What Are Tube Laser Cutting Machines and How Can They Revolutionize Manufacturing?

Are you tired of slow, imprecise, and labor-intensive tube fabrication processes that drain resources and limit your design possibilities? These outdated methods often lead to material waste and production bottlenecks, hindering your business's growth. Imagine a world where complex tube cutting is fast, accurate, and efficient, unlocking new potentials.

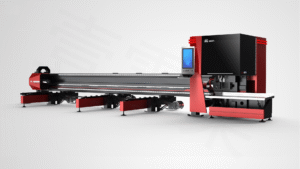

Tube laser cutting machines are advanced manufacturing tools that use a focused laser beam to cut, perforate, or engrave tubes and pipes with exceptional precision and speed. They are revolutionizing industries by enabling intricate designs, reducing material waste, and significantly boosting production efficiency.

As someone who has spent 25 years in metal fabrication at MZBNL, I've witnessed firsthand the evolution of manufacturing technologies. The shift towards automation and precision is undeniable, and tube laser cutting machines are at the forefront of this transformation. In this article, we'll explore what these machines are, their impact, and how they can address common manufacturing challenges, much like the ones faced by clients such as Ahmed Al-Farsi from the UAE.

The journey from manual cutting to sophisticated laser systems represents a significant leap in manufacturing capabilities. This evolution isn't just about speed; it’s about a fundamental change in how we approach design, material utilization, and overall production strategy. For instance, at MZBNL, we've seen how our innovations, like the No-CAD system, directly address the complexities and skill gaps that previously plagued the industry. This technology isn't just a tool; it’s a catalyst for rethinking what's possible in metal fabrication, enabling businesses to achieve unprecedented levels of efficiency and creativity. We'll delve into how these machines are not just an upgrade but a strategic investment for future growth.

What is the background and history of tube laser cutting machines?

For decades, fabricators struggled with cumbersome manual methods for tube processing, leading to errors and slow turnaround times. This inefficiency hampered growth and innovation, making complex designs nearly impossible. The introduction of laser technology promised a solution, but early systems were often complex and not optimized for tube work.

Tube laser cutting machines evolved from early flat-sheet laser cutters, adapting the technology specifically for cylindrical and profiled tubes. Their history traces back to the mid-20th century's laser invention, with dedicated tube cutting systems emerging more prominently in the late 20th and early 21st centuries.

The path from a theoretical concept to a workshop staple is a fascinating one. I remember early discussions about the potential of lasers, and it’s incredible to see how far we've come. The initial laser applications were groundbreaking but often limited in scope. As the technology matured, engineers began to explore its application to more complex geometries, like tubes. This shift wasn't just about adapting existing tech; it required significant innovation in beam delivery, material handling, and control software. At MZBNL, we've built upon this legacy, focusing on making the technology more accessible and efficient for businesses like Ahmed Al-Farsi's, who seek to automate and enhance their production capabilities. Understanding this history helps appreciate the advanced solutions available today.

[img placehold]

The development of tube laser cutting machines is a story of incremental innovation building upon foundational laser technology. Initially, CO2 lasers dominated the industrial landscape, and their application to cutting tubes was a natural progression from flat sheet metal. However, the unique challenges posed by tubular materials – such as varying wall thicknesses, different profiles (round, square, rectangular, custom), and the need for precise rotational control – spurred dedicated research and development. Early systems were often retrofitted flatbed cutters or custom-built solutions, which, while functional, lacked the integration and efficiency of today's specialized machines. The transition from 2D cutting to 3D processing of tubes marked a significant engineering achievement, requiring sophisticated software for path planning and precise control systems for multi-axis movement. This evolution laid the groundwork for the highly automated and versatile machines we see in modern fabrication shops, capable of handling complex tasks that were once deemed too difficult or time-consuming.

