Applications of Metal Tube Cutting Machines in Automotive Parts Production

Are traditional manufacturing methods for automotive parts slowing down your production and limiting design innovation? Many struggle with the precision and speed required by the modern automotive industry. Embrace advanced metal tube cutting technology to meet the rigorous demands of this evolving sector.

Metal tube cutting machines are pivotal in automotive manufacturing, delivering the high precision and speed essential for producing critical components like chassis, exhaust systems, and safety structures. These machines enhance production efficiency, reduce material waste, and enable complex designs, significantly advancing the automotive sector.

For years, I’ve seen firsthand how manufacturing processes evolve, and the automotive industry stands at the forefront of this transformation. As new vehicle designs emerge and the demand for lighter, stronger components intensifies, the role of precise metal fabrication becomes increasingly crucial. This shift directly impacts how parts are produced, from initial design to final assembly.

In my 25 years in metal fabrication, particularly with MZBNL, I’ve observed a dramatic shift in how automotive components are manufactured. Gone are the days when simple bending and welding sufficed for every part. Today's vehicles demand intricate, lightweight, and incredibly precise tubular structures1 for enhanced safety, fuel efficiency, and performance. This evolution necessitates cutting-edge technology, and that's precisely where advanced metal tube cutting machines2, like our solutions at MZBNL, come into play. These machines are not just tools; they are strategic assets that enable manufacturers to meet stringent industry standards, respond to rapid market changes, and even reduce the environmental footprint through optimized material use. For instance, a recent industry report highlighted that precise tube cutting can reduce material waste by up to 15% in complex automotive assemblies, a significant gain for both cost-efficiency and sustainability. We empower companies like Ahmed Al-Farsi’s metal fabrication business in the UAE to transition from labor-intensive manual processes to highly automated, digitalized workflows, ensuring they remain competitive and innovative in a global market.

What is the significance of metal tube cutting machines in the automotive industry?

Faced with the automotive industry’s demand for high precision and efficiency? Traditional cutting methods often fall short, leading to material waste and production bottlenecks. Advanced metal tube cutting machines offer a revolutionary solution, ensuring components meet strict quality and design standards.

Metal tube cutting machines are indispensable in the automotive industry due to their ability to achieve extreme precision and high efficiency in producing tubular components. They ensure critical safety standards are met, facilitate lightweight designs for fuel efficiency, and accelerate mass production cycles, driving innovation.

When I started my journey in this industry, the automotive sector was already known for its demanding standards. However, the complexity and precision required for modern vehicles have escalated exponentially. Today, every millimeter counts, especially when it comes to components that directly influence vehicle performance, safety, and fuel efficiency. This isn’t just about making parts; it’s about crafting the very backbone of a vehicle with unwavering accuracy. From high-strength steel chassis elements to intricate exhaust systems, the foundational role of precise tube cutting cannot be overstated. It’s about enabling designers to push boundaries and engineers to build safer, more efficient cars, all while keeping production lines running smoothly and cost-effectively.

The significance of metal tube cutting machines in the automotive industry is multifaceted, touching upon core aspects of modern vehicle manufacturing: precision for safety, material optimization for lightweighting, and speed for mass production. Without these capabilities, achieving the stringent requirements of today's automotive designs would be impossible.

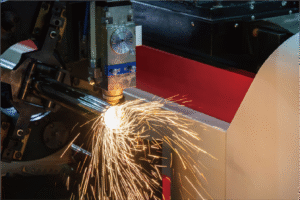

Precision for Safety Components and Structural Integrity

The safety of a vehicle is paramount, and a significant portion of that safety relies on the integrity and precision of its tubular components. From roll cages and chassis frames to crumple zones and seat structures, these parts must withstand immense forces during impacts. Metal tube cutting machines, especially those equipped with advanced laser technology like our MZBNL machines, provide unparalleled precision. This precision ensures that components fit together perfectly, reducing stress points and enhancing the overall structural integrity of the vehicle. For instance, when designing complex hydroformed chassis components, even a fractional misalignment in a tube cut can compromise the entire structure's ability to absorb impact effectively. Our systems, with their ability to perform intricate cuts and multi-axis processing, guarantee the exact tolerances required for critical safety applications, translating directly into safer vehicles on the road.

