How Metal Tube Cutting Machines Support Furniture Manufacturing

Are you facing the complexities of traditional metal tube fabrication in furniture production? Inefficient cutting methods can significantly hinder innovation and escalate operational costs. Modern metal tube cutting machines are the key to unlocking new efficiencies and design possibilities.

Metal tube cutting machines are indispensable in furniture manufacturing, enabling precise, high-speed production of components for chairs, tables, and frames. They streamline workflows by automating cutting, punching, and shaping, ensuring consistency, reducing waste, and facilitating intricate designs crucial for today’s diverse furniture styles and market demands.

Having grasped their immediate impact, you might be curious about the foundational role these machines play and their evolutionary journey. Join me as we delve deeper into how these sophisticated tools are not just improving existing processes but are fundamentally reshaping the landscape of furniture manufacturing, offering unparalleled precision and efficiency for businesses like yours.

For years, furniture manufacturers wrestled with manual or semi-automated processes for metal tube fabrication, often encountering issues with inconsistent quality, slow production cycles, and significant material waste. This traditional approach, while perhaps cost-effective for small-scale operations, became a severe bottleneck as consumer demand for diverse, custom, and high-quality furniture surged. The paradigm shifted with the advent of advanced CNC-controlled tube cutting machines1, moving from a labor-intensive craft to a precision-engineered process. For instance, in an industry where bespoke designs are becoming the norm, the ability to rapidly prototype and produce complex geometries—like those seen in contemporary minimalist furniture or ergonomic office chairs—is no longer a luxury but a necessity. This technological leap has allowed companies to expand their product lines, respond quickly to market trends, and reduce lead times, directly impacting their bottom line. It’s a transition from simply making furniture to engineering solutions that meet modern aesthetic and functional demands.

Background on the use of metal tubes in furniture manufacturing

Do you truly appreciate the foundational role metal tubes2 play in modern furniture? Underestimating their structural and aesthetic versatility can limit design potential and product durability. Grasping their widespread application is key to understanding why precise processing is so critical for robust, innovative furniture.

Metal tubes, particularly steel and aluminum, are widely used in furniture for their strength, durability, and versatility, forming frames for chairs, tables, beds, and shelving units. They enable lightweight yet robust designs, support modern aesthetics, and are essential for mass production due to their consistent quality and cost-effectiveness, making them a core material in contemporary furniture manufacturing.

Understanding the omnipresence of metal tubes in furniture—from the sleek lines of a minimalist desk to the robust framework of an industrial-style shelving unit—reveals a clear trend: designers and manufacturers are increasingly embracing these materials for their inherent strength-to-weight ratio and design flexibility. Beyond mere structural support, metal tubes offer a contemporary aesthetic that aligns with current market demands for durable, versatile, and visually appealing pieces. This widespread adoption, however, also presents significant manufacturing challenges. Achieving the precise cuts, intricate bends, and perfect joints required for high-quality furniture demands more than traditional methods can offer. It necessitates a deep dive into the evolution of cutting technology and its direct impact on both design possibilities and production efficiencies, laying the groundwork for the innovations we see today.

A. The Evolution of Metal in Furniture Design

Historically, furniture design predominantly relied on wood, a material cherished for its warmth, workability, and traditional aesthetic. However, the early 20th century marked a pivotal shift with the advent of industrialization, introducing new materials and manufacturing capabilities that fundamentally reshaped how furniture was conceived and produced. Metal, particularly tubular forms, emerged as a revolutionary medium, offering unparalleled strength, durability, and a distinct minimalist aesthetic that perfectly resonated with the burgeoning Modernist movement. Pioneering designers from the Bauhaus school, like Marcel Breuer with his iconic Wassily Chair3, famously utilized tubular steel to create pieces that were not only lighter and more adaptable but also easier to mass-produce, challenging the conventional notions of furniture craftsmanship.

This foundational shift was not merely an aesthetic choice but a practical evolution. The inherent strength-to-weight ratio of metal tubes allowed for the creation of open, airy designs that were both robust and visually lightweight, a stark contrast to the often bulky wooden furniture of previous eras. As manufacturing processes became more sophisticated, so did the potential for intricate metalwork, leading to the development of sleek, ergonomic designs that prioritized both form and function. For my typical customer, Ahmed Al-Farsi, who operates a mid-sized metal fabrication business and actively expands into architectural metalwork and vehicle parts, this understanding of material science and its application is second nature. He appreciates how materials like steel and aluminum, when expertly processed, can transform raw components into highly durable and aesthetically pleasing finished products, whether for a vehicle chassis or a custom architectural railing.

