Why a Tube Laser Cutter is a Smart Business Investment

Are production bottlenecks, material waste, and high labor costs slowing your growth? These challenges can erode profits and leave you behind the competition. Investing in a tube laser cutter is the solution.

A tube laser cutter is a smart business investment because it dramatically increases operational efficiency, minimizes material waste, and reduces the need for highly skilled labor. It streamlines production by consolidating multiple processes, directly boosting profitability and giving your manufacturing business a significant competitive advantage.

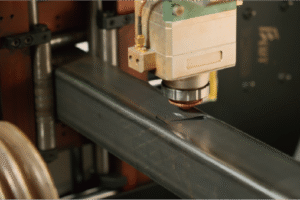

Machine Laser tube cutting machine processing a metal pipe with precision, emitting bright sparks during operation.](https://mzbnl.com/wp-content/uploads/2025/08/advanced-laser-tube-cutting-machine-5.webp)

This technology is more than just a piece of equipment; it's a strategic move toward a more agile and cost-effective future for your company. I've seen it transform businesses time and again. Let's dive deeper into why this investment makes so much sense for modern manufacturers.

What makes tube laser cutters an advantageous choice for businesses?

Are you still relying on traditional cutting, drilling, and punching methods? These slow, multi-step processes are prone to error and limit your design capabilities. A tube laser cutter offers a single, precise, and rapid solution.

Tube laser cutters are advantageous because they combine high-speed precision, incredible versatility with different materials and profiles, and advanced automation. This powerful combination streamlines production, eliminates human error, and allows for complex designs without adding operational complexity, making them a superior choice over conventional methods.

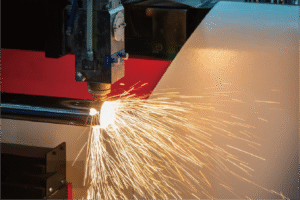

Close-up of a laser cutting machine precisely cutting metal sheet](https://mzbnl.com/wp-content/uploads/2025/08/precision-laser-cutting-machine.webp)

Let's break that down. When I talk to factory owners, their biggest frustrations often come from the limitations of older equipment. A traditional workflow might involve a saw for cutting to length, a drill press for holes, and a separate station for deburring. Each step introduces potential for error, requires material handling, and takes up valuable floor space and time. A tube laser cutter consolidates all of these operations into one seamless process. It can cut, perforate, and etch complex geometries on round, square, or custom-profile tubes in a single pass. This isn't just an incremental improvement; it's a fundamental change in how you approach production. It means you can take on more complex jobs, deliver higher quality parts, and do it all faster than your competitors. This advantage is crucial in industries from automotive parts to medical equipment, where precision and speed are paramount.

Why is laser cutting technology beneficial in modern manufacturing?

Modern manufacturing demands agility and responsiveness. Sticking with old, rigid processes means you can't adapt to changing customer needs or market demands. Laser technology provides the core flexibility required to thrive today.

Laser cutting is beneficial for modern manufacturing because it's a non-contact process that eliminates tool wear and reduces material distortion. It offers unmatched accuracy and repeatability for complex parts, enabling rapid prototyping, on-demand production, and a superior finish that aligns perfectly with lean manufacturing principles.

In my experience visiting over a thousand factories, I see a clear divide between those who are struggling and those who are leading. The leaders embrace principles of modern, lean manufacturing, and laser technology is often at the heart of their success. Because it’s a non-contact process, you don't have to worry about tool wear, replacement costs, or the downtime associated with changing blades or punches. This alone saves significant time and money. Furthermore, the precision of the laser beam allows for incredibly tight nesting of parts, which drastically reduces scrap material. This aligns perfectly with the lean goal of waste elimination. The technology is also digitally driven, meaning you can go from a design file to a finished part in minutes. This agility is a game-changer for rapid prototyping and fulfilling custom, low-volume orders profitably, which is something traditional methods simply can't handle efficiently.

What are the common challenges in manufacturing that tube laser cutters address?

Are you constantly battling skilled labor shortages, high material costs from waste, and production delays? These common challenges can feel insurmountable. A modern tube laser cutter is designed to solve these exact problems.

Tube laser cutters directly solve critical manufacturing challenges like high material waste from offcuts, the dependency on highly skilled operators for complex setups, and production bottlenecks caused by multiple, separate processing steps. They achieve this by optimizing material usage, simplifying machine operation, and consolidating processes.