Furthermore, the integration of features like our "Start Cutting Without CAD Drawings" system significantly reduces the potential for human error in the design-to-production process. This means that even complex cuts for safety components, which previously required skilled CAD operators—a pain point for clients like Ahmed Al-Farsi who faced high operator turnover—can now be executed with simplified parameter inputs. This ease of use doesn’t compromise precision; rather, it democratizes high-precision manufacturing, making it more accessible and consistent, directly contributing to the consistent quality of vital safety parts.

Finally, beyond just cutting, the ability of these machines to integrate other processes, such as punching or marking, in a single setup further enhances the precision and reliability of safety-critical components. By minimizing manual handling and transfers between different machines, the risk of deformation or misalignment is drastically reduced. This streamlined approach ensures that every tube segment, whether destined for a rollover protection system or a side-impact beam, meets the exact specifications required to protect occupants.

Material Optimization for Lightweighting Initiatives

The automotive industry is in a relentless pursuit of lightweighting to improve fuel efficiency and reduce emissions, especially with the surge in electric vehicles. Every gram saved contributes to better performance and range. Tubular structures are inherently efficient in terms of strength-to-weight ratio, and precise metal tube cutting machines maximize this advantage by minimizing material waste. Conventional cutting methods often leave significant "tail material" or require large scrap allowances, driving up costs and environmental impact.

Our MZBNL "Zero-Waste Tail Material Innovation" directly addresses this challenge. By rethinking the cutting logic from the rear chuck as the origin, our machines are designed to utilize nearly every inch of the tube, eliminating unusable remnants. This innovation directly translates into substantial material savings, which is crucial for manufacturers dealing with expensive high-strength steel or aluminum alloys. For a large-scale automotive parts supplier, even a 5% reduction in material waste can amount to hundreds of thousands of dollars in annual savings, making production more sustainable and cost-effective.

Moreover, the precision offered by these machines allows for the creation of intricate, optimized designs that use less material without compromising strength. For example, creating hollow profiles or precise interlocking joints for components means designers can achieve the desired structural integrity with lighter-gauge tubes, further contributing to overall vehicle weight reduction. This level of material efficiency is not just an economic benefit; it aligns perfectly with the automotive industry’s broader environmental goals and customer demand for greener vehicles.

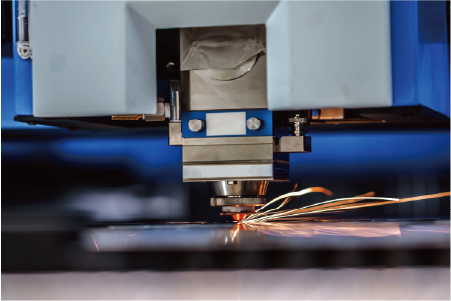

Speed and Efficiency for Mass Production

The automotive industry operates on tight production schedules and high volumes. Manual cutting or less efficient methods can quickly become bottlenecks, impacting delivery times and overall profitability. Metal tube cutting machines are built for speed and efficiency, enabling rapid production cycles that are essential for mass manufacturing. High-speed and high-precision cutting, coupled with automated loading and unloading systems, dramatically reduces cycle times per part.

Our "Front-Feeding Innovation," for example, significantly boosts efficiency by automatically pulling tubes from the front, increasing feeding efficiency by approximately 40%. This not only accelerates the overall production rate but also reduces operator labor intensity, which is a key advantage for our clients like Ahmed Al-Farsi, who are looking to automate existing manual workflows and reduce the reliance on intensive labor. This improved efficiency means more parts can be produced in less time, allowing manufacturers to meet demanding production quotas and accelerate time-to-market for new vehicle models.

Furthermore, the integration of advanced digitalized systems allows for seamless transitions between different part geometries and production batches, minimizing downtime for setup changes. This agility is vital in an industry that frequently adapts to new models, customization options, and global supply chain demands. The ability to quickly reconfigure and execute production runs with minimal human intervention ensures that automotive manufacturers can maintain a competitive edge, responding swiftly to market needs without sacrificing quality or escalating costs.

Precision cuts enhance safetyTrue

Laser-cut tubular components ensure perfect alignment in vehicle safety structures like roll cages and crumple zones.

