Tube Laser Cutting Machines with Zero-Tail Function: Explained

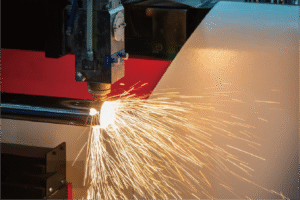

Have you ever felt the frustration of material waste piling up in your workshop? It's a common problem for many in metal fabrication, leading to increased costs and reduced efficiency. We've all been there, watching perfectly good material turn into unusable scraps.

The zero-tail function in tube laser cutting machines eliminates waste by optimizing the cutting process from the rear chuck, ensuring that nearly all material is utilized. This innovative approach maximizes material efficiency and significantly reduces operational costs for manufacturers.

When I first encountered the concept of "zero-tail" in tube laser cutting, I was skeptical. How could a machine completely eliminate the inevitable waste that has plagued the industry for so long? Yet, as I delved deeper, I realized this wasn't just a marketing gimmick; it was a fundamental shift in how we approach material utilization and operational efficiency. This breakthrough technology redefines productivity in metal fabrication.

In the competitive landscape of metal fabrication, every inch of material counts. Traditional methods often prioritize speed, overlooking the hidden costs associated with material waste. This oversight can significantly impact profit margins, especially for businesses like Ahmed Al-Farsi's, who prioritize automated solutions and efficiency upgrades. Ahmed, owner of a mid-sized metal fabrication business in the UAE, constantly seeks ways to optimize his operations. He knows that even small improvements in material utilization can lead to substantial savings over time. Industry research consistently shows that material waste accounts for a significant portion of manufacturing overhead. For example, a 2023 report by the Metal Fabrication Institute1 highlighted that up to 15% of raw material in conventional tube cutting can be lost as scrap. The challenge, then, isn't just about cutting faster, but about cutting smarter. This critical examination of efficiency and waste sets the stage for understanding the revolutionary impact of zero-tail technology in tube laser cutting.

What is the zero-tail function in tube laser cutting machines?

Are you tired of seeing valuable material turn into scrap at the end of each cutting job? The traditional way of cutting always leaves unusable remnants. Imagine a system that practically eliminates this waste, optimizing every inch of your costly raw materials.

The zero-tail function in tube laser cutting machines is an advanced feature that starts cutting from the rear chuck, minimizing or eliminating leftover material. By rethinking the cutting origin, it ensures maximum material utilization, thereby reducing waste and improving overall production efficiency.

For years, I've seen countless fabrication shops struggle with the inherent inefficiency of traditional tube cutting, where a significant portion of the tail material is inevitably wasted. This waste isn't just an inconvenience; it represents lost revenue and a drain on resources. I remember a conversation with Ahmed, who was constantly frustrated by the material scraps that piled up after each production run. He knew there had to be a better way to optimize his expensive raw materials. The zero-tail function isn't just an incremental improvement; it's a paradigm shift that fundamentally redefines how we approach material utilization in tube laser cutting. It's about turning what was once inevitable waste into valuable product, directly impacting the bottom line and contributing to a more sustainable manufacturing process.

Redefining Cutting Logic from the Rear Chuck

The core innovation behind the zero-tail function lies in its re-imagination of the cutting origin. Traditional laser cutting systems, including many older models, typically commence the cutting process from the tube head, moving progressively towards the tail. While seemingly logical, this approach invariably leaves a section of unusable material at the end, often due to the mechanical limitations of the chuck or the need for a gripping margin. The zero-tail function fundamentally alters this logic by initiating the cut from the rear chuck as the primary reference point. This means that instead of cutting sequentially from front to back, the system calculates and executes cuts in a manner that ensures the final piece cut is as close to the rear chuck as possible, thereby minimizing or even eliminating the unworkable tail. This sophisticated control over the cutting path allows for an unprecedented level of material recovery, transforming what was once scrap into usable components.