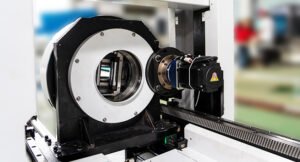

Close-up of high-tech laser cutting machine processing metal tube with precision](https://mzbnl.com/wp-content/uploads/2025/08/innovative-laser-tube-cutting-machine-1.webp)

At MZBNL, we've focused our R&D on solving these core industry pain points. I remember talking to a client who was turning down jobs because he couldn't find enough experienced machine operators. This is a story I hear all the time. Here’s how we address these issues head-on:

The Skilled Labor Gap

Finding and retaining operators who can read complex CAD drawings and perform intricate machine setups is a huge challenge. Our solution is the No-CAD System. We designed it so that for standard tubes, an operator can simply input parameters like length and hole position. The machine does the rest. This innovation reduces the required training time from a typical 15 days down to just one day.

Inefficient and Laborious Processes

Manually loading heavy tubes and managing a multi-machine workflow is slow and physically demanding. Our Front-Feeding Innovation automates the loading process, improving feeding efficiency and reducing the operator's labor intensity by about 40%. This frees up your team to focus on more valuable tasks.

Profit-Killing Material Waste

Every inch of scrap tube is money thrown away. The "tail material"—the last unusable piece of the tube—is a major source of waste. We engineered our Zero-Waste Tail Material Innovation, which uses a unique chucking and calculation logic to ensure the entire tube is usable. This feature alone can save businesses thousands of dollars annually.

How can investing in a tube laser cutter enhance operational efficiency?

Is your workshop floor a maze of different machines for different tasks? This disjointed workflow is a hidden killer of efficiency and profit. Imagine consolidating all those steps into one streamlined, automated process.

A tube laser cutter enhances operational efficiency by consolidating multiple processes—sawing, drilling, punching, and deburring—into a single automated step. This drastically reduces material handling, minimizes setup times, increases throughput, and allows for continuous operation, fundamentally boosting productivity and output.

The impact on operational efficiency is profound. Let's picture a typical "before" scenario for a company making display racks. A long tube is moved to a saw, cut to length, then moved to a drill press for holes, and finally to a deburring station to clean up the edges. That's at least three separate operations, three machine setups, and three instances of material handling. Now, picture the "after" scenario with an MZBNL laser tube cutter. A full bundle of raw tubes is loaded into the automatic feeder. The operator selects the program, and the machine takes over. It feeds, measures, cuts, drills, and etches each part to perfection before neatly ejecting the finished component. The process is consolidated, automated, and continuous. This transformation from a multi-step, labor-intensive workflow to a single, streamlined operation is where our 4,000+ global clients see the biggest gains. They're not just cutting tubes faster; they're fundamentally changing their production capacity.

What are the best practices for maximizing the ROI of a tube laser cutter investment?

Buying a powerful new machine is a significant investment. How do you ensure it pays for itself as quickly as possible? Without the right strategy, even the best technology can fall short of its potential.

To maximize the ROI on a tube laser cutter, you must first choose a machine with innovations that solve your specific pain points, like waste reduction. Second, ensure operators are properly trained to leverage all its capabilities. Finally, integrate the machine into a lean workflow to eliminate surrounding bottlenecks.

High-tech laser cutting machine slicing metal tube with precision sparks](https://mzbnl.com/wp-content/uploads/2025/08/advanced-laser-cutting-machine-6.webp)

Getting a great return on your investment goes beyond the initial purchase. It requires a holistic approach. First, don't just buy a machine; buy a targeted solution. If material cost is your biggest issue, prioritize a machine with features like our Zero-Waste Tail Material Innovation. If labor is your challenge, our No-CAD System offers a direct and immediate return. Second, invest in your people. While our system is easy to learn, empowering your team to understand the machine's full potential for nesting parts and optimizing cutting paths will unlock even greater efficiency. Third, look beyond the machine itself. A laser cutter is incredibly fast, and it will quickly highlight bottlenecks elsewhere in your process. You must analyze your entire workflow, from how raw material is delivered to how finished parts are moved to the next stage, to ensure you're not just moving the bottleneck. We see our role as a partner in this process, helping clients optimize their entire operation for maximum productivity and profitability.

Conclusion

Investing in a tube laser cutter is not just an equipment upgrade; it's a strategic business decision. It directly addresses the core manufacturing challenges of material waste, labor shortages, and operational inefficiency. By consolidating processes and embracing automation, you can unlock new levels of productivity and profitability.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.