Tube Laser Cutting Machine: A Guide to Boosting Your Productivity with Zero Waste?

Material waste eats into your profits with every cut. This slow drain on resources adds up, hindering your growth. What if you could eliminate tail material waste entirely?

A tube laser cutting machine boosts productivity by automating complex cuts, increasing speed, and ensuring precision. Innovations like zero-waste technology maximize material use, significantly reducing costs and improving efficiency, which is crucial for competitive manufacturing in sectors like automotive parts and furniture production.

I've been in this industry for a long time, and I’ve seen how seemingly small inefficiencies can cripple an entire operation. The difference between a market leader and a struggling competitor often comes down to how they manage resources and productivity. Let's dive deep into how modern tube laser cutting technology, especially zero-waste solutions, can fundamentally transform your production line and give you a powerful competitive edge.

What are the current challenges in traditional tube laser cutting processes?

Traditional cutting is often slow and wasteful. This inefficiency directly impacts your bottom line and production schedules. Advanced automation is the key to overcoming these long-standing operational hurdles.

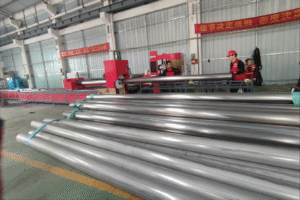

Traditional tube laser cutting faces challenges like significant tail material waste, complex programming requiring skilled CAD operators, and slow manual loading processes. These issues lead to higher material costs, longer production cycles, and a dependency on a limited pool of highly trained technicians.

Let's dive deeper. For years, I've walked through factories and seen the same problems repeated. These aren't minor inconveniences; they are fundamental barriers to growth and profitability, especially in high-volume industries like furniture, automotive parts, and architectural decoration.

The Three Core Challenges

- Significant Material Waste: The most visible problem is the "tail material"—the last unusable piece of the tube left in the chuck. In traditional setups, this piece, often several inches long, is discarded. Over thousands of cycles, this translates into tons of wasted material and a huge financial loss. I remember visiting a client whose scrap pile was a monument to lost profits. It's a cost that many have accepted as unavoidable, but it doesn't have to be.

- The Operator Skill Gap: Traditional machines require complex 3D drawings (CAD files) to operate. This means you need highly skilled, and often highly paid, technicians to create these files for every job. Finding and retaining this talent is a major challenge. It also creates a bottleneck; production can't start until the drawings are perfect. This dependency slows down your entire workflow and makes you less agile.

- Inefficient Manual Processes: Manual or side-loading of long, heavy tubes is slow, labor-intensive, and poses a safety risk. It requires significant physical effort from operators and introduces downtime between each tube. This manual handling is a classic example of a non-value-added activity that directly hurts your overall equipment effectiveness (OEE).

These challenges combine to create a system that is expensive, slow, and inflexible—the exact opposite of what today's market demands.

How does zero waste innovation transform tube laser cutting efficiency?

Wasted material is wasted money. This loss accumulates daily, hurting your competitiveness. Zero-waste technology reclaims that lost revenue by using every inch of your raw material stock.

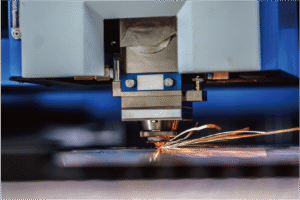

Zero-waste innovation transforms efficiency by redesigning the cutting process to eliminate tail material. By initiating the cut from the rear chuck, the entire tube is utilized. This directly maximizes material yield, reduces scrap disposal costs, and contributes to more sustainable and profitable manufacturing operations.

Let's dive deeper. When my team and I at MZBNL looked at the problem of tail material, we didn't just see scrap metal; we saw a fundamental flaw in the process logic. The traditional method of feeding a tube past the cutting head and leaving the last bit in the chuck was inefficient by design. Our solution, the Zero-Waste Tail Material Innovation, flips this logic on its head. By redesigning the machine to allow the rear chuck to feed the tube forward through the front chuck, we can use the laser to cut the very last workable piece of the material. There is no "unreachable" section left.

This simple but powerful change has a massive impact. For our clients in the metal pipe processing and display rack industries, where material costs are a huge part of their overhead, this innovation translates directly into savings. It’s not a 1% or 2% improvement; it's a complete elimination of a specific type of waste. This approach also aligns perfectly with the growing demand for sustainable and green manufacturing practices, a key differentiator for companies exporting to Europe and North America. By reducing scrap, you not only save money but also enhance your brand's reputation as an environmentally responsible partner. It’s about transforming a cost center—scrap material—into a profit center through maximum utilization.

What are the productivity benefits of implementing advanced tube laser cutting machine?

Slow production lines miss deadlines. This damages client trust and limits growth. Advanced machines accelerate every step, from loading to cutting, ensuring you meet demand and scale effectively.

