How Smart Systems Power Today’s Tube Laser Cutting Machines

I've witnessed the struggles many metal fabrication businesses face with traditional tube cutting processes – the complexity of CAD, the material waste, and the constant need for highly skilled operators. These inefficiencies can severely impact your bottom line and project timelines. But what if there was a way to overcome these hurdles, transforming your operations into a model of precision and efficiency? Smart systems in tube laser cutting machines1 are precisely that solution, turning common pain points into competitive advantages.

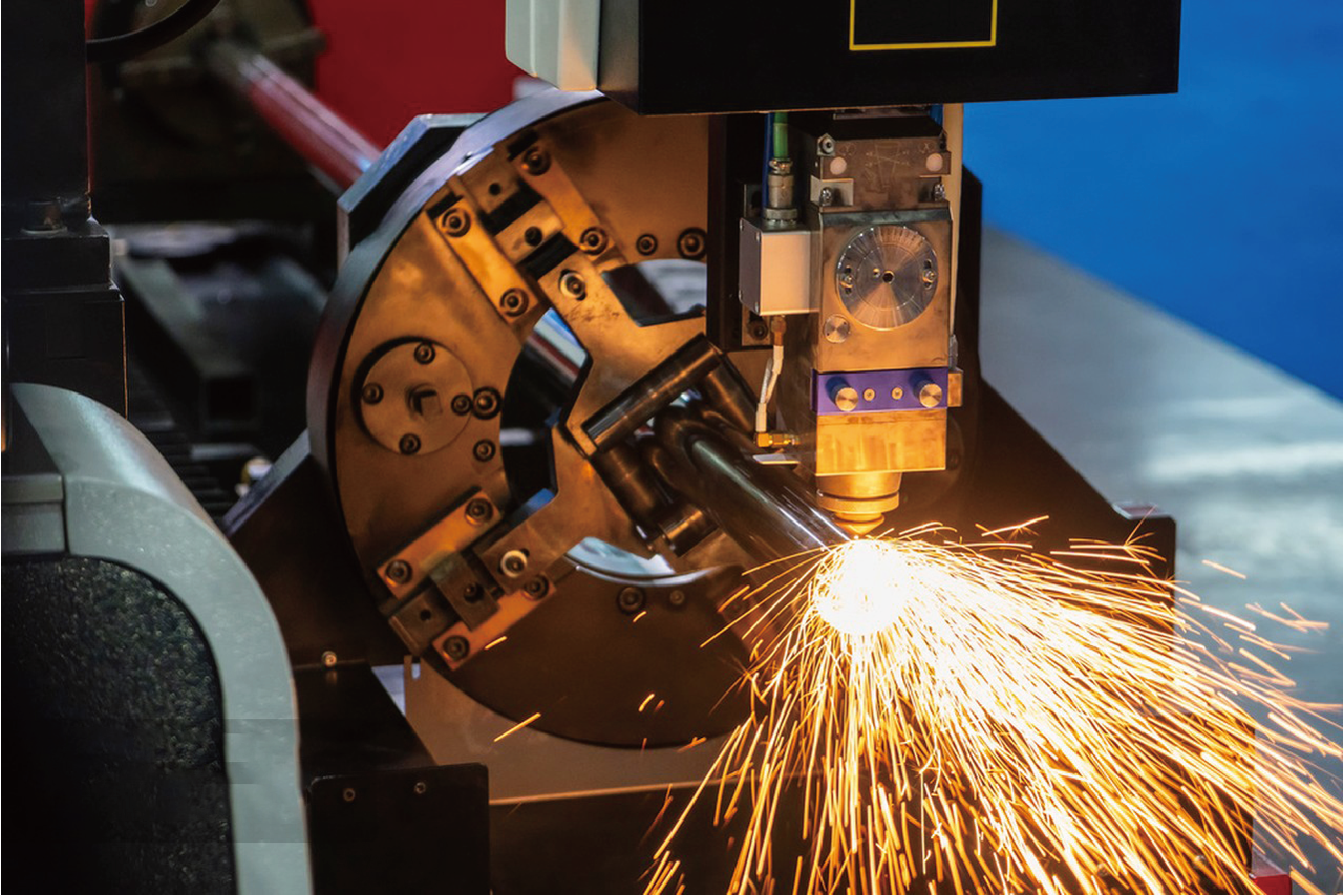

Smart systems leverage advanced software, sensors, and automation to optimize every stage of tube laser cutting. By integrating real-time data analysis, predictive maintenance, and user-friendly interfaces, they drastically enhance precision, reduce material waste, and streamline workflows, making machines easier to operate and significantly boosting overall productivity in modern fabrication.

In a world where speed, precision, and cost-efficiency dictate success, the evolution of tube laser cutting machines2 has been nothing short of revolutionary. I’ve personally seen how the integration of intelligent technologies is not just an upgrade, but a fundamental shift in how we approach metal fabrication. This transformation is about more than just cutting; it's about creating a seamless, intuitive, and highly productive manufacturing environment that empowers businesses to achieve unprecedented levels of operational excellence.