The Genesis: Early Laser Applications and Tube Processing Challenges

The invention of the laser in 1960 by Theodore Maiman was a monumental scientific breakthrough, but its industrial applications took time to materialize. Early lasers, primarily CO2 and Nd:YAG, found their first major industrial use in cutting flat sheet metal during the late 1960s and 1970s. I recall seeing some of these early machines; they were massive and required significant expertise to operate. Applying this technology to tubes presented a new set of challenges. Unlike flat sheets, tubes require rotational accuracy, precise handling to avoid deformation, and software capable of calculating complex cutting paths on a curved surface. Traditional methods like sawing, drilling, and milling were time-consuming, often required multiple setups, and struggled with intricate patterns or precise hole placements, especially on non-round profiles. Early attempts to automate tube cutting with lasers involved adapting flat-sheet systems, but these often lacked the specialized chucking mechanisms and software needed for efficient 3D processing. For instance, achieving a clean, perpendicular cut through a rotating tube without beam distortion or thermal damage required significant engineering refinement. According to a 2019 market report by Grand View Research1, the global laser cutting machine market was already substantial, indicating the broad adoption of laser technology, which paved the way for specialized applications like tube cutting. The need for higher precision and faster throughput in industries like automotive and construction fueled the drive for dedicated tube laser solutions.

Emergence of Specialized Tube Laser Cutting Systems

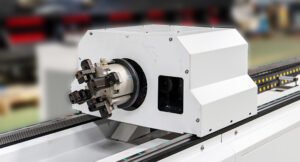

The 1980s and 1990s saw the emergence of more specialized tube laser cutting machines. Manufacturers began designing systems with integrated loading and unloading mechanisms, rotary chucks capable of precise indexing, and multi-axis cutting heads. This period was crucial as it marked the shift from adapting existing technology to creating purpose-built solutions. I remember visiting trade shows during this era and being impressed by the increasing sophistication. Software development played a pivotal role, with CAD/CAM systems becoming more adept at handling 3D tube geometries and generating complex cutting programs. This allowed for features like bevel cutting, slotting, and intricate pattern generation, which were previously very difficult or impossible. One of the key innovations was the \"flying optics\" system, where the laser beam is moved by mirrors while the tube remains stationary or rotates, allowing for higher cutting speeds and better accuracy. Companies like TRUMPF and Bystronic were early pioneers in developing these advanced systems. The ability to process a wide range of tube sizes and profiles on a single machine also became a significant selling point, offering manufacturers greater flexibility. This specialization directly addressed the limitations of earlier methods, leading to significant improvements in productivity and part quality. For businesses like Ahmed's, who might have relied on manual or semi-automated processes, these new machines represented a quantum leap in capability.