Manual cutting is more efficientFalse

Automated tube cutting machines increase production speed by 40% and reduce labor intensity compared to manual methods.

How are metal tube cutting machines currently utilized in automotive parts production?

Wondering how modern vehicles achieve their intricate designs and robust structures? Traditional methods often restrict complex component fabrication. Metal tube cutting machines are at the forefront, enabling the precise and efficient production of diverse automotive parts.

Metal tube cutting machines are extensively utilized in automotive manufacturing for creating various components, including chassis frames, exhaust systems, seating structures, and engine mounts. They enable precise cuts, complex geometries, and multi-process integration, driving efficiency and design innovation in the sector.

As someone who has watched the automotive sector evolve, it’s clear that today’s vehicles are marvels of engineering, combining strength, lightweight design, and complex functionality. This sophistication isn’t accidental; it’s a direct result of advanced manufacturing technologies. When we talk about how metal tube cutting machines are used, we’re not just talking about simple cuts. We're discussing the intricate ballet of precision, speed, and material handling that brings critical components to life. From the foundational structure of a car to its interior comfort and emissions control, these machines are silently shaping every aspect. They allow manufacturers to move beyond traditional limitations, creating parts that were once considered impossible or prohibitively expensive to produce.

The application of metal tube cutting machines in automotive parts production is incredibly diverse, spanning across almost every major system within a vehicle. They are crucial for creating high-precision, robust, and often lightweight components for chassis and frames, exhaust and powertrain systems, and interior and seating structures. Each area benefits from the unique capabilities of these advanced machines.

Chassis and Frame Components

The chassis and frame form the skeletal structure of a vehicle, providing support, rigidity, and crash protection. Many modern chassis designs incorporate complex tubular structures for optimal strength-to-weight ratios. Metal tube cutting machines are indispensable here for cutting and shaping various types of tubes, including high-strength steel (HSS) and ultra-high-strength steel (UHSS), into precise components. These might include cross members, subframes, body-in-white structures, and even bespoke components for electric vehicle battery enclosures. The ability to make precise angle cuts, notches, and holes on various tube profiles (round, square, rectangular, oval) in a single setup is critical. For instance, hydroformed frame components3, common in trucks and SUVs, rely on perfectly pre-cut and perforated tubes for the forming process to achieve the desired complex shapes without material distortion.

Our MZBNL laser tube cutting machines excel in handling these demanding materials and complex geometries. Their high-precision cutting capabilities ensure that every joint, every mounting point, and every structural element aligns perfectly, which is paramount for vehicle safety and performance. This precision minimizes the need for secondary operations, reducing manufacturing time and costs. Furthermore, the capacity for "Multi-process integration" on our machines means that beyond just cutting, operations like punching holes for mounting points or etching alignment marks can be performed simultaneously, streamlining the production of chassis and frame components significantly.

Consider a leading automotive OEM that transitioned from traditional sawing and drilling to automated laser tube cutting for its truck chassis components. They reported a 30% reduction in part fabrication time and a 5% increase in material utilization, primarily due to the laser's ability to produce highly accurate cuts and intricate joint designs that optimize material nesting. This efficiency gain directly translates into higher production volumes and cost savings, underscoring the vital role of these machines in core vehicle structures.

Exhaust and Powertrain Systems

Exhaust systems, including manifolds, catalytic converter casings, and tailpipes, are predominantly made from stainless steel or other heat-resistant alloys. These components require precise tube cutting to ensure proper fit-up, optimal gas flow, and compliance with strict emissions regulations. Metal tube cutting machines are used to cut and shape these tubes with extreme accuracy, creating complex bends, junctions, and mounting features. Similarly, powertrain components, such as engine mounts, drive shafts, and transmission housing elements, often incorporate tubular sections that demand robust and precise fabrication.

The ability of laser tube cutting machines to create intricate cuts and perforations, even on complex 3D profiles, is a game-changer for exhaust and powertrain systems. For example, creating precise slots for sensor mounting or cutting intricate patterns for flow optimization within an exhaust manifold can be achieved with unparalleled accuracy. This not only improves performance but also reduces the risk of leaks and failures, which are critical for meeting emission standards and ensuring vehicle longevity. The "High-speed and high-precision cutting" of MZBNL machines ensures that these intricate parts can be mass-produced efficiently without sacrificing quality.

