How Tube Laser Cutting Machines Are Used in Furniture Production

The furniture industry is constantly evolving, driven by demands for innovative designs and efficient production. Have you ever wondered how complex metal furniture components are crafted with such precision and speed? This is where tube laser cutting machines1 play a pivotal role, transforming raw materials into sophisticated furniture pieces.

Tube laser cutting machines revolutionize furniture production by enabling high-precision, high-speed fabrication of complex metal components. They enhance design flexibility, reduce material waste, and streamline manufacturing processes, making customized and intricate furniture designs economically viable while significantly improving efficiency and product quality.

As an expert in metal fabrication machinery, I've seen firsthand how these advanced tools have reshaped manufacturing landscapes. Furniture manufacturers, in particular, are leveraging tube laser cutting technology to push the boundaries of design and efficiency. Let's delve deeper into how these machines are not just tools but strategic assets in creating the furniture of tomorrow.

In the realm of modern manufacturing, the integration of advanced technology is paramount for staying competitive. For furniture production, this means moving beyond traditional methods that often involve multiple, time-consuming steps like sawing, drilling, and deburring. Tube laser cutting machines offer a paradigm shift, consolidating these processes into one efficient operation. From a critical perspective, while the initial investment might seem substantial, the long-term benefits in terms of precision, speed, and material optimization are undeniable. For instance, a recent industry report2 indicated that manufacturers adopting laser cutting solutions experienced up to a 30% reduction in production time and a 15% decrease in material scrap. Companies like MZBNL have spearheaded this transformation by developing machines with features like "No-CAD System Innovation," which dramatically simplifies design input and accelerates production cycles. This innovation not only reduces the skill threshold for operators but also empowers designers3 to experiment with more intricate geometries, pushing the boundaries of aesthetic and functional furniture design. The ability to produce complex joints and precise cuts in a single pass minimizes errors and rework, directly impacting the bottom line and allowing manufacturers to meet stringent quality standards while catering to the growing demand for bespoke furniture solutions.

What is the role of tube laser cutting machines in modern furniture manufacturing?

In an industry where precision and aesthetic appeal are paramount, tube laser cutting machines are no longer just an advantage but a necessity. They serve as the backbone for creating intricate designs and ensuring consistent quality in modern furniture production.

Tube laser cutting machines are indispensable in modern furniture manufacturing, enabling precise, complex cuts on various metal tubes for chairs, tables, and frames. They support innovative designs, reduce manual labor, minimize material waste, and accelerate production cycles, significantly boosting overall efficiency and product quality in an automated process.

The impact of tube laser cutting technology extends far beyond simple cutting; it fundamentally redefines what's possible in furniture design and production. From automating tedious manual tasks to unlocking new creative possibilities, these machines are at the heart of the industry's evolution. They allow manufacturers to achieve levels of precision and efficiency previously unimaginable, paving the way for more complex, aesthetically pleasing, and durable furniture pieces. Let's explore how these capabilities translate into tangible benefits for furniture makers.

In my 25 years in metal fabrication, I've seen countless technologies emerge, but few have had as profound an impact on furniture manufacturing as tube laser cutting. It’s not just about cutting metal; it’s about transforming raw materials into high-value components with unparalleled precision and efficiency.

Enhanced Design Flexibility and Complexity

One of the most significant roles of tube laser cutting machines is enabling unprecedented design freedom. Traditional methods, involving sawing, drilling, and manual shaping, were limited by the complexity they could achieve without incurring prohibitive costs or compromising structural integrity. Laser cutting, however, can execute intricate geometries, curved lines, and complex joint designs with ease. This capability allows furniture designers to break free from conventional constraints, leading to more innovative and aesthetically pleasing products. For example, a furniture designer can now incorporate custom perforations, interlocking mechanisms, or unique decorative patterns directly into the metal frame of a chair or table, elements that would be incredibly difficult or expensive to produce conventionally. This shift means furniture pieces can be lighter, stronger, and more visually appealing, differentiating them in a competitive market. Our "No-CAD System Innovation" at MZBNL further empowers designers and manufacturers by simplifying the process of bringing complex designs to life, reducing the need for extensive CAD expertise and accelerating prototyping and production cycles.