The transition from wood to metal also ushered in an era of greater consistency and scalability in furniture production. Unlike wood, which can vary significantly in grain, strength, and moisture content, standardized metal tubes offer predictable properties, making them ideal for high-volume manufacturing. This consistency is crucial for industries seeking to replicate designs precisely across large batches, ensuring uniformity and reducing defects. The adoption of metal tubes enabled factories to streamline assembly lines, moving from artisanal workshops to industrialized production hubs. This mass production capability directly aligns with the operational needs of businesses like Ahmed’s, which are constantly seeking automated solutions to upgrade their production efficiency and deliver consistent quality to clients, emphasizing the foundational importance of reliable material processing.

B. Functional and Aesthetic Versatility of Tubular Components

Beyond their structural integrity, metal tubes contribute significantly to the aesthetic versatility of contemporary furniture. Their ability to be bent, welded, and shaped into virtually any form allows designers an unprecedented degree of creative freedom. Clean lines, minimalist profiles, and sophisticated geometries, often characteristic of modern and post-modern furniture, are largely achievable due to the precise manipulation of tubular metal. Whether it's the sleek, polished chrome of an executive office chair base, the matte black frame of an industrial bookshelf, or the elegant curve of a chaise lounge, the aesthetic appeal of metal tubing is undeniable.

The diverse range of tube shapes—round, square, rectangular, oval—each offers distinct functional and aesthetic properties, expanding design possibilities exponentially. For instance, square tubes provide strong, angular support, often favored in industrial or contemporary designs, while round tubes lend themselves to softer, more fluid forms, commonly seen in mid-century modern or highly ergonomic pieces. The choice of tube profile, combined with various finishes like powder coating, plating, or polishing, allows manufacturers to tailor products to specific market segments and design sensibilities. This adaptability is precisely what allows furniture makers to integrate metal components seamlessly with other materials such as wood, glass, fabric, and plastic, creating hybrid designs that capitalize on the strengths of each material.

Consider the intricate requirements of today’s ergonomic office chairs or modular shelving systems. These designs often necessitate multiple precisely cut and joined tube sections to achieve optimal functionality and stability. My experience has shown that clients like Ahmed often tackle projects demanding not just volume but also complex component geometry. His interest in automated solutions with punching capabilities for architectural and vehicle parts echoes the need for versatile processing. For example, creating a high-performance office chair might involve dozens of unique tube segments, each requiring specific cuts, holes for fasteners, and sometimes complex bending, highlighting the indispensable role of advanced tube processing capabilities in meeting sophisticated design briefs.

| Tube Type | Common Furniture Use | Key Attribute | Processing Need |

|---|---|---|---|

| Round | Chairs, Tables, Beds | Smooth curves | Bending, Notching |

| Square | Shelving, Desks | Structural stability | Straight cuts, Joints |

| Rectangular | Benches, Frames | Load-bearing, Modern aesthetics | Precise length, Hole punching |

| Oval | Designer pieces | Unique aesthetic, Ergonomic handles | Complex shaping, Finishes |

C. Economic and Environmental Advantages

The widespread adoption of metal tubes in furniture manufacturing is also driven by significant economic and environmental benefits. From an economic perspective, metal tubes offer superior material consistency, which translates directly into lower scrap rates and more predictable production costs, especially in high-volume manufacturing. Automated metal tube cutting machines significantly reduce labor costs and improve throughput, allowing manufacturers to produce more units in less time with fewer human errors. For a business like MZBNL, our focus on integrated solutions means we see how crucial this is. For example, my conversations with Ahmed reveal his constant drive to automate existing manual workflows and reduce high operator turnover, which directly impacts his bottom line and competitiveness.

Furthermore, the longevity and durability of metal furniture mean a longer product lifecycle, reducing the frequency of replacement and contributing to overall cost savings for the end-user. From an environmental standpoint, metals like steel and aluminum are highly recyclable, often containing a significant percentage of recycled content, which minimizes the demand for virgin resources and reduces carbon footprint. This aligns with a growing global emphasis on sustainable manufacturing practices. Our Zero-Waste Tail Material Innovation4, for instance, directly addresses this by maximizing material utilization. Conventionally, up to 10% of a tube could be wasted as an unusable tail, but by redesigning the cutting logic to calculate from the rear chuck as the origin, we’ve effectively eliminated this waste, boosting material efficiency and reducing environmental impact.