An example from a global automotive supplier illustrates this: they adopted advanced tube laser cutting for their exhaust manifold production, replacing a multi-step process involving sawing, punching, and deburring. The new system, which included capabilities similar to our "Automatic Punching & Cutting Integrated Machine," reduced processing steps from five to two, cut production time by 45%, and significantly improved part consistency. This case highlights how integrated tube cutting solutions are essential for high-volume, high-precision applications in powertrain manufacturing.

Interior and Seating Structures

While perhaps less visible, the interior and seating structures of a vehicle also heavily rely on precisely cut metal tubes. Seat frames, headrest supports, steering column components, and various dashboard sub-assemblies frequently use tubular elements for strength and ergonomic design. These components often require intricate bends and connections that demand perfectly cut tube ends to ensure secure welding and assembly.

Metal tube cutting machines provide the necessary precision for these components, ensuring that seats are safe and comfortable, and that interior elements fit seamlessly. The ability to process various material types, including lighter alloys for weight reduction in interiors, is also a key advantage. Furthermore, the aesthetic appeal and smooth operation of interior components often depend on burr-free cuts and clean finishes, which are inherent to advanced laser cutting processes.

Consider a manufacturer of luxury car seating. They faced challenges producing lightweight yet robust seat frames using traditional methods, which led to excessive material waste and inconsistent fit-up. By implementing a high-precision laser tube cutting system, they were able to utilize thinner-walled tubes and execute complex joint designs that optimized strength while reducing weight by 10%. This not only improved vehicle performance but also enhanced the passenger experience. The "Cost-effective customized solutions" offered by companies like MZBNL are particularly beneficial here, allowing manufacturers to tailor machine capabilities to their specific product lines, whether it's high-volume standard seats or bespoke luxury interiors.

Tube cutters enable multi-process integrationTrue

Modern machines combine cutting, punching and marking in one setup, eliminating secondary operations.

Traditional methods outperform laser cuttingFalse

Case studies show laser cutting reduces processing steps by 60% while improving precision.

What challenges are faced in using metal tube cutting machines for automotive manufacturing?

Are you encountering obstacles in optimizing your metal tube cutting processes for automotive manufacturing? Many businesses struggle with the complexity of operations and integrating new technologies. Overcoming these challenges is crucial for maintaining competitive edge and operational efficiency.

Challenges in automotive tube cutting include the need for highly skilled CAD operators, managing diverse material properties, and seamless integration into automated production lines. These factors can lead to increased training burdens, material waste, and production bottlenecks, affecting overall efficiency and cost.

In my decades of experience in the metal fabrication industry, I’ve seen incredible advancements, yet also persistent challenges that can hinder even the most innovative manufacturers. The automotive sector, with its relentless pursuit of perfection and efficiency, often magnifies these issues. While metal tube cutting machines offer immense potential, their successful implementation isn't without hurdles. From the steep learning curve for new operators to the complexities of handling a vast array of materials, these challenges can impact everything from production schedules to your bottom line. It's not enough to simply invest in the latest technology; understanding and addressing the practical difficulties of its application is what truly separates the industry leaders from the rest.

Despite their numerous advantages, the use of metal tube cutting machines in automotive manufacturing presents several challenges. These often revolve around the human element, material diversity, and the integration into complex production ecosystems. Understanding these hurdles is the first step toward developing effective solutions.

Skill Gap and Training Burden

One of the most significant challenges for manufacturers, including businesses like Ahmed Al-Farsi’s, has been the traditional reliance on highly skilled CAD operators for programming and operating complex tube cutting machines. Historically, setting up a machine for a new part involved creating or modifying intricate 3D drawings, a process that could take days or even weeks of specialized training. This created a significant skill gap within the workforce and a heavy training burden, especially with high operator turnover rates. When a skilled operator leaves, the production line can face substantial delays as new personnel need extensive, costly training.

