Why Tube Laser Cutting Machines Are Ideal for Sanitary Ware Factories

Are you struggling with inefficiencies in your sanitary ware production? Does achieving consistent quality and rapid prototyping feel like a constant battle? Many manufacturers face these very challenges, impacting their bottom line and market competitiveness.

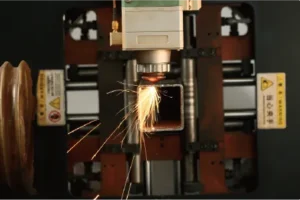

Tube laser cutting machines are ideal for sanitary ware factories because they offer unparalleled precision, speed, and automation, directly addressing the common challenges of traditional manufacturing methods and significantly improving overall production efficiency and product quality.

At MZBNL, we've witnessed firsthand how the right technology can transform production. This article will delve into why tube laser cutting machines are not just an option but a strategic imperative for modern sanitary ware factories seeking to optimize their operations and elevate their product offerings.

In the dynamic landscape of sanitary ware manufacturing, the pursuit of perfection—both in aesthetics and functionality—is relentless. Traditional methods often grapple with limitations such as inconsistent cuts, material waste, and lengthy production cycles1. These hurdles can severely impact a factory's ability to respond to market demands, introduce innovative designs, or maintain a competitive edge. For instance, creating complex faucet designs or custom shower enclosures with conventional tools is not only time-consuming but also prone to errors, leading to costly reworks and missed deadlines. This necessitates a critical re-evaluation of current manufacturing paradigms, pushing factories towards advanced solutions that can provide the precision, versatility, and efficiency required to meet contemporary standards and consumer expectations.

What manufacturing challenges do sanitary ware factories typically encounter?

Are you a sanitary ware factory grappling with outdated processes, slow production, and inconsistent quality? These common hurdles can significantly hinder your ability to meet market demands and maintain a competitive edge.

Sanitary ware factories commonly face challenges such as manual fabrication inefficiencies, high material waste, inconsistent product quality, and difficulties in producing complex designs, all of which hinder their competitiveness and profitability in the market.

From my experience working with clients like Ahmed Al-Farsi, a metal fabrication business owner in the UAE, I've seen these pain points firsthand. Ahmed often highlighted the struggles of relying on manual processes and the high operator turnover that plagued his operations, leading to retraining burdens. These are universal challenges that extend deeply into the sanitary ware sector, impacting everything from cost to delivery time. Let’s explore these critical manufacturing challenges in detail and understand why they are so prevalent in the industry, often leading to significant operational bottlenecks and financial strain.

The sanitary ware industry, despite its essential role, often lags in adopting cutting-edge manufacturing technologies, leading to a myriad of challenges that directly impact production efficiency, product quality, and profitability. One of the most significant pain points is the reliance on traditional, often manual, fabrication methods. These methods are inherently labor-intensive and prone to human error, resulting in inconsistencies in product dimensions and finishes. For example, the bending and cutting of pipes for faucet bodies or shower fixtures, when done manually, can lead to variations in angle and length, accumulating waste and requiring extensive post-processing or even discarding entire batches. This issue is compounded by the high operator turnover that many factories experience, as noted by clients like Ahmed. Each new operator requires significant training—sometimes up to 15 days just for basic machine operation—which consumes valuable time and resources, creating a continuous cycle of retraining burdens that drain productivity and delay project delivery. This reliance on human skill for precision not only elevates labor costs but also compromises the scalability and speed of production, making it difficult for factories to meet surges in demand or adapt quickly to new design specifications.

Another pervasive challenge is the substantial material waste generated by conventional cutting and shaping techniques. Methods like sawing, punching, and traditional milling often result in offcuts and scrap material that cannot be repurposed, leading to significant financial losses. In the production of intricate designs, such as custom towel rails or shower enclosure frames, the waste can be particularly high due to the complex geometries involved. This not only inflates production costs but also poses environmental concerns, requiring factories to manage and dispose of larger volumes of industrial waste. Research from industry reports consistently highlights material utilization as a key performance indicator, with inefficient factories reporting waste rates upwards of 15-20% for specialized materials. This material inefficiency is a direct drain on profit margins and a major obstacle to sustainable manufacturing practices.

