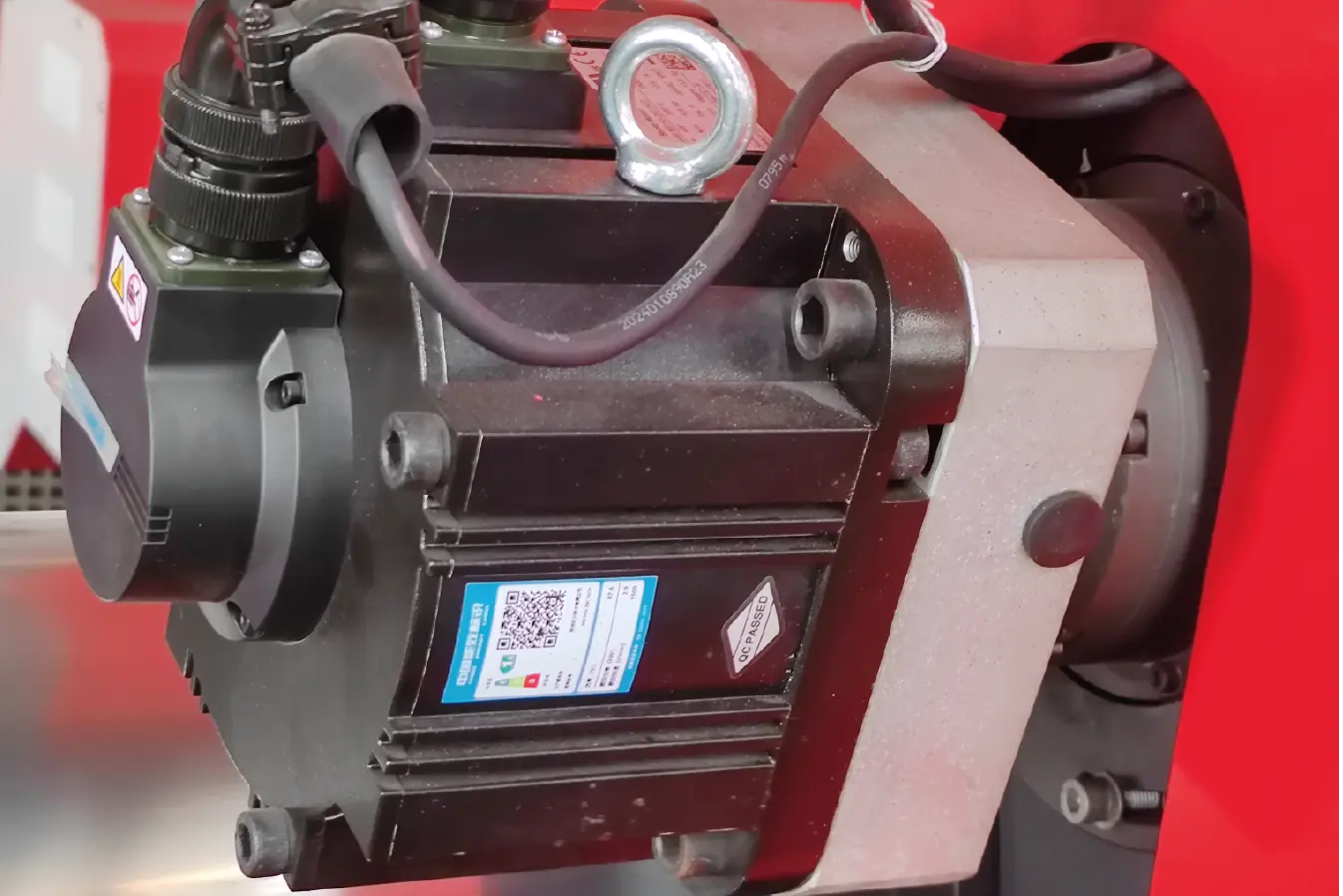

3D Robot Fiber Laser Cutting Machine

Struggling with complex 3D parts that are slow and costly to produce? This inefficiency eats into your margins and slows down your entire operation, hurting your bottom line.

