Improving Pipe Processing for a Southeast Asian Client with MZBNL Solutions

Are you struggling with outdated pipe processing methods that slow down your production and eat into your profits? The pain of inefficient workflows and wasted materials is real, but as Eric Liu from MZBNL, I see a clear path forward. Our advanced solutions are precisely what businesses need to revolutionize their operations.

Improving pipe processing for Southeast Asian clients involves adopting advanced automated solutions, like those offered by MZBNL, which enhance efficiency, reduce material waste, and lower operational skill requirements. Our integrated machines address regional demands for precision and cost-effective production, empowering businesses to achieve higher throughput and profitability.

In an increasingly competitive global market, clinging to traditional, labor-intensive pipe processing methods is no longer sustainable. Businesses across dynamic regions like Southeast Asia are actively seeking innovative solutions to boost efficiency, reduce operational costs, and produce higher-quality products. As Eric Liu, with 25 years in metal fabrication, I’ve witnessed firsthand this urgent shift, and I believe understanding these evolving demands is crucial for any business aiming for long-term success.

From my perspective at MZBNL, a high-tech enterprise with over 30 patents and 4000 global clients1, the landscape of metal pipe processing is undergoing a significant transformation. Across Southeast Asia and other emerging markets, the drive towards industrial automation is accelerating, spurred by demands for increased precision, reduced labor dependency, and sustainable manufacturing practices. Industries ranging from furniture and sanitary ware to automotive components and architectural structures are actively seeking integrated solutions that can handle complex geometries with speed and accuracy. This evolution isn't merely about upgrading machinery; it's about fundamentally rethinking production workflows to achieve greater agility and cost-effectiveness. The need for smart, digitalized systems that minimize human error and material waste is paramount, as businesses strive to meet stringent quality standards while maintaining competitive pricing in a rapidly expanding global market. My observations confirm that traditional, manual processes are no longer sufficient to keep pace with these modern demands, prompting a critical re-evaluation of current practices and a shift towards more sophisticated technological adoption.

What is the background of pipe processing in Southeast Asia?

Many businesses in Southeast Asia still rely on conventional, labor-intensive pipe processing methods, leading to bottlenecks and inconsistent quality. This often hinders their growth potential and ability to compete on a global scale. I've observed this challenge repeatedly across various industries.

Traditionally, pipe processing in Southeast Asia has been characterized by manual labor, basic machinery, and fragmented workflows across diverse industries like furniture, construction, and automotive. This background often leads to inefficiencies, higher labor costs, and challenges in achieving consistent quality and precision, impacting overall productivity.

While Southeast Asia has experienced remarkable economic growth and industrialization over the past decades, the underlying methods of pipe processing in many sectors have lagged behind global technological advancements. Historically, the abundance of relatively low-cost labor meant that investing heavily in automation was not always seen as a top priority. This fostered a landscape where manual cutting, bending, and punching operations were commonplace, often relying on skilled workers and basic, standalone machines. My experience, spanning 25 years in this field, has shown me that this approach, while initially cost-effective, inherently limits scalability, introduces variability in product quality, and creates significant dependencies on human skill, which can be inconsistent. This foundational reliance on manual processes has set the stage for the current challenges and the urgent need for a paradigm shift in how pipes are processed throughout the region.

Traditional Methods and Their Limitations

Traditionally, pipe processing in Southeast Asia has been heavily reliant on manual and semi-manual techniques, a legacy shaped by historical labor availability and lower initial capital investment requirements. This often involves processes such as manual measurement, hand-grinding, and basic cutting tools, which inherently introduce limitations in terms of precision, speed, and consistency. For many small to mid-sized enterprises, particularly in sectors like furniture manufacturing or simple architectural components, this approach was once sufficient to meet local demands.