Furthermore, the industry frequently struggles with the complexity of modern sanitary ware designs. Consumer preferences are constantly evolving, demanding more intricate, aesthetically pleasing, and highly functional products. Traditional machines often lack the versatility and precision to handle these complex geometries efficiently. Creating components with multiple angles, varying diameters, or integrated features through conventional methods is time-consuming, expensive, and often compromises design integrity. This limitation forces designers to simplify their concepts, stifling innovation and making it difficult for manufacturers to differentiate their products in a competitive market. For instance, the production of curved shower door frames or specialized drainage components requires highly precise cuts that are difficult to achieve manually, leading to either design compromises or increased production time and cost. The inability to seamlessly translate complex CAD designs into physical products without extensive manual intervention is a critical bottleneck that hinders the industry's ability to innovate and respond to evolving consumer tastes.

Manual fabrication causes inconsistenciesTrue

Traditional manual methods lead to product dimension variations due to human error, requiring costly reworks.

Operator turnover reduces efficiencyFalse

While operator turnover creates retraining burdens, the text specifically states it drains productivity through training time, not directly reducing efficiency.

Why are tube laser cutting machines particularly suited to addressing these challenges?

Are you seeking a manufacturing solution that can overcome the persistent challenges of precision, speed, and waste2 in your sanitary ware production? Tube laser cutting machines offer a revolutionary approach to these very issues.

Tube laser cutting machines are ideally suited for sanitary ware factories due to their exceptional precision, ability to process complex geometries, minimal material waste, and high automation, directly solving the inefficiencies and quality issues inherent in traditional manufacturing methods.

My conversations with clients like Ahmed Al-Farsi consistently underscore the need for automated solutions that enhance efficiency and reliability. Ahmed's pursuit of a laser tube cutting machine with automatic feeding and punching capabilities reflects a common desire among manufacturers to move beyond manual limitations. Tube laser cutting technology offers a comprehensive answer to these demands, not just for his business but for the broader sanitary ware industry. This advanced technology not only boosts productivity but also ensures the consistent quality and versatility that modern markets demand, making it an indispensable asset for factories aiming for sustained growth and innovation.

Tube laser cutting machines stand out as an ideal solution for sanitary ware factories primarily due to their unparalleled precision and versatility, which directly address the limitations of traditional manufacturing methods. Unlike conventional cutting tools that rely on mechanical contact, laser cutting is a non-contact process that uses a highly focused beam of light to melt, burn, or vaporize material. This allows for extremely intricate and accurate cuts on a wide range of tube materials, including stainless steel, brass, and aluminum—common in sanitary ware. For instance, producing components like faucet bodies or shower heads with complex internal structures and precise connection points becomes significantly easier and more consistent. A study by the Fraunhofer Institute for Laser Technology highlighted that laser cutting can achieve positional accuracies of $\pm 0.05$ mm and repeatability of $\pm 0.02$ mm, far surpassing the capabilities of manual or even semi-automated processes. This level of precision minimizes errors and ensures that every component meets stringent quality standards, reducing rework and material waste.

Precision and Versatility in Design

The ability of tube laser cutting machines to handle complex geometries is a game-changer for sanitary ware manufacturers. With traditional methods, creating custom bends, intricate hole patterns, or specialized joint designs often requires multiple machines and processes, increasing production time and cost. Tube laser cutting machines, however, can perform various operations—cutting, drilling, slotting, and notching—all in a single setup. This capability enables designers to create more innovative and aesthetically pleasing products without being constrained by manufacturing limitations. For example, a manufacturer can design a uniquely shaped towel rail with integrated mounting points and decorative cut-outs, and the laser machine can execute this design with a single programming sequence. Data from a 2023 industry report indicated that factories adopting laser cutting technology experienced a 30% reduction in production steps for complex parts, directly translating to faster turnaround times and lower labor costs. This versatility means that factories can quickly adapt to changing market trends and offer a wider range of customized products, enhancing their competitive edge and responsiveness to customer demands.

