3D Laser Cutting Machines

Struggling with complex 3D parts? Traditional methods are slow, wasteful, and limit your designs. 3D laser cutting technology[^1] offers a precise, efficient solution for modern manufacturing challenges.

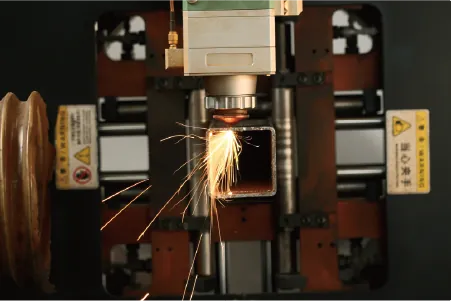

A 3D laser cutting machine is an advanced tool that uses a focused laser beam to cut complex, three-dimensional shapes with extreme precision. It enhances design freedom, reduces material waste, and is crucial for industries like automotive, medical, and architectural manufacturing for high-efficiency production.

As the General Manager of MZBNL, I've seen firsthand how companies transform their operations with the right technology. This isn't just about a new piece of equipment. It's about a fundamental shift in how we approach manufacturing—moving from flat, two-dimensional thinking to a world of three-dimensional possibility. Let's explore what this technology is, where it's making an impact, and how you can leverage it for your business.

What Exactly is 3D Laser Cutting Technology?

Confused by the jump from 2D to 3D? Standard cutters can't handle complex curves and angles. This technology redefines what is possible in modern fabrication.

3D laser cutting technology uses a multi-axis robotic arm or gantry system to direct a high-powered laser. This allows it to cut intricate patterns on pre-formed or three-dimensional surfaces, moving beyond the limitations of flat-sheet cutting to enable true multidimensional manufacturing.

To dive deeper, let's break down what makes this technology so revolutionary. Unlike a traditional 2D laser cutter that only moves on an X and Y axis to cut flat sheets, a 3D machine adds multiple axes of movement. Think of a highly precise robotic arm holding a powerful cutting tool. This arm can twist, turn, and tilt, allowing the laser beam to approach the workpiece from virtually any angle. This capability is what allows us to process complex three-dimensional shapes, like hydroformed tubes[^2] or stamped metal parts, with incredible accuracy after they have already been formed.

The Strategic Shift from 2D to 3D

At MZBNL, we see this as more than an upgrade; it's a strategic necessity. The market demands more innovative and complex product designs. And traditional manufacturing methods often can't keep up. They require multiple steps, complex jigs, and a lot of manual labor, which drives up costs and waste. 3D laser cutting consolidates many of these processes into a single, automated step.

- Unmatched Precision: It can cut holes, slots, and complex profiles on curved surfaces with tolerances[^3] that are impossible to achieve manually.

- Design Freedom: Engineers are no longer limited by the constraints of traditional tools. They can design stronger, lighter, and more complex parts.

- Reduced Waste: By precisely cutting pre-formed parts, you eliminate the material waste common in multi-stage fabrication processes.

I remember a client in the automotive sector who was struggling to produce a complex exhaust component. They were welding multiple pieces together, a slow and error-prone process. By implementing one of our 3D laser cutters, they were able to cut the entire pattern from a single hydroformed tube. Their production time for that part dropped by 60%, and their rejection rate fell to nearly zero. That is the power of this technology.

Where Are 3D Laser Cutting Machines Used Today?

Wondering if this tech is right for your business? It's easy to think it's only for niche aerospace. But its practical applications are transforming everyday industries right now.

3D laser cutting machines are widely used in automotive manufacturing for chassis and hydroformed parts, medical for custom implants, and architecture for decorative metalwork. They are essential for any industry requiring high-precision cutting of complex, non-flat components, boosting efficiency and product quality.

To dive deeper, the applications are incredibly diverse because the core problem it solves—cutting complex shapes efficiently—is universal. In my years leading MZBNL, I've seen our machines become indispensable tools across a wide range of sectors. It's not just about doing the old things faster; it's about enabling entirely new products and processes. The ability to save on material and production time directly addresses the market's dual pressures of cost-effectiveness and sustainable development.

Here’s a look at where we see the biggest impact:

| Industry | Common Application | Key Benefit |

|---|---|---|

| Automotive | Cutting chassis components, exhaust systems, hydroformed parts | Higher structural integrity, reduced weight, faster production cycles. |

| Furniture | Creating complex joints and decorative patterns in metal tubes | Unlocking unique design possibilities, reducing assembly time. |

| Medical Devices | Manufacturing custom prosthetics and surgical instruments | Extreme precision for patient-specific devices, use of advanced alloys. |

| Architecture | Fabricating intricate metal facades and structural nodes | Enabling complex architectural visions, ensuring perfect fit-up on site. |

| Fitness Equipment | Profiling and cutting holes in structural tubing | Improved product aesthetics, stronger and more reliable frames. |

I recently visited a client who manufactures high-end office furniture. They were using manual drilling and cutting for their chair frames, which was slow and led to inconsistencies. After we installed a 3D laser cutting system, they were able to create a new, award-winning chair design with complex curved tubing that would have been impossible before. They not only improved their efficiency but also elevated their brand as an innovator. This is a common story. The machine becomes a catalyst for growth.

What Are the Biggest Challenges in Adopting 3D Laser Cutting?

Thinking about an upgrade? The initial investment and technical learning curve can seem daunting. Many businesses hesitate, fearing the complexity and potential downtime during transition.