However, as I’ve seen through years of working with factories in various countries, these conventional methods lead to significant operational inefficiencies. For instance, the time taken for cutting and shaping a batch of pipes manually can be several times longer than with an automated system, leading to substantial production bottlenecks. Moreover, the lack of precise control often results in higher material waste due due to errors or inconsistent cuts, directly impacting profitability. This reliance on manual skill also means quality can fluctuate greatly from one operator to another, making it difficult to maintain high standards consistently across large production runs.

My observations, reinforced by industry reports, indicate that while manual labor costs might appear lower upfront, the cumulative expenses from slower production cycles, material wastage, and quality control issues often make these traditional methods more expensive in the long run. This is a critical point that many businesses, like some smaller fabrication shops I've visited in Vietnam or Indonesia, are now confronting as they strive to expand and compete beyond local markets, where quality and efficiency are paramount.

Key Industries and Demands

The demand for pipe processing in Southeast Asia spans a diverse array of industries, each with its unique requirements and growth trajectories. Sectors such as furniture and sanitary ware manufacturing, automotive and motorcycle parts production, and architectural decoration form the backbone of this demand. For example, the booming construction sector across major cities like Bangkok, Jakarta, and Ho Chi Minh City necessitates a high volume of precisely cut and fabricated pipes for structural elements, railings, and decorative finishes. Similarly, the robust automotive and motorcycle industries, particularly in Thailand and Indonesia, require precision-engineered tubular components for frames, exhaust systems, and safety structures.

In my discussions with potential clients, like Ahmed Al-Farsi, who is expanding his business in architectural metalwork and vehicle parts, it's clear that their needs go beyond mere cutting. They require complex shapes, multiple hole patterns, and consistent quality across large batches. This contrasts sharply with the capabilities of basic, traditional machinery, which struggles with intricate designs and high-volume, repetitive tasks. The demand is not just for quantity but for quality, precision, and the ability to handle diverse project specifications efficiently.

This evolving landscape means that suppliers are increasingly being judged not just on price, but on their ability to deliver turnkey solutions that integrate various processing steps and ensure high output. For instance, a furniture manufacturer seeking to mass-produce metal chair frames needs a system that can cut, punch, and perhaps even mark pipes in a single, continuous flow, minimizing handling and maximizing throughput.

Emerging Trends in Regional Manufacturing

The manufacturing sector in Southeast Asia is undeniably shifting towards automation and digital integration, driven by rising labor costs, global competitive pressures, and the increasing complexity of product designs. Countries like Singapore, Malaysia, and Thailand are leading this charge, but even developing economies like Vietnam and Indonesia are rapidly catching up. This trend is not just about adopting new machinery; it’s about a fundamental transformation of factory floor operations, moving towards smart manufacturing and Industry 4.0 principles.

My company, MZBNL, recognized this shift early, which aligns with our vision of providing intelligent, integrated solutions. We understand that businesses are increasingly looking for systems that not only perform cutting but also integrate punching, drilling, and other processes automatically. This holistic approach reduces the need for multiple machines and manual transfers, thereby minimizing errors and maximizing efficiency.

The push for customization and flexible production is also a significant trend. Manufacturers need machines that can quickly adapt to changing product specifications and smaller batch sizes without extensive retooling. This necessitates highly adaptable and programmable systems. For example, a client needing to produce different railing designs daily benefits immensely from a machine that can switch between programs with minimal setup time, rather than requiring manual adjustments for each new design.

| Feature | Traditional Pipe Processing | Modern Automated Processing |

|---|---|---|

| Precision | Low to Medium | High to Very High |

| Speed | Slow | Fast |

| Labor Dependency | High | Low |

| Material Waste | High | Low |

| Consistency | Variable | High |

| Setup Time | Manual (long) | Digital (short) |

| Cost Efficiency | Low (long-term) | High (long-term) |

Automation reduces material wasteTrue

Automated pipe processing systems minimize human error and optimize material usage through precise digital controls.

Manual methods are more cost-effectiveFalse

While manual labor has lower upfront costs, automation proves more economical long-term through higher productivity and reduced waste.

How is the current pipe processing market evolving in Southeast Asia?