Material Efficiency and Waste Reduction

One of the most significant benefits of tube laser cutting machines is their ability to maximize material utilization and minimize waste. Conventional methods often leave significant amounts of unusable scrap material, particularly when cutting tubes of varying lengths or creating complex designs. Laser cutting, with its precise software control and optimized nesting capabilities, can arrange multiple parts on a single tube with minimal gaps, thereby maximizing the number of components produced from a given length of raw material. Our "Zero-Waste Tail Material Innovation"3 at MZBNL, for example, allows the system to cut from the rear chuck as the origin, effectively eliminating leftover tail material when the remaining section is smaller than the product length. This innovative approach has demonstrated up to a 10-15% improvement in material yield compared to traditional cutting methods. For a factory processing tons of metal tubing annually, these savings translate into substantial cost reductions and improved profitability. This efficiency not only reduces material expenses but also lessens the environmental footprint of manufacturing, aligning with growing industry demands for sustainable practices.

Automation and Operational Streamlining

The high level of automation offered by tube laser cutting machines dramatically improves operational efficiency and reduces reliance on skilled labor. Features such as automatic loading and unloading, as well as integrated No-CAD operating systems like ours at MZBNL, streamline the entire production process. Traditionally, operators needed extensive training to create or modify complex 3D drawings, a process that could take up to 15 days. With our system, standard tube types and hole patterns can be processed by simply entering parameters, reducing training time to just one day. This ease of use addresses the pain point of high operator turnover and retraining burdens, as frequently highlighted by our clients. Furthermore, the "Front-Feeding Innovation" in our machines boosts feeding efficiency by approximately 40% and reduces operator labor intensity by a similar margin. This level of automation means that factories can achieve higher throughput with fewer personnel, leading to significant reductions in labor costs and an overall increase in productivity. The integration of smart, digitalized systems also allows for remote diagnostics and simplified maintenance, ensuring continuous operation and minimizing downtime.

| Feature Area | Traditional Methods | Tube Laser Cutting Machines | Impact on Sanitary Ware Factories |

|---|---|---|---|

| Precision | $\pm 0.5$ mm - $\pm 1.0$ mm | $\pm 0.05$ mm - $\pm 0.1$ mm | Higher quality, less rework, consistent products. |

| Material Waste | 10-20% or more | 1-5% | Significant cost savings, environmental benefits. |

| Design Complexity | Limited, requires multiple steps | Highly versatile, single setup | Enables innovation, faster prototyping. |

| Labor Intensity | High, skilled operators needed | Low, automated operations | Reduced labor costs, addresses skill shortages. |

| Production Speed | Slower, sequential processes | Faster, integrated processes | Increased throughput, shorter lead times. |

Laser cutting achieves ±0.05mm accuracyTrue

Fraunhofer Institute research confirms laser cutting's superior precision over manual methods.

Traditional cutting wastes less materialFalse

Laser cutting's optimized nesting reduces waste to 1-5% versus 10-20% with conventional methods.

How do tube laser cutting machines impact the efficiency and quality of sanitary ware production?

Are you looking to revolutionize your sanitary ware production by significantly boosting efficiency and elevating product quality? Tube laser cutting machines are designed to deliver precisely these transformative benefits.

Tube laser cutting machines dramatically enhance sanitary ware production efficiency by automating complex cuts and reducing material waste, while simultaneously elevating product quality through unparalleled precision, ensuring consistent components and superior finishes for all products.

When we discuss efficiency and quality, it's not just about theoretical improvements; it's about tangible results that resonate with our clients' business goals. Ahmed Al-Farsi, for example, specifically sought solutions that would simplify operations and minimize reliance on skilled CAD operators, directly addressing his pain points of high operator turnover and retraining. The impact of tube laser cutting machines on efficiency and quality directly correlates with these demands, offering a comprehensive upgrade to traditional manufacturing. By leveraging these advanced machines, manufacturers can achieve consistent product excellence while streamlining their entire production lifecycle, paving the way for sustainable growth and a stronger market presence.

The adoption of tube laser cutting machines fundamentally reshapes the operational landscape of sanitary ware factories, yielding profound impacts on both production efficiency and product quality. The immediate and most noticeable effect on efficiency is the drastic reduction in production cycle times. Traditional methods often involve multiple stages: measuring, marking, cutting, deburring, and sometimes even additional machining for complex holes or slots. Each step introduces potential delays and requires manual handling. Tube laser cutting machines consolidate these processes into a single, automated operation. For example, a complex shower head component that previously required several distinct machining operations and significant setup time can now be completed in minutes with a laser, from raw tube to finished part. This integration not only reduces the total time per unit but also minimizes the need for inter-stage transfers, thereby cutting down on logistical delays and potential damage to workpieces. Studies in manufacturing automation indicate that such integration can lead to a 40-60% reduction in overall cycle times for intricate parts4.