The combination of robust design, efficient production, and recyclability positions metal tube furniture as a sustainable choice in an increasingly environmentally conscious market. By embracing advanced processing technologies, manufacturers can not only enhance their economic viability through improved efficiency and reduced waste but also bolster their brand image as environmentally responsible entities. This dual benefit—economic gain coupled with ecological stewardship—is a compelling argument for the continued evolution and adoption of sophisticated metal tube cutting solutions across the furniture industry, ensuring a resilient and responsible future.

Metal tubes enable lightweight furnitureTrue

Their high strength-to-weight ratio allows for durable yet lightweight designs, crucial for modern furniture.

Wood offers better consistency than metalFalse

Standardized metal tubes provide more predictable properties than wood, which varies in grain and moisture content.

Current trends in metal tube cutting technology

Are you relying on outdated metal tube cutting methods, hindering your furniture production? Traditional approaches often lead to inefficiency, excessive waste, and an inability to realize complex designs. Embracing current cutting technology is essential for gaining a competitive edge and fostering innovation.

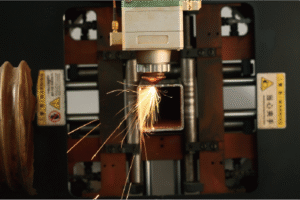

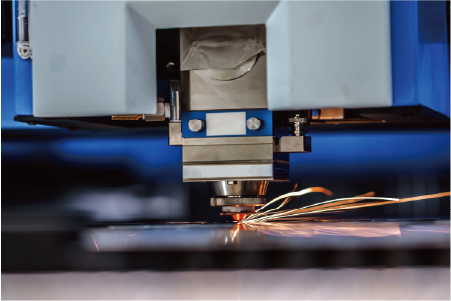

Current trends in metal tube cutting technology are characterized by increased automation, precision, and integration of smart systems. Fiber laser cutting machines lead the way with high-speed, contactless processing, minimal material distortion, and the ability to handle diverse metals. Software advancements enable complex geometries, optimize material usage, and simplify operation, pushing the boundaries of furniture design and manufacturing efficiency.

As we’ve established the critical role of metal tubes in furniture, it's equally important to examine the technologies that make their precise application possible. The landscape of metal tube cutting is far from static; it’s a dynamic field experiencing rapid innovation, driven by demands for greater speed, accuracy, and versatility. The days of purely manual or even basic automated cutting are giving way to sophisticated systems that incorporate advanced laser technology, robotics, and intelligent software. These trends are not just incremental improvements; they represent a fundamental shift in production capabilities, enabling manufacturers to achieve previously unattainable levels of precision and design complexity while simultaneously optimizing material usage and reducing operational costs. Let's explore the cutting-edge advancements currently redefining the possibilities for metal tube fabrication5 in the furniture sector and beyond.

A. The Dominance of Fiber Laser Technology

In the evolving landscape of metal tube cutting, fiber laser technology has emerged as the unequivocal leader, fundamentally transforming how metal components are processed for furniture and other industries. Unlike traditional methods such as sawing, plasma cutting, or even CO2 lasers, fiber lasers offer unparalleled speed, precision, and versatility. Their highly focused beam enables ultra-fine cuts with minimal heat affected zones (HAZ), reducing material distortion and eliminating the need for extensive post-processing. This precision is critical for furniture manufacturers, where perfectly fitting joints and aesthetically pleasing finishes are paramount for the final product's quality and appearance.

The efficiency gains from fiber laser technology are substantial. For instance, a typical fiber laser tube cutting machine can process multiple cuts, holes, and complex contours on a single tube in a fraction of the time it would take using conventional methods. Data from industry reports indicate that fiber laser systems can achieve cutting speeds up to three times faster than CO2 lasers for thin-gauge materials, and significantly reduce power consumption by up to 50%. This not only accelerates production cycles but also lowers operational costs, making it a compelling investment for businesses aiming to scale their output without compromising on precision. This aligns perfectly with MZBNL's commitment to high-speed and high-precision cutting, offering solutions that directly contribute to our clients' efficiency goals.

Furthermore, the non-contact nature of fiber laser cutting means less tool wear and consistent performance across a wide range of metal types, including stainless steel, mild steel, aluminum, and brass, in various thicknesses. This versatility is crucial for furniture manufacturers who work with diverse materials and design specifications. For example, a single machine can efficiently handle the intricate cuts for a lightweight aluminum chair frame and then seamlessly transition to cutting robust steel tubes for a heavy-duty industrial shelving unit, highlighting the adaptive capabilities that modern furniture production demands.