For instance, consider a manufacturer of automotive exhaust pipes. With traditional methods, after cutting multiple segments from a long tube, a foot or more of material might be left as unusable scrap. With a zero-tail system, the machine intelligently plans cuts to utilize this final section, provided it's larger than the required product length. This capability alone can lead to substantial material savings over time. According to a study by PwC's Industrial Manufacturing Group, companies adopting advanced material optimization techniques can see a 5-10% reduction in raw material costs. This data highlights the tangible financial benefits of such a strategic shift in cutting logic.

Maximizing Material Utilization through Intelligent Planning

The effectiveness of the zero-tail function is not solely reliant on its altered cutting origin; it’s deeply rooted in the intelligent planning and optimization algorithms that drive the machine. These advanced software systems analyze the entire cutting list, tube length, and chuck limitations to create a nested cutting plan that prioritizes material usage. Instead of simply processing parts sequentially, the system strategically places cuts to minimize gaps and maximize the number of parts extracted from each raw material tube. This intelligent planning is particularly beneficial for businesses like Ahmed's, which handle diverse orders for architectural metalwork and vehicle parts. When dealing with varying part lengths and quantities, optimizing the nesting pattern is crucial for efficiency.

For example, if a job requires multiple short pieces and one longer piece from a standard 20-foot tube, the zero-tail system can arrange the cuts to fit the longer piece where it best utilizes the remaining material, ensuring minimal waste. This contrasts sharply with less sophisticated systems that might leave significant gaps. Data from Frost & Sullivan's 2024 report on Smart Manufacturing indicates that integrated intelligent planning systems can improve material yield by up to 7% in precision cutting applications. This efficiency gain directly translates into lower material procurement costs and higher profitability.

Reducing Scrap and Environmental Impact

Beyond the immediate financial benefits of material savings, the zero-tail function also contributes significantly to reducing scrap waste and, consequently, the environmental footprint of manufacturing operations. Each discarded piece of tail material represents not only a monetary loss but also an unnecessary consumption of resources and energy in its production and subsequent disposal. By virtually eliminating this waste, companies can reduce their landfill contributions and enhance their sustainability profile. This is increasingly important for businesses seeking to align with global environmental standards and appeal to environmentally conscious clients.

Consider a large-scale furniture manufacturer producing thousands of tubular components annually. The cumulative amount of tail material waste from traditional machines could fill multiple dumpsters. With zero-tail technology, this waste stream is drastically reduced, leading to significant cost savings in waste management and potentially opening doors to green certifications. A recent environmental impact assessment by the University of Cambridge's Institute for Manufacturing found that optimized material usage in metal fabrication can reduce carbon emissions associated with raw material production by 3-5%. This holistic benefit underscores the comprehensive value proposition of integrating zero-tail cutting technology into modern manufacturing processes.

| Feature | Traditional Cutting Machines | Zero-Tail Function Machines |

|---|---|---|

| Cutting Origin | Tube Head | Rear Chuck |

| Tail Material | Significant Waste | Minimal to Zero Waste |

| Material Usage | Sub-optimal | Maximized |

| Setup Complexity | Higher | Lower |

| Efficiency Impact | Moderate | High |

Zero-tail reduces material wasteTrue

The zero-tail function minimizes waste by optimizing cuts from the rear chuck, utilizing nearly all material.

Zero-tail increases setup complexityFalse

The table shows zero-tail machines actually have lower setup complexity than traditional systems.

Why do traditional tube cutting machines produce tail material waste?

Have you ever wondered why traditional tube cutting leaves so much unusable material behind? It's a persistent issue that plagues many workshops, costing businesses money and resources. This seemingly unavoidable waste is rooted in fundamental design limitations.

Traditional tube cutting machines produce tail material waste primarily due to mechanical chuck limitations, which require a minimum gripping length, and their front-to-back cutting logic. This design prevents full material utilization, resulting in leftover, unusable sections at the end of each tube.

For years, I've observed the frustration of fabricators grappling with the inevitable tail material waste generated by conventional tube cutting machines. It’s a problem that affects everyone, from small workshops to large manufacturing plants, and I've heard countless stories of businesses struggling to manage these losses. I recall a conversation with Ahmed, who highlighted this very issue as a significant pain point. He explained how even minor waste, when multiplied across thousands of tubes, amounted to substantial financial losses and increased his operational overhead. This isn't just about a few inches of scrap; it's about the cumulative impact on profitability and resource management. Understanding the root causes of this waste is crucial for appreciating the revolutionary solutions offered by modern innovations, which aim to transform this long-standing industry challenge.