For years, I've dedicated my work to pushing the boundaries of what’s possible in metal fabrication, and I can tell you that the advent of smart systems marks a pivotal moment. These systems don't just automate tasks; they learn, adapt, and optimize, fundamentally changing the operator's role from a manual laborer to a strategic manager. They empower us to tackle increasingly complex designs, minimize human error, and achieve a level of consistency previously unattainable. As we delve deeper, I'll share insights from my own experiences and how we at MZBNL have integrated these very innovations to solve real-world challenges for clients worldwide.

What technological advancements led to the integration of smart systems in laser cutting?

The journey from basic laser cutting to sophisticated smart systems has been driven by an insatiable demand for efficiency and precision in manufacturing. I recall early systems that were remarkable for their time but paled in comparison to today's capabilities. Operators faced steep learning curves and significant setup times. This constant pressure for faster, more accurate, and more accessible technology fueled a wave of innovation.

The integration of smart systems in laser cutting was propelled by advancements in several key areas: artificial intelligence, machine learning, enhanced sensor technology, real-time data processing, and intuitive human-machine interfaces. These innovations collectively enabled machines to automate complex tasks, optimize processes, and become significantly more user-friendly, pushing beyond simple automation to genuine intelligence.

The push for smarter systems stems from a continuous quest for perfection in manufacturing. From my perspective, working within this industry for over two decades, I’ve seen how traditional methods, while foundational, often introduced bottlenecks. We constantly searched for ways to reduce human intervention errors, speed up production cycles, and make highly complex processes accessible to a broader range of operators. The advent of faster processors, more sensitive sensors, and powerful algorithms began to make "smart" not just a concept, but a tangible reality for laser cutting technology.

1.1 The Maturation of Automation and Control Systems

The initial step towards smart systems was the refinement of automation and control. Early laser cutting machines relied on rudimentary numerical control (NC) systems, which were essentially programmable logic controllers (PLCs) that executed predefined G-code instructions. While revolutionary at the time, these systems lacked the flexibility and adaptability required for complex, on-the-fly adjustments. The breakthrough came with the integration of advanced computer numerical control systems3, offering multi-axis control, interpolation capabilities, and dynamic error compensation. This allowed for more intricate cuts and improved accuracy. My team at MZBNL focused heavily on enhancing these core control systems, laying the groundwork for more intelligent operations. We understood that robust, precise control was the bedrock upon which any smart system would be built, ensuring that even the most innovative software could be reliably executed on the hardware.

The evolution didn't stop there. As microprocessors became more powerful and affordable, it became feasible to embed complex algorithms directly into the machine's control unit, enabling real-time feedback loops. This meant that the machine could not only execute instructions but also react to changing conditions during the cutting process. For instance, temperature fluctuations, material inconsistencies, or even minor machine wear could be detected and compensated for automatically, preventing costly errors and ensuring consistent quality. This marked a significant leap from simple automation to a more responsive, semi-intelligent system, paving the way for truly adaptive manufacturing. We've seen first-hand how this responsiveness translates into tangible benefits for our clients, reducing rework and improving overall output quality.

Furthermore, the development of sophisticated motion control algorithms allowed for extremely precise manipulation of the laser head and workpiece. Technologies like direct drive motors and high-resolution encoders provided unprecedented accuracy and repeatability. This precision is critical for tube cutting, where complex contours and intricate patterns are common. Imagine cutting a series of holes in a tube that need to align perfectly for a subsequent assembly – without advanced motion control, such precision would be incredibly difficult to achieve consistently. These advancements in mechanical and electrical control systems created the necessary hardware foundation for the complex software layers that define modern smart laser cutters.

1.2 Data Sensing and Analysis Capabilities

The ability to gather and interpret data is the hallmark of any smart system. Early laser cutting machines provided minimal feedback, often requiring manual inspection to detect issues. However, the proliferation of advanced sensors revolutionized this. High-resolution cameras, proximity sensors, temperature sensors, and pressure sensors began to be integrated directly into the machine's framework, providing a constant stream of operational data. This data includes everything from real-time cutting parameters like power output and gas flow to material properties and machine status. This wealth of information is no longer just for diagnostics; it's actively used to optimize the cutting process.

I've seen how critical this data is. Consider a client like Ahmed Al-Farsi, who prioritizes consistent quality for architectural metalwork. For him, every cut needs to be perfect. By continuously monitoring cutting parameters, the machine can automatically adjust settings to maintain optimal performance, even if there are slight variations in the material or ambient conditions. This predictive capability significantly reduces defects and material waste. Moreover, the data collected over time provides valuable insights into machine performance, enabling predictive maintenance schedules and minimizing costly downtime. This shift from reactive problem-solving to proactive optimization is a key enabler of smart systems.