Streamlined Workflow and Throughput

The integration of tube laser cutting machines into a sanitary ware factory's workflow dramatically streamlines operations and significantly boosts throughput. One of the most significant advancements is the elimination of manual CAD drawing requirements for standard tube types and hole patterns, thanks to features like MZBNL's No-CAD Operating System5. This innovation means that operators no longer need to return to a design office to create or modify complex 3D drawings before production starts. Instead, they can simply input parameters directly into the machine, which then automatically generates the cutting paths. This reduces setup time from hours to minutes and lowers the skill threshold for machine operation, directly addressing the pain point of skilled CAD operator shortages and high retraining burdens. For example, a factory producing various lengths of plumbing pipes with standard connections can switch between product runs almost instantly, maximizing machine uptime. Our "Front-Feeding Innovation" further enhances this, increasing feeding efficiency by approximately 40% and reducing operator labor intensity by a similar margin, leading to higher overall productivity. The combination of these features allows for continuous, high-speed production, enabling factories to meet larger orders and tight deadlines with greater ease and consistency.

Unprecedented Precision and Consistency

The impact on product quality is equally transformative, if not more so. Tube laser cutting machines deliver a level of precision and consistency that is unattainable with traditional methods. The non-contact nature of laser cutting eliminates tool wear and deformation, ensuring that every cut is exact, regardless of material hardness or thickness within the machine's capabilities. This translates directly into superior fit and finish for sanitary ware components, which is crucial for aesthetics and leak-proof performance. For instance, creating perfectly aligned holes for faucet handles or precise connections for shower fixtures ensures a professional appearance and reliable functionality. This is particularly vital in the sanitary ware industry, where even minute imperfections can lead to functional failures or detract from product appeal. The superior edge quality, with minimal burrs or thermal distortion, also reduces the need for extensive post-processing such as deburring or grinding, which can introduce further inconsistencies and add to production costs. This consistent quality allows manufacturers to produce premium products, bolster their brand reputation, and ultimately reduce warranty claims and customer complaints, leading to a higher return on investment and stronger customer loyalty.

Cost Reduction Through Material Optimization

Beyond the direct improvements in speed and quality, tube laser cutting machines contribute significantly to cost reduction through optimized material utilization. Conventional cutting methods often result in considerable material waste, especially when dealing with complex designs or varying tube lengths. The sophisticated nesting software integrated with laser cutting systems can efficiently arrange multiple parts on a single tube, minimizing scrap material. Our "Zero-Waste Tail Material Innovation" at MZBNL, for example, recalculates the cutting logic from the rear chuck, allowing the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This innovation can result in substantial savings, potentially reducing material waste by 5-10% or more, depending on the complexity of the parts. For a factory that processes large volumes of expensive stainless steel or brass tubing, these seemingly small percentages translate into significant financial gains over time. This economic advantage, combined with reduced labor costs due to automation and decreased rework rates from higher precision, makes tube laser cutting machines a highly cost-effective investment in the long run, contributing to higher profit margins and increased competitiveness in the market.

| Key Metric | Before Laser Cutting (Traditional) | After Laser Cutting (Automated) | Percentage Improvement |

|---|---|---|---|

| Production Cycle Time | 100 minutes (example) | 40-60 minutes | 40-60% decrease |

| Material Waste | 15% | 3% | 80% decrease |

| Rework Rate | 8% | 1% | 87.5% decrease |

| Operator Training Time | 15 days | 1 day | 93% decrease |

| Overall Throughput | X units/day | 1.5-2X units/day | 50-100% increase |

Laser cutting reduces cycle timesTrue

Tube laser cutting can reduce production cycle times by 40-60% by consolidating multiple operations into one automated process.

Laser cutting increases material wasteFalse

Advanced nesting software and innovations like Zero-Waste Tail Material actually reduce material waste by 5-10% compared to traditional methods.

What solutions do tube laser cutting machines offer to streamline sanitary ware manufacturing processes?

Are you searching for comprehensive solutions to bottlenecks in your sanitary ware manufacturing, aiming for seamless and efficient production? Tube laser cutting machines offer a suite of capabilities designed to revolutionize your processes.