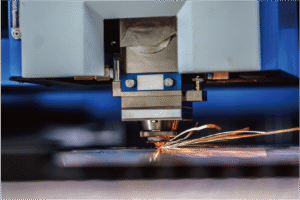

Increased Precision and Quality Consistency

The precision offered by tube laser cutting machines is unparalleled. With tolerances often measured in microns, these machines ensure that every cut is exact, leading to perfectly fitting components and superior product quality. This level of accuracy drastically reduces assembly time and minimizes errors, eliminating the need for manual adjustments or rework. In furniture manufacturing, where consistency is key to brand reputation, this capability is invaluable. Imagine producing hundreds of chair frames, each requiring multiple precise cuts for joints and connections; inconsistencies in even a few millimeters can lead to structural weaknesses or an unattractive finished product. Laser cutting guarantees uniformity across batches, ensuring that every piece of furniture meets the highest standards. This reliability not only enhances customer satisfaction but also reduces material waste from rejected parts, contributing to a more sustainable manufacturing process.

Optimized Material Utilization and Waste Reduction

Material cost is a significant factor in furniture production. Tube laser cutting machines are designed for optimal material utilization through advanced nesting software. This software intelligently arranges multiple parts on a single tube length, minimizing scrap material. Unlike traditional cutting methods that often leave substantial unusable remnants, laser cutting’s precision and flexibility allow for "zero-waste tail material innovation." At MZBNL, our redesigned cutting logic starts from the rear chuck, allowing us to utilize nearly the entire length of the tube, drastically reducing leftover material. For a large-scale furniture manufacturer, this can translate into significant cost savings over time. For instance, if a company processes thousands of meters of metal tubing annually, even a small percentage reduction in waste can save tens of thousands of dollars. This efficiency is not just about cost; it’s also about environmental responsibility, reducing the carbon footprint of manufacturing operations. This approach aligns perfectly with modern sustainability goals, making the production process not only more economical but also more eco-friendly.

| Feature Area | Traditional Methods | Tube Laser Cutting | MZBNL's Innovation | Impact on Furniture Production |

|---|---|---|---|---|

| Design Complexity | Limited to basic shapes, high cost for intricate designs | High flexibility for complex geometries and intricate patterns | "No-CAD System Innovation" simplifies complex design input, faster prototyping | Enables innovative, aesthetically unique furniture designs; faster product development |

| Precision | Manual processes prone to errors, inconsistent quality | High precision (microns), consistent quality | Advanced motion control and optics | Perfect fit of components, reduced assembly time, higher product quality and durability |

| Material Utilization | Significant scrap from cutting and shaping processes | Optimized nesting, reduced waste | "Zero-Waste Tail Material Innovation" maximizes material usage | Significant cost savings, reduced environmental footprint, improved sustainability |

| Speed/Efficiency | Multi-step, time-consuming processes (sawing, drilling) | Single-pass cutting, high speed | "Front-Feeding Innovation" increases feeding efficiency by ~40% | Faster production cycles, higher throughput, quicker time-to-market |

| Operator Skill | Requires highly skilled manual operators | Lower skill threshold with automated systems | Intuitive interfaces, 1-day training (vs. 15 days) | Reduced labor costs, easier workforce training, less reliance on specialized skills |

Laser cutting reduces material wasteTrue

Advanced nesting software and precision cutting minimize scrap material, optimizing resource utilization.

Traditional methods offer better precisionFalse

Laser cutting achieves micron-level tolerances, far surpassing manual sawing/drilling in accuracy and consistency.

How are tube laser cutting machines currently integrated into furniture production workflows?

Integrating new technology into existing workflows can seem daunting, but tube laser cutting machines are proving to be seamless additions. They are transforming traditional linear processes into highly efficient, automated systems within furniture factories.

Tube laser cutting machines are integrated into furniture production workflows by replacing multiple manual processes like sawing, drilling, and deburring with a single automated operation. This streamlines material preparation, enhances design flexibility, and accelerates component fabrication, enabling just-in-time production and reducing lead times for various furniture pieces.

The true power of tube laser cutting machines lies not just in their standalone capabilities but in how they are strategically woven into the fabric of a furniture manufacturing facility4. From the initial design phase to final assembly, these machines are optimizing every step, allowing for a more agile and responsive production environment. This integration is changing the dynamics of how furniture is designed, produced, and delivered, enabling manufacturers to respond rapidly to market trends and custom orders. Let's explore the practical ways these machines are integrated.

As someone deeply involved in providing advanced manufacturing solutions, I've observed a clear trend5: successful integration of tube laser cutting machines in furniture production involves a holistic approach, redefining traditional workflows for maximum efficiency and innovation.