This challenge directly impacts operational efficiency and increases labor costs. Companies are forced to invest heavily in training programs, or worse, face downtime while waiting for experienced personnel. Ahmed himself highlighted that "previous machines required skilled CAD operators" and "high operator turnover caused retraining burdens." This is a widespread issue in advanced manufacturing, where the sophistication of the machinery often demands a parallel level of human expertise. The complexity of translating engineering designs into machine-ready code requires not just technical proficiency but also a deep understanding of the cutting process itself, including material properties and machine kinematics.

To quantify this, consider that traditional machine training might involve 15 days at the equipment factory, followed by weeks of on-site familiarization. This represents a significant investment in terms of lost productivity and direct training costs. This challenge underscores the need for more intuitive, user-friendly machine interfaces and automation features that reduce the dependency on highly specialized personnel, allowing for quicker onboarding and reduced training expenditures, a critical factor for maintaining profitability in a competitive market.

Material Variability and Complexity

Automotive components are made from an incredibly diverse range of materials, each with unique properties that affect cutting performance. Manufacturers use everything from mild steel and aluminum to various grades of stainless steel, high-strength low-alloy (HSLA) steels, and even advanced composites. Each material responds differently to laser cutting4, requiring specific power settings, gas types, and cutting speeds to achieve optimal results and avoid issues like dross, burrs, or heat deformation. For instance, cutting highly reflective materials like aluminum or brass requires different laser parameters than cutting standard steel, and failure to adjust can lead to poor cut quality or even damage to the machine optics.

The challenge is further compounded by variations within the same material type, such as differences in alloy composition or surface finish from different suppliers. These subtle variations can impact cut quality and consistency, leading to increased scrap rates or the need for time-consuming post-processing. Ensuring consistent quality across different material batches and types requires sophisticated machine control and often, experienced operators who can fine-tune parameters on the fly. This variability adds complexity to programming and can slow down production if frequent adjustments are needed, reducing overall throughput and increasing operational costs due to waste.

| Feature Comparison | Traditional Tube Cutting | BNL Laser Tube Cutting |

|---|---|---|

| CAD Operator Requirement | High | Low (No-CAD System) |

| Operator Training Time5 | ~15 days (factory) | ~1 day (on-site) |

| Material Handling | Manual / Side Loading | Automatic Front-Feeding |

| Tail Material Waste | Significant | Zero-Waste |

| Setup Time | Long | Short |

Integration with Automated Production Lines

Modern automotive manufacturing facilities are increasingly adopting highly automated and integrated production lines, where each machine seamlessly communicates and operates in sequence with others. Integrating metal tube cutting machines into these complex systems can be a significant challenge. This requires robust software interfaces, precise material handling automation, and reliable data exchange protocols to ensure smooth workflow from design to finished part. Issues such as machine downtime, calibration errors, or communication failures can disrupt the entire line, leading to costly production halts.

For many manufacturers, the sheer scale and complexity of integrating a new, high-tech cutting machine into an existing, often heterogeneous, automation environment is daunting. It involves not just the machine itself, but also conveyors, robotic arms for loading and unloading, quality inspection systems, and central control software. Ensuring that the tube cutting machine operates at the optimal speed and precision to keep up with the demands of downstream processes, without creating bottlenecks or overwhelming subsequent stages, is critical. A delay in the cutting phase can ripple through the entire assembly line, causing cascading inefficiencies.

Furthermore, post-sales support and the availability of local service are crucial for successful integration and ongoing operation. Ahmed Al-Farsi's concern about "equipment from some suppliers lacked local service support" is a very real pain point. Without reliable technical assistance for integration, troubleshooting, and maintenance, even the most advanced machine can become a liability rather than an asset. This underscores the importance of choosing a supplier like MZBNL, which offers not only innovative technology but also comprehensive support and service to ensure seamless integration and sustained performance within a fully automated manufacturing environment.

Material variability affects cut qualityTrue

Different metals require specific laser settings to achieve optimal cutting results, as explained in the Material Variability section.

Traditional machines need no CAD skillsFalse

The article clearly states traditional tube cutting machines require highly skilled CAD operators, creating significant training burdens.

What strategies can be implemented to overcome these challenges?

Struggling with the complexities of metal tube cutting in automotive production? Many manufacturers face skill gaps and integration hurdles. Implementing strategic technological and operational changes is essential for streamlining your processes and boosting efficiency.