Beyond real-time process control, this data also feeds into larger analytical systems. Machine learning algorithms can analyze historical cutting data to identify patterns, predict potential failures, and even suggest optimal cutting strategies for new materials or designs. This allows for continuous improvement and refinement of the cutting process, moving beyond human intuition to data-driven decision-making. For us at MZBNL, this capability has been instrumental in developing features like our "Zero-Waste Tail Material Innovation," where the machine intelligently calculates cutting paths to maximize material utilization based on real-time tube length and product requirements. This level of data integration transforms a cutting machine into an intelligent, self-optimizing manufacturing unit.

1.3 The Rise of Intuitive Software and Connectivity

Perhaps one of the most impactful advancements leading to smart systems is the development of user-friendly software interfaces4 and robust connectivity options. Historically, operating laser cutting machines required extensive training in complex CAD/CAM software. This was a significant barrier to entry and a pain point for businesses like Ahmed's, who often faced high operator turnover and retraining burdens. The innovation of intuitive, graphics-based interfaces has dramatically simplified operation, reducing the skill threshold required. For example, MZBNL's "No-CAD Operating System Innovation" directly addresses this, allowing operators to process standard tube types and hole patterns by simply entering parameters, eliminating the need for complex 3D drawings. I've seen operators with just one day of training become proficient with our system, a stark contrast to the 15 days previously required.

Furthermore, the rise of the Industrial Internet of Things (IIoT) has enabled seamless connectivity between machines, production lines, and enterprise resource planning (ERP) systems. This connectivity allows for real-time monitoring of production status, remote diagnostics, and over-the-air software updates. Businesses can monitor machine performance from anywhere, identify potential issues before they cause downtime, and integrate their cutting operations directly into their broader manufacturing ecosystem. This interconnectedness fosters a truly smart factory environment where data flows freely, enabling comprehensive control and optimization across the entire production chain.

This integration extends to customer support and maintenance. Remote diagnostics, a feature many clients now expect, allows our engineers to troubleshoot issues from afar, reducing response times and minimizing on-site service calls. This level of connectivity not only enhances operational efficiency but also strengthens the partnership between the manufacturer and the client, ensuring continuous support and performance optimization. The combination of easy-to-use software and pervasive connectivity has democratized access to advanced laser cutting technology, making it a viable and attractive solution for a wider range of businesses.

Smart systems reduce material wasteTrue

Smart systems optimize cutting paths and material usage through real-time data analysis, significantly reducing waste compared to traditional methods.

Smart systems eliminate the need for operatorsFalse

While smart systems automate many tasks, they still require skilled operators to oversee processes and make strategic decisions.

What is the current state of smart systems in tube laser cutting machines?

The current landscape of tube laser cutting is vastly different from even a decade ago. I remember conversations where "automation" was the buzzword, but now we're talking about true "intelligence" and "autonomy." The industry has moved beyond simply making machines faster to making them smarter, more self-aware, and ultimately, more productive. This evolution is redefining what’s possible for metal fabricators globally.

Currently, smart systems in tube laser cutting machines integrate AI-driven automation, advanced sensor technology for real-time process monitoring, predictive maintenance capabilities, and highly intuitive, often CAD-free, operating interfaces. These systems offer significant improvements in operational efficiency, material utilization, and precision, establishing a new benchmark for productivity and ease of use in metal fabrication.

Having spent 25 years in this industry, I've seen the progression from manually intensive operations to highly automated processes5. Today, the focus isn't just on automation but on creating a truly intelligent manufacturing environment. This means machines that can not only execute commands with unparalleled precision but also learn from data, predict potential issues, and even optimize their own processes. It’s a leap towards true lights-out manufacturing for certain applications, freeing up human operators for more strategic and complex tasks. We at MZBNL have been at the forefront of this shift, integrating proprietary smart features that address long-standing industry pain points.

2.1 Autonomous Operation and AI Integration

The most striking aspect of current smart systems is their growing autonomy, largely driven by artificial intelligence and machine learning. Modern tube laser cutting machines can perform complex tasks with minimal human intervention, from automatic material loading and unloading to intelligent nesting and cutting path optimization. For instance, our "Front-Feeding Innovation6" at MZBNL dramatically increases feeding efficiency and reduces operator labor intensity by automating the tube feeding process. This isn't just about faster movement; it's about the machine intelligently sensing the tube, positioning it, and initiating the cut without manual alignment. This level of automation significantly boosts throughput, allowing businesses like Ahmed Al-Farsi's to expand production capacity without proportionally increasing labor costs.

Furthermore, AI algorithms are now routinely employed for optimizing cutting parameters. These algorithms can analyze material type, thickness, and even real-time feedback from sensors to dynamically adjust laser power, cutting speed, and gas pressure for optimal results. This minimizes defects, reduces material waste, and extends consumable life. I’ve personally seen how this leads to superior edge quality and dimensional accuracy, critical for high-end applications like architectural metalwork. Beyond optimization, AI is also being used for quality control, where machine vision systems can inspect cut parts for flaws, ensuring every component meets stringent quality standards before it leaves the machine. This proactive quality assurance is a game-changer for consistency.