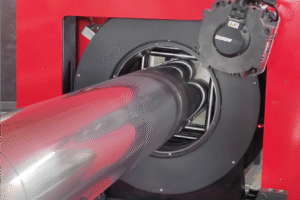

Streamlining Material Preparation and Fabrication

Historically, preparing metal tubes for furniture involved a series of discrete, time-consuming steps: measuring, manual cutting with saws, drilling holes, and deburring edges. Each step introduced potential for error and required dedicated machinery and labor. With tube laser cutting machines, these processes are consolidated into one highly efficient operation. For example, consider Ahmed Al-Farsi, a client in the UAE who runs a metal fabrication business. He needed to automate his existing manual workflows for architectural metalwork and vehicle parts. By adopting a laser tube cutting machine from MZBNL, he could feed raw metal tubes into the machine, which then precisely cuts, drills, and even etches parts in a single pass according to digital designs. This integration eliminates bottlenecks, reduces human error, and ensures that parts are ready for welding or assembly almost immediately. The "Front-Feeding Innovation" we've developed further enhances this by automatically pulling the tube in, increasing feeding efficiency by about 40% and reducing operator labor intensity by a similar margin, effectively streamlining the entire material preparation and fabrication phase.

Enabling Just-In-Time (JIT) Production and Customization

The furniture industry often faces challenges with inventory management and adapting to rapidly changing consumer preferences. Tube laser cutting machines facilitate a shift towards Just-In-Time (JIT) production, where components are manufactured precisely when needed, minimizing inventory holding costs and storage space. Because laser cutting is digitally driven, design changes can be implemented swiftly by simply updating the CAD/CAM files. This capability is crucial for offering customized furniture solutions—a growing market segment. A customer like Ahmed, who focuses on contract-based fabrication services for railing, shelving, and auto parts, benefits immensely from this agility. He can take on unique, bespoke projects with intricate designs without having to retool extensively or incur significant setup costs. For instance, if a client requests a custom shelving unit with unique dimensions and hole patterns, the design can be quickly uploaded to the machine, and the parts can be cut on demand, eliminating the need for large production runs of standard components. This responsiveness allows furniture manufacturers to cater to niche markets and deliver personalized products, giving them a competitive edge.

Enhancing Assembly Efficiency and Reducing Rework

The precision of laser-cut components directly translates into more efficient and less error-prone assembly processes. When every part fits perfectly, the time spent on alignment, adjustments, and rework is drastically reduced. This is particularly vital for complex furniture pieces with multiple intersecting tubes. For example, if a chair frame requires precise interlocking joints, conventional methods might result in slight misalignments, leading to difficulties during welding or bolting. Laser-cut parts, however, fit together seamlessly, akin to a puzzle. This precision not only speeds up assembly but also contributes to the structural integrity and aesthetic quality of the final product. Furthermore, some advanced tube laser cutting machines can even engrave or mark parts with assembly instructions or identification numbers, further simplifying the assembly process and reducing the likelihood of mistakes on the shop floor. This level of integration, from design to precision fabrication to streamlined assembly, underscores the comprehensive role tube laser cutting machines play in modern furniture manufacturing workflows.

Tube lasers replace multiple manual processesTrue

Tube laser cutting machines consolidate sawing, drilling and deburring into one automated operation, as explained in the material preparation section.

Laser cutting requires large production runsFalse

The article specifically highlights how tube lasers enable Just-In-Time production and customization, allowing for small batches or even single-piece production.

What challenges do furniture manufacturers face when using tube laser cutting machines?

Adopting advanced technology like tube laser cutting machines undoubtedly brings numerous benefits, but it also introduces new complexities. Furniture manufacturers often encounter specific challenges that require careful consideration and strategic planning.

Furniture manufacturers face challenges with tube laser cutting machines, including high initial investment costs, the need for skilled operators, and optimizing software integration for complex designs. Material variability and maintenance demands also pose hurdles, requiring thorough planning and training to maximize efficiency and achieve desired quality output in production.

While the allure of enhanced precision and efficiency is strong, the path to seamless integration of tube laser cutting machines is not without its obstacles. From initial financial outlays to the intricacies of daily operation and maintenance, manufacturers must navigate several hurdles. Understanding these challenges is the first step toward developing effective strategies to overcome them and fully leverage the potential of this transformative technology. Let's dive into some of the primary difficulties encountered.

In my experience working with various industries, including furniture, the adoption of sophisticated machinery like tube laser cutters often comes with a distinct set of challenges that need proactive management to ensure a successful return on investment.