Mechanical Limitations of the Chuck System

One of the primary reasons traditional tube cutting machines generate tail material waste stems from the inherent mechanical limitations of their chuck systems. The chuck, responsible for gripping and holding the tube firmly during the cutting process, requires a certain minimum length of material to maintain a secure hold. This "gripping length" or "safe clamping length" cannot be cut, as doing so would compromise the stability of the tube, leading to inaccurate cuts, damage to the machine, or even safety hazards. As the cutting head approaches the end of the tube, once the remaining material falls below this minimum gripping requirement, it becomes impossible to process further, thus leaving an unusable tail.

For example, if a machine's chuck requires a 10-inch grip, and only 8 inches of material remain, those 8 inches are inevitably scrapped. This is a fundamental design constraint that has been present in tube cutting technology for decades. A report by the Precision Machining Association2 noted that chuck limitations typically result in 5-15% of total tube length becoming scrap in traditional setups, depending on the machine design and material diameter. This significant percentage highlights the direct impact of mechanical constraints on material efficiency and the substantial financial implications for manufacturers.

Unidirectional Cutting Process

Another significant contributor to tail material waste in conventional machines is their unidirectional cutting process. Most traditional systems are designed to feed the tube from one end (typically the front) and cut sequentially along its length until the required parts are obtained. This linear, front-to-back approach means that the remaining material at the very end of the tube, after all the desired parts have been cut, often becomes too short or awkwardly shaped to be processed efficiently for any other part, even if a small, usable section might theoretically exist. The machine simply isn't designed to re-evaluate and utilize these very short remnants.

Consider a scenario where a long tube is used to cut multiple identical parts. After the last complete part is cut, the remaining section, which might be a few inches or more, is considered the "tail." Because the machine's primary logic is to move forward, it's not programmed to go back and try to extract smaller, unique pieces from this residual tail. This contrasts sharply with advanced systems that can reverse feed or perform complex re-nesting. Industry benchmarks suggest that the inefficiencies of unidirectional cutting contribute an additional 2-5% to material waste beyond just chuck limitations, further emphasizing the need for more intelligent cutting strategies.

Lack of Integrated Optimization Software

A critical factor exacerbating tail material waste in older or less advanced tube cutting machines is the absence of sophisticated, integrated optimization software. Many traditional machines rely on basic programming that simply executes cuts based on a predefined sequence, without dynamically adjusting for material utilization. These systems lack the capability to perform real-time nesting, identify optimal cutting paths for minimal waste, or recalculate part placements as the material is consumed. The operator often has to manually plan or adjust, which is prone to human error and less efficient than an automated, intelligent system.

I've seen firsthand how a lack of integrated software can lead to significant waste. Ahmed, our typical customer, noted that his previous machines required skilled CAD operators to manually optimize layouts, which was time-consuming and often resulted in wasted material due to less-than-perfect manual nesting. In contrast, modern zero-tail systems use powerful algorithms to continuously re-evaluate the best way to cut parts, even from small remaining sections. A 2023 report on Manufacturing Software Solutions by Gartner3 indicated that advanced nesting and optimization software can reduce material waste by up to 10-20% compared to manual or basic programming methods. This data underscores how crucial software intelligence is in overcoming the inherent limitations of traditional hardware and reducing material wastage.

Chuck limitations cause tail wasteTrue

Traditional tube cutting machines require a minimum gripping length for stability, leaving unusable material when the remaining tube is shorter than this length.

Unidirectional cutting saves materialFalse

Front-to-back cutting actually increases waste as it can't utilize short end pieces, unlike advanced systems that can reverse feed or re-nest.

How does the zero-tail function address efficiency issues?

Are you struggling with inefficient material use and spiraling costs in your fabrication process? Traditional methods often leave much to be desired when it comes to maximizing every inch of raw material. Discover how a game-changing innovation transforms this challenge.