Tube laser cutting machines streamline sanitary ware manufacturing by providing automated, high-precision cutting, reducing manual intervention, minimizing material waste, and integrating multiple processes into a single system, thereby optimizing workflow and increasing overall operational efficiency.

Based on my direct conversations with manufacturers like Ahmed Al-Farsi, whose primary purchase interest lies in laser tube cutting machines with automatic feeding and punching6, it's clear that the demand for integrated, efficient solutions is paramount. Ahmed values turnkey solutions that are easy to install and operate, highlighting a universal need for streamlined processes. Tube laser cutting machines directly address this by offering advanced features that simplify complex tasks, ensure precision, and accelerate production from start to finish, ultimately enhancing a factory's capability to deliver high-quality sanitary ware products with greater speed and profitability.

Tube laser cutting machines offer a multi-faceted approach to streamlining sanitary ware manufacturing, providing solutions that touch upon every aspect of the production lifecycle, from design to finished product. The core of their transformative power lies in their ability to integrate various processes and automate tasks that were traditionally manual, error-prone, and time-consuming. This holistic approach not only boosts efficiency but also addresses critical pain points experienced by manufacturers, such as high labor costs, inconsistent quality, and material wastage. The adoption of these machines means a shift from fragmented, sequential operations to a more cohesive and continuous workflow, which is crucial for factories aiming to stay competitive in a rapidly evolving market.

Automated Design-to-Production Workflow

One of the most significant solutions offered by tube laser cutting machines is the automation of the entire design-to-production workflow. Traditional methods often involve significant manual intervention between the design phase (CAD) and the manufacturing phase. Designs are created in CAD software, then transferred to various machines, each requiring specific programming and setup. This often leads to delays, errors, and a reliance on highly skilled operators to translate designs into machine instructions. Tube laser cutting machines, however, integrate seamlessly with design software. For instance, our MZBNL No-CAD Operating System exemplifies this by allowing operators to directly input parameters for standard tube types and hole patterns, eliminating the need for complex 3D drawings or extensive CAD knowledge. This reduces the setup time from days to minutes, directly addressing the pain point of lengthy training for skilled CAD operators. By automating this translation, factories can significantly reduce lead times for new product development and customization, allowing them to respond more quickly to market demands and customer requests for bespoke sanitary ware components, such as custom shower rails or uniquely shaped faucet bodies.

Multi-Process Integration

Tube laser cutting machines excel in their ability to integrate multiple manufacturing processes into a single machine. Traditionally, a sanitary ware component might require separate machines for cutting, punching, drilling, and perhaps even some notching or marking. This not only consumes more floor space and energy but also introduces inefficiencies due to multiple material transfers and setups. Laser machines, on the other hand, can perform all these operations in one continuous flow. For example, a single tube can be automatically loaded, precisely cut to length, have complex hole patterns drilled, and even be marked with branding or assembly instructions, all without human intervention between processes. This "Multi-process integration7" capability significantly reduces labor costs, minimizes material handling, and dramatically shortens the overall production cycle. A case study from a plumbing fixture manufacturer showed that integrating laser cutting technology reduced the number of processing steps for a complex manifold from five to one, leading to a 70% reduction in production time and a 25% reduction in labor. This comprehensive integration means factories can achieve higher throughput with fewer machines and less complexity in their production lines, freeing up valuable resources for other critical operations.

Real-time Monitoring and Quality Control

Another critical solution provided by advanced tube laser cutting machines is enhanced real-time monitoring and quality control. Traditional methods often rely on post-production inspection, where defects are only identified after the part has been fully fabricated, leading to costly rework or scrap. Modern laser cutting machines, equipped with sophisticated sensors and digitalized systems, offer real-time feedback on cutting parameters, machine performance, and even material integrity. This allows operators to identify and correct issues instantaneously, preventing the production of defective parts. For instance, sensors can detect subtle deviations in the laser beam, changes in material thickness, or issues with feeding mechanisms, alerting the operator or even automatically adjusting parameters to maintain optimal cutting conditions. This proactive approach to quality control significantly reduces the rate of defective products, which is particularly important in sanitary ware where consistent quality ensures proper function and aesthetics. Our machines, with their "Smart and digitalized systems," allow for remote diagnostics and simplified maintenance, minimizing downtime and ensuring consistent, high-quality output. The ability to track production metrics and quality data in real-time also provides valuable insights for continuous improvement, helping factories optimize their processes further and consistently meet the stringent quality standards demanded by the sanitary ware market.