The predictive capabilities of AI also extend to maintenance. By continuously monitoring machine performance data—such as motor vibrations, temperature fluctuations, and laser source output—AI models can predict potential equipment failures before they occur. This enables manufacturers to schedule maintenance proactively, minimizing unplanned downtime and maximizing machine uptime. This is a crucial advantage for busy production environments where every minute of downtime translates into lost revenue. The ability to predict and prevent issues rather than react to them is a hallmark of truly smart manufacturing.

2.2 User-Centric Design and No-CAD Systems

A defining characteristic of the current generation of smart systems is their emphasis on user-friendliness, a direct response to the industry's need for simplified operations. The traditional reliance on highly skilled CAD operators has been a significant barrier, leading to increased training costs and potential production bottlenecks. This is precisely why MZBNL pioneered and perfected our "No-CAD Operating System7." This innovation allows operators to process standard tube types and hole patterns by simply entering parameters, completely eliminating the need for complex 3D drawings. I’ve personally observed how this reduces the skill threshold for machine operation, allowing new operators to become proficient in just one day of on-site training, as opposed to the typical 15 days spent at the equipment factory.

This shift towards intuitive interfaces is not just about making machines easier to use; it's about democratizing access to advanced manufacturing technology. Operators can now focus on optimizing production flows rather than wrestling with complex software. Graphical interfaces, touchscreens, and pre-programmed libraries for common geometries significantly streamline the setup process. This ease of use translates directly into faster project turnaround times and reduced operational costs. For a business owner like Ahmed Al-Farsi, who values turnkey solutions and ease of installation, such systems are incredibly appealing because they mitigate the common pain points of skilled labor shortages and high retraining burdens.

Beyond individual machine operation, smart systems are also integrating with broader factory management systems. This allows for seamless data exchange between design, production scheduling, and inventory management. An operator can, for example, receive job orders directly from the ERP system, load the material, and initiate cutting with minimal manual input. This level of integration streamlines the entire workflow, enhancing overall factory efficiency and responsiveness. It’s a future where machines aren't just tools but intelligent participants in a larger, interconnected manufacturing ecosystem.

2.3 Resource Optimization and Sustainability

Modern smart systems are fundamentally changing how manufacturers approach resource utilization, moving towards a more sustainable and cost-effective production model. One of the most impactful innovations in this area is intelligent material nesting and waste reduction. Traditional laser cutting systems often generate unusable tail material at the end of the process. At MZBNL, we addressed this with our "Zero-Waste Tail Material Innovation8," which redesigned the cutting logic to calculate from the rear chuck as the origin. This allows the system to eliminate leftover tail material as long as the remaining section is smaller than the product length, significantly maximizing material utilization and boosting cutting efficiency. I’ve seen this feature alone save clients substantial costs on raw materials, directly impacting their bottom line.

| Traditional System | Smart System (MZBNL Example) |

|---|---|

| Manual CAD/CAM setup | No-CAD parameter input |

| Side/rear manual loading | Optimized Front-Feeding |

| Significant tail waste | Zero-Waste Tail Material |

| High operator skill needed | Low skill threshold |

| Reactive maintenance | Predictive maintenance |

| Isolated operation | Integrated, connected system |

Beyond material savings, smart systems also optimize energy consumption. By precisely controlling laser power, gas usage, and cooling, these machines can operate with remarkable energy efficiency. They can also enter intelligent standby modes during idle periods, further reducing power consumption. This focus on resource efficiency not only cuts operational costs but also aligns with global sustainability goals, appealing to environmentally conscious businesses and markets. For instance, our machines are designed to deliver high precision with optimized energy use, reflecting our commitment to both performance and ecological responsibility.

Furthermore, smart systems contribute to a healthier work environment by automating hazardous tasks and reducing manual handling. This enhances worker safety and ergonomics, addressing concerns that some of our clients, like Ahmed, might have about workplace intensity. The overall impact of these smart features is a more streamlined, economical, and environmentally responsible manufacturing process that is well-suited to the demands of modern industry. It's about achieving peak performance without compromising on sustainability or safety.

AI optimizes cutting parametersTrue

Modern systems use AI to dynamically adjust laser power and speed based on material feedback.

No-CAD systems require complex drawingsFalse

Advanced systems allow parameter input without CAD files, simplifying operations significantly.

What challenges do conventional tube cutting systems face without smart technologies?

Before the advent of smart systems, tube cutting presented a distinct set of challenges that impacted efficiency, cost, and overall productivity. I frequently encountered businesses struggling with these issues, feeling stuck in a cycle of manual intervention and wasted resources. These problems weren't minor inconveniences; they were fundamental roadblocks to growth and profitability.