The pipe processing market in Southeast Asia is rapidly transforming, driven by a growing demand for efficiency, precision, and automation. Businesses are increasingly seeking advanced solutions to stay competitive and overcome the limitations of traditional methods.

The Southeast Asian pipe processing market is evolving towards greater automation, digitalization, and higher precision, driven by rising labor costs, global competitiveness, and demand for complex products. This shift emphasizes integrated solutions, smart systems, and user-friendly technology to enhance productivity and reduce operational dependencies.

As I observe the Southeast Asian market, it's clear that the days of rudimentary pipe processing are fading. The drive for higher quality, faster turnaround times, and reduced operational costs is pushing manufacturers towards more sophisticated solutions. This evolution is not merely a preference but a necessity, especially as regional economies integrate more deeply into global supply chains. Businesses are recognizing that investing in advanced machinery is no longer a luxury but a strategic imperative to remain viable and competitive. This shift encompasses everything from embracing automated feeding systems1 to adopting intelligent software that streamlines design and production. My role at MZBNL has allowed me to witness this firsthand, where clients are increasingly looking for partners who can offer not just equipment but comprehensive solutions that tackle their specific pain points and help them leapfrog their competition.

Rise of Automation and Digitalization

The most prominent evolution in the Southeast Asian pipe processing market is the undeniable surge towards automation and digitalization. For years, the region’s manufacturing sectors, including those heavily reliant on pipe fabrication, benefited from readily available manual labor. However, as economies mature, labor costs are rising, and the pool of skilled workers is becoming more constrained. This economic shift, coupled with a growing global emphasis on efficiency and precision, has propelled businesses to invest in automated machinery. My team at MZBNL sees this daily; inquiries for our automatic punching and laser tube cutting machines are steadily increasing from countries like Vietnam and Thailand, where factories are eager to minimize human intervention and maximize output.

Digitalization plays a complementary role, transforming how these machines are operated and managed. Smart control systems, predictive maintenance capabilities, and integration with factory-wide ERP (Enterprise Resource Planning) systems are no longer niche features but increasingly expected standards. This allows for real-time monitoring of production, better resource allocation, and enhanced quality control. For instance, a client I spoke with recently from a major furniture hub mentioned how implementing a digitalized system drastically reduced their error rate and improved material traceability, something that was almost impossible with their previous manual processes. This digital leap empowers businesses to achieve consistency and scalability that were previously unattainable.

This technological adoption isn't just about replacing human hands with robots; it’s about creating a more intelligent, interconnected manufacturing ecosystem. It signifies a strategic move to optimize every stage of the pipe processing journey, from initial design to final product.

Shifting Demand for High-Precision Products

Another significant trend I’ve observed is the escalating demand for high-precision pipe products across various industries in Southeast Asia. This shift is a direct consequence of global quality standards and increasingly complex product designs. Industries like automotive, medical equipment, and high-end architectural decoration now require components with extremely tight tolerances and intricate geometries that traditional cutting and punching methods simply cannot achieve reliably. For example, a component for a vehicle chassis must meet exact specifications to ensure structural integrity and safety, leaving no room for human error.

This demand for precision directly translates into a need for advanced machinery like laser tube cutting machines, which can achieve micron-level accuracy and handle complex cuts with ease. My clients, including those producing display racks and shelves, report a strong preference from their customers for cleaner cuts and perfectly aligned holes, which only high-precision equipment can deliver. This also extends to multi-process integration; a machine that can perform both high-precision cutting and punching in one setup offers a significant competitive advantage by reducing handling and potential misalignment.

The market is no longer satisfied with "good enough." It demands perfection and consistency, pushing manufacturers to upgrade their capabilities significantly. This focus on precision is not just about meeting current market needs but also about preparing for future demands where customization and intricate designs will become even more prevalent.