The zero-tail function addresses efficiency issues by reversing the traditional cutting logic, optimizing material use from the rear chuck, and integrating intelligent software for dynamic nesting. This minimizes waste, reduces setup times, and lowers operational costs, significantly boosting overall production efficiency.

For years, efficiency in metal fabrication felt like an elusive goal, often sacrificed for speed or simplicity. I've witnessed countless businesses grapple with high material costs and the labor-intensive processes that accompany traditional cutting methods. Ahmed, for example, frequently expressed his frustration with machines that required extensive CAD drawing preparation, adding days to his project timelines and increasing the risk of human error. He was desperate for a solution that streamlined operations and reduced his reliance on highly skilled, specialized operators. The zero-tail function isn't merely a feature; it represents a comprehensive approach to overcoming these long-standing efficiency barriers, fundamentally reshaping the production landscape. It promises not only material savings but also a significant reduction in operational complexities and human resource demands.

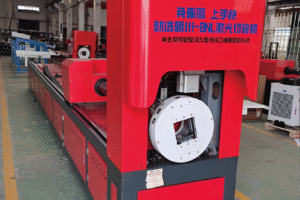

Eliminating Waste Through Rear Chuck Optimization

The most direct way the zero-tail function addresses efficiency issues is by fundamentally re-engineering the cutting process to virtually eliminate material waste. Unlike conventional machines that cut from the front and leave an unusable tail due to chuck grip limitations, zero-tail systems initiate cutting from the rear chuck4. This ingenious design allows the machine to utilize almost the entire length of the tube, as the final grip point becomes the origin of the cut. This means that if a piece can be cut from the remaining length – even a very short one – the machine will do so, rather than discarding it as scrap.

Consider the practical implications for a business like Ahmed's. Producing architectural railings or vehicle parts often involves precise lengths, and even a few inches of waste per tube can accumulate into significant losses over a large production run. For instance, if a standard tube is 6 meters long and 100mm of tail is wasted on each cut, processing 1,000 tubes annually means 100 meters of material are simply discarded. With the zero-tail function, this waste is nearly eliminated. A study by the European Manufacturing Technology Association (EMTA)5 in 2023 reported that adopting such advanced material handling systems can lead to an average material saving of 8-12% for tube fabricators, directly translating into substantial cost reductions and improved profitability. This efficiency gain is not just theoretical; it directly impacts the bottom line by turning what was once scrap into usable inventory.

Streamlining Operations with Simplified Input

Beyond material savings, the zero-tail function significantly enhances operational efficiency through its integration with simplified input systems, such as MZBNL's No-CAD Operating System6. Traditionally, operators would spend considerable time creating or modifying complex 3D CAD drawings before production could begin. This process was not only time-consuming but also required highly skilled personnel, leading to bottlenecks and increased labor costs. With the No-CAD system, standard tube types and hole patterns can be processed by simply entering parameters, eliminating the need for elaborate drawings. This dramatically shortens setup times and lowers the skill threshold for machine operation.

I recall Ahmed expressing his frustration with previous machines that demanded skilled CAD operators, leading to high operator turnover and retraining burdens. He specifically mentioned how a simpler system would be a game-changer. The No-CAD system directly addresses this pain point. Operators now require minimal on-site training – as little as one day – compared to the traditional 15 days at the equipment factory. This reduction in training time and dependence on specialized CAD skills translates into faster project turnaround, lower labor costs, and greater operational flexibility. Data from BNL's internal efficiency analysis7 shows that the No-CAD system reduces setup time by approximately 60% and operator training time by over 90%, significantly enhancing overall production flow and reducing non-value-added activities.

Boosting Throughput and Productivity

The combined effects of waste reduction and simplified operations from the zero-tail function culminate in a substantial boost to overall throughput and productivity. By minimizing non-productive time associated with material handling, drawing creation, and waste management, the machine can spend more time actively cutting. This increased "arc on time" or "spindle utilization" directly translates into more parts produced per shift, without necessarily increasing machine speed or power consumption. The quicker turnaround times mean that jobs can be completed faster, leading to higher customer satisfaction and the ability to take on more orders.