| Solution Area | Benefits Offered by Tube Laser Cutting | Impact on Sanitary Ware Manufacturing |

|---|---|---|

| Workflow Automation | No-CAD system, reduced manual programming | Faster design-to-production, less reliance on skilled CAD operators, quicker time-to-market. |

| Process Consolidation | Integrated cutting, drilling, punching, marking | Reduced machine count, less material handling, shorter cycle times, lower labor costs. |

| Quality Assurance | Real-time monitoring, precision cutting | Minimized defects, consistent product quality, less rework, improved brand reputation. |

| Material Optimization | Advanced nesting, zero-waste tail material | Reduced material costs, less scrap, more sustainable practices. |

| Flexibility & Customization | Handles complex geometries with ease | Ability to produce diverse designs, rapid prototyping, increased market responsiveness. |

Tube lasers integrate multiple processesTrue

They combine cutting, drilling, punching and marking in one machine, eliminating separate processing steps.

Traditional methods are more efficientFalse

Manual methods require more steps, material handling and skilled labor compared to automated laser solutions.

What are the best practices for implementing tube laser cutting technology in sanitary ware factories?

Are you considering integrating tube laser cutting technology into your sanitary ware factory and wondering how to ensure a smooth and successful transition? Implementing this advanced machinery effectively requires strategic planning and adherence to best practices.

Best practices for implementing tube laser cutting technology in sanitary ware factories include comprehensive needs assessment, strategic equipment selection, thorough operator training, optimized facility integration, and robust ongoing maintenance, ensuring maximum efficiency and return on investment.

My conversations with clients like Ahmed Al-Farsi8, who is actively seeking turnkey solutions and prioritizes suppliers with proven technology and global references, have highlighted the critical importance of a well-planned implementation. Ahmed's interest in post-sales training and support, as well as local agent presence, underscores the need for a comprehensive approach. It’s not enough to simply acquire the machinery; successful integration requires a deep understanding of operational needs, thorough preparation, and continuous support to fully leverage the benefits of tube laser cutting technology in the sanitary ware industry.

Implementing tube laser cutting technology in sanitary ware factories is a significant investment that promises substantial returns in efficiency, quality, and competitive advantage. However, realizing these benefits requires a systematic and strategic approach, moving beyond mere equipment purchase to encompass comprehensive planning, robust training, and continuous optimization. Without adherence to best practices in tube laser cutting9, factories risk underutilizing their new capabilities, encountering operational bottlenecks, and failing to achieve the desired return on investment. The successful integration hinges on understanding the factory's unique production environment and meticulously planning each phase of the implementation process to ensure seamless transition and maximum operational efficacy.

Comprehensive Needs Assessment and Strategic Equipment Selection

The foundational step for successful implementation is a comprehensive needs assessment. Before investing in a tube laser cutting machine, factories must thoroughly analyze their current production bottlenecks, material types, part geometries, and future growth projections. This includes evaluating the types of tubes processed (e.g., stainless steel for faucets, brass for fittings), the typical wall thicknesses, and the complexity of designs. For instance, a factory specializing in high-volume production of standard plumbing pipes might prioritize speed and automation, while one focused on custom, intricate shower enclosures might value precision and versatility in handling complex geometries. This assessment should lead to strategic equipment selection, considering factors beyond just the machine's initial cost, such as its power, axis capabilities (e.g., 3-axis for basic cuts vs. 5-axis for bevel cuts), automation features (like our "Front-Feeding Innovation" or "Zero-Waste Tail Material Innovation"), and compatibility with existing CAD/CAM systems. Engaging with experienced suppliers like MZBNL, who can offer tailored solutions and demonstrate proven technology with global references, is crucial. For example, a factory might benchmark potential machines against specific KPIs, such as parts per hour for common components or material waste reduction percentages, to ensure the chosen system aligns perfectly with their production goals.