The Impact of Fiber Lasers and Modern Innovations

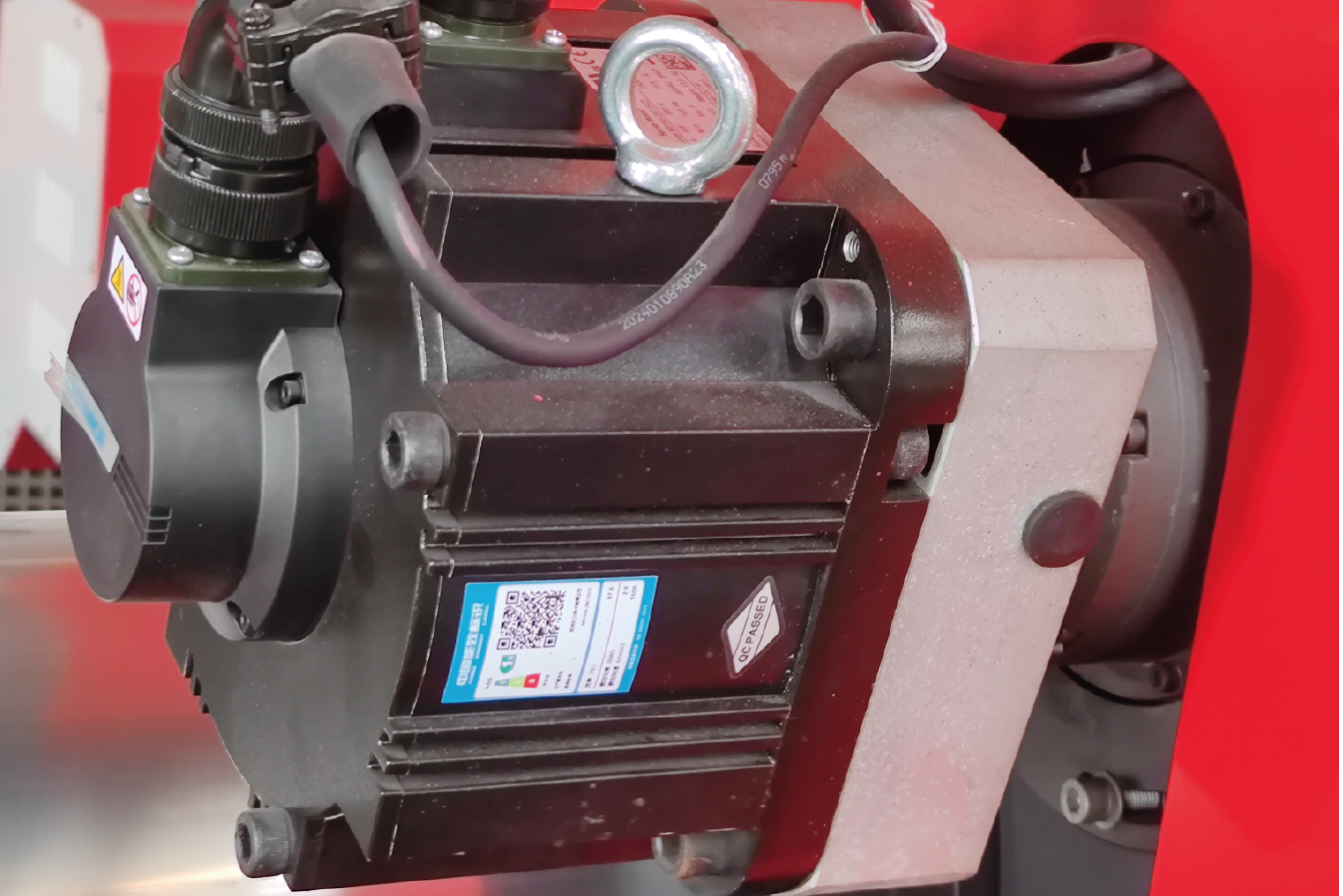

The introduction of fiber laser technology2 in the early 2000s marked another significant turning point for tube laser cutting. Fiber lasers offered several advantages over traditional CO2 lasers, including higher energy efficiency, lower maintenance requirements, and better beam quality for cutting reflective materials like brass and copper. Their shorter wavelength also allowed for faster cutting speeds on thinner materials. This shift has been transformative. At MZBNL, we embraced fiber laser technology for its clear benefits in speed and operational cost. Modern tube laser cutting machines are now highly automated, often featuring automatic bundle loaders, sophisticated sensors for material detection and alignment, and advanced control systems. Innovations like our No-CAD system at MZBNL further simplify operation, allowing users to program standard cuts directly at the machine by entering parameters, drastically reducing setup times and the need for skilled CAD operators – a common pain point for many businesses, including those like Ahmed Al-Farsi's. Furthermore, features like front-feeding mechanisms, which we've developed, improve loading efficiency by around 40%, and our zero-waste tail material innovation maximizes material utilization. These advancements are not just about cutting metal; they are about optimizing the entire workflow, reducing waste, and making advanced manufacturing more accessible. The industry continues to evolve, with ongoing research into areas like artificial intelligence for process optimization and even more powerful and efficient laser sources.

Tube laser cutting reduces material wasteTrue

Laser cutting's precision minimizes excess material removal compared to traditional methods.

Early lasers could easily cut complex tube shapesFalse

Early laser systems struggled with tubular geometries and required significant adaptation.

What is the current state of the tube laser cutting industry?

Businesses are constantly seeking faster, more precise, and cost-effective manufacturing methods. Traditional tube processing often falls short, creating bottlenecks. This demand for higher efficiency and flexibility fuels the growth and innovation within the tube laser cutting sector, pushing the boundaries of what's achievable.

The current tube laser cutting industry is characterized by rapid technological advancements, including fiber laser adoption, increased automation, and sophisticated software integration. It's a dynamic market driven by demands for precision, speed, and versatility across various manufacturing sectors globally.

