Industrial 3D Robotic Fiber Laser Cutting Machine for Metal

Struggling with complex metal parts? Traditional methods are slow, wasteful, and costly. Our 3D robotic laser cutters deliver the precision, speed, and agility needed to transform your production line.

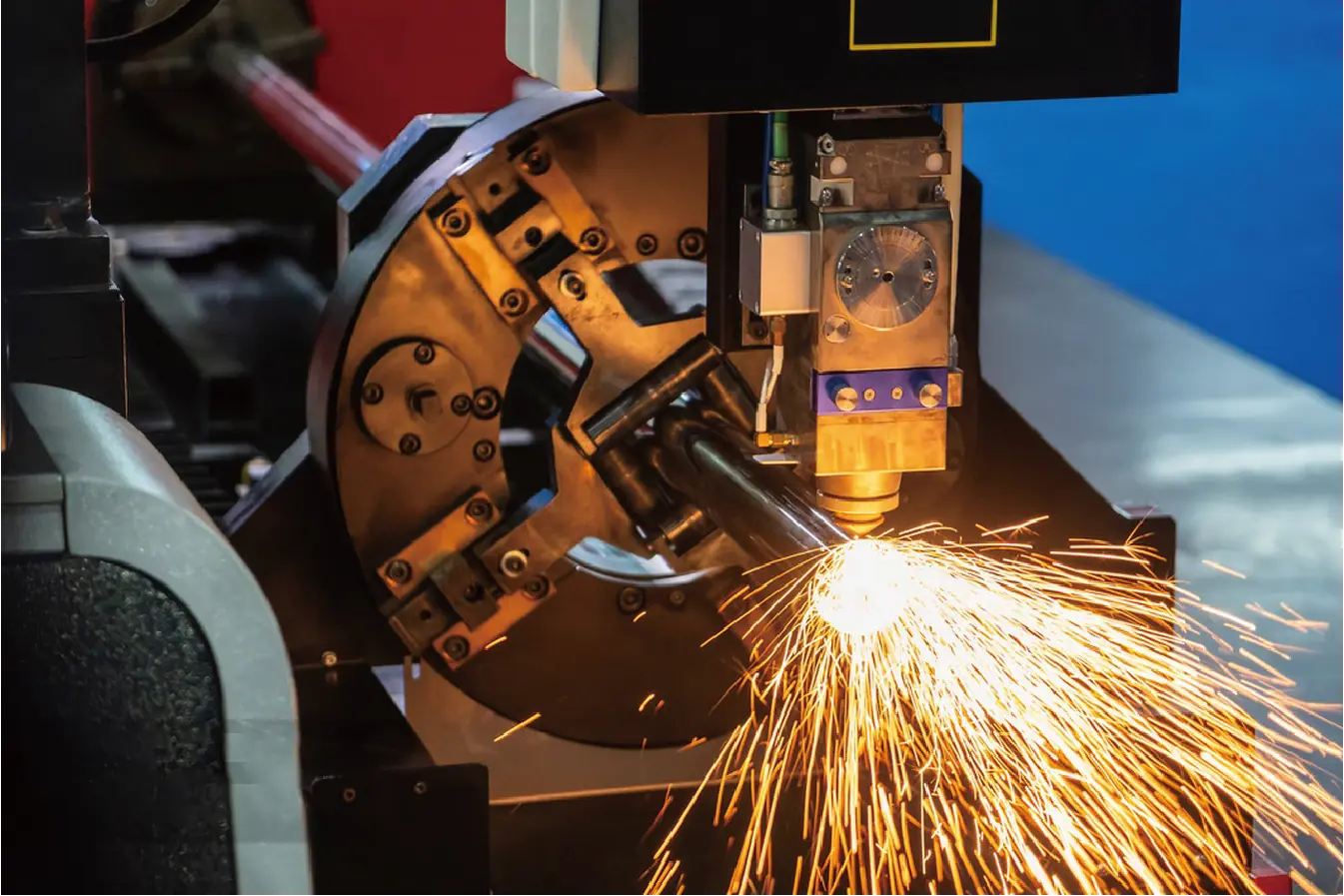

An industrial 3D robotic fiber laser cutting machine uses advanced robotics and a high-powered fiber laser to execute intricate, multi-axis cuts on metal. It boosts efficiency, minimizes waste, and enables rapid adaptation to complex designs, making it a key competitive advantage in modern manufacturing.

As the General Manager of MZBNL, I've seen firsthand how technology can solve real-world production problems. This isn't just about a new piece of equipment; it's about a fundamental shift in how we approach metal fabrication. It's about empowering businesses to innovate faster and operate more profitably. So, let's explore how this technology has evolved and what it can do for you.