Impact of Global Supply Chains

The integration of Southeast Asian manufacturers into global supply chains has had a profound impact on the pipe processing market. As I’ve witnessed through MZBNL’s expansive global reach, businesses in the region are no longer just serving local markets; they are becoming crucial links in international manufacturing networks. This means they must adhere to global quality standards, delivery schedules, and cost efficiencies. When producing components for a multinational automotive OEM, for example, a factory in Thailand must ensure its pipe parts meet the same rigorous specifications as those produced in Germany or Japan.

This global exposure brings intense competitive pressure, forcing local manufacturers to innovate and improve their production methods continuously. They need machines that are reliable, high-performing, and capable of sustained operation to meet tight international deadlines. Furthermore, the availability of comprehensive after-sales service, spare parts, and remote diagnostics, which MZBNL offers globally, becomes critically important. Clients like Ahmed Al-Farsi from UAE, who source from China, Germany, and Turkey, specifically prioritize suppliers with proven technology and robust support networks, highlighting a universal need for dependable global partners.

My experience indicates that this global interconnectedness is compelling Southeast Asian businesses to embrace advanced technologies, as it's the only way to effectively compete, secure, and grow their share in the highly demanding international manufacturing arena. It's a race for efficiency and quality, and only those with the most advanced tools will thrive.

Automation is rising in Southeast AsiaTrue

Rising labor costs and global competition are driving manufacturers to adopt automated pipe processing solutions.

Manual labor remains dominantFalse

The market is rapidly shifting away from manual processes due to demands for precision and efficiency.

What challenges do Southeast Asian clients face in pipe processing?

Despite promising growth, Southeast Asian clients in pipe processing encounter significant hurdles, including reliance on skilled labor, high operational inefficiencies, and a lack of integrated solutions. These challenges directly impact their profitability and market competitiveness, as I've observed in various factories.

Southeast Asian pipe processing clients face key challenges such as over-reliance on skilled CAD operators, high retraining burdens due to turnover, significant material waste from traditional methods, and limited local after-sales service for imported machinery, hindering their automation goals and overall efficiency.

My conversations with numerous clients across Southeast Asia and similar emerging markets consistently highlight a set of common pain points that impede their pipe processing operations. These aren't isolated incidents but systemic issues that often prevent businesses from scaling up, improving quality, or achieving desired profit margins. From the challenge of finding and retaining skilled labor to the frustration of dealing with inefficient workflows and unpredictable machine downtimes, these obstacles are very real. My observations, gained over decades in this industry, confirm that without addressing these core issues, businesses struggle to unlock their full potential and embrace the future of advanced manufacturing. Let's delve deeper into these specific hurdles that clients are grappling with today.

Labor Skills and Retention

One of the most persistent challenges I’ve encountered for Southeast Asian clients in pipe processing is the increasing difficulty in finding, training, and retaining skilled labor, particularly for sophisticated machine operations. Traditional machines often require operators with extensive knowledge of CAD software2 to create or modify complex 3D drawings before production can begin. This creates a significant skill threshold, meaning businesses are heavily dependent on a small pool of highly specialized individuals.

As Ahmed Al-Farsi, the owner of a mid-sized metal fabrication business in the UAE, articulated during our discussions, his previous machines required skilled CAD operators, and high operator turnover caused substantial retraining burdens. This sentiment echoes across Southeast Asia where, despite a large workforce, there’s a noticeable shortage of talent specifically trained for advanced manufacturing processes. When a skilled operator leaves, it doesn't just mean a temporary halt in production; it also means a significant investment in time and resources for retraining new personnel, often impacting project delivery timelines. This constant cycle of hiring and training new operators who need weeks, if not months, to become proficient, is a major drain on resources and a source of operational instability for many factories.

My experience tells me that reducing this dependency on highly specialized, difficult-to-find labor is critical for sustained growth. Businesses need solutions that democratize machine operation, making it accessible to a broader range of the workforce with minimal specialized training.