Overcoming challenges in automotive tube cutting involves adopting user-friendly, intelligent systems like No-CAD System Innovation for reduced training, investing in advanced automation for seamless integration, and prioritizing comprehensive training and reliable post-sales support. These strategies enhance efficiency, minimize waste, and improve operational flexibility.

Having identified the key obstacles in utilizing metal tube cutting machines in automotive manufacturing, the next crucial step is to devise and implement effective strategies to mitigate them. It’s not enough to simply acknowledge these problems; we must actively seek out and apply solutions that will empower manufacturers to leverage these advanced technologies to their fullest potential. This means looking beyond just the machine itself and considering the entire ecosystem of operations, from operator training to seamless integration into existing workflows. The goal is to transform potential pain points into competitive advantages, ensuring that production remains agile, cost-effective, and of the highest quality.

To truly unlock the full potential of metal tube cutting machines in automotive manufacturing, a multi-faceted approach addressing the identified challenges is necessary. This involves adopting user-friendly technology, investing in advanced automation, and prioritizing comprehensive training and support.

Adopting User-Friendly Technology and Intelligent Systems

One of the most effective strategies to overcome the skill gap and training burden is to adopt metal tube cutting machines equipped with user-friendly interfaces and intelligent operating systems. The reliance on highly specialized CAD operators has historically been a bottleneck. By simplifying the programming and operation process, manufacturers can drastically reduce the training time required for new personnel and increase operational flexibility. This is precisely where MZBNL's "No-CAD System Innovation" shines. This pioneering system allows operators to process standard tube types and hole patterns by simply entering parameters, eliminating the need for complex 3D drawings.

This innovation addresses Ahmed Al-Farsi’s pain point directly, as it lowers the skill threshold for machine operation. Instead of 15 days of factory training, operators now only need one day of on-site training to become proficient. This dramatic reduction in training time not only saves significant costs but also minimizes downtime associated with operator turnover. Furthermore, an intuitive interface reduces the likelihood of human error, leading to more consistent cut quality and less material waste. By making the technology accessible to a wider range of technical personnel, companies can build a more resilient and adaptable workforce.

Intelligent systems also extend to features like automatic parameter adjustments for different materials or tube dimensions. Instead of manual trial-and-error, the machine can suggest or even automatically apply optimal cutting parameters, further simplifying operations and ensuring high-quality output regardless of material variability. This predictive capability reduces material waste and speeds up setup times, making production more efficient and predictable, which is essential for meeting the high demands of automotive production schedules.

Investing in Advanced Automation and Integrated Solutions

To counter the challenges of integration into complex automated lines and to maximize efficiency, a strategic investment in advanced automation and multi-process integrated solutions is crucial. While manual loading and separate punching machines were once common, modern automotive manufacturing demands seamless, automated workflows to achieve high throughput and consistent quality. This includes automated loading and unloading systems, robotic handling, and integrated punching and cutting capabilities.

MZBNL's "Front-Feeding Innovation6" is a prime example of this strategy in action. By automatically pulling the tube in from the front, this design increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%. This not only accelerates the overall production cycle but also minimizes manual intervention, reducing the risk of errors and improving workplace ergonomics. When paired with downstream robotic handling, this creates a truly streamlined production process. Furthermore, our "Automatic Punching & Cutting Integrated Machine" consolidates multiple processes into one system. Instead of cutting on one machine and then transferring parts to another for punching, which increases handling time and potential for misalignment, this integrated solution performs both tasks in a single setup.

This integrated approach significantly enhances productivity and reduces bottlenecks. For an automotive parts manufacturer, this means higher production volumes, tighter tolerances, and ultimately, a more competitive edge. By minimizing the number of manual transfers and separate machine setups, the overall cycle time for each part is drastically reduced. This strategy directly addresses the need for turnkey solutions that are easy to install and operate, a key buying preference for clients like Ahmed, who are looking to automate their existing manual workflows and achieve end-to-end efficiency in their fabrication processes.