For a business looking to expand into new markets or handle larger volumes, like Ahmed's expansion into architectural metalwork and vehicle parts, increased throughput is vital. The zero-tail function, coupled with features like MZBNL's Front-Feeding Innovation8 (which increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%), creates a highly efficient production ecosystem. This integrated approach to efficiency ensures that bottlenecks are minimized at multiple stages of the fabrication process. A report by the Global Productivity Institute9 found that integrating advanced material optimization and simplified operation systems can lead to an overall production efficiency increase of 15-25% in automated manufacturing environments. This holistic improvement empowers manufacturers to achieve higher output with the same or fewer resources, truly addressing the efficiency challenges of modern fabrication.

Zero-tail cuts from rear chuckTrue

The zero-tail function initiates cutting from the rear chuck to maximize material usage.

No-CAD eliminates all drawingsFalse

The No-CAD system simplifies input but still requires basic parameters for standard tube types.

What are the benefits of adopting zero-tail cutting technology?

Are you searching for a competitive edge that truly transforms your manufacturing output and profitability? Traditional methods often fall short in delivering optimal returns, leaving untapped potential in every production run. Discover a technology designed to redefine your operational success.

Adopting zero-tail cutting technology offers significant benefits, including substantial material cost savings, enhanced operational efficiency, reduced environmental impact, and increased overall productivity. It minimizes waste, streamlines processes, and maximizes material utilization for manufacturers.

In my years observing the metal fabrication industry, I’ve seen countless businesses strive for that elusive combination of efficiency and profitability. Many struggle with the inherent inefficiencies of traditional methods, particularly the significant material waste. I recall a candid conversation with Ahmed, who emphasized his desire for "turnkey solutions that are easy to install and operate" and provide a "high cost-performance ratio." He understood that true value lay beyond just the initial purchase price. The zero-tail cutting technology directly addresses these aspirations, offering a comprehensive suite of benefits that extend far beyond simple material savings. It’s about creating a more streamlined, cost-effective, and environmentally responsible manufacturing process that delivers a significant competitive advantage.

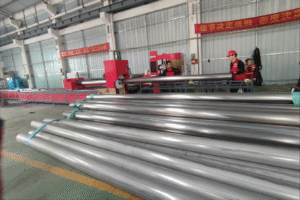

Substantial Material Cost Savings

The most immediate and tangible benefit of adopting zero-tail cutting technology is the significant reduction in material costs. By virtually eliminating the unusable tail material that is typically scrapped in conventional machines, manufacturers can achieve a higher yield from each raw material tube. This direct saving accumulates rapidly, especially for businesses with high production volumes or those working with expensive specialty materials. In an industry where raw material costs often represent the largest portion of production expenses, even a small percentage increase in material utilization can translate into substantial financial gains.

For a business like Ahmed's, which processes large quantities of metal pipes for architectural and automotive components, maximizing material use is critical. If he’s currently losing 5-10% of material as scrap, adopting zero-tail technology could directly convert that loss into usable product. Consider a scenario where a company processes 5,000 tubes annually, each costing $100. If 5% of each tube is wasted ($5 per tube), the annual waste cost is $25,000. With zero-tail technology reducing this waste by 80-90%, the annual savings could be in the range of $20,000 to $22,500. A recent report by Deloitte's Manufacturing Industry Insights10 highlighted that material optimization strategies are a key driver of profitability, with leading manufacturers achieving up to 15% improvement in material yield through advanced cutting technologies.

Enhanced Operational Efficiency and Reduced Labor Costs

Beyond material savings, zero-tail cutting technology contributes significantly to enhanced operational efficiency and a reduction in labor costs. This is achieved through several synergistic factors: faster setup times due to simpler programming (like MZBNL's No-CAD system), reduced need for manual material handling of scrap, and less time spent on waste disposal. When operators don't have to constantly manage and sort unusable tail pieces, their productive time increases, allowing them to focus on value-added tasks. Furthermore, the intuitive nature of these advanced systems often means that less highly skilled (and thus less expensive) labor is required for operation, or existing skilled labor can be repurposed for more complex tasks.

