximizes their return and ensures sustainable profitability for years to come. This disciplined approach guarantees that the machine you choose is not just a tool, but a cornerstone of your future success.

Prioritize TCO over initial priceTrue

Total Cost of Ownership (TCO) includes long-term operational costs like energy, maintenance, and material waste, making it more important than just the purchase price.

Supplier experience doesn't matterFalse

A supplier's track record, R&D capabilities, and global support network are crucial for long-term machine performance and maintenance.

Conclusion

Ultimately, evaluating a metal tube cutting machine's quality transcends simple specifications; it's about comprehensive excellence. Prioritize robust build, precision, smart automation, and strong supplier support to ensure optimal performance, minimal waste, and sustained profitability. A well-chosen machine, like those we offer at MZBNL, is a cornerstone for your business's long-term success.

-

Learn about the long-term benefits of robust construction in cutting machines. ↩

-

Understand how inferior materials can compromise cut quality and precision. ↩

-

Explore the advantages of using durable alloys in cutting machine components. ↩

-

Explore the role of linear encoders in enhancing CNC machine precision. ↩

-

Discover how laser beam quality impacts cut edge precision and overall machine performance. ↩

-

Learn about common issues with complex machines and the benefits of simplified systems. ↩

-

Understand how MZBNL's innovation simplifies machine usage and training. ↩

-

Learn how TCO analysis can lead to wiser long-term investments and savings ↩

-

Find criteria to evaluate suppliers ensuring reliable partnerships and support ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.