3D Robotic Laser Cutter

Struggling with complex, shaped parts? Traditional cutting is slow, wasteful, and lacks precision. This technology offers a solution by automating intricate cuts, boosting your factory's output and quality.

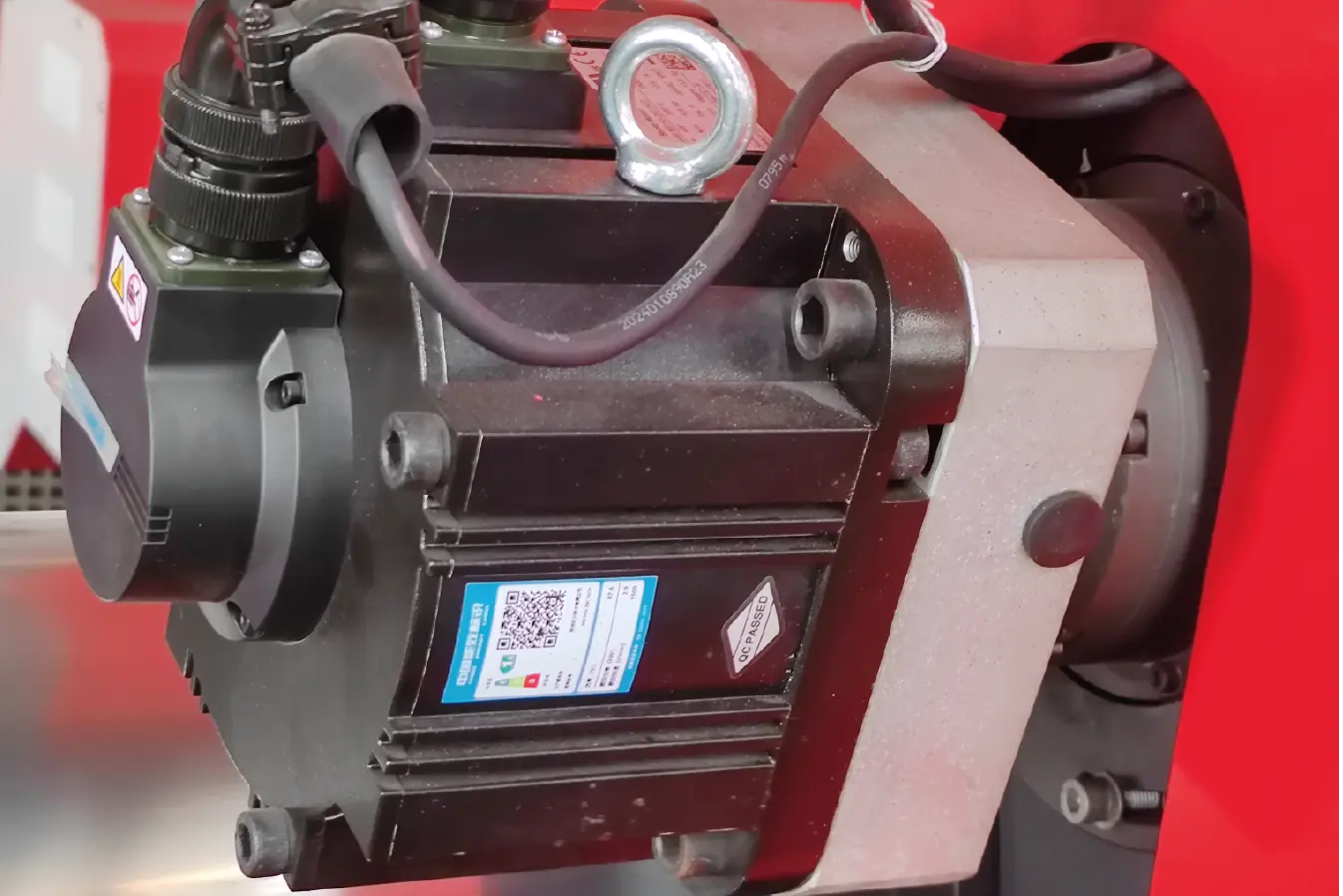

A 3D robotic laser cutter is an advanced manufacturing system that combines a high-precision laser with a multi-axis industrial robot. This allows it to accurately cut complex shapes and profiles on three-dimensional parts, such as pre-formed tubes or stamped components, with exceptional speed and repeatability.

As the General Manager of MZBNL, I have seen firsthand how this technology transforms production floors. It is not just about cutting metal; it is about redefining what is possible in manufacturing. This technology addresses the core challenges of modern industry: the need for speed, precision, and efficiency. In this article, I will share my insights on its evolution, applications, challenges, and the strategies your business can use to leverage its power.