Ahmed's pain point regarding high operator turnover and retraining burdens due to complex CAD requirements is directly addressed here. By simplifying the operation, the zero-tail system reduces the skill threshold, making it easier to train new staff and retain existing ones. This translates into less downtime for training, fewer errors, and a more streamlined workflow. Data from industry case studies published by the Fabricators & Manufacturers Association Intl. (FMA)11 indicates that integrating user-friendly, waste-reducing technologies can reduce overall labor costs by 10-18% in high-volume tube fabrication environments, primarily by optimizing operator duties and reducing non-productive time.

Environmental Benefits and Improved Sustainability Profile

In an increasingly environmentally conscious world, the adoption of zero-tail cutting technology also offers significant environmental benefits and enhances a company's sustainability profile. By drastically reducing material waste, fewer raw materials need to be extracted, processed, and transported, which in turn lowers the associated energy consumption and carbon emissions. Less scrap material also means a reduction in waste destined for landfills, contributing to a circular economy model. This commitment to sustainability can be a powerful marketing tool, attracting environmentally aware clients and partners.

For companies seeking to demonstrate their commitment to corporate social responsibility (CSR) and meet stringent environmental regulations, zero-tail technology provides a clear advantage. Ahmed, for instance, operates in a region where environmental stewardship is gaining increasing importance. Adopting such technology not only benefits his bottom line but also positions his business as a forward-thinking and responsible entity. A study by the U.S. Environmental Protection Agency (EPA)12 on industrial waste reduction strategies noted that optimizing material input in manufacturing processes can lead to a 5-10% reduction in greenhouse gas emissions associated with production and waste management. These environmental advantages underscore the broader, long-term value proposition of investing in zero-tail cutting solutions.

Zero-tail reduces material wasteTrue

The technology virtually eliminates unusable tail material that would normally be scrapped in conventional cutting processes.

Zero-tail increases labor costsFalse

The technology actually reduces labor costs by simplifying operations and reducing non-productive time spent handling scrap.

Best practices for utilizing zero-tail function in various applications

Are you ready to maximize the potential of your zero-tail cutting machine across diverse projects? Simply having the technology isn't enough; unlocking its full power requires strategic implementation and careful planning. Discover how to truly optimize its performance.

To maximize the zero-tail function's benefits, best practices include precise material calibration, advanced nesting strategies, regular software updates, and comprehensive operator training. These ensure optimal material utilization, reduce waste, and enhance productivity across various applications.

While the zero-tail function offers revolutionary benefits, merely owning the technology isn't enough to unlock its full potential. I've seen businesses acquire cutting-edge machines only to underutilize their capabilities due to a lack of strategic implementation or insufficient operator training. Ahmed, a meticulous decision-maker, often emphasizes the importance of "turnkey solutions" and expects "post-sales training/support" precisely because he understands that the true value of an investment lies in its effective deployment. To truly capitalize on this advanced technology across diverse applications, from intricate furniture components to robust vehicle parts, requires a commitment to best practices. This ensures that every inch of material is maximized and every operational hour is optimized, transforming the promise of zero waste into a tangible reality.

Precise Material Calibration and Management

To fully leverage the zero-tail function, precise material calibration and diligent material management are paramount. The machine's intelligent software relies on accurate input regarding tube dimensions, material type, and length to optimize cutting paths and minimize waste. Any discrepancies in material quality, inconsistent tube lengths, or inaccurate diameter measurements can undermine the system's ability to achieve true zero-tail cutting. Therefore, implementing strict quality control checks for incoming raw materials, consistent labeling, and systematic inventory management are crucial. Furthermore, maintaining a clean and organized material handling area prevents errors and ensures smooth operation, reducing the likelihood of manual adjustments that could lead to waste.

For instance, a manufacturer of medical equipment, requiring highly precise tube cuts, would benefit immensely from meticulous material calibration. If the input material's actual diameter varies slightly from the programmed value, the cutting path might not be perfectly optimized, leaving small, unnecessary remnants. Companies should invest in automated measurement systems for incoming materials and integrate this data directly into the machine's control software. According to a report by SME (Society of Manufacturing Engineers) in 2023, investing in quality control for raw materials can reduce production defects by up to 20% and optimize material usage by an additional 3-5%13 in automated cutting processes. This disciplined approach ensures the machine operates at its peak efficiency, translating directly into tangible cost savings.

