Tube and Pipe Laser Cutting Machine: What's the Difference?

Confused about which laser cutter you need? The wrong choice costs time, money, and materials. Making the right one boosts your entire production line.

The key difference is specialization: tube laser cutters are built for complex geometric shapes used in industries like furniture, while pipe laser cutters are optimized for high-speed, high-precision cutting of simpler profiles for sectors like automotive parts.

As the General Manager of MZBNL, I've spoken with thousands of factory owners over the last decade. A common point of confusion is the distinction between a "tube" and a "pipe" laser cutter. They seem similar, but their impact on your bottom line is vastly different. Let's break down exactly what you need to know to make a smart investment for your business.

What are the fundamental differences between tube and pipe laser cutting machine?

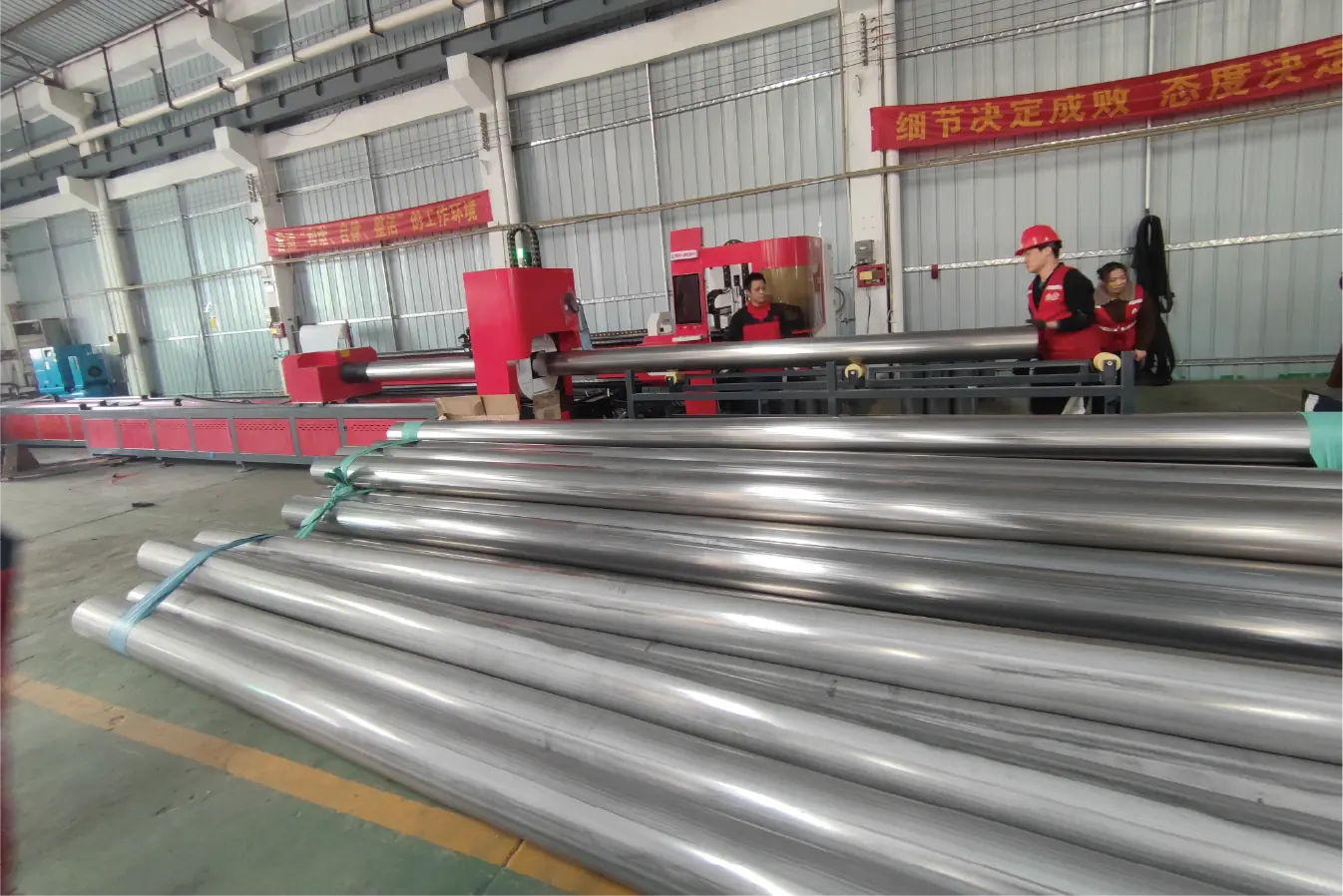

They might look alike on the factory floor. But their internal design and software tell a completely different story, impacting everything from setup to final product quality.

Fundamentally, tube cutters are designed for versatility to handle complex profiles and diverse materials. Pipe cutters are engineered for speed and consistency on standardized, often round, profiles, prioritizing throughput and precision.

To really understand the difference, we need to dive deeper into how these machines are built and what they are designed to accomplish. It's not just about the name; it's about the core engineering philosophy that drives their performance and, ultimately, your production efficiency.

Chuck Design and Material Handling

The most significant mechanical difference lies in the chucking and material support systems. A tube laser cutter, like the ones we build for furniture manufacturers, needs a highly adaptable chuck. It must securely grip square, rectangular, oval, and other custom-shaped tubes without deforming them. This flexibility is crucial for creating the intricate joints and angles required in modern design. In contrast, a pipe cutting machine is a specialist. Its chuck is optimized to clamp round pipes with immense force and rotate them at very high speeds for fast, clean cuts, which is essential for industries like automotive parts where thousands of identical components are needed daily.

Software and Control Systems