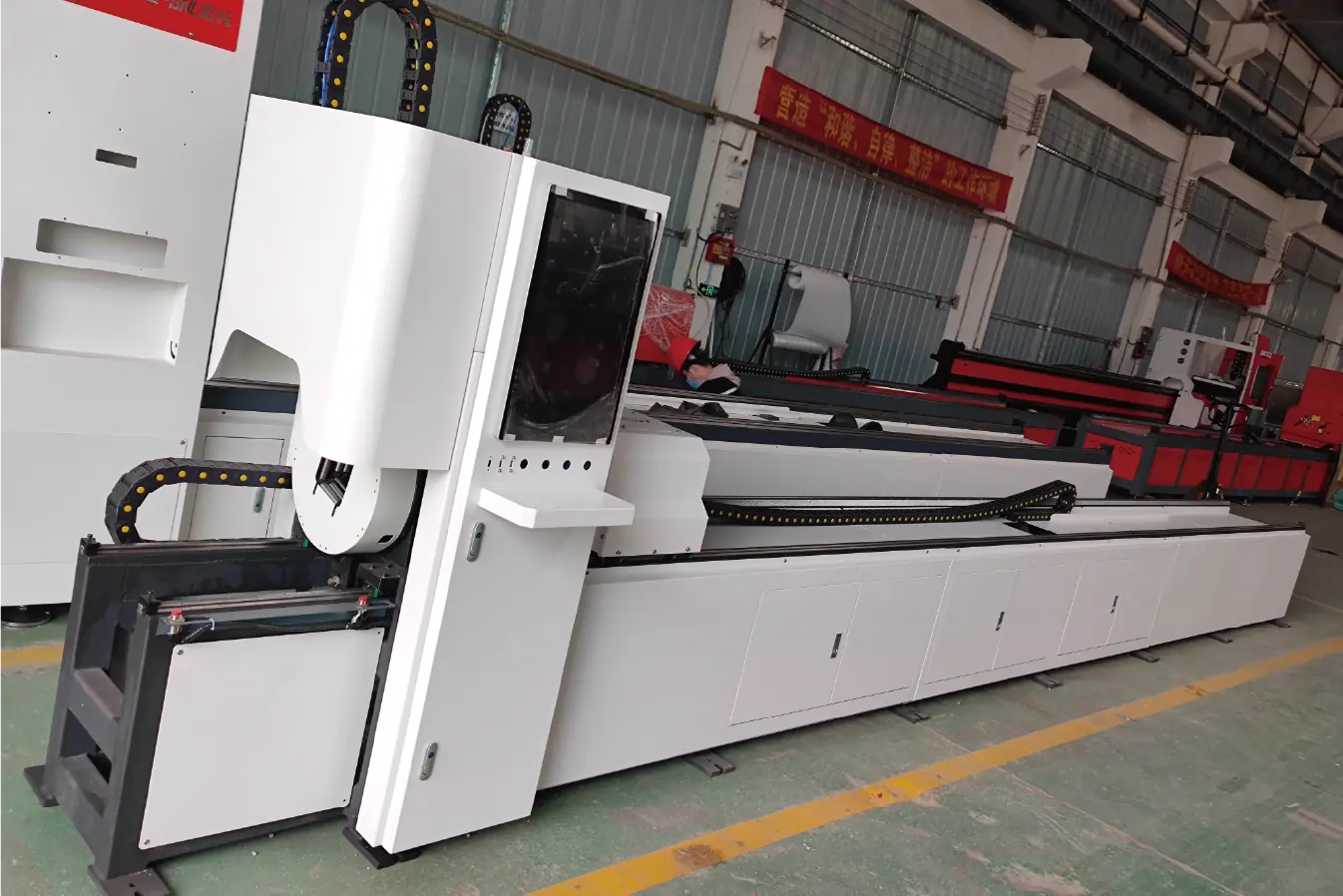

Advanced tube laser cutting machines offer immense productivity benefits. They provide faster cutting speeds, higher precision, and reduced labor dependency through automation. Innovations like automated front-feeding and simplified programming drastically cut down cycle times, boosting overall throughput and operational agility for manufacturers.

Let's dive deeper. Beyond just eliminating waste, advanced machines attack the other core challenges I mentioned earlier: the skills gap and manual inefficiency. At MZBNL, we've focused on two other key innovations that work in tandem with our zero-waste technology to create a productivity powerhouse.

First is our No-CAD System. We realized that for standard shapes—rounds, squares, rectangles—creating a full 3D drawing was overkill. Our system allows an operator to simply input the desired parameters (length, hole diameter, angle, etc.) directly into the machine's interface. This reduces the need for a dedicated CAD engineer and, crucially, cuts on-site training time from a typical 15 days down to just one day. Anyone can learn to operate the machine quickly, which is a game-changer for factories struggling to find skilled labor.