B. Automation and Smart Systems Integration

A key trend in advanced metal tube cutting is the increasing level of automation and the integration of smart systems, moving beyond simple cutting to comprehensive, intelligent fabrication processes. This involves sophisticated automatic feeding and loading mechanisms that significantly reduce manual labor and improve throughput. At MZBNL, our Front-Feeding Innovation is a prime example of this, where an optimized mechanism automatically pulls the tube in from the front, boosting feeding efficiency by approximately 40% and reducing operator labor intensity by a similar margin. This directly addresses the pain points of high operator turnover and the need for greater efficiency that clients like Ahmed Al-Farsi frequently articulate.

Beyond loading, smart systems integrate real-time monitoring, predictive maintenance, and quality control. Sensors on the machine collect data on cutting parameters, material usage, and machine health, feeding this information into digitalized systems. This allows manufacturers to track production progress, identify potential issues before they lead to downtime, and optimize processes for maximum output and minimal waste. This level of digitalization ensures consistent product quality and enhances overall operational transparency, aligning with MZBNL's focus on smart and digitalized systems that empower intelligent manufacturing.

The convergence of automation and smart technology creates a highly responsive and adaptable manufacturing environment. For instance, in a scenario where a furniture factory needs to quickly shift production from one design to another, an automated system with integrated smart controls can rapidly reconfigure cutting parameters and material handling processes, minimizing setup times and maximizing flexibility. This agility is invaluable in today's fast-paced market, enabling manufacturers to respond swiftly to changing consumer demands and emerging design trends, providing a distinct competitive advantage over those relying on less integrated systems.

C. Software Advancements and User Interface Simplification

Perhaps one of the most transformative trends in metal tube cutting technology is the evolution of software, making complex operations more accessible and efficient. Traditionally, operating these machines required skilled CAD (Computer-Aided Design) operators to create or modify intricate 3D drawings, a time-consuming and often bottleneck-inducing process. This was a significant pain point for Ahmed Al-Farsi, who expressed concerns about needing skilled CAD operators and the burden of retraining due to high operator turnover. Our No-CAD Operating System directly addresses this.

With MZBNL’s pioneering No-CAD system, standard tube types and hole patterns can now be processed simply by entering parameters—no complex drawing required. This innovation dramatically improves ease of use, shortens setup time, and significantly lowers the skill threshold for machine operation. Operators now only need one day of on-site training instead of spending fifteen days at an equipment factory, translating into immediate productivity gains and reduced training costs for businesses. This simplification not only democratizes access to advanced manufacturing capabilities but also empowers smaller businesses or those with less specialized workforces to leverage high-tech machinery.

Furthermore, advanced nesting software integrated within these systems optimizes material utilization by strategically arranging cuts to minimize scrap, directly contributing to cost savings and environmental sustainability. Simulation software allows operators to visualize the cutting process before execution, identifying potential errors or inefficiencies, thereby reducing material waste and machine downtime. This combination of intuitive interfaces, powerful optimization algorithms, and simplified programming makes modern metal tube cutting machines not just tools, but intelligent manufacturing partners that enhance productivity and profitability for furniture manufacturers globally.

Fiber lasers reduce material distortionTrue

Fiber lasers' focused beam minimizes heat affected zones, preserving material integrity.

CO2 lasers cut faster than fiberFalse

Fiber lasers achieve speeds up to 3x faster than CO2 lasers for thin materials.

Challenges faced in metal tube processing for furniture

Even with technological strides, metal tube processing for furniture still presents significant hurdles. These challenges often lead to material waste, production bottlenecks, and compromised product quality. Recognizing and understanding these issues is crucial for implementing effective, long-term solutions.

Challenges in metal tube processing for furniture include achieving high precision for complex joints, managing material waste from tail ends, ensuring consistent quality across batches, and the high skill requirement for operating traditional machinery. Additionally, balancing customization demands with efficient mass production and addressing long machine lead times remain persistent difficulties for manufacturers.

While advanced technologies offer immense potential, it's vital to acknowledge that the path to optimized metal tube processing is not without its obstacles. Furniture manufacturers, regardless of their scale, consistently grapple with a range of challenges that can impact everything from design flexibility to profitability. From the inherent complexities of achieving perfectly aligned joints for intricate furniture pieces to the often-overlooked issue of material waste generated during cutting, these hurdles demand strategic consideration. Furthermore, the operational aspects—such as the need for highly skilled labor to manage complex CAD designs or the pervasive issue of long machine lead times—can create significant bottlenecks. Understanding these core pain points is crucial, as it lays the groundwork for appreciating how truly innovative solutions can alleviate these pressures and drive industry-wide improvements.