What is the evolution of 3D robotic laser cutting technology?

Were your early automation efforts limited by flat, 2D cutting? This restriction could not keep pace with modern product design. Integrating flexible robotics was the key to unlocking true 3D capabilities.

The technology evolved from simple 2D flatbed cutters to more complex 5-axis gantry systems. The most significant leap was integrating flexible, six-axis robotic arms with fiber lasers, which made cutting complex, pre-formed parts both technically feasible and commercially viable for a wider range of industries.

To dive deeper, the journey from 2D to 3D cutting has been remarkable. In the early days, when we started MZBNL back in 2010, laser cutting was mostly confined to flat sheets. The machines were large, expensive gantry systems. They were powerful but rigid. The real demand I saw from our clients, especially in the automotive and furniture sectors, was for cutting parts that were already bent, stamped, or hydroformed. This is where the evolution became a revolution.

From Gantry Systems to Robotic Arms

The integration of industrial robots was the game-changer. Instead of moving a heavy part under a fixed cutting head, a lightweight robot could move a compact cutting head around a fixed part. This shift provided:

- Greater Flexibility: A 6-axis robot can reach almost any point on a complex part, enabling intricate cuts that were previously impossible.

- Smaller Footprint: Robotic cells typically take up less floor space than large gantry machines.

- Lower Cost: For many applications, a robotic solution became more cost-effective, opening the door for small and medium-sized enterprises.

I remember visiting a client who was struggling to manually trim hydroformed automotive frame parts. The process was slow, and scrap rates were high due to human error. When they installed one of our first robotic cutters, their cycle time per part dropped by over 70%. This is the kind of hyper-precision and automation that defines modern manufacturing. It is a pivotal shift that we have built our company around.

How is 3D robotic laser cutting currently being utilized in various industries?

Do you need to produce custom, high-precision parts efficiently? Standard manufacturing methods are often too slow and rigid for this. 3D robotic cutting enables the agile, on-demand production that modern markets demand.

It is heavily used in the automotive industry for cutting chassis parts, exhaust systems, and hydroformed tubes. In aerospace, it fabricates lightweight components with tight tolerances. And in architectural design, it creates intricate metalwork and structural elements. It excels wherever precision is non-negotiable.

Diving deeper, the applications are a direct reflection of the technology's core strengths: precision on complex surfaces. At MZBNL, we have equipped over 4,000 clients globally, and the use cases continue to expand. The strategic significance lies in its ability to streamline production. It allows companies to move from prototyping to full-scale production on the same machine, enhancing competitiveness by minimizing waste and maximizing efficiency.

Here is a look at how some key industries benefit:

| Industry | Application | Value Delivered by Robotic Cutting |

|---|---|---|

| Automotive Parts | Trimming stamped body panels, cutting holes in frames, shaping exhaust components. | Reduces cycle times drastically, ensures perfect fitment, and lowers material waste. |

| Furniture Manufacturing | Cutting complex joints and profiles in metal chair and table frames. | Enables unique, complex designs that are impossible with traditional tube benders and saws. |

| Fitness & Medical Equipment | Creating precise holes and slots in structural tubing for assembly. | Guarantees high strength and safety standards through repeatable, accurate cuts. |

| Architectural Metalwork | Fabricating custom facades, sculptures, and complex structural nodes. | Allows for artistic freedom and structural integrity in one process. |

One of our clients, a manufacturer of high-end office furniture, was able to launch a new product line with a very complex geometric frame. They told me it would have been commercially unviable without the robotic laser cutter we provided. That is the power of this technology—it turns design limitations into manufacturing opportunities.

What are the main challenges faced by 3D robotic laser cutter technology today?

Does the technology seem intimidatingly complex? This perception of high-tech machinery often creates barriers to adoption. But understanding the real, solvable challenges helps you overcome them effectively.

The primary challenges are the high initial investment cost, the perceived complexity of programming the robot for intricate 3D paths, and the need to ensure consistent calibration for accuracy. Finding operators with the right skills can also be a significant hurdle for many companies.

Let's dive deeper into these concerns because they are the main questions I get from potential clients. As a business owner or plant manager, you need to see a clear path to ROI, and these challenges can seem like roadblocks.

The Programming Hurdle

This is perhaps the biggest fear I encounter. People envision needing a PhD to program a 6-axis robot. In the past, they were not wrong. It was a complex, time-consuming task. But this is precisely the problem we at MZBNL set out to solve. We invested millions in R&D to create an intuitive software interface. Our core value proposition is that we can take an operator with no prior experience and have them producing parts in a single day. We eliminated the need for complex G-code or robotic programming languages for 95% of applications.