Conventional tube cutting systems without smart technologies face significant challenges including high reliance on skilled CAD operators, inefficient material utilization leading to excessive waste, prolonged setup and changeover times, and a lack of real-time operational insights. These limitations result in higher operating costs, reduced throughput, and frequent production bottlenecks, hindering overall competitiveness in modern manufacturing.

My personal journey in metal fabrication, spanning over two decades, has allowed me to see the evolution of challenges as much as the solutions. Early in my career, the frustrations associated with traditional tube cutting were palpable on shop floors. The issues weren't just about slower speeds; they were about a fundamental lack of agility and responsiveness, leading to a host of cascading problems that impacted everything from material inventory to final product delivery. Without the intelligent integration we see today, businesses were often operating with significant blind spots.

3.1 High Skill Dependency and Training Burdens

One of the most significant challenges for conventional tube cutting systems is their heavy reliance on highly skilled operators, particularly those proficient in CAD/CAM software9. I’ve seen countless times how this creates a bottleneck. Creating or modifying complex 3D drawings for tube parts is not trivial; it requires specialized training and considerable experience. If a design needs a minor tweak or a new prototype is required, the operator often has to return to the design office, leading to delays and breaking the production flow. This dependence on expert knowledge translates directly into higher labor costs and significant retraining burdens for businesses, especially in regions with high operator turnover.

Consider the scenario for a client like Ahmed Al-Farsi. He's looking to automate existing manual workflows and values turnkey solutions that are easy to install and operate. His pain point regarding "previous machines required skilled CAD operators" and "high operator turnover caused retraining burdens" perfectly illustrates this challenge. Without smart systems, every job change or new design means re-engaging a highly paid specialist, which slows down production and impacts project delivery. This isn’t just about the initial investment in training; it's about the ongoing operational expense and vulnerability to skilled labor shortages.

Moreover, the complexity of these traditional systems means that even minor errors in programming can lead to significant material waste or machine downtime. Human error, though unintentional, is an inherent risk when tasks are complex and manual. The learning curve is steep, and achieving mastery takes years, not days. This means that a business's productivity is directly tied to the availability and proficiency of a limited pool of highly specialized individuals, making the entire operation less resilient and adaptable to market demands.

3.2 Inefficient Material Utilization and Waste Generation

Conventional tube cutting systems often struggle with efficient material utilization, leading to substantial waste and increased operational costs. The fundamental problem lies in their cutting logic and loading mechanisms. Many traditional machines cut from the tube head, inevitably leaving an unusable "tail material" at the end of each process. This tail, while small per piece, accumulates rapidly over thousands of cuts, becoming a significant financial drain. I've heard countless stories from fabricators about their scrap bins overflowing with these perfectly good but unutilizable remnants. This waste directly impacts profitability, especially when dealing with expensive raw materials.

Furthermore, without intelligent nesting capabilities10, operators often resort to simpler, less efficient cutting layouts, even for batch production. This is often due to the limitations of older software or the sheer complexity of manually optimizing nested patterns for various tube lengths and geometries. The result is more offcuts and unusable sections than necessary, further contributing to material waste. For a business that processes large volumes of tubes, even a small percentage of waste can translate into hundreds of thousands of dollars in lost material value annually. This is a critical factor for any business aiming for a high cost-performance ratio.

Beyond the tail material, the lack of precise feedback mechanisms in conventional systems means that minor imperfections or misalignments can lead to scrapped parts. If a cut is slightly off-tolerance, the entire component might be rendered unusable. This not only wastes material but also consumes valuable machine time and energy, adding to the overall cost of production. The inability to dynamically adjust cutting parameters or detect issues in real-time exacerbates these problems, leading to a higher defect rate compared to smart systems. This inefficiency makes it harder for businesses to remain competitive in a market that demands lean manufacturing.

3.3 Lack of Real-Time Monitoring and Proactive Maintenance

A significant challenge with older tube cutting systems is the absence of comprehensive real-time monitoring and predictive maintenance capabilities. Operators typically rely on visual inspection or periodic checks to identify issues. This reactive approach means that problems are only addressed after they occur, leading to unplanned downtime, missed deadlines, and costly emergency repairs. I’ve seen this scenario play out many times: a critical machine breaks down unexpectedly, bringing production to a halt, causing a ripple effect throughout the entire supply chain. Without smart sensors and data analytics, diagnosing the root cause of a failure can also be a time-consuming process, extending the downtime further.

Consider the case of a mid-sized metal fabrication business owner like Ahmed Al-Farsi. He operates a stable, long-term business with 100+ staff and relies on consistent machine operation. If his traditional machine breaks down unexpectedly, it impacts his ability to deliver finished parts to builders, decorators, and OEMs, potentially damaging his reputation and contract agreements. The lack of "spare parts availability and remote diagnostics" was one of his pain points with some suppliers. This highlights how traditional systems leave businesses vulnerable to unforeseen operational disruptions and higher maintenance costs due to emergency repairs and the need for immediate, often expensive, spare parts.