A. Precision and Complexity of Joins

One of the most persistent challenges in metal tube processing for furniture manufacturing6 lies in achieving the extreme precision required for flawless joints. Unlike other applications where slight discrepancies might be acceptable, furniture demands seamless, aesthetically pleasing connections that also contribute to structural integrity and durability. Any deviation in cut angles, lengths, or hole placements can lead to ill-fitting parts, requiring costly rework or, worse, becoming unusable scrap. This issue is magnified when dealing with intricate designs involving multiple angles, curves, or complex interlocks, such as those found in ergonomic office chairs or multi-component shelving systems.

Historically, achieving these precise joins often relied on highly skilled manual labor or rudimentary machinery, which made mass production challenging and inconsistent. Even with semi-automated solutions, variations in operator skill could lead to significant quality fluctuations. For example, creating a perfect fishmouth joint—a common requirement for attaching one tube perpendicularly to another—demands incredibly accurate profiling and cutting, which is exceedingly difficult to achieve manually without extensive grinding and deburring. Industry data suggests that manual methods can lead to scrap rates upwards of 15%7 for complex components due to human error and inconsistency, directly impacting profitability.

The demand for customization and unique design elements further compounds this challenge. Modern furniture trends often lean towards bespoke pieces or limited production runs, each potentially requiring unique joint configurations. This necessitates a cutting system capable of rapid, precise adaptation. The ability to program complex cuts with minimal setup changes is no longer a luxury but a fundamental requirement to address this challenge effectively, ensuring that every joint, whether a miter, coping, or saddle, fits perfectly the first time, every time.

B. Material Waste and Cost Management

Another critical challenge for furniture manufacturers is managing material waste and its direct impact on production costs. Traditional tube cutting methods, particularly those involving manual feeding or older automated systems, often result in significant unusable tail material at the end of each tube. This leftover section, too short to be processed into a usable component, accumulates quickly, representing a substantial economic loss. Depending on the tube length and product design, this waste can account for a considerable percentage of raw material expenditure, directly eroding profit margins.

Furthermore, inefficient nesting—the process of arranging multiple parts on a single tube to maximize material utilization—can exacerbate this waste. Without intelligent software algorithms, parts might be cut in a suboptimal sequence, leading to more unusable offcuts or larger scrap pieces than necessary. For a mid-sized metal fabrication business like Ahmed Al-Farsi’s, where cost-performance ratio is highly valued, minimizing material waste is paramount. Every inch of wasted metal directly translates to lost revenue and increased operational expenses, making inefficient cutting a critical pain point that undermines overall profitability and competitiveness in a demanding market.

Our Zero-Waste Tail Material Innovation at MZBNL directly addresses this persistent problem. Unlike conventional laser cutting systems that start cutting from the tube head and typically generate unusable tail material, we redesigned the cutting logic to calculate from the rear chuck as the origin. This allows the system to eliminate leftover tail material entirely, as long as the remaining section is smaller than the product length. This revolutionary approach maximizes material utilization, potentially reducing waste by up to 10-15% per tube, which translates directly into substantial savings on raw material costs for our clients, demonstrating how targeted technological solutions can turn a significant challenge into a key competitive advantage.

C. Operational and Workforce Challenges

The operational environment within furniture manufacturing presents its own set of challenges, particularly concerning workforce skills and machine lead times. A major pain point, as highlighted by clients like Ahmed Al-Farsi, is the reliance on highly skilled CAD operators for traditional metal tube cutting machines. Finding and retaining such specialized talent is increasingly difficult, and high operator turnover—a common issue in manufacturing—leads to constant retraining burdens and disruptions in production. This dependence on expert human intervention creates bottlenecks and increases labor costs, making it difficult for businesses to scale efficiently.

Moreover, the training period for these complex systems can be extensive, often requiring weeks of off-site instruction at the equipment factory. This not only incurs direct training costs but also represents lost productivity while key personnel are away from the production floor. Ahmed's experience confirms this, as he seeks turnkey solutions that are easy to install and operate, valuing suppliers who provide comprehensive post-sales training and support. The aspiration for automation, driven by the desire to reduce dependency on specialized skills and minimize training overheads, is a universal need across the industry.