The Initial Investment

Yes, the upfront cost is higher than a manual bandsaw. But the analysis cannot stop there. You must look at the Total Cost of Ownership (TCO)[^1]. A robotic cutter often replaces multiple manual stations. It reduces labor costs, virtually eliminates material waste from bad cuts, and operates 24/7 with minimal supervision. When we run the numbers with our clients, the payback period is often surprisingly short—typically 12 to 24 months.

Maintaining Precision and Quality

The final challenge is ensuring the machine stays accurate over its lifetime. This comes down to build quality and service. A well-built machine from an ISO-certified manufacturer[^2] like us will hold its calibration. Furthermore, partnering with a supplier who provides excellent training and support is crucial. We don't just sell machines; we build long-term relationships to ensure our clients succeed.

What strategies can overcome these challenges in 3D robotic laser cutting?

Do these challenges seem daunting? Ignoring them means you will miss out on massive efficiency gains. But with strategic planning and the right technology partner, adopting this technology is very manageable.

To overcome these challenges, focus on the total ROI, not just the upfront cost. Prioritize systems with user-friendly software that drastically reduces training time. And partner with a vendor who provides comprehensive training, support, and a clear path to profitability.

To dive deeper, overcoming these barriers is about making smart, informed decisions. It is less about the technology's limits and more about your approach to implementation. Here are the practical strategies I recommend to every plant manager I speak with.

-

Choose a Partner, Not Just a Supplier: Look for a company with a proven track record and deep industry experience. With over 30 patents and a decade of experience, we have seen what works. A good partner will analyze your specific parts and processes to configure a solution that guarantees ROI. They should be transparent about costs, capabilities, and support.

-

Demand Simplicity in Software: This is non-negotiable. The single biggest drain on productivity is a complex human-machine interface. Before you buy, ask for a live demonstration. Ask them to program a new part in front of you. If it takes an expert hours, walk away. Our one-day training promise is our commitment to simplicity and a direct solution to the skills gap challenge.

-

Start with a Clear Business Case: We help our clients build this. We analyze your current costs—labor, material waste, cycle times—and compare them to the projected performance of the robotic cell. The numbers almost always speak for themselves. This data-driven approach removes emotion and makes the investment decision clear for everyone, from the production supervisor to the CFO.

Adopting this technology is a strategic move. And with the right approach, it is one of the safest and most profitable investments a modern manufacturing business can make.

What technological advancements are recommended for optimizing 3D robotic laser cutters?

You have the machine, but can it perform even better? Without continuous optimization, you are leaving money on the table. New advancements can unlock even more potential from your investment.

Key advancements include integrating machine vision for automatic part recognition and path correction, using AI for predictive maintenance alerts, and developing more powerful, energy-efficient fiber laser sources. Offline programming software is also crucial for maximizing machine uptime by preparing jobs in advance.

Diving deeper, the goal of any technology is to become smarter, faster, and more reliable. At MZBNL, our R&D is relentlessly focused on this. The machine you buy today should be a platform for future growth, not a technological dead end.

Here are the advancements we are pioneering and recommend you look for:

Intelligent Vision Systems

Imagine the robot could "see" the part. If a part is placed in the fixture slightly askew, a vision system can detect the deviation and automatically adjust the cutting path in real-time. This eliminates failed cuts due to operator loading errors and is a huge step towards fully autonomous production.

AI and Predictive Maintenance

Factory downtime is a profit killer. We are embedding sensors and AI algorithms into our machines to monitor their health. The system can predict when a component, like a nozzle or lens, is degrading and alert the operator to perform maintenance before a failure occurs. This moves maintenance from a reactive to a proactive model, maximizing uptime.

Offline Programming and Simulation

Why stop the machine to program the next job? With advanced offline software, your engineer can use a 3D model of a new part to create and simulate the entire cutting program on a separate computer while the machine is still running production. When the current job is done, they load the new program in minutes. This maximizes the machine's productive hours and is a standard feature we provide.

These advancements are turning robotic cutters from simple tools into intelligent manufacturing assets, driving a new standard in manufacturing excellence.

Conclusion

3D robotic laser cutting is no longer a technology of the future; it is a practical, proven solution for today's manufacturing pains. By focusing on user-friendly systems, clear ROI, and a strong partnership with your supplier, you can unlock unprecedented precision and efficiency for your factory.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.