Operational Inefficiencies and Material Waste

Another critical pain point that I frequently hear about is the pervasive issue of operational inefficiencies and significant material waste in pipe processing3 inherent in traditional pipe processing methods. Many existing setups rely on manual loading, multiple process steps involving material transfer between machines, and outdated cutting logics that are prone to errors and yield considerable unusable scrap.

For example, conventional laser cutting systems often start cutting from the tube head, inevitably leaving an unusable "tail" section at the end of the process, especially when the remaining material is too short for the next product. This tail material, though sometimes small, accumulates rapidly in high-volume production environments, leading to substantial financial losses over time. A factory processing hundreds of meters of pipe daily could easily see several meters of perfectly good material turned into scrap just from tail ends. This directly impacts their profit margins and overall sustainability.

Furthermore, manual loading and transfer processes are not only labor-intensive but also inefficient. They introduce delays, increase the risk of material damage, and require significant physical effort from operators, which can lead to fatigue and errors. I've seen factories where operators spend almost as much time manually handling pipes as they do processing them, drastically reducing actual machine utilization rates. These inefficiencies contribute to longer production cycles, higher operational costs, and diminished competitiveness for businesses aiming to fulfill large orders or adhere to strict deadlines.

Supply Chain and After-Sales Support

A third major challenge for clients in Southeast Asia, particularly those sourcing machinery internationally, revolves around the crucial aspects of supply chain reliability and robust after-sales support4. Many businesses, including Ahmed Al-Farsi, have experienced situations where equipment from some suppliers lacked local service support, leading to prolonged downtime when technical issues arose. Long machine lead times also significantly affect project delivery, creating anxiety and potential penalties for businesses committed to tight schedules.

This is a critical concern because even the most advanced machinery is only as good as the support network behind it. If a machine breaks down, and there's no immediate local assistance or quick access to spare parts, the entire production line can grind to a halt, costing the business immense amounts in lost productivity and unmet deadlines. The process of shipping parts internationally, navigating customs, and waiting for overseas technicians can take weeks, during which time the client is losing money and reputation.

My interactions confirm that clients prioritize suppliers who can offer not just cutting-edge technology but also comprehensive post-sales training, readily available spare parts, and remote diagnostic capabilities. The absence of a strong local agent or distributor presence often deters potential buyers, as it signifies a potential void in critical support. For companies like MZBNL, having a reliable global distributor network and a proactive customer service strategy is paramount to addressing this specific pain point and building long-term trust with our international clients.

Skilled labor shortage affects productionTrue

The article highlights how dependence on specialized CAD operators creates bottlenecks when these skilled workers leave, requiring costly retraining.

Material waste is insignificantFalse

The text specifically mentions how tail-end waste accumulates substantially in high-volume production, directly impacting profit margins.

What solutions does MZBNL offer to enhance pipe processing for these clients?

As Eric Liu, I can confidently say MZBNL provides targeted solutions that directly address the core challenges faced by Southeast Asian pipe processing clients. Our integrated R&D, manufacturing, sales, and service model ensures we deliver innovative, tailored solutions designed for real-world impact.

MZBNL offers advanced laser tube cutting and automatic punching machines featuring No-CAD operation, high-speed precision, and multi-process integration. Our solutions directly address challenges like labor dependency, material waste, and operational complexity, providing cost-effective, smart, and easy-to-operate systems for enhanced efficiency in Southeast Asia.

At MZBNL, our 25 years of experience in metal fabrication, combined with our status as a high-tech enterprise holding over 30 patents, has equipped us with a deep understanding of the industry's evolving needs. We don't just sell machines; we develop comprehensive, tailored solutions designed to overcome the specific pain points I've discussed. Our products, including Laser Tube Cutting Machines, Automatic Punching & Cutting Integrated Machines, and Automatic Punching Machines, are engineered with a focus on innovation, ease of use, and long-term cost-effectiveness. We understand that clients in Southeast Asia, much like Ahmed Al-Farsi who seeks turnkey solutions, need equipment that is not only high-performing but also simple to integrate into their existing workflows and comes with reliable support. This commitment to delivering complete, value-driven solutions sets MZBNL apart in the global market.