Second is our Front-Feeding Innovation. Instead of slow and strenuous side-loading, our automated front-loading system manages the material handling. This single change increases feeding efficiency by approximately 40% and reduces the physical labor intensity for the operator by a similar amount. The operator can focus on overseeing production, not wrestling with heavy tubes.

| Feature | Traditional Process | MZBNL Advanced Process | Productivity Impact |

|---|---|---|---|

| Programming | Requires skilled CAD engineer | Operator inputs parameters directly | Faster setup, less dependency |

| Training Time | ~15 days | 1 day | Faster operator onboarding |

| Material Loading | Manual side/rear loading | Automated front-feeding | ~40% higher efficiency |

| Material Waste | 5-10 cm tail waste per tube | Zero tail waste | 100% material utilization |

When you combine these three innovations, the cumulative effect on productivity is enormous. You're not just cutting faster; you're setting up faster, loading faster, and using less material.

What strategies can be employed to overcome existing challenges in tube cutting?

Operational bottlenecks are frustrating. They create delays and increase stress on your team. A strategic technology upgrade can smooth out your workflow and empower your operators to be more efficient.

To overcome tube cutting challenges, manufacturers should adopt integrated solutions. This includes implementing machines with zero-waste capabilities to cut material costs, using simplified control systems to reduce reliance on skilled CAD designers, and automating material handling to speed up the entire production workflow.

Let's dive deeper. Overcoming long-standing challenges requires more than just a new machine; it requires a new strategy. Based on my experience helping over 4,000 clients globally, the most successful firms adopt a multi-pronged approach that targets the root causes of inefficiency. Here are the core strategies that deliver the best results.

Strategy 1: Attack Material Costs at the Source

Instead of just negotiating better prices for raw materials, focus on maximizing the yield from the materials you already have. The most direct way to do this is by adopting a zero-waste cutting technology. This isn't a marginal gain; it's a fundamental shift in how you view your inventory. Every tube you purchase should be 100% usable. Implementing a machine designed for zero-tail-material cutting is a direct investment in your bottom line.

Strategy 2: Democratize Machine Operation

Your production shouldn't be held hostage by the availability of a few highly skilled programmers. The strategy here is to simplify the human-machine interface. By choosing equipment with a No-CAD system, you empower a wider range of employees to become productive operators. This breaks down the programming bottleneck, increases your operational flexibility, and makes your team more resilient to staffing changes. It puts control back on the factory floor.

Strategy 3: Automate Non-Value-Added Tasks

Analyze your workflow and identify the most time-consuming, physically demanding, and non-skilled tasks. Material handling is almost always at the top of the list. Implementing an automated front-feeding system is a strategic move to eliminate this bottleneck. It frees up your operators to focus on quality control and managing multiple machines, turning a labor-intensive role into a high-value supervisory one. This boosts throughput and improves worker safety and morale.

How to effectively integrate zero waste technology into your manufacturing process?

New technology can seem daunting. The fear of disruption can prevent progress. A phased, well-supported integration plan ensures a smooth transition and rapid return on investment.

To effectively integrate zero-waste technology, start with a workflow analysis to identify key areas of material waste. Partner with a provider like MZBNL that offers customized solutions and robust training. A phased implementation, starting with a single production line, ensures a smooth transition and quick wins.

Let's dive deeper. Integrating any new technology successfully is all about the process. From my experience, a rushed or poorly planned implementation can cause more problems than it solves. Here is the four-step framework we guide our clients through to ensure a seamless and profitable transition to zero-waste manufacturing.

- Audit and Analyze Your Current State: Before you make any changes, you need a clear baseline. Start by meticulously tracking your current material waste. How much tail material are you scrapping per day, per week, per month? Quantify this waste in both length and cost. This data will not only build the business case for the investment but will also be the benchmark you use to measure your success.

- Partner with an Integration Expert: Don't go it alone. Work with a technology provider who understands your industry and sees themselves as a partner, not just a vendor. At MZBNL, we develop customized solutions because we know a furniture manufacturer has different needs than an automotive parts supplier. A good partner will help you analyze your workflow and configure a machine that solves your specific problems.

- Prioritize Operator Onboarding: The success of new technology rests on the people who use it. The integration plan must include comprehensive and efficient training. This is where our No-CAD system becomes a critical asset. Because we can train operators in just one day, the transition period is dramatically shortened. Your team feels confident and empowered, and you start seeing productivity gains almost immediately.

- Measure, Optimize, and Scale: Once the new machine is running, refer back to your initial audit. Track the reduction in material waste and the increase in throughput. The return on investment (ROI) for zero-waste technology is often incredibly fast. Use these initial wins to build momentum and plan the rollout of the technology across other production lines.

Conclusion

Traditional tube cutting methods are inefficient, wasteful, and create operational bottlenecks. By adopting advanced machines with integrated zero-waste, No-CAD, and automated feeding systems, you can directly attack these challenges, boost productivity, maximize material utilization, and secure a decisive competitive advantage in a demanding global market.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.