How Has 3D Robotic Fiber Laser Cutting Technology Evolved?

Remember clunky, slow cutting methods? They created bottlenecks and wasted expensive material. Today's technology offers a streamlined, automated solution that was once just a concept for most factory floors.

3D robotic fiber laser cutting has evolved from basic 2D systems to highly flexible, multi-axis robotic arms. This progression allows for complex geometries, faster processing speeds, and integration into fully automated production lines, driven by powerful fiber laser sources and sophisticated software.

When I first entered this industry over a decade ago, the landscape was very different. We were proud of our 2D laser cutters, but they had limitations. They were great for flat sheets, but anything with a third dimension required multiple steps, complex jigs, and a lot of manual handling. I remember visiting a client in the early 2010s who needed three separate machines and several setups to create a single complex automotive part. The process was slow and prone to error.

The big change came with two key innovations.

The Rise of Fiber Lasers

First, fiber laser technology replaced older CO2 lasers. Fiber lasers are more efficient, require less maintenance, and can cut reflective metals more effectively. This made the technology more reliable and cost-effective for a wider range of applications. Because the beam is delivered through a flexible fiber optic cable, it was perfect for mounting on a moving platform.

The Integration of Robotics

Second, we integrated these powerful fiber lasers with advanced 6-axis robotic arms[^1]. This was the true leap forward. Suddenly, we could move the cutting head in almost any direction, following complex curves and reaching difficult angles on a 3D part. This eliminated the need for multiple setups. And as software became more intuitive, programming these complex movements went from a specialized skill to something we could teach an operator in a single day. This evolution is at the core of what we do at MZBNL—making powerful technology accessible.

How Are 3D Robotic Fiber Laser Cutting Machines Used in Metal Industries Today?

Need to produce complex parts for the automotive or aerospace industry? Manual processes can't keep up with the demand for speed or the strict requirements for precision. This technology is the current industry standard for a reason.

In metal industries, these machines are used for trimming stamped parts, cutting complex profiles in tubes, and fabricating intricate components for automotive chassis, aerospace brackets, and custom metal furniture. Their agility allows for high-mix, low-volume production without costly retooling.

The applications for this technology are vast, but I see them solving critical problems for our clients in a few key sectors every day. The core benefit is always the same: achieving complex cuts with speed and repeatability.

Automotive Applications

The automotive industry moves fast. Designs change, and the need for lightweight, high-strength parts is constant. Our 3D robotic cutters are essential for trimming hydroformed parts, which are complex, hollow metal components used in car frames. Before this technology, that was a messy, inaccurate process. Now, a robot can trim the part perfectly in seconds. This speed and precision are critical for keeping assembly lines moving.

Aerospace Precision

In aerospace, there is no room for error. Parts must meet incredibly tight tolerances. Here, our machines are used to cut holes and features in complex formed components or to create specialized brackets. Because the process is robotically controlled, every part is identical. This level of repeatability is essential for safety and certification in the aerospace industry.

Custom Fabrication and Furniture

This technology has also opened up new possibilities for designers. A furniture manufacturer we work with was struggling to produce a new chair design with intricate, curved metal tube legs. Creating the jigs for manual cutting was too expensive and slow. We brought in one of our robotic tube cutters. So, they were able to program the cuts directly from their CAD file and start production immediately. They launched the new design in half the expected time. This is the agility that modern manufacturing demands.

What Are the Common Challenges in Implementing This Technology?

Are you worried about the high cost and complexity of new technology? The initial investment and the potential training curve can seem daunting. But I've found these obstacles are easily overcome with the right plan and partner.

The primary challenges in implementing 3D robotic laser cutting are the high initial capital investment, the need for skilled programmers and operators, and integrating the system into existing workflows. Ensuring a clear ROI and providing proper training are crucial steps to mitigate these obstacles.

I believe in being direct with our clients. Adopting this technology is a significant decision, and it's important to understand the challenges. My team and I have helped over 4,000 clients navigate this process, and we've learned that every challenge has a clear solution.