Comprehensive Training and Robust Post-Sales Support

Perhaps one of the most overlooked yet critical strategies is to ensure comprehensive training and robust post-sales support from the machine supplier. Even the most advanced technology can fall short if operators are not adequately trained or if technical issues cannot be promptly resolved. As Ahmed Al-Farsi's pain point highlights, "equipment from some suppliers lacked local service support" and "long machine lead times affected project delivery." This underscores the need for suppliers who offer a complete support package, extending beyond just the initial machine sale.

A comprehensive training program should cover not only the basics of operation but also advanced troubleshooting, maintenance, and optimization techniques. This empowers the customer's team to maximize the machine's capabilities and quickly address minor issues without external intervention. MZBNL emphasizes hands-on training, ensuring that our clients are confident and competent users of our equipment. This commitment to training builds a long-term partnership and ensures the sustained high performance of the machinery.

Moreover, reliable post-sales support, including spare parts availability, remote diagnostics, and the presence of local agents or distributors, is paramount. For global clients like those in Southeast Asia, the Middle East, Europe, and North America, having access to quick and efficient service is non-negotiable. This support system minimizes downtime and ensures that any technical challenges are resolved swiftly, preventing disruptions to automotive production schedules. Companies seeking to become regional distributors, like Ahmed is considering, also prioritize this aspect, knowing that a strong support network is essential for their own success in the market.

No-CAD reduces training timeTrue

The No-CAD system cuts operator training from 15 days to just 1 day by eliminating complex 3D drawing requirements.

Front-feeding decreases efficiencyFalse

Front-feeding innovation actually increases feeding efficiency by 40% while reducing operator labor intensity.

What technological advancements improve metal tube cutting processes in the automotive sector?

Are you struggling to keep pace with the evolving demands of automotive manufacturing? Traditional tube cutting methods often limit innovation and efficiency. Embrace the latest technological advancements to revolutionize your production capabilities and unlock new design possibilities.

Technological advancements in metal tube cutting, such as AI-powered optimization, multi-process integration, and enhanced material handling, are revolutionizing automotive manufacturing. These innovations boost precision, increase efficiency, enable complex designs, and significantly reduce operational costs and material waste.

Throughout my career, I’ve witnessed how technology acts as the ultimate game-changer, especially in highly demanding sectors like automotive manufacturing. What was once considered cutting-edge yesterday can be standard practice today, and tomorrow’s innovations are constantly pushing the boundaries of what’s possible. In the realm of metal tube cutting, these advancements are not just incremental improvements; they are transformative shifts that are fundamentally reshaping how automotive components are designed and produced. From smarter software to more efficient hardware, these technological leaps are enabling manufacturers to achieve unprecedented levels of precision, speed, and versatility, directly addressing the core needs of a dynamic industry.

The continuous evolution of technology has profoundly impacted metal tube cutting processes, bringing forth innovations that directly benefit the automotive sector. These advancements are centered around AI-powered optimization, integrated multi-process capabilities, and enhanced material handling, each contributing significantly to improved efficiency, precision, and cost-effectiveness.

AI-Powered Optimization and Digitalization

The integration of Artificial Intelligence (AI) and advanced digitalization is revolutionizing how metal tube cutting machines operate, particularly in the automotive sector. AI algorithms can analyze vast amounts of data from cutting operations – including material type, thickness, laser power, and cut quality – to continuously optimize parameters in real-time. This predictive optimization minimizes common issues like dross formation, heat-affected zones, and deformation, ensuring consistent, high-quality cuts even on challenging materials like high-strength steel. For automotive components where precision and structural integrity are non-negotiable, this level of automated optimization is invaluable.

Furthermore, digitalization means machines are becoming "smart." They can self-diagnose potential issues, predict maintenance needs, and seamlessly integrate with factory-wide Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) systems. This provides unparalleled transparency into the production process, allowing managers to monitor performance, track material usage, and identify bottlenecks remotely. For a large-scale metal fabrication business like Ahmed Al-Farsi’s, the ability to have "smart and digitalized systems" that offer remote diagnostics and real-time data insights is a significant advantage. It allows for proactive maintenance, reduces downtime, and enables data-driven decision-making to optimize production schedules and material flow.