Integrated & Automated Machine Solutions

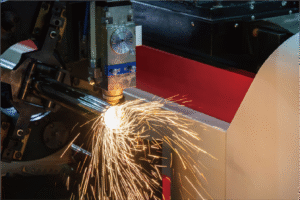

At MZBNL, our core offering revolves around integrated and automated machine solutions designed to streamline the entire pipe processing workflow. We recognize that modern manufacturing demands more than just a single-function machine; it requires a holistic system capable of handling multiple processes seamlessly. Our flagship Laser Tube Cutting Machine5 exemplifies this, providing high-speed and high-precision cutting capabilities. However, we also offer Automatic Punching & Cutting Integrated Machines and Automatic Punching Machines, allowing clients to choose solutions that perfectly match their specific production needs, from basic punching to complex laser cuts combined with punching operations.

My focus has always been on delivering solutions that enhance productivity from start to finish. For a client like Ahmed Al-Farsi, who is planning to automate existing manual workflows, our machines offer the ideal transition. Instead of having separate stations for cutting, punching, and potentially marking, our integrated systems perform these tasks in one continuous operation. This multi-process integration significantly reduces material handling, minimizes the potential for errors between stages, and drastically shortens overall production times. It means a furniture manufacturer can produce perfectly cut and punched chair frames without needing to move parts from one machine to another, saving time and labor. Our 4000+ global enterprise clients attest to the tangible benefits of such integrated solutions in achieving higher throughput and consistent quality.

This approach not only boosts efficiency but also frees up valuable floor space that would otherwise be occupied by multiple standalone machines. It's about optimizing the entire value chain for our clients, ensuring that every step of their pipe processing is as efficient and precise as possible.

User-Friendly Design and Operation

A critical aspect of MZBNL's solution philosophy, and one that directly addresses the pain point of skilled labor dependency, is our emphasis on user-friendly design and operation. We've pioneered and perfected a No-CAD Operating System for our laser tube cutting machines. Traditionally, operators had to return to a design office to create or modify complex 3D drawings for every new part or adjustment. This process was not only inefficient and time-consuming but also required a highly skilled CAD operator, a resource often scarce in rapidly developing markets.

With MZBNL’s No-CAD system, standard tube types and hole patterns can now be processed simply by entering parameters directly at the machine interface—no drawing required. This innovation dramatically improves ease of use, shortens setup time, and significantly lowers the skill threshold for machine operation. I've seen this transformation firsthand: operators now only need 1 day of on-site training instead of spending 15 days at the equipment factory to become proficient. This directly addresses the "high operator turnover caused retraining burdens" faced by clients like Ahmed Al-Farsi. He prefers turnkey solutions that are easy to install and operate, and our No-CAD system perfectly aligns with this preference, empowering a broader range of his staff to manage operations effectively.

This intuitive design ensures that even businesses with limited access to specialized CAD talent can quickly adopt advanced laser cutting technology, maximizing their investment and ensuring continuous, uninterrupted production. It's about making sophisticated technology accessible and practical for everyday use on the factory floor.

Customization and Support Infrastructure

At MZBNL, we firmly believe that a machine is only as good as the support and customization options that accompany it. Our business model integrates R&D, manufacturing, sales, and service, allowing us to offer cost-effective customized solutions that precisely meet unique client requirements. We understand that no two businesses are exactly alike, and a "one-size-fits-all" approach rarely delivers optimal results. Whether it's a specific tube length, a unique material, or a specialized cutting pattern, our R&D team works closely with clients to tailor our machines to their exact specifications.

Furthermore, our commitment extends well beyond the point of sale. For clients like Ahmed Al-Farsi, who expects customization and robust post-sales training/support, MZBNL ensures comprehensive assistance. This includes on-site installation, thorough operator training (as simplified by our No-CAD system), and readily available spare parts. We also leverage remote diagnostics capabilities, allowing our expert technicians to troubleshoot issues from afar, minimizing downtime and ensuring continuous operation for our global clients, including those in Southeast Asia. This directly addresses the pain point of "equipment from some suppliers lacked local service support." Our global distributor networks and dedicated after-sales team are strategically positioned to provide prompt and reliable assistance, ensuring that clients can maximize their machine uptime and productivity.