Challenge 1: The Initial Investment

A 3D robotic laser cutting cell is a major capital expense. It's easy to get "sticker shock" and question if the investment is worth it. But the purchase price is only part of the story. The real calculation is the Total Cost of Ownership[^2] and the Return on Investment (ROI). We help clients build a business case by looking at the numbers.

| Cost Factor | Traditional Method (Manual/Multi-Machine) | 3D Robotic Laser Cutter |

|---|---|---|

| Labor Cost | High (Multiple operators, setups) | Low (1 operator for multiple machines) |

| Material Waste | High (Errors, complex fixtures) | Minimal (High precision, no errors) |

| Throughput | Low (Slow cycle times) | High (Fast, continuous operation) |

| Agility | Low (Expensive, slow retooling) | High (Instant changeover via software) |

When you factor in the savings from reduced labor, less wasted material, and increased output, the ROI is often realized much faster than expected.

Challenge 2: The Skills Gap

Many managers worry that they don't have operators with the skills to program and run a complex robot. This was a valid concern ten years ago. But today, the software has changed everything. At MZBNL, our core mission is to make technology simple. We've designed our systems so that a person with basic computer skills can be trained to operate the machine proficiently in a single day. We handle the complex programming so your team can focus on production.

What Are the Best Strategies for Effective Integration?

Are you unsure how to integrate this powerful machine into your factory? A poor plan can lead to downtime and frustration. A strategic, phased approach ensures a smooth transition and immediate benefits for your team.

Effective integration involves a phased approach: start with a detailed needs analysis, choose a modular system that can scale, and prioritize comprehensive operator training. Partnering with a supplier who provides end-to-end support, from installation to process optimization, is critical for success.

Bringing a new system online should be an exciting moment, not a stressful one. Over the years, my team has developed a simple, four-phase process to guarantee a successful integration for every client. We don't just sell a machine; we deliver a complete, production-ready solution.

Phase 1: Collaborative Assessment

It starts with a conversation. We don't begin by talking about our machines; we begin by talking about your parts, your production goals, and your pain points. My team works with you to understand your exact needs. We analyze your workflow to identify the biggest opportunities for improvement. This ensures the solution we propose will deliver a real, measurable impact.

Phase 2: System Customization

There is no "one-size-fits-all" solution in manufacturing. Based on our assessment, we configure the right system for you. This means selecting the appropriate robot size, laser power, and safety features. We design a cell layout that fits seamlessly into your existing floor space and workflow. This customized approach prevents you from overpaying for features you don't need or getting a system that can't handle your future growth.

Phase 3: Seamless Installation & Training

This is where our commitment to simplicity really shows. Our expert technicians handle the entire installation and commissioning process. But we don't leave once the machine is running. We stay to train your operators. As I mentioned, our goal is to make your team confident and self-sufficient in just one day. We stay until they are comfortable running parts on their own.

What Are the Best Practices for Optimizing Operations?

Is your new machine not performing at its peak? Sub-optimal settings can lead to poor cut quality and slower speeds. A few simple adjustments and best practices can unlock its full potential and maximize your return on investment.

To optimize operations, regularly maintain the laser source and optics, use the correct assist gas pressures for different materials, and refine robot path programming to minimize non-cutting movements. Calibrating the Tool Center Point (TCP) is also essential for consistent accuracy.

Once your machine is running, the goal is to get the most out of it every single day. High performance comes from a combination of good programming, proper settings, and consistent maintenance. Here are a few key practices I always share with our clients to ensure they get the best possible results.

Master Your Assist Gas

The type and pressure of the assist gas you use are critical for cut quality.

- Oxygen: Use for mild steel. It creates an exothermic reaction that aids the cutting process, allowing for faster speeds on thick material. But the edge will have a thin oxide layer.

- Nitrogen: Use for stainless steel and aluminum. It acts as a shield, preventing oxidation and leaving a clean, shiny, weld-ready edge. It requires higher pressure and volume.

- Air: A cost-effective option for thin materials where edge quality is less critical. It's a mix of nitrogen and oxygen.

Program for Efficiency

The speed of the robot's movement between cuts (the "air moves") can add up. Efficient programming minimizes this non-productive time. Your software should help you optimize the cutting path to be as short and smooth as possible. Small changes here can shave seconds off every cycle, which adds up to hours of extra production time over a year.

Implement a Simple Maintenance Checklist

Preventative maintenance is the key to uptime. You don't need a complex plan. A simple daily and weekly checklist is enough.

- Daily: Inspect and clean the cutting nozzle. Check the protective lens for any spatter.

- Weekly: Clean the machine's external optics and check assist gas filters.

This simple routine takes only a few minutes but can prevent hours of costly downtime.

Conclusion

Adopting a 3D robotic fiber laser cutter is a strategic investment in precision, efficiency, and agility. It solves key production challenges, reduces long-term operational costs, and positions your business as an innovative leader. My team at MZBNL is here to guide you through every step of the process.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.