This shift towards AI and digitalization not only improves operational efficiency but also facilitates rapid prototyping and mass customization. Designers can quickly iterate on complex tubular designs, knowing that the intelligent cutting system can adapt to new geometries and material specifications with minimal manual intervention. This agility is crucial in the automotive industry, which constantly introduces new models and variants, requiring flexible and responsive manufacturing processes. The insights gained from digitalized data also feed back into the design process, creating a continuous loop of improvement from manufacturing to engineering.

Integrated Multi-Process Capabilities

A significant advancement in metal tube cutting is the integration of multiple processing capabilities into a single machine. Traditionally, a tube might undergo separate steps for cutting, punching holes, drilling, or even welding preparation. This multi-step process often involved transferring the tube between different machines, leading to increased handling time, potential for errors, and greater overall production time. Modern laser tube cutting machines now offer "Multi-process integration," allowing for complex operations to be completed in one setup.

For the automotive industry, this means unprecedented efficiency. Imagine producing a chassis component that requires precise cuts, multiple punched holes for fasteners, and etched marks for robotic welding, all on a single machine pass. Our MZBNL Automatic Punching & Cutting Integrated Machine exemplifies this by combining high-speed laser cutting with efficient punching capabilities. This reduces setup times, minimizes material handling, and significantly improves overall throughput. The reduction in work-in-progress (WIP) and the elimination of redundant transfers directly translate into lower manufacturing costs and shorter lead times.

This integration also contributes to higher component accuracy and consistency. By performing all operations on one machine, the cumulative error from multiple setups is eliminated. For safety-critical automotive parts, this consistent precision is paramount. It allows manufacturers to produce more complex and functional tubular components that were previously impractical or too costly to fabricate using conventional methods. The ability to perform operations like notching, slotting, and even specialized joint preparation in a single automated sequence empowers designers to create lighter, stronger, and more intricate vehicle structures.

Enhanced Material Handling and Automation

The efficiency of any cutting process is highly dependent on how materials are loaded, positioned, and unloaded. Technological advancements in material handling and automation have dramatically improved the throughput and safety of metal tube cutting machines. Automated bundle loaders, robotically controlled feeding systems, and sophisticated unloading mechanisms are now standard features on advanced machines, significantly reducing manual labor and increasing operational speed.

Our MZBNL "Front-Feeding Innovation" is a prime example of this. Unlike traditional side or rear manual loading, our optimized front-feeding mechanism automatically pulls the tube from the front of the machine. This significantly increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%. This not only accelerates the overall production rate but also makes the process safer and less physically demanding for operators. Automated systems also ensure consistent positioning of the tube, which is critical for maintaining cut accuracy and minimizing material waste, especially with our "Zero-Waste Tail Material Innovation" where precise calculations are made from the rear chuck.

These advancements in automation extend beyond simple loading. They include intelligent nesting software that optimizes material utilization across multiple part geometries, minimizing scrap rates. Integrated conveyor systems and robotic arms can seamlessly transfer finished parts to subsequent processing stages or directly to packaging, creating a fully automated production cell. For the automotive sector, where high volumes and minimal waste are key performance indicators, these automated material handling solutions are indispensable. They enable continuous, lights-out manufacturing capabilities, further boosting productivity and ensuring that components are delivered on time and within budget, directly addressing a pain point like Ahmed's concerning long machine lead times.

AI optimizes tube cutting parametersTrue

AI algorithms analyze material data to automatically adjust laser power and cutting speed for optimal results.

Traditional methods are more preciseFalse

Modern laser cutting with AI achieves higher precision than manual methods by eliminating human error.

Conclusion

As Eric Liu, from MZBNL, I see metal tube cutting machines as indispensable for the automotive sector. They ensure precision, enable lightweight designs, and accelerate production. With innovations like No-CAD and zero-waste, we address key industry challenges, helping partners like Ahmed achieve efficiency and lead in a demanding market.

-

Learn why tubular structures are critical for innovative and efficient automotive design ↩

-

Discover improvements in precision, efficiency, and waste reduction with metal tube cutting machines ↩

-

Understand the significance of hydroforming in creating strong yet lightweight vehicle structures ↩

-

Learn about laser cutting's effectiveness on diverse materials and settings required ↩

-

Discover how modern systems reduce training time and enhance productivity ↩

-

Discover how Front-Feeding boosts feeding efficiency and reduces labor ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.