Another critical challenge is the issue of long machine lead times. For many suppliers, the waiting period for new, advanced machinery can stretch into several months, significantly impacting project delivery schedules and business expansion plans. This delay can stifle growth and prevent manufacturers from capitalizing on new market opportunities or fulfilling large orders promptly. Addressing these operational hurdles—from simplifying machine operation to ensuring timely equipment delivery and robust after-sales support—is essential for any supplier aiming to genuinely partner with and empower furniture manufacturers in their pursuit of efficiency and sustained growth.

Precision is critical for metal furniture jointsTrue

Metal furniture requires perfect joint alignment for both aesthetics and structural integrity, unlike other applications where minor deviations might be acceptable.

Manual cutting eliminates material wasteFalse

Manual cutting often generates more waste due to inconsistent measurements and inefficient nesting compared to advanced automated systems with intelligent software.

Solutions offered by advanced metal tube cutting machines

Are the complexities of metal tube processing for furniture holding back your innovation and efficiency? These challenges often lead to frustration, increased costs, and missed growth opportunities. Advanced metal tube cutting machines offer comprehensive solutions, transforming pain points into competitive advantages for your business.

Advanced metal tube cutting machines provide solutions through superior precision, automated material handling, and intelligent software. Features like MZBNL's No-CAD system simplify operation, while Zero-Waste Tail Material technology minimizes waste. Integrated multi-process capabilities, high-speed cutting, and digitalized systems collectively enhance efficiency, reduce labor costs, and enable intricate, customized furniture designs.

Having thoroughly explored the persistent challenges that furniture manufacturers face in metal tube processing, it’s time to pivot towards the innovative solutions that are reshaping the industry. The good news is that technological advancements in metal tube cutting machines are not merely incremental; they are truly transformative, directly addressing the pain points we’ve discussed. These aren't just machines; they are sophisticated systems designed to optimize every stage of the fabrication process, from design input to material utilization and final product output. By leveraging cutting-edge features like enhanced automation, intelligent software, and unparalleled precision, manufacturers can overcome previous limitations and unlock new levels of efficiency, cost-effectiveness, and design freedom. Let's delve into how these advanced solutions are empowering businesses to thrive in a demanding market.

A. Precision and Efficiency through Automation

Advanced metal tube cutting machines offer unparalleled precision and efficiency, fundamentally transforming furniture manufacturing. These machines, particularly those employing fiber laser technology, can execute complex cuts with micron-level accuracy, ensuring that every component fits perfectly without the need for extensive rework or manual adjustments. This high precision is crucial for intricate furniture designs where multiple tube segments must align flawlessly to form strong, aesthetically pleasing joints. MZBNL's machines are specifically designed for high-speed and high-precision cutting, enabling furniture manufacturers to consistently produce components that meet the most stringent quality standards, reducing scrap rates and boosting overall output.

Furthermore, integrated automation features significantly enhance efficiency by minimizing manual intervention. Automated loading and unloading systems, for instance, ensure a continuous flow of material, eliminating bottlenecks and maximizing machine uptime. Our Front-Feeding Innovation is a prime example of this: by automatically pulling tubes from the front, we increase feeding efficiency by approximately 40% and drastically reduce operator labor intensity. This not only accelerates production cycles but also frees up human resources for more complex, value-added tasks, directly translating into higher productivity and lower labor costs for our clients.

For a client like Ahmed Al-Farsi, whose business demands automation to upgrade production efficiency and reduce operator turnover, these features are invaluable. He seeks turnkey solutions that are easy to install and operate, and our automated systems provide just that. By streamlining the entire cutting process, from raw material handling to precise component fabrication, these advanced machines ensure consistent quality across large batches, making mass production more reliable and cost-effective than ever before.

B. Smart Software and User-Friendly Operation

A cornerstone of modern metal tube cutting solutions is intelligent software combined with user-friendly interfaces, dramatically simplifying complex operations. One of the most significant breakthroughs in this area is MZBNL's pioneering No-CAD Operating System. Traditionally, operating a laser tube cutting machine required highly skilled CAD operators to create or modify intricate 3D drawings, a time-consuming process that often caused production delays and increased labor costs. This was a particular pain point for Ahmed, who grappled with the need for skilled CAD operators and the burdens of retraining.

With our No-CAD system, standard tube types and hole patterns can be processed by simply entering parameters, eliminating the need for complex drawings. This innovation significantly lowers the skill threshold for machine operation, meaning operators now need only one day of on-site training instead of a conventional 15-day factory training period. This ease of use not only reduces training costs and time but also mitigates the impact of operator turnover, ensuring that production can continue smoothly with minimal disruption. It empowers a broader range of personnel to manage the machinery, making advanced technology accessible to more businesses.