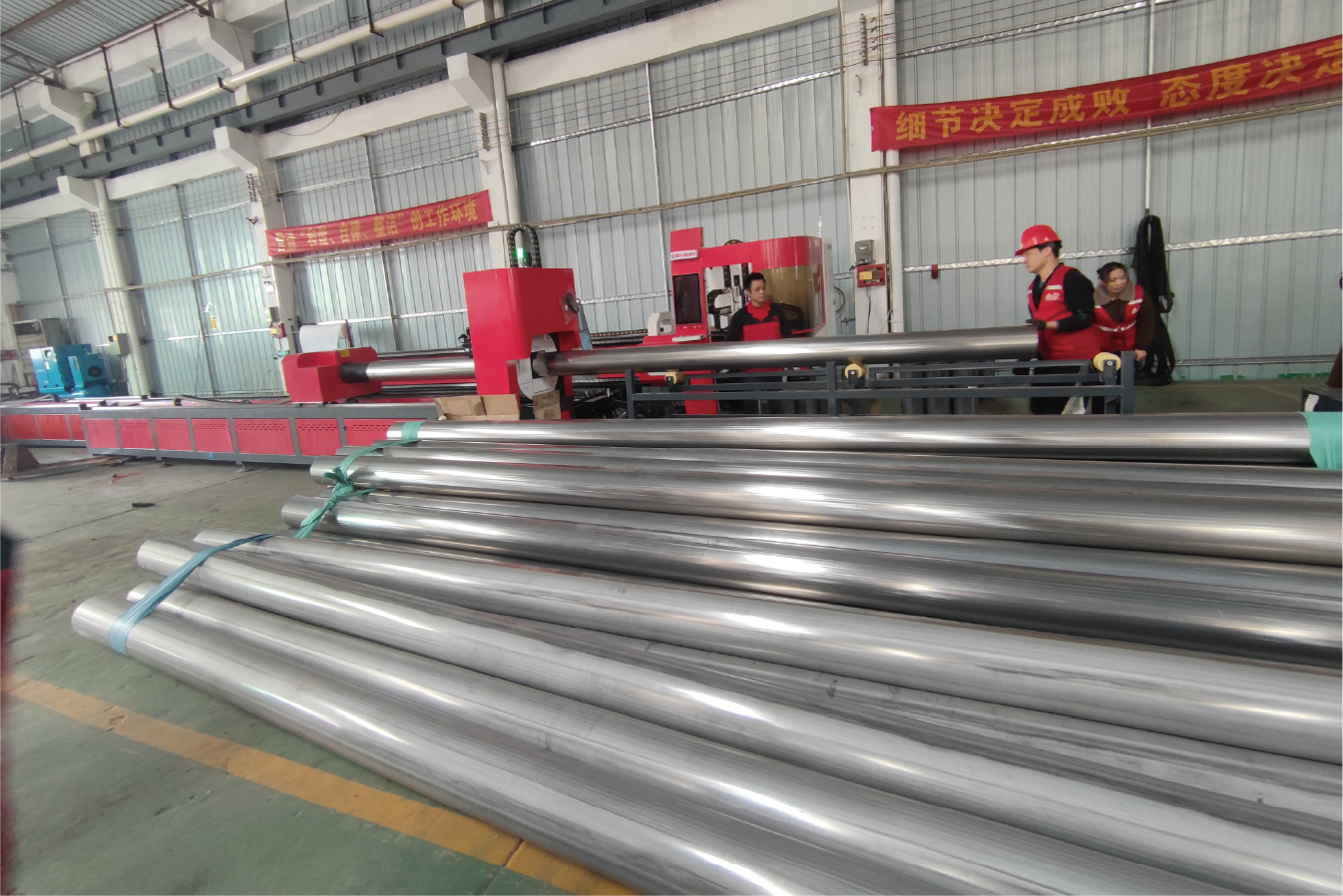

As I navigate the industry with MZBNL, I see a landscape brimming with potential. The technology is maturing rapidly, moving beyond simple cutting to encompass complex, multi-process operations on a single platform. Clients like Ahmed, who value turnkey solutions and high cost-performance ratios, are increasingly looking to advanced tube laser cutters to upgrade their capabilities in architectural metalwork and automotive parts. The global market is expanding, particularly in regions like Southeast Asia and the Middle East, reflecting a worldwide trend towards modernizing manufacturing. This isn't just about buying a new machine; it's about investing in a future where production is smarter, faster, and more adaptable to ever-changing market needs. We are committed to leading this charge with innovations that make a tangible difference.

The tube laser cutting industry today is a far cry from its early days. It's a highly competitive and technologically advanced sector, driven by the relentless pursuit of efficiency, precision, and automation. Key trends shaping the current state include the widespread adoption of fiber laser sources, the integration of Industry 4.0 principles3 like smart connectivity and data analytics, and an increasing focus on ease of use and reduced operator dependency. Manufacturers of these machines are constantly innovating, introducing features that enhance productivity, reduce waste, and expand the range of applications. We see this in the sophisticated loading and unloading systems, intelligent sensor technology for real-time process monitoring, and advanced software that simplifies complex programming tasks. The market is also becoming more segmented, with solutions tailored to specific industries or material types, from small-diameter medical tubing to large structural sections for construction. This specialization ensures that businesses can find machines that precisely match their production requirements, optimizing their investment. My experience at MZBNL, serving over 4000 global clients, confirms that the demand for these advanced solutions is robust, particularly from businesses looking to scale operations and improve their competitive edge.