A 3D robot fiber laser cutting machine revolutionizes production by combining high precision with extreme flexibility. It handles complex 3D shapes, boosts efficiency, and with MZBNL's innovations, reduces labor intensity by 40% and minimizes material waste, directly increasing your profitability.

As the General Manager of MZBNL, I've seen firsthand how the right technology can transform a business. The leap to 3D robotic cutting isn't just an upgrade; it's a fundamental shift in how you approach manufacturing. It opens doors to more complex designs, faster turnaround times, and a stronger competitive position. Let's explore how this technology works and how you can make it work for you.

What is the historical development of 3D robot fiber laser cutting machines?

Manufacturing used to rely on rigid, single-purpose machines. As designs became more complex, these old methods couldn't adapt, creating production bottlenecks. The evolution to robotic lasers changed everything.

The development began with simple 2D laser cutters. As manufacturing demanded more complex, three-dimensional parts, these evolved by integrating multi-axis industrial robots with powerful fiber lasers, creating the highly flexible and precise machines we see today.

I remember visiting factories 15 years ago where creating a complex cut on a tube was a multi-step, error-prone process. It involved manual measurements, multiple setups, and a lot of wasted material. We knew there had to be a better way. The journey started with basic CNC machines, which brought automation but were still limited to simpler geometries. The introduction of 2D laser cutters was a major step forward, offering speed and precision on flat sheets. But the real game-changer was combining the power of a fiber laser with the agility of a 6-axis robotic arm[^1]. This fusion created a machine that could move and cut in virtually any direction, on any contoured surface. This wasn't just an incremental improvement; it was a response to a growing market need. Industries like automotive and custom furniture were demanding parts that were impossible to make efficiently with old technology. The 3D robot fiber laser cutter was born from this necessity, marking a new era of manufacturing freedom.

How are 3D robot fiber laser cutting machines currently being utilized in various industries?

In today's competitive market, you need versatile equipment. A machine that performs only one task is a poor investment. This technology, however, adapts across multiple sectors, maximizing its value.

These machines are vital in automotive manufacturing for chassis and exhaust parts, in furniture for complex tube joints, and in fitness equipment for precise, strong frames. Their flexibility makes them invaluable for any industry requiring high-precision cutting of 3D metal components.

At MZBNL, we've equipped over 4,000 clients, and I've seen our machines tackle an incredible variety of challenges. A client in the automotive parts sector told me they cut production time for a complex chassis bracket by 60% after installing our machine. In the furniture industry, designers are no longer limited by traditional joinery methods; they can create intricate, strong, and aesthetically pleasing joints that were previously too expensive to produce. We see the same impact in everything from sanitary ware to institutional equipment. The core benefit is the ability to process formed or hydroformed parts after the initial shaping process. This is where the machine's precision truly shines, allowing for perfect cuts and holes on already-bent tubes and profiles.

Here is a simple breakdown of its use:

| Industry | Application | Key Benefit |

|---|---|---|

| Automotive | Cutting chassis, exhausts, body panels | High precision for safety components |

| Furniture | Complex tube joints, custom frames | Design freedom and structural integrity |

| Fitness Equipment | Frame cutting, hole punching | Speed and repeatability for mass production |

| Sanitary Ware | Faucet and fixture profiling | Flawless finish on contoured surfaces |

This versatility ensures that the machine is never idle, constantly providing value across different product lines.

What challenges do manufacturers face when implementing 3D robot fiber laser cutting technology?

New technology can seem daunting. The fear of high costs, complex training, and operational disruption are major barriers for many business owners I speak with.

The primary challenges are the high initial investment, the perceived complexity of programming the robotic arm, and the need for skilled operators. Manufacturers also worry about integration with existing workflows and ensuring a clear return on investment.

I've spoken with hundreds of plant managers over the years. Their biggest fear isn't the machine itself; it's the disruption. They ask me, "Eric, how much will this cost upfront? And how long will my production line be down while my team learns to use it?" These are valid concerns that we have to address head-on.