Moreover, intelligent software enables rapid prototyping and flexible design changes. Designers can quickly modify part parameters or even completely reconfigure a design, and the machine can adapt almost instantly, allowing furniture manufacturers to respond swiftly to market trends and customize products on demand. This agility, combined with the simplified operational experience, makes these advanced machines indispensable tools for businesses aiming for both high efficiency and unparalleled design flexibility in the competitive furniture industry.

C. Cost Optimization and Material Utilization

Advanced metal tube cutting machines offer substantial opportunities for cost optimization, primarily through superior material utilization and multi-process integration. Our Zero-Waste Tail Material Innovation exemplifies this. Conventional laser cutting systems typically generate unusable tail material, leading to significant scrap. By redesigning the cutting logic to calculate from the rear chuck as the origin, our system eliminates leftover tail material as long as the remaining section is smaller than the product length. This revolutionary approach maximizes material utilization, potentially reducing waste by up to 10-15% per tube, which translates directly into substantial savings on raw material costs for our clients.

Beyond waste reduction, the integration of multiple processes within a single machine, such as cutting and punching, further enhances cost-effectiveness. For instance, MZBNL offers Automatic Punching & Cutting Integrated Machines. This multi-process capability means furniture components requiring both cutting and hole punching can be completed in one continuous operation, eliminating the need for separate machines, additional setups, and material transfers between workstations. This integrated workflow significantly reduces production time, labor, and the potential for errors, driving down the cost per part.

For customers like Ahmed, who prioritize a high cost-performance ratio and are looking for automatic feeding and punching capabilities, these integrated solutions are a game-changer. They provide a complete, streamlined manufacturing solution that not only produces high-quality components efficiently but also minimizes operational overheads. This holistic approach to efficiency and material management ensures that every investment in advanced metal tube cutting technology yields significant returns, strengthening the manufacturer's competitive position in the furniture market.

Fiber lasers enable micron-level precisionTrue

Advanced fiber laser cutting systems achieve ±0.1mm accuracy, crucial for complex furniture joints.

No-CAD systems require extensive trainingFalse

MZBNL's No-CAD system reduces operator training from 15 days to just 1 day.

Future prospects for metal tube cutting in the furniture industry

Is your furniture manufacturing prepared for tomorrow's demands for adaptability and efficiency? Relying solely on current methods might limit your capacity to meet evolving consumer expectations and market dynamics. Embracing emerging trends in metal tube cutting is vital for future-proofing your production and unlocking new possibilities.

The future of metal tube cutting in furniture envisions greater integration with AI, real-time data analytics, and full automation, moving towards 'lights-out' manufacturing. Further advancements will enable seamless mass customization, utilize novel materials, and promote sustainable production through enhanced waste reduction and energy efficiency, ensuring the industry remains agile and responsive to evolving design and market demands.

Having explored the current state and solutions offered by advanced metal tube cutting machines, it’s only natural to gaze into the future. The furniture industry is in a constant state of evolution, driven by shifting consumer preferences, technological breakthroughs, and an increasing emphasis on sustainability. What new innovations can we anticipate, and how will they further transform the fabrication of metal furniture components? The trajectory suggests an even more integrated, intelligent, and autonomous manufacturing environment. From the pervasive influence of Artificial Intelligence to the advent of 'lights-out' factories, the coming years promise to redefine the very essence of production, offering unprecedented levels of efficiency, customization, and environmental responsibility. Let's explore these exciting prospects and their potential impact.

A. The Rise of "Smart Factories" and AI Integration

The future of metal tube cutting in the furniture industry is inextricably linked to the concept of "Smart Factories" and the pervasive integration of Artificial Intelligence (AI). We are moving towards fully autonomous "lights-out" manufacturing environments where machines can operate with minimal human supervision, driven by intelligent algorithms that optimize every aspect of the production process. AI and Machine Learning (ML) will revolutionize predictive maintenance, enabling machines to anticipate failures and schedule maintenance proactively, dramatically reducing downtime and extending equipment lifespan. This proactive approach ensures continuous operation, a critical factor for high-volume furniture production.

Beyond maintenance, AI will enhance process optimization and quality control. Real-time data collected from sensors on machines will be analyzed by AI to adjust cutting parameters, material flow, and even design specifications on the fly, ensuring peak performance and consistent product quality. For example, AI-powered vision systems could detect minuscule defects in tube material or cut components, automatically adjusting the process or flagging issues before they lead to significant waste. This level of intelligent automation pushes the boundaries of efficiency and precision beyond current capabilities.