The brain of the machine—the software—is where the differences become even more apparent. Tube cutting software is all about managing complex geometries. It has to calculate intricate cutting paths for interlocking parts and unique designs. This is a big reason why operator training has historically been a major pain point for businesses. At MZBNL, we tackled this head-on. We developed a No-CAD system[^1] that simplifies this entire process. It allows operators to become proficient in a single day, not weeks. Pipe cutting software, on the other hand, is built for efficiency. It focuses on nesting parts[^2] tightly on a single length of pipe to minimize waste and programming the fastest possible cutting path for simple, repeatable jobs.

How do the applications of tube and pipe laser cutting machines vary across industries?

You have a specific product to make. Using a machine designed for a different application leads to inefficiency, material waste, and lower quality, hurting your competitiveness.

Tube cutters dominate industries where design and aesthetics are key, like metal furniture, fitness equipment, and architectural decoration. Pipe cutters are the workhorses in sectors demanding structural integrity and precision, such as automotive, medical equipment, and industrial pipelines.

The best way to see the difference is to look at the final products. I remember visiting a client who manufactured high-end office furniture. They were struggling with manual cutting and welding for complex joints, which was slow and inconsistent. By investing in one of our tube laser cutters, they were able to automate this process, improve quality, and launch new, more creative designs. Their problem was a perfect match for the machine's capability. This is why understanding the application is the most important step.

Here’s a simple breakdown of where each machine excels:

| Machine Type | Key Industries | Common Products | Core Requirement |

|---|---|---|---|

| Tube Laser Cutter | Metal Furniture, Fitness Equipment, Architectural Decor | Chair frames, gym machines, custom railings, display racks | Geometric Complexity |

| Pipe Laser Cutter | Automotive, Medical Devices, Oil & Gas, Construction | Exhaust systems, surgical tools, pipeline components, scaffolding | Precision & Consistency |

As you can see, if your business relies on creating products with unique shapes and varied designs, a tube cutter provides the necessary flexibility. But if your success depends on producing thousands of structurally sound, identical parts with tight tolerances, a pipe cutter is the clear choice.

What factors should you consider when choosing between a tube and pipe laser cutting machine?

Making a capital equipment investment is a big decision. A poor choice can become a bottleneck for years, while the right one can unlock new levels of growth.

Your decision should be based on three core factors: the complexity of your material profiles, your required production volume, and the skill level of your workforce. Answering these questions honestly will point you to the right machine.