High Capital Outlay

There's no denying that a 3D robot fiber laser cutter is a significant investment. Business owners need to see a clear and rapid path to profitability to justify the expenditure. The focus must be on total cost of ownership, not just the sticker price.

The Skills Gap

Traditionally, programming a 6-axis robot required a specialized engineer. The fear is that you'll invest in a powerful machine that sits idle because you can't find or afford the talent to run it. This operational dependency is a huge risk for any factory.

Integration Headaches

Bringing a new, advanced piece of equipment into an established workflow can be complicated. Ensuring it communicates with other systems and that the material flow is optimized requires careful planning.

What strategies can be employed to overcome the challenges in adopting 3D robot fiber laser cutting machines?

The challenges of adoption can seem insurmountable. But ignoring them means falling behind more agile competitors. We've focused our entire business on developing specific strategies to make this transition seamless.

To overcome challenges, focus on technology that simplifies operation, like MZBNL's non-CAD system. Also, conduct a thorough ROI analysis before purchase, and partner with a supplier that provides comprehensive training and support to ensure a smooth integration.

Solving these problems is at the core of what we do at MZBNL. We realized early on that selling a powerful machine wasn't enough. We had to sell a complete solution that addressed the real-world fears of our customers.

Tackling Complexity with Simplicity

The biggest barrier was programming. So, we developed our "non-CAD system." It's a revolutionary approach that allows an operator to program complex cutting paths directly on the machine without needing any CAD/CAM experience. We've reduced the training time from weeks or months down to a single day. This directly solves the skills gap problem and empowers our clients' existing workforce.

Maximizing Material and Labor ROI

To address the high initial cost, we focused on operational savings. Our "zero waste tail material innovation[^2]" ensures that almost every inch of the metal tube is used, drastically cutting material costs. And by simplifying the process, we've found our machines reduce overall labor intensity by up to 40%. These savings create a very fast return on investment.

Choosing the Right Partner

We don't see ourselves as just a vendor. We are a partner in our clients' success. With over 30 patents and an ISO certification, we provide reliable technology backed by comprehensive service and support to ensure a smooth, successful implementation.

What are the technological recommendations for enhancing the performance of 3D robot fiber laser cutting machines?

You have the machine, so now what? Without continuous optimization, you are leaving money and efficiency on the table. Constant innovation is the key to unlocking peak performance.

Enhance performance by integrating smart sensors for real-time adjustments, adopting software that simplifies programming without CAD expertise, and implementing automated loading systems. Innovations like pre-feeding and zero-waste cutting are also crucial for maximizing throughput.

At MZBNL, we believe the machine's launch is just the beginning of the performance journey. We build our technology not just for today's needs, but for tomorrow's opportunities. Here are the key areas we focus on to help our clients get the absolute most out of their investment.

- Software Simplification: This is our number one priority. Our "non-CAD system" is a living project, constantly being updated to be more intuitive and powerful. The goal is to put all the machine's power in the hands of the operator, not a programmer in an office.

- Automation Integration: Speed is everything. That's why we developed our "pre-feeding innovation." This automated system prepares the next workpiece while the current one is being cut, virtually eliminating downtime between cycles and maximizing throughput.

- Material Efficiency: Wasted material is wasted profit. Our "zero waste tail material innovation" is a crucial feature that enhances performance by directly boosting the bottom line on every single job.

- Intelligent Operation: The future is in machines that can think for themselves. We are integrating sensors and feedback systems that allow the machine to make micro-adjustments on the fly, ensuring perfect cuts every time, regardless of minor variations in material.

By focusing on these areas, we ensure that an investment in an MZBNL machine is an investment in a platform that will continue to grow and improve over time.

Conclusion

Adopting a 3D robot fiber laser cutter is a strategic move towards lean, automated manufacturing. By overcoming implementation challenges with user-friendly technology like ours, you can unlock unparalleled precision, efficiency, and profitability, securing your competitive edge in a demanding global market.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.