High Initial Investment and Operating Costs

The most immediate challenge for many furniture manufacturers is the significant upfront capital investment required to purchase a high-quality tube laser cutting machine. These machines, especially those with advanced features like automation and multi-axis cutting capabilities6, can represent a substantial financial commitment. Beyond the purchase price, there are ongoing operating costs, including electricity consumption, specialized gases (like nitrogen and oxygen), and consumables such as nozzles, lenses, and filters, which need regular replacement. Furthermore, the specialized software licenses for CAD/CAM programming and nesting can add to the overall cost. For mid-sized businesses, like Ahmed Al-Farsi's operation in the UAE, justifying this investment requires a clear understanding of the long-term benefits and a robust financial plan. He prefers a high cost-performance ratio over a low price, indicating an awareness of these ongoing costs. However, smaller manufacturers might find the initial hurdle too high without adequate financing or a clear projected ROI. The challenge then becomes demonstrating that the efficiency gains, material savings, and enhanced product quality will outweigh these considerable expenses over the machine's lifespan.

Skill Gap and Operator Training

Despite advancements like MZBNL's "No-CAD System Innovation" that simplify operation, tube laser cutting machines still require skilled operators for optimal performance, maintenance, and troubleshooting. The industry faces a pervasive skill gap, as traditional metal fabricators may not possess the necessary expertise in digital manufacturing, machine programming, or laser technology. This scarcity of skilled labor leads to higher operator salaries and can make recruitment challenging. Even with simplified interfaces, comprehensive training is essential to ensure operators can effectively program complex cuts, identify potential issues, perform routine maintenance, and troubleshoot minor problems. Ahmed, for example, cited "high operator turnover caused retraining burdens" as a pain point. While MZBNL's 1-day on-site training contrasts sharply with traditional 15-day factory training7, ensuring ongoing proficiency and problem-solving skills remains crucial. Without adequately trained personnel, manufacturers risk underutilizing their machines, incurring costly downtime, or producing substandard parts, negating the benefits of the technology.

Integration with Existing Systems and Workflow Optimization

Successfully integrating a new tube laser cutting machine goes beyond simply plugging it in. It involves seamlessly connecting it with existing design software (CAD), enterprise resource planning (ERP) systems, and overall production planning. This can be a complex undertaking, especially for manufacturers with legacy systems or those not yet fully digitized. Data exchange, workflow automation, and ensuring real-time production visibility become critical. For instance, if the laser cutting machine cannot easily import designs from the furniture designer’s preferred CAD software or if production schedules aren’t automatically updated in the ERP system, bottlenecks can arise. Furthermore, optimizing the production workflow around the laser cutter, such as material handling, part sorting, and subsequent assembly processes, requires careful planning and often a re-evaluation of the entire factory layout. Companies need to invest time and resources in IT infrastructure and process redesign to truly unlock the machine's potential, avoiding situations where the advanced machine is an isolated island of efficiency within an otherwise traditional workflow.

Tube laser cutters require skilled operatorsTrue

Even with simplified interfaces, operators need training in digital manufacturing and laser technology to maximize machine performance.

Laser cutters have low operating costsFalse

Beyond initial purchase, these machines incur ongoing costs for specialized gases, consumables, and software licenses.

What strategies can be employed to improve efficiency and outcomes with tube laser cutting machines in furniture manufacturing?

Maximizing the benefits of tube laser cutting machines in furniture production requires more than just acquiring the technology; it demands strategic planning and implementation. Effective strategies can significantly improve efficiency and overall outcomes.

To enhance efficiency and outcomes with tube laser cutting machines in furniture manufacturing, manufacturers should prioritize comprehensive operator training, invest in advanced nesting software, and implement regular preventative maintenance. Additionally, integrating machines with broader digital manufacturing ecosystems and focusing on continuous process optimization can significantly boost productivity and product quality.

The investment in a tube laser cutting machine is substantial, and to truly unlock its potential, manufacturers must adopt a proactive approach. It's about creating an ecosystem where technology, talent, and processes converge to deliver superior results. By implementing targeted strategies, furniture makers can not only overcome common challenges but also elevate their production capabilities, reduce costs, and enhance their competitive edge. Let's explore these critical strategies in detail.

Based on my quarter-century of experience in metal fabrication solutions, I've identified several key strategies that empower furniture manufacturers to not just use but master tube laser cutting technology, transforming it into a cornerstone of their operational excellence.