Moreover, the absence of real-time performance data means it’s difficult to truly optimize the machine's operation. Without insights into actual cutting speeds, power consumption, or component wear, it’s challenging to identify areas for improvement or to precisely estimate job completion times. This lack of transparency makes production planning less accurate and prevents continuous process improvement. The reliance on manual records or rough estimates hinders a business's ability to operate at peak efficiency, making it difficult to compete with companies leveraging data-driven insights from smart systems.

Traditional systems waste tail materialTrue

Conventional tube cutting leaves unusable tail remnants that accumulate into significant material waste.

CAD operators prevent all material wasteFalse

Even skilled CAD operators can't eliminate inherent waste from traditional cutting methods.

How do smart systems address these challenges in tube laser cutting operations?

The challenges I just outlined, from demanding CAD skills to wasteful production, are exactly what smart systems were designed to conquer. I’ve witnessed firsthand how these technologies transform the shop floor, turning frustration into efficiency. It’s not just about incremental improvements; it’s a paradigm shift that fundamentally redefines productivity and ease of use in tube laser cutting.

Smart systems revolutionize tube laser cutting by eliminating the need for complex CAD operations through intuitive interfaces, dramatically reducing material waste with intelligent nesting, and ensuring continuous operation via real-time monitoring and predictive maintenance. These integrated solutions boost efficiency, lower operational costs, and significantly enhance overall productivity and machine accessibility for diverse manufacturing needs.

From my vantage point, the development of smart systems wasn't merely about adding features; it was about systematically dismantling the core pain points that plagued conventional tube cutting. We at MZBNL, for example, took these very challenges as our design benchmarks. When I look at a client like Ahmed Al-Farsi and his need for "ease of use (preferably No-CAD system)," "cutting speed and accuracy," and "after-sales service and training support," I see how our smart system innovations directly respond to every one of those critical requirements. It’s about building solutions that make advanced technology approachable and profitable for every user.

4.1 Simplifying Operation and Reducing Skill Dependency

One of the most impactful ways smart systems address traditional challenges is by significantly simplifying machine operation, thereby reducing the reliance on highly skilled CAD operators. This is precisely where MZBNL's "No-CAD Operating System Innovation" shines. Instead of requiring complex 3D drawings, our system allows operators to process standard tube types and hole patterns by simply entering parameters. This dramatically lowers the skill threshold, making it possible for new operators to become proficient in just one day of on-site training, as opposed to the traditional 15 days at the equipment factory. I've personally seen how this transforms a client's workforce, enabling them to expand production capacity without the constant burden of retraining or the search for specialized CAD experts.

This intuitive design extends beyond just programming. Modern smart systems incorporate graphical user interfaces (GUIs) that are easy to navigate, with touchscreens and visual cues that guide the operator through the entire cutting process. They often include extensive libraries of pre-programmed shapes and cutting routines, allowing for quick setup of common jobs. For businesses looking to automate existing manual workflows, this ease of use means a much smoother transition and quicker return on investment. It's about empowering operators to be productive quickly, reducing human error, and making the cutting process more accessible to a broader range of personnel.

Furthermore, the integration of smart diagnostics and guided troubleshooting within the interface helps operators quickly identify and resolve minor issues without needing expert intervention. This self-sufficiency reduces downtime and reliance on external support for routine problems. For example, if a sensor reports an anomaly, the system can display clear instructions on how to address it. This proactive support system ensures continuous operation and minimizes disruptions, contributing directly to higher throughput and greater overall efficiency on the shop floor.

4.2 Maximizing Material Utilization and Minimizing Waste

Smart systems fundamentally transform material utilization by implementing intelligent algorithms11 and innovative mechanical designs to virtually eliminate waste. MZBNL's "Zero-Waste Tail Material Innovation" is a prime example of this. Unlike conventional systems that leave unusable tail material, our redesigned cutting logic calculates from the rear chuck as the origin. This allows the system to efficiently cut the entire tube, eliminating leftover tail material as long as the remaining section is smaller than the product length. This single innovation maximizes material utilization and significantly boosts cutting efficiency, leading to substantial cost savings for our clients.

Beyond eliminating tail waste, smart systems employ advanced nesting algorithms that automatically optimize the layout of multiple parts on a single tube. These algorithms can consider various factors, such as part dimensions, material thickness, and desired edge quality, to create the most efficient cutting plan, minimizing offcuts and maximizing the number of parts produced from each length of material. This level of optimization is impossible with manual methods or older software, particularly for complex geometries or varying part sizes. The direct result is a significant reduction in raw material costs, improving the profit margins for fabricators.