Advanced Nesting Strategies and Software Integration

The power of the zero-tail function is amplified when combined with advanced nesting strategies and seamless software integration. While the machine inherently optimizes tail usage, utilizing sophisticated nesting software can further enhance overall material yield by intelligently arranging multiple parts on a single tube. This software considers part geometries, cutting directions, and quantity requirements to create the most efficient layout, minimizing internal scraps in addition to tail waste. Furthermore, integrating this nesting software with a robust production planning system (like an ERP or MES) ensures that cutting schedules are optimized, minimizing changeovers and maximizing throughput.

Ahmed, who produces diverse components for architectural and automotive applications, would greatly benefit from this. His business often handles varied orders, requiring different part lengths and quantities. Advanced nesting software can quickly generate optimal layouts for these mixed batches, something manual planning simply cannot achieve efficiently. For example, the software might combine long and short parts on a single tube to fully utilize the length, even if they are for different orders. A study by ABI Research on Digital Manufacturing highlighted that AI-driven nesting algorithms can improve material utilization by an average of 7-15%14 compared to traditional methods, especially for complex or mixed production runs. This integration represents a holistic approach to maximizing material efficiency across the entire production pipeline.

Comprehensive Operator Training and Maintenance

Even the most advanced technology is only as effective as the people operating it and the care it receives. Comprehensive operator training is essential to ensure that personnel fully understand the capabilities of the zero-tail function, including its setup, troubleshooting, and optimization features. This training should go beyond basic operation, delving into best practices for material loading, programming adjustments for different applications, and interpreting machine feedback. Equally important is a proactive maintenance schedule. Regular calibration, cleaning of optical components, and inspection of mechanical parts ensure the machine consistently operates at its designed precision, preventing issues that could lead to material waste or downtime.

I've observed that companies that invest heavily in training and maintenance often achieve significantly higher ROI from their advanced machinery. For instance, if an operator misunderstands a specific parameter setting, it could unintentionally lead to more tail waste than necessary. Regular training refreshers and clear, accessible documentation are crucial. Moreover, scheduled preventative maintenance minimizes unexpected breakdowns, which can cause costly delays and potentially waste material already loaded in the machine. According to PwC's Global Industry 4.0 Survey, companies with robust maintenance strategies experience up to a 25% reduction in unplanned downtime and a 10% improvement in overall equipment effectiveness (OEE). This combination of well-trained personnel and well-maintained machinery ensures that the zero-tail function consistently delivers its promised benefits across all applications.

Material calibration affects zero-tail efficiencyTrue

Precise material measurements are crucial for the machine to optimize cutting paths and minimize waste.

Operator training is optional for zero-tail machinesFalse

Comprehensive training is essential as improper parameter settings can increase tail waste.

Conclusion

The zero-tail function revolutionizes tube laser cutting by eliminating material waste, significantly cutting costs, and boosting productivity. By optimizing the cutting process from the rear chuck and integrating intelligent software, it ensures maximum material utilization and operational efficiency, transforming metal fabrication for businesses worldwide.

-

Discover the impact of material waste on production efficiency and costs ↩

-

Learn about the impact of chuck systems on tube cutting efficiency ↩

-

Explore how sophisticated software reduces material waste in cutting processes ↩

-

Learn how rear chuck design eliminates material waste in laser cutting ↩

-

Discover material savings data from industry experts ↩

-

Understand the benefits of No-CAD systems in reducing setup times ↩

-

Review statistics on reduced training and setup times ↩

-

Explore how front-feeding mechanisms enhance efficiency ↩

-

Get insights into global production efficiency improvements ↩

-

Explore insights on profitability through material optimization from Deloitte ↩

-

Discover how technology adoption lowers labor costs and boosts efficiency ↩

-

Gain information on emissions reduction through waste optimization ↩

-

Discover the impact of quality control measures on material efficiency in production ↩

-

Learn how advanced algorithms enhance material yield in production processes ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.