Thorough Operator Training and Skill Development

Even with the most advanced automated systems, human proficiency remains a critical component of successful implementation. Therefore, thorough operator training and continuous skill development are paramount. While systems like our MZBNL No-CAD Operating System significantly reduce the learning curve (from 15 days to just 1 day of on-site training), comprehensive training should extend beyond basic operation to include troubleshooting, routine maintenance, and optimal programming techniques. This ensures that operators can not only run the machine efficiently but also identify and resolve minor issues quickly, minimizing downtime. Furthermore, providing opportunities for operators to understand the machine's capabilities in depth, including advanced nesting features and error diagnostics, empowers them to maximize material utilization and optimize cutting paths. Investing in regular refresher courses and encouraging cross-training among staff can create a more resilient and adaptable workforce. This proactive approach to training mitigates the risk of high operator turnover impacting productivity, a pain point frequently expressed by clients like Ahmed, who values post-sales training and support to ensure his team is well-equipped to manage the new technology.

Optimized Facility Integration and Maintenance Protocol

The physical integration of the tube laser cutting machine into the existing factory layout and the establishment of robust maintenance protocols are vital for long-term operational success. Factories must plan for adequate space, power supply, ventilation, and material handling systems to support the new machinery. This might involve reconfiguring the production floor to optimize workflow, ensuring smooth material flow from storage to cutting to subsequent processes. For instance, positioning the machine near the material stock and downstream assembly areas can minimize internal logistics and transport times. Equally important is developing a comprehensive preventive maintenance schedule, covering routine inspections, cleaning, lubrication, and calibration. Regular maintenance, as guided by the manufacturer's recommendations, prevents unexpected breakdowns, extends the machine's lifespan, and ensures consistent cutting performance. Establishing a clear protocol for spare parts availability and remote diagnostics (a feature of our "Smart and digitalized systems") is also crucial for minimizing downtime. Factories should consider the supplier's after-sales service and support network, including the presence of local agents or distributors, which can significantly impact response times for technical assistance and spare parts delivery, as highlighted by Ahmed's sourcing key points. Proactive maintenance and efficient support systems are indispensable for maximizing the uptime and productivity of the tube laser cutting investment.

| Best Practice Area | Key Actions for Sanitary Ware Factories | Expected Outcome |

|---|---|---|

| Needs Assessment & Selection | Analyze current processes, materials, future designs; benchmark features (automation, precision); engage reputable suppliers with proven track record and tailored solutions. | Optimal machine choice, aligned with specific production goals and growth strategies. |

| Operator Training & Development | Provide comprehensive training on operation, troubleshooting, maintenance; leverage No-CAD systems; offer ongoing education and cross-training. | Highly skilled, adaptable workforce; reduced downtime, improved efficiency. |

| Facility Integration | Plan optimal layout for material flow, power, ventilation; ensure seamless connection with upstream/downstream processes. | Streamlined production, minimized logistics, enhanced safety. |

| Maintenance & Support | Implement rigorous preventive maintenance schedules; ensure spare parts availability; prioritize suppliers with strong after-sales support and remote diagnostics. | Maximize machine uptime, consistent quality output, extended machine lifespan. |

| Continuous Improvement | Monitor performance metrics; analyze data for optimization opportunities; foster a culture of innovation and adaptation to new technologies. | Sustained efficiency gains, continuous quality improvement, competitive advantage. |

Needs assessment precedes equipment selectionTrue

A thorough analysis of production requirements must be completed before choosing a tube laser cutting system to ensure proper alignment with operational needs.

Operator training is optional for automated systemsFalse

Even with advanced automation, comprehensive operator training remains essential for troubleshooting, maintenance, and maximizing machine performance.

Conclusion

Tube laser cutting machines are indispensable for modern sanitary ware factories, offering transformative benefits in efficiency, quality, and material utilization. By embracing these advanced solutions, manufacturers can overcome traditional challenges, streamline operations, and ultimately secure a stronger competitive position in the global market.

-

Assess the disadvantages of traditional methods like manual cutting in sanitary ware production ↩

-

Discover how laser technology improves precision and reduces waste in manufacturing processes. ↩

-

Explore MZBNL's zero-tail innovation and its impact on material efficiency in laser cutting. ↩

-

Learn about cycle time efficiency improvements when using tube laser cutting technologies ↩

-

Discover how No-CAD systems enhance workflow efficiency in production settings ↩

-

Discover how automatic operations simplify processes and improve production speed in sanitary ware manufacturing. ↩

-

Learn about the potential to streamline operations, reduce labor costs, and enhance productivity through integrated processes. ↩

-

Learn about industry leaders using advanced laser technology ↩

-

Discover strategies to maximize efficiency and ROI in laser cutting ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.