Moreover, real-time process monitoring within smart systems contributes to waste reduction by preventing defects during cutting. Sensors continuously monitor parameters like laser power, gas pressure, and cutting speed, making instantaneous adjustments to ensure optimal cutting quality. If an anomaly is detected that could lead to a flawed part, the system can alert the operator or even automatically pause the process, preventing further material waste. This proactive defect prevention, combined with intelligent material management, leads to a much leaner and more sustainable production process, directly benefiting a client's bottom line.

4.3 Enhancing Operational Transparency and Proactive Maintenance

Smart systems revolutionize machine reliability and operational transparency through continuous real-time monitoring and sophisticated predictive maintenance12 capabilities. Instead of relying on reactive repairs, these systems constantly collect data from embedded sensors—monitoring everything from motor temperatures and vibration levels to laser source output and consumable wear. This data is then analyzed by integrated AI algorithms to identify trends and predict potential failures before they occur. This means businesses can schedule maintenance proactively, during planned downtime, rather than experiencing costly and disruptive unexpected breakdowns. This proactive approach significantly enhances machine uptime and overall productivity.

For a client like Ahmed Al-Farsi, whose business relies on consistent delivery, this capability is invaluable. His pain point, "equipment from some suppliers lacked local service support" and "long machine lead times affected project delivery," is directly addressed by machines that can anticipate their own maintenance needs. My team offers remote diagnostics and support, using the very data streams from these smart systems to troubleshoot issues from afar, reducing response times and minimizing the need for on-site visits. This level of connectivity ensures that support is immediate and precise, keeping production running smoothly.

Furthermore, this real-time data provides unparalleled insights into machine performance and production efficiency. Operators and managers can access dashboards showing key performance indicators (KPIs) such as cutting speed, production rates, material consumption, and energy usage. This transparency allows for data-driven decision-making, enabling businesses to identify bottlenecks, optimize workflows, and continuously improve their manufacturing processes. The ability to track and analyze every aspect of the cutting operation transforms a traditional machine into an intelligent hub of information, leading to smarter production planning and more efficient resource allocation.

Smart systems reduce CAD skill dependencyTrue

Smart systems use intuitive interfaces and parameter-based input to minimize the need for complex CAD skills, making tube laser cutting more accessible.

Smart systems increase material wasteFalse

Smart systems actually minimize waste through intelligent nesting algorithms and zero-waste cutting logic, significantly improving material utilization.

What are the future possibilities and advancements for smart systems in laser cutting?

Looking ahead, the trajectory of smart systems in laser cutting is incredibly exciting. What we see today is just the beginning of a truly autonomous and interconnected manufacturing future. I envision a landscape where machines aren't just cutting tools, but active, intelligent participants in a global supply chain, learning and evolving with every operation.

The future of smart systems in laser cutting points towards deeper integration of AI for fully autonomous decision-making, advanced robotics for lights-out manufacturing, and seamless connectivity within fully digitalized factories. We can anticipate more self-optimizing, self-diagnosing, and potentially self-repairing machines, further enhancing efficiency, personalization, and sustainability across the entire production lifecycle, ushering in an era of hyper-flexible manufacturing.

My 25 years in the metal fabrication industry have taught me that innovation is never static. We're constantly pushing the boundaries, and the next wave of advancements in smart laser cutting systems promises to be even more transformative. I believe we'll see machines that aren't just intelligent, but truly intuitive and proactive, requiring even less human intervention while delivering unparalleled precision and efficiency. Our work at MZBNL is already leaning into these future possibilities, ensuring our clients remain at the cutting edge of manufacturing technology.

5.1 Enhanced Autonomy and Adaptive Learning

The next frontier for smart systems in laser cutting is truly enhanced autonomy, driven by more sophisticated AI and machine learning models13. I envision machines that can not only optimize their cutting parameters based on real-time data but also learn from past operations and adapt to unforeseen challenges without human input. This means a machine could autonomously adjust its strategy for a new, unknown material, or dynamically re-route its cutting path if a minor defect is detected during the process. This level of adaptive learning moves beyond pre-programmed responses to genuine problem-solving capabilities, pushing towards true "lights-out" manufacturing.

Consider a scenario where a production schedule suddenly shifts, requiring a different material or a priority change. In the future, a smart laser cutting machine, leveraging advanced AI, could automatically reconfigure itself, access new material specifications from a cloud database, and re-optimize the entire cutting sequence without operator intervention. This level of self-management will dramatically increase production flexibility and responsiveness, allowing businesses to react almost instantaneously to market demands or supply chain disruptions. This flexibility is crucial for contract-based fabrication services like Ahmed Al-Farsi's, where project timelines and material variations are common.

Furthermore, this enhanced autonomy will extend to self-calibration and self-diagnosis with greater precision. Machines will continuously monitor their own components, anticipating wear and tear with incredible accuracy, and even suggesting or initiating micro-adjustments to maintain peak performance. Some systems might even perform minor self-repairs or automatically order replacement parts when needed, truly minimizing downtime and further reducing the need for constant human oversight. This will allow highly skilled personnel to focus on more complex, value-added tasks like design and strategic planning.