This robust support infrastructure, coupled with our customization capabilities, provides peace of mind and builds long-term partnerships. It’s a core tenet of how MZBNL delivers value and helps our clients thrive in competitive markets.

MZBNL offers No-CAD operationTrue

MZBNL's laser tube cutting machines feature a No-CAD operating system that simplifies parameter entry without complex drawings.

MZBNL machines require CAD expertiseFalse

Their No-CAD system specifically eliminates the need for specialized CAD skills, enabling operation after just 1-day training.

How can MZBNL's technological advancements benefit pipe processing businesses in the region?

As Eric Liu, I believe MZBNL's innovative technologies offer transformative benefits for pipe processing businesses in Southeast Asia. Our unique advancements are specifically designed to overcome critical industry challenges, driving efficiency, reducing waste, and simplifying operations for all.

MZBNL's technological advancements, including its No-CAD Operating System, Front-Feeding innovation, and Zero-Waste Tail Material logic, significantly benefit Southeast Asian pipe processing businesses. These innovations enhance ease of use, increase feeding efficiency by 40%, reduce labor intensity by 40%, and maximize material utilization, leading to substantial cost savings and improved productivity.

The true power of MZBNL's solutions lies not just in their sophisticated engineering, but in how our three major innovations directly translate into tangible, measurable benefits for our clients. Having spent 25 years in this industry, I've seen countless technologies emerge, but few offer such a direct impact on operational efficiency, material cost, and ease of use. These aren't just incremental improvements; they represent fundamental shifts in how pipe processing can be executed, making advanced capabilities accessible and highly profitable. From simplifying complex design processes to optimizing material usage, these innovations are poised to redefine industry standards in Southeast Asia and beyond, empowering businesses to achieve unprecedented levels of productivity and sustainability. Let's explore how each innovation brings unique advantages to the forefront.

Revolutionizing Operation with No-CAD System

The No-CAD Operating System6 pioneered by MZBNL stands as a monumental leap forward in simplifying laser tube cutting operations, directly benefiting businesses in Southeast Asia struggling with skilled labor shortages. Traditionally, the process of preparing a design for tube cutting was bottlenecked by the necessity of complex 3D CAD drawings. Operators would often need to send requests to a design office, or possess highly specialized CAD skills themselves, to create or modify these intricate designs. This not only added significant time to the production cycle but also created a heavy dependency on a limited pool of highly trained personnel. For a business owner like Ahmed Al-Farsi, who faced high operator turnover and subsequent retraining burdens, this conventional requirement was a major pain point.

Our No-CAD system fundamentally changes this paradigm. Instead of requiring detailed drawings, operators can now simply input parameters for standard tube types and common hole patterns directly into the machine's interface. This intuitive, parameter-driven approach means that complex geometries can be generated on the fly, eliminating the need for external design software or specialized CAD expertise. I've seen firsthand how this innovation reduces the learning curve dramatically; operators who once needed 15 days of intensive factory training to become proficient can now be fully operational after just 1 day of on-site training. This immediate productivity gain is invaluable for factories aiming to reduce training costs and accelerate their production timelines.

This ease of use translates into significant operational flexibility. Businesses can quickly adapt to changing order specifications, produce smaller batches with minimal setup time, and empower a wider range of their workforce to operate the machinery efficiently. It democratizes advanced laser cutting technology, making it accessible to more businesses and significantly mitigating the challenges associated with skilled labor dependency in the region.

Enhancing Productivity with Front-Feeding

Another groundbreaking innovation from MZBNL that offers substantial benefits to pipe processing businesses is our optimized Front-Feeding mechanism7. While traditional machines typically rely on side or rear manual loading, which can be cumbersome and labor-intensive, our design automatically pulls the tube in from the front of the machine. This seemingly simple change yields profound improvements in operational efficiency and ergonomics.