Before any of our clients sign a purchase order, I ask them to walk me through their daily operations. We don't just sell machines; we provide production solutions. The goal is to find the perfect fit for their specific needs, and that always starts with a clear-eyed assessment of their current and future production demands.

Here are the key factors to evaluate:

- 1. Material Profile & Complexity: Look at your product drawings. Are you cutting primarily round pipes for simple connections, or are you working with square, rectangular, and L-shaped tubes to create complex, multi-part assemblies? The more varied and complex your shapes, the more you need a tube laser cutter.

- 2. Production Volume & Speed: Do you run high-volume, low-mix production, making thousands of the same part? Or are you a high-mix, low-volume shop that needs to switch between different jobs quickly? Pipe cutters are built for the former, excelling at high-speed, automated runs. Tube cutters offer the flexibility needed for the latter.

- 3. Operator Skill & Training Costs: This is a huge, often overlooked, cost. Complex machines traditionally require highly skilled, highly paid operators. This is a major pain point we hear about constantly. It’s why we engineered our MZBNL machines with a No-CAD system. We've proven that we can reduce operator training time from several weeks down to a single day. This drastically lowers operational costs and makes our clients more agile.

How do machine specifications impact the performance of tube versus pipe cutting?

A spec sheet can be overwhelming. Focusing on the wrong metrics can lead you to buy a machine that is either underpowered or over-engineered for your actual needs.

For tube cutting, prioritize chuck versatility and advanced software features for complex paths. For pipe cutting, focus on raw laser power for material thickness, maximum cutting speed (m/min), and automation features like automatic loading for high throughput.

Let's cut through the noise and focus on the numbers that translate directly to performance on your factory floor. While there are dozens of specifications, only a few are critical for this specific decision.

Laser Power and Cutting Speed

Laser power, measured in kilowatts (kW), determines the thickness of the metal you can cut and how fast you can cut it. For a factory producing thick-walled structural pipes, higher power (e.g., 3kW or 6kW) is essential to maintain high production speeds. For a business cutting thinner tubes for decorative items, a lower power source (e.g., 1.5kW) might be more than sufficient and more cost-effective.

Automation and Material Handling

For a pipe cutting operation in the automotive sector, every second counts. An automatic bundle loader[^3] that can feed material into the machine without manual intervention is not a luxury; it's a necessity for competitive production. It allows for "lights-out" operation and maximizes throughput. For a custom fabrication shop using a tube cutter, where jobs change frequently, a simpler, semi-automatic loading system is often more practical and economical.

What are my expert recommendations for selecting the right laser cutting machine?

You've done the research, but now you need to make the final call. The pressure is on to make an investment that will pay dividends for years to come.

My recommendation is straightforward: match the machine's primary strength to your main product line. If your business is built on design flexibility and custom shapes, get a tube cutter. If it's built on speed and consistency for simple profiles, get a pipe cutter.

After more than a decade in this industry and helping over 4,000 clients, I've learned that the most successful investments happen when a company is honest about its core business. Don't buy a machine for the 5% of jobs you might do one day; buy it for the 95% of jobs you do every day.

Here is my simple decision framework:

-

Choose a Tube Laser Cutter if:

- Your products require complex joints, miters, and copes.

- You work with a variety of profiles (square, rectangular, oval).

- Your business model is based on custom fabrication or frequent design changes.

- Industries: Furniture, Fitness Equipment, Architecture, Retail Displays.

-

Choose a Pipe Laser Cutter if:

- Your products are primarily made from round pipe.

- Your top priorities are high speed and repeatable accuracy.

- You are running high-volume production of identical or similar parts.

- Industries: Automotive, Aerospace, Medical, Industrial Equipment.

And once you've chosen the machine type, consider the human element. How quickly can your team become productive on this new equipment? A machine is only as good as the operator running it. That's why at MZBNL, we focus on making advanced technology simple to use. Our No-CAD system is our commitment to ensuring our clients see a return on their investment from day one.

Conclusion

The choice between a tube and pipe laser cutter is not about which is "better," but which is right for your specific application. Understanding this distinction saves you from a costly mistake and positions your company to maximize productivity, reduce waste, and improve profitability.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.