Invest in Comprehensive Training and Skill Development

Addressing the skill gap is paramount. While machines like ours at MZBNL simplify operation with innovations like "No-CAD System," continuous investment in comprehensive operator training and skill development is crucial for long-term success. This goes beyond basic machine operation to include understanding laser technology principles, optimizing cutting parameters for different materials and thicknesses, performing routine maintenance, and advanced troubleshooting. For a client like Ahmed Al-Farsi, whose pain point included high operator turnover and retraining burdens, a robust training program could be a game-changer. This could involve not only initial training but also ongoing workshops, online modules, and certifications. Furthermore, cross-training operators for various roles (e.g., programming, maintenance, material handling) creates a more flexible and resilient workforce. Empowering operators with deeper knowledge allows them to identify inefficiencies, suggest improvements, and quickly resolve minor issues, minimizing costly downtime and ensuring consistent output quality. This human capital investment directly translates into higher machine utilization and better overall efficiency.

Optimize Software and Workflow Integration

The true power of tube laser cutting machines is unleashed when they are seamlessly integrated into a broader digital manufacturing ecosystem8. This means optimizing the use of CAD/CAM software for design and programming, leveraging nesting software for maximum material utilization, and connecting these systems to ERP or MES (Manufacturing Execution System) for production planning and tracking. For instance, sophisticated nesting software can automatically arrange multiple furniture components on a single tube length, minimizing scrap material and maximizing throughput—a direct benefit of MZBNL's "Zero-Waste Tail Material Innovation." Manufacturers should actively seek solutions that offer intuitive interfaces and robust integration capabilities. Implementing real-time data analytics from the machine can provide insights into performance, identify bottlenecks, and inform continuous process improvements. This holistic approach ensures that the laser cutter isn't an isolated piece of advanced equipment but a fully integrated component of an intelligent, data-driven production line, making operations more agile and responsive to market demands.

Implement Proactive Maintenance and Quality Control

To ensure consistent performance and longevity, a rigorous proactive maintenance schedule is indispensable. This includes daily checks, weekly cleanings of optical components, monthly calibrations, and periodic professional servicing. Neglecting maintenance can lead to reduced cutting quality, increased material waste, costly breakdowns, and extended downtime, all of which directly impact profitability. Furthermore, robust quality control measures must be integrated throughout the production process. This involves regularly checking cut dimensions, verifying hole positions, and inspecting edges for burrs or slag. Utilizing in-process monitoring features, if available on the machine, can provide early warnings of potential issues. For a company like MZBNL, offering remote diagnostics and easily available spare parts is crucial, as Ahmed also prioritizes "spare parts availability and remote diagnostics" and "local agent or distributor presence." By coupling proactive maintenance with stringent quality control, furniture manufacturers can ensure that their tube laser cutting machines operate at peak efficiency, consistently producing high-quality components and maintaining competitive edge.

Operator training improves laser cutting efficiencyTrue

Comprehensive training enables operators to optimize cutting parameters and quickly resolve minor issues, reducing downtime.

Maintenance can be ignored without consequencesFalse

Proactive maintenance is crucial to prevent reduced cutting quality, material waste, and costly breakdowns.

What are some technical recommendations for optimizing tube laser cutting machine use in furniture production?

Achieving optimal performance from tube laser cutting machines in furniture production requires a deep understanding of their technical capabilities and limitations. Implementing specific technical recommendations can unlock peak efficiency and superior quality.

To optimize tube laser cutting machine use in furniture production, technically recommend precise parameter calibration for various materials, integrating advanced nesting software to minimize waste, and leveraging automated loading/unloading systems for continuous operation. Regular optical component inspection and specialized fixture use also enhance cutting quality and machine longevity, boosting overall productivity.

Beyond general strategies, specific technical adjustments and practices can significantly impact the performance and output quality of tube laser cutting machines in furniture manufacturing. These recommendations delve into the mechanics of operation, material interaction, and system integration, aiming to squeeze every ounce of efficiency and precision from the equipment. By focusing on these granular details, manufacturers can truly differentiate their products and streamline their operations. Let's explore these technical nuances.

From my vantage point, specializing in high-precision metal fabrication machinery, optimizing tube laser cutting machines for furniture production demands a keen eye on technical specifics, moving beyond mere operation to fine-tuning every aspect for superior results.