I’ve witnessed the physical strain and time consumption involved in manually loading heavy and long pipes onto conventional machines. Operators often have to maneuver large tubes into tight spaces, a process that is not only slow but also prone to causing fatigue and potential injuries. Our Front-Feeding system addresses these issues head-on. By automating the loading process from the front, we've increased feeding efficiency by approximately 40%. This means that the machine spends more time actively cutting and less time waiting for manual loading, significantly boosting overall throughput. For a high-volume production facility, this 40% increase in efficiency translates directly into a substantial rise in daily output, allowing them to fulfill more orders and meet tighter deadlines.

Furthermore, this innovative design also reduces operator labor intensity by approximately 40%. The need for heavy lifting and awkward maneuvering is drastically minimized, leading to a more comfortable and safer working environment for the machine operators. This not only improves workplace ergonomics but also contributes to higher job satisfaction and potentially reduces operator turnover. For businesses in Southeast Asia where labor efficiency and safety are increasingly prioritized, the Front-Feeding innovation offers a compelling advantage, allowing them to maximize productivity while simultaneously caring for their workforce.

Maximizing Material Utilization with Zero-Waste Tail Logic

One of the most significant and often overlooked sources of waste in traditional laser cutting systems is the Zero-Waste Tail Material Innovation8. Conventional systems typically start cutting from the tube head, and when the machine reaches the end of the pipe, a certain length of material is left unusable in the chuck, simply because the cutting logic cannot utilize the very last section efficiently. This leftover material, accumulated across numerous pipes, translates into considerable financial losses over time for any metal fabrication business.

MZBNL’s Zero-Waste Tail Material Innovation fundamentally redesigns this cutting logic. Instead of starting from the tube head, our system calculates from the rear chuck as the origin. This intelligent reorientation allows the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. In essence, if the final piece of tube that would traditionally be discarded can still accommodate a required product length, our system is designed to use it. This maximizes material utilization, virtually eliminating scrap from tail ends, and directly contributing to a business’s bottom line. For a client concerned about cost-performance ratio like Ahmed Al-Farsi, this innovation provides tangible savings on raw material costs.

I've observed the impact of this innovation on various factory floors; what used to be a bin full of short, unusable pipe remnants now contains significantly less waste. This not only boosts cutting efficiency by optimizing every inch of the raw material but also aligns with modern manufacturing principles of sustainability and resource conservation. It’s a smart, economical solution that differentiates MZBNL’s machines and delivers clear, measurable financial benefits to our clients in Southeast Asia and globally.

No-CAD reduces training timeTrue

The No-CAD system reduces operator training from 15 days to just 1 day by eliminating complex CAD requirements.

Front-Feeding increases laborFalse

Front-Feeding actually reduces operator labor intensity by 40% through automated loading.

Conclusion

As Eric Liu, I see MZBNL’s solutions as pivotal for Southeast Asian pipe processing. Our No-CAD, Front-Feeding, and Zero-Waste innovations directly address challenges, offering high-speed, precise, and user-friendly machines. We empower businesses to boost efficiency, cut costs, and enhance quality, ensuring long-term competitiveness and growth in a rapidly evolving market.

-

Discover the efficiency gains from implementing automated feeding systems ↩ ↩

-

Learn the importance of CAD skills in metal fabrication and pipe processing ↩

-

Understand the financial impact of material waste on manufacturing profits ↩

-

Discover the importance of reliable after-sales support in manufacturing ↩

-

Explore the capabilities of MZBNL's high-precision cutting solutions ↩

-

Understand the No-CAD System’s benefits in operational flexibility and skills reduction ↩

-

Discover benefits of automated loading systems in enhancing productivity and ergonomics ↩

-

Explore how to improve material utilization and sustainability with zero-waste solutions ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.