5.2 Deeper Integration with Industry 4.0 Ecosystems

The future will see smart laser cutting machines becoming even more deeply embedded within broader Industry 4.014 and IIoT ecosystems. This means seamless, bidirectional data flow between the cutting machine and every other component of the manufacturing enterprise—from CAD/CAM systems and ERP (Enterprise Resource Planning) to MES (Manufacturing Execution Systems), supply chain management, and even customer relationship management (CRM) platforms. I foresee a future where a customer's order placed online can trigger a series of automated actions: design validation, material allocation, optimal cutting path generation, machine scheduling, production, quality inspection, and even shipping notification, all orchestrated by intelligent software.

This level of integration will unlock unprecedented levels of transparency and efficiency across the entire value chain. Managers will have real-time visibility into every aspect of production, from raw material stock levels to the precise status of each cut part. This granular data will enable sophisticated predictive analytics, allowing businesses to optimize not just individual machine operations but also entire production lines and supply chains. For example, by integrating with inventory systems, the machine could automatically reorder materials when stock runs low or adjust production schedules based on material delivery times, ensuring continuous flow.

Moreover, this pervasive connectivity will facilitate the widespread adoption of digital twins—virtual replicas of physical machines or entire factories. These digital twins will allow for simulation of cutting processes, testing of new designs, and predictive maintenance scenarios in a virtual environment before implementing them physically. This reduces risk, accelerates product development, and optimizes operational strategies. The ability to simulate and predict performance will be a powerful tool for continuous improvement and innovation, ensuring that manufacturers can always operate at peak efficiency and adapt quickly to new market opportunities.

5.3 Advanced Personalization and Hyper-Flexible Manufacturing

The ultimate promise of future smart systems in laser cutting is the capability for hyper-personalization and highly flexible manufacturing. As AI and automation become more sophisticated, it will be feasible to produce custom parts or small batches with the same efficiency and cost-effectiveness as mass production. This means "batch size one" could become the new norm, enabling businesses to cater to highly specific customer demands without incurring prohibitive costs. I believe this will redefine niche markets and specialized fabrication, opening up new business models for my clients. For a potential client like Ahmed Al-Farsi, interested in customization and expanding business in architectural metalwork, this is a significant advantage.

This personalization will be supported by advancements in material handling and multi-process integration. Future machines might seamlessly switch between different tube types, sizes, and even combine cutting with other processes like drilling, tapping, or welding, all within a single automated work cell. This multi-functionality will reduce the need for transferring parts between different machines or stations, further streamlining production and reducing lead times. Imagine a single machine that can take a raw tube, cut complex shapes, punch holes, and even prepare the edges for welding, all autonomously.

Furthermore, smart systems will enable truly responsive and distributed manufacturing networks. With advanced connectivity and intelligent logistics, production could be decentralized, with parts produced exactly where and when they are needed, reducing transportation costs and environmental impact. This vision of on-demand, localized manufacturing, powered by smart laser cutting systems, represents a truly transformative future for the metal fabrication industry, allowing unparalleled agility and customer responsiveness.

Smart laser cutters will self-diagnoseTrue

Future systems will monitor components and anticipate maintenance needs autonomously.

Laser cutters will replace human designersFalse

While autonomous, these systems will augment rather than replace human creativity in design.

Conclusion

Smart systems have fundamentally reshaped tube laser cutting, transforming it from a complex, labor-intensive process into a highly efficient, automated, and accessible operation. By simplifying controls, maximizing material use, and enabling proactive maintenance, these intelligent machines are driving productivity and cost savings. This evolution promises even greater autonomy and integration, ensuring the industry remains at the forefront of manufacturing innovation.

-

Discover how automation and sensors enhance efficiencies in tube laser cutting ↩

-

Learn about cutting-edge upgrades in laser cutting machine technology ↩

-

Explore the impact of CNC on accuracy and complexity in laser cutting ↩

-

Understand the ease and efficiency improvements of modern software in laser cutting ↩

-

Discover advancements in automation and their impact on manufacturing efficiency ↩

-

Understand how front-feeding boosts efficiency and reduces labor costs ↩

-

Explore advantages of CAD-free systems in simplifying machine use ↩

-

Learn how this innovation maximizes material use and reduces waste ↩

-

Learn about the importance of CAD/CAM software in traditional tube cutting systems. ↩

-

Discover how nesting technology reduces waste and improves efficiency in tube cutting. ↩

-

Understand the use of intelligent algorithms in optimizing material usage. ↩

-

Uncover strategies behind predictive maintenance in cutting technology. ↩

-

Discover how advanced algorithms optimize cutting parameters and enhance machine learning ↩

-

Explore the connectivity between laser cutting and broader manufacturing ecosystems ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.