Dominance of Fiber Laser Technology and Automation

One of the most significant aspects of the current industry is the dominance of fiber laser technology. Compared to older CO2 lasers, fiber lasers offer superior energy efficiency (often cited as 2-3 times more efficient), lower maintenance costs due to their solid-state design, and faster cutting speeds, especially on thinner materials and reflective metals like brass, copper, and aluminum. This has led to a major shift in new machine sales. For instance, a study by the Laser Institute of America highlighted that fiber lasers now account for the majority of laser cutting system sales. Coupled with this is a massive push towards automation. Modern tube laser cutters are often sold as complete production cells, featuring automatic bundle loaders that can handle tons of raw material, robotic unloading and sorting systems, and seamless integration with factory-wide MES (Manufacturing Execution Systems)4. I've seen how our MZBNL machines, equipped with features like front-feeding which boosts loading efficiency by approximately 40%, dramatically reduce manual intervention. This level of automation addresses the shortage of skilled labor, a concern for many manufacturers like Ahmed, and significantly increases throughput. The goal is often "lights-out" operation for certain tasks, maximizing machine utilization around the clock. This trend is critical for businesses aiming to compete globally by minimizing operational costs and maximizing output.

Software Sophistication and Ease of Use

The software driving tube laser cutting machines has become incredibly sophisticated yet paradoxically easier to use. Advanced CAD/CAM packages can now automatically generate optimal cutting paths for complex 3D geometries, simulate the entire cutting process to detect potential collisions or errors, and integrate features like weld seam detection and automatic compensation. This reduces programming time and the likelihood of costly mistakes. A key development, which we at MZBNL have pioneered, is the No-CAD operating system. This innovation allows operators to process standard tube types and hole patterns simply by inputting parameters directly at the machine control, eliminating the need to go back to a design office for 3D drawings for many common tasks. This drastically shortens setup times from potentially days to just minutes for routine jobs and lowers the skill threshold for machine operation, meaning operators can be trained in as little as one day on-site instead of the traditional 15 days at the equipment factory. This directly addresses a major pain point for businesses like Ahmed's, which struggle with high operator turnover and the associated retraining burdens. The focus is on intuitive interfaces, often touchscreen-based, that guide the user through the setup and operation process, making powerful technology accessible to a wider range of personnel.

| Feature Category | Traditional Approach | Modern Tube Laser (e.g., MZBNL) | Impact for Businesses (like Ahmed's) |

|---|---|---|---|

| Design Input | Requires skilled CAD operator & 3D drawing | No-CAD system for standard profiles | Reduced skill dependency, faster setup |

| Material Loading | Manual side/rear loading | Automatic Front-Feeding | ~40% increased efficiency, less labor |

| Material Utilization | Significant tail material waste | Zero-Waste Tail Material calculation | Maximized material use, cost savings |

| Operator Training | Extensive (e.g., 15 days off-site) | Minimal (e.g., 1 day on-site) | Lower training costs, faster deployment |

| Process Integration | Separate machines for different steps | Multi-process on one machine | Streamlined workflow, space saving |

Expanding Applications and Market Growth

The capabilities of modern tube laser cutting machines have opened up a vast array of applications across diverse industries. Beyond traditional metal fabrication, these machines are indispensable in sectors like automotive (for chassis components, exhaust systems), aerospace (for lightweight structures), furniture manufacturing (for intricate designs), fitness equipment (for durable frames), medical devices (for precise, small-diameter tubing), and architectural construction (for complex facades and structural elements). I've worked with clients like Ahmed who are expanding into architectural metalwork and vehicle parts precisely because this technology enables them to meet the demanding specifications of these markets. The global tube laser cutting machine market is experiencing steady growth. According to a report by Fortune Business Insights, the global laser cutting machine market size5 was valued at USD 4.65 billion in 2020 and is projected to reach USD 8.49 billion by 2028, growing at a CAGR of 7.8% during the forecast period. While this covers all laser cutting, tube laser cutters are a significant and rapidly growing segment within this. This growth is driven by increasing industrial automation, the demand for customized products, and the need for higher productivity and precision. Regions like Asia-Pacific, particularly China, are major manufacturing hubs and key markets, but we also see strong demand from Europe, North America, and emerging economies in the Middle East and Southeast Asia, areas where MZBNL actively exports. The ability to process a wider range of materials, including high-strength steels and exotic alloys, further broadens their applicability.