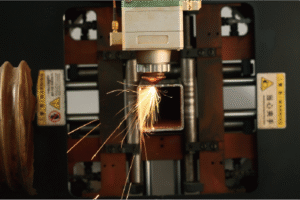

Precise Parameter Calibration for Material Versatility

Furniture production often involves working with a variety of tube materials, including mild steel, stainless steel, aluminum, and sometimes brass or copper, each with different thicknesses and surface conditions. Achieving optimal cut quality, speed, and minimal heat-affected zones (HAZ) for each material requires precise calibration of laser parameters. This includes adjusting laser power and cutting speed settings9, focal position, assist gas pressure (oxygen for mild steel, nitrogen for stainless steel/aluminum), and nozzle type. For example, cutting thin-wall stainless steel for delicate furniture components requires lower power and higher speed with nitrogen to achieve a clean, dross-free edge, whereas thicker mild steel for robust frames needs higher power and oxygen. Manufacturers should establish a comprehensive library of validated cutting parameters for every material and thickness they use. Regular calibration checks and test cuts10 are essential to ensure these parameters remain accurate over time, accounting for wear on consumables or slight variations in material batches. This meticulous approach ensures consistent cut quality, reduces rework, and maximizes material utilization, directly impacting profitability.

Advanced Nesting Software and "Zero-Waste" Logic Implementation

Optimizing material utilization is a critical technical recommendation. This goes beyond basic nesting to implementing advanced algorithms that can arrange complex parts on the tube with minimal scrap. Leveraging features like MZBNL's "Zero-Waste Tail Material Innovation" is paramount. This innovative logic calculates from the rear chuck as the origin, allowing the system to eliminate leftover tail material by processing it if it’s smaller than the product length. For furniture components, which often vary widely in size and shape, this capability can dramatically reduce material waste—a significant cost saving given the rising price of raw metals. Furthermore, advanced nesting software11 can consider common cuts, shared lines, and optimal part orientation to reduce cutting time and minimize thermal distortion. Manufacturers should actively engage with their machine suppliers to ensure they are fully utilizing the nesting capabilities of their software, exploring features like common-line cutting and micro-joints to maximize efficiency and minimize post-processing. This technical deep dive into software utilization directly translates to higher material yield and lower operational costs.

Integration of Automated Material Handling and Sensing Systems

To truly optimize production, the laser cutting machine should be integrated with automated material handling systems. This includes automatic bundle loaders that feed raw tubes into the machine, and automated unloading systems that sort and collect finished parts. For a manufacturer like Ahmed Al-Farsi, who is planning to automate existing manual workflows, implementing such systems would address his pain points related to operator labor intensity and turnover. MZBNL’s "Front-Feeding Innovation," which increases feeding efficiency by about 40%, is a prime example of this. Beyond loading and unloading, advanced sensing systems—such as seam detection, which automatically rotates the tube to avoid cutting through welds, or deflection compensation, which adjusts for tube bending—can further enhance precision and machine autonomy. These technical integrations minimize manual intervention, reduce cycle times, and allow for continuous, lights-out operation in some cases. By automating material flow, manufacturers not only boost productivity but also improve workplace safety and reduce reliance on manual labor, ensuring a more consistent and efficient furniture production line.

Material-specific calibration improves cut qualityTrue

Different metals require unique laser power, speed and gas settings to achieve optimal cutting results with minimal heat distortion.

Oxygen assist gas works for all metalsFalse

While oxygen works for mild steel, stainless steel and aluminum require nitrogen assist gas to prevent oxidation and achieve clean cuts.

Conclusion

Tube laser cutting machines are transforming furniture manufacturing by offering unparalleled precision, design flexibility, and efficiency. Despite challenges like investment costs and skill gaps, strategic integration and technical optimization can unlock significant benefits, leading to higher quality products and more sustainable, cost-effective production processes.

-

Discover the capabilities and benefits of tube laser cutting in the furniture industry. ↩

-

Learn about the efficiency gains from using laser cutting technology in furniture manufacturing. ↩

-

Understand how MZBNL's innovation simplifies complex design processes in furniture crafting. ↩

-

Discover how tube laser cutting optimizes furniture manufacturing processes. ↩

-

Understand the trends in laser cutting machine integration in the furniture industry. ↩

-

Discover how multi-axis cutting improves flexibility and precision in laser cutting. ↩

-

Understand the efficiency and benefits of MZBNL's short training period compared to traditional methods. ↩

-

Advanced troubleshooting techniques for laser technology ↩

-

Learn how to adjust settings for optimal laser cutting results ↩

-

Understand the value of test cuts in maintaining cut quality ↩

-

Discover how nesting software reduces waste and enhances efficiency ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.