The primary challenges in implementing 3D laser cutting are the high initial capital investment, the need for specialized operator training and programming skills, and integrating the machine into existing production workflows. Proper planning and choosing the right partner are critical for success.

To dive deeper, I believe in being direct and honest with our potential partners. Adopting this level of technology is a significant decision, and it's important to understand the hurdles. Ignoring them is a recipe for failure. From my conversations with hundreds of plant managers, the concerns almost always fall into three main categories.

Financial Investment

There's no getting around it: these are sophisticated machines, and they represent a major capital expenditure. Business owners need to see a clear path to return on investment (ROI). The cost isn't just the machine itself, but also potential facility upgrades, software, and auxiliary equipment. It requires careful financial planning and a solid business case built on projected savings in labor, materials, and rework, as well as the potential for new revenue streams.

The Skills Gap

A common fear I hear is, "My team can't run something that complex." The programming and operation of a multi-axis machine can seem intimidating. Finding operators with experience in 3D CAD/CAM software and robotics can be difficult. This is why we at MZBNL have focused relentlessly on making our technology accessible. We believe the machine should adapt to the user, not the other way around. A long and difficult training period is a direct hit to productivity.

Workflow Integration

A new 3D laser cutter doesn't exist in a vacuum. You have to integrate it into your entire production flow, from design to finishing. This can mean changing how your engineering team designs parts, how materials are handled on the shop floor, and how finished components move to the next stage. Without a clear integration plan, the new machine can become a bottleneck instead of a solution. It requires a holistic view of your entire operation.

How Can You Overcome 3D Laser Cutting Implementation Challenges?

Are implementation hurdles holding you back? Don't let fear of complexity stop your growth. There are clear, actionable strategies to ensure a smooth and profitable adoption.

Overcome challenges by conducting a thorough ROI analysis to justify the investment, partnering with a supplier who provides comprehensive training and support, and starting with a pilot project. Phased implementation and focusing on user-friendly machines can significantly de-risk the transition.

To dive deeper, overcoming these challenges is not only possible, it's straightforward with the right approach. It's about turning potential problems into a structured plan. At MZBNL, we don't just sell machines; we guide our clients through this exact process. Here are the practical strategies I recommend to every business owner and plant manager I speak with.

-

Build a Data-Driven Business Case: Don't rely on guesswork. Calculate your potential ROI. How much do you currently spend on labor for cutting and drilling? What is your material scrap rate? How many production steps can be eliminated? Quantify these numbers. When you see that the machine can pay for itself in 18-24 months through direct savings, the investment becomes a logical business decision, not a leap of faith.

-

Prioritize Simplicity and Training: The skills gap is real, but it can be solved. When you evaluate suppliers, ask them about their training program. How long does it take? Is it on-site? Is the machine's software intuitive? My company's core philosophy is to reduce operator training time from weeks to a single day. A machine that is easy to learn and operate is one that will deliver value from day one.

-

Choose a Partner, Not a Vendor: A vendor sells you a box and leaves. A partner is invested in your success. They should help you with workflow analysis, integration planning, and provide responsive technical support after the sale. Before you buy, talk to their existing customers. Ask about their support experience. A strong partnership is the single most important factor in a successful implementation.

-

Start with a Pilot Project: You don't have to revolutionize your entire factory overnight. Identify one specific product line or component that is causing a bottleneck. Use the implementation of the 3D laser cutter to solve that single problem first. This creates a quick win, builds team confidence, and provides a clear model for expanding its use across other areas of your operation.

What is the Future of 3D Laser Cutting Machines?

Is this technology future-proof? You need to invest in what's next, not what's obsolete. The evolution of this technology is accelerating towards full automation and intelligence.

The future of 3D laser cutting is in greater automation, integration with AI for self-optimization, and enhanced software for seamless design-to-production workflows. These machines will become key enablers of personalized, on-demand manufacturing and smart factories (Industry 4.0).

To dive deeper, we are on the cusp of the next industrial revolution, often called Industry 4.0. And 3D laser cutting machines are not just a part of this future; they are a critical component of it. As we look ahead, the development isn't just about making the machines faster or more powerful. It's about making them smarter, more connected, and more autonomous.

Smarter Automation and AI

The next generation of machines will require even less human intervention. I envision machines that can automatically adjust cutting parameters based on sensor feedback, compensating for material variations in real-time. Artificial intelligence (AI) will be used to optimize cutting paths for speed and quality, and predictive maintenance algorithms will alert us to a potential problem before it ever causes downtime. The goal is a "lights-out" manufacturing environment where the machine manages its own production queue with maximum efficiency.

The Rise of Customization

The demand for personalized and customized products is growing rapidly. Consumers want products tailored to their specific needs. 3D laser cutting is perfectly suited for this trend. Because reprogramming the machine for a new design is purely a software change, it enables cost-effective, high-volume customization. A factory will be able to produce a thousand slightly different versions of a product as easily as a thousand identical ones. This technology is the key weapon for manufacturers to enhance their competitiveness in an era of mass personalization.

At MZBNL, our R&D is heavily focused on this future. We are building the machines that will power the smart factories of tomorrow, ensuring our clients are not just keeping up, but leading the way.

Conclusion

3D laser cutting is no longer a niche technology; it is a strategic necessity for modern manufacturing. It solves complex production challenges, drives product innovation, and offers a clear, data-backed path to higher efficiency and profitability. Embracing it is key to staying competitive in a multidimensional world.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.