The Internet of Things (IoT) will facilitate seamless communication between machines, creating a cohesive production ecosystem. From automated material storage systems delivering tubes to the cutting machine, to robotic arms transferring cut components to the next processing stage (like bending or welding), every element will be interconnected. This integrated system will allow for unprecedented levels of coordination and efficiency, minimizing human intervention and maximizing throughput, epitomizing MZBNL's vision of smart and digitalized systems that are ready for the factory of tomorrow.

B. Mass Customization and On-Demand Production

One of the most exciting prospects for metal tube cutting in the furniture industry is the acceleration of mass customization and true on-demand production. As consumer preferences shift from standardized products to personalized items, manufacturers must adapt. Advanced tube cutting technologies, coupled with sophisticated software, will enable factories to produce unique, customized furniture pieces at the efficiency levels previously reserved for mass production. This means a customer could specify unique dimensions, specific joint types, or even personalized designs for a chair or shelving unit, and the factory could produce it rapidly and cost-effectively.

This shift will significantly reduce the need for large inventories, a major cost for furniture companies. Instead of manufacturing large batches of a few designs, factories can produce exactly what is ordered, when it is ordered. This "pull" system of manufacturing minimizes waste, warehousing costs, and the risk of obsolete stock. For my typical customer, Ahmed Al-Farsi, whose business thrives on contract-based fabrication services for architectural metalwork and auto parts, this capability to swiftly produce highly customized components on demand would be a powerful differentiator, allowing him to cater to niche markets and specific client requirements with unprecedented agility.

The flexibility inherent in these future systems will also allow furniture manufacturers to respond almost instantaneously to new design trends and market demands. A popular design might quickly be adapted into multiple variants, or entirely new product lines can be launched with minimal retooling. This agility will transform the competitive landscape, favoring companies that can rapidly innovate and deliver personalized products, further cementing the role of advanced, adaptive tube cutting technologies as essential for future business success.

C. Sustainability and Circular Economy Principles

The future of metal tube cutting will place an even greater emphasis on sustainability and adherence to circular economy principles. While current technologies, like MZBNL's Zero-Waste Tail Material Innovation, already make significant strides in reducing scrap, future advancements will push this even further. Expect improved nesting algorithms that can achieve near-perfect material utilization across diverse part geometries and dynamic production schedules, leading to virtually no raw material waste during the cutting process. This will not only reduce costs but also significantly lower the environmental footprint of furniture manufacturing.

Energy efficiency will continue to be a primary focus in machine design and operation. Future laser systems will consume even less power while delivering higher performance, and smart factory grids might dynamically adjust energy usage based on production loads and renewable energy availability. This aligns with a global movement towards greener manufacturing. Furthermore, the inherent recyclability of metals like steel and aluminum will be leveraged more systematically, with closed-loop systems that facilitate the collection, reprocessing, and reintroduction of metal waste back into the production cycle, minimizing reliance on virgin resources.

This commitment to a circular economy will influence furniture design itself, encouraging "design for disassembly" and the use of modular components that can be easily repaired, upgraded, or recycled at the end of their lifecycle. For businesses, embracing these sustainable practices will not only meet increasing regulatory pressures but also appeal to a growing segment of environmentally conscious consumers. By integrating advanced metal tube cutting technologies that champion resource efficiency and waste reduction, the furniture industry can pave the way for a more responsible, resilient, and environmentally sound future.

AI enables predictive maintenanceTrue

AI algorithms can analyze machine data to predict failures before they occur, reducing downtime in metal tube cutting operations.

Mass customization increases inventoryFalse

On-demand production actually reduces inventory needs by manufacturing only what's ordered, minimizing warehousing costs.

Conclusion

Advanced metal tube cutting machines revolutionize furniture manufacturing through unparalleled precision, automation, and efficiency. Innovations like MZBNL’s No-CAD and Zero-Waste systems address key pain points. They enable intricate designs, mass customization, and sustainable production, crucial for businesses optimizing costs, enhancing quality, and thriving in evolving markets.

-

Discover how CNC machines enhance precision and efficiency in cutting metal tubes. ↩

-

Learn about the structural and aesthetic applications of metal tubes in furniture. ↩

-

Explore the significance of tubular steel in modernist furniture design. ↩

-

Understand how Zero-Waste technology reduces material waste in metal tube cutting. ↩

-

Learn about innovations in metal cutting that optimize efficiency and design in furniture manufacturing ↩

-

Learn about the specific issues faced in metal tube processing for furniture ↩

-

Understand the profitability impact of manual processing scrap rates ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.