Fiber lasers dominate tube cuttingTrue

Fiber lasers have largely replaced CO2 lasers due to their superior efficiency and cutting speed, especially for thin materials.

Tube lasers require CAD expertiseFalse

Modern systems like MZBNL's No-CAD allow operators to process standard tubes without 3D drawings, reducing skill requirements.

What challenges do businesses face when adopting tube laser cutting machines?

The allure of advanced technology is strong, but the path to adoption can be fraught with hurdles. Many businesses, eager to modernize, find themselves unprepared for the financial outlay or the operational shifts required. This initial enthusiasm can quickly turn into frustration if challenges aren't anticipated.

Businesses adopting tube laser cutting machines often face challenges such as high initial investment costs, the need for skilled operators and programmers, integration with existing workflows and systems, and ensuring adequate maintenance and support for the advanced technology.

From my experience at MZBNL, I've seen many companies, including those similar to Ahmed Al-Farsi's mid-sized fabrication business, grapple with these issues. The decision to invest in a tube laser cutter is significant, and it's not just about the machine's price tag. It's about ensuring you have the right people, processes, and support structures in place to truly leverage its capabilities. For example, Ahmed’s previous machines required skilled CAD operators, and high turnover led to retraining burdens – a common story. Understanding these potential roadblocks is the first step towards overcoming them and successfully integrating this transformative technology into your operations, turning a potential headache into a powerful competitive advantage.

Adopting any new, sophisticated technology like tube laser cutting machines comes with its set of challenges. While the benefits are compelling – increased productivity, higher precision, greater design flexibility, and reduced waste – the journey to successful implementation requires careful planning and consideration of potential obstacles. Businesses, especially small to medium-sized enterprises (SMEs), must weigh the substantial initial investment against the long-term returns. Beyond the financial aspect, there are operational challenges, including the need to train or hire personnel with the skills to operate and maintain these advanced systems. Integrating a new, highly automated machine into existing, perhaps more traditional, workflows can also present logistical and cultural hurdles. Furthermore, ensuring consistent performance requires a commitment to regular maintenance and access to reliable technical support, which can be a concern, especially if suppliers lack local presence or quick response times – a point Ahmed specifically considers in his sourcing. Recognizing these challenges proactively allows businesses to develop strategies to mitigate them effectively.

High Initial Investment and ROI Justification

The most immediate challenge for many businesses is the significant upfront cost of a tube laser cutting machine. These are complex pieces of equipment, incorporating advanced laser sources, precision mechanics, sophisticated control systems, and often automated loading/unloading peripherals. Prices can range from tens of thousands to over a million dollars, depending on the machine's capabilities, size, power, and level of automation. For an SME like Ahmed's, this represents a major capital expenditure that requires careful financial planning and robust ROI (Return on Investment) justification. I've seen businesses hesitate because quantifying the full spectrum of benefits – beyond just faster cutting speeds – can be complex. Factors like reduced labor costs per part, minimized material waste (especially with features like MZBNL's zero-waste tail material innovation), lower error rates, the ability to take on more complex and higher-margin jobs, and reduced inventory needs (due to faster, on-demand production) all contribute to the ROI. However, building a comprehensive business case that accounts for these variables takes effort. Furthermore, financing such an investment can be a hurdle, requiring businesses to explore loans, leases, or other financial instruments. The key is a thorough analysis of current production costs versus the projected efficiencies and new business opportunities the machine will unlock.

Skill Gap and Training Requirements

While modern tube laser cutting machines are becoming more user-friendly, particularly with innovations like MZBNL's No-CAD system that simplifies programming for common tasks, operating and maintaining them still requires a certain level of technical expertise. The "skill gap" is a widely acknowledged challenge in manufacturing. Finding and retaining operators who are proficient in CAD/CAM software (for complex custom designs), machine setup, troubleshooting, and routine maintenance can be difficult and costly. Ahmed Al-Farsi, for instance, highlighted that his previous machines required skilled CAD operators, and high operator turnover created significant retraining burdens. This is a common pain point I hear from many clients. While our No-CAD system reduces reliance on specialized CAD skills for many operations and allows for training in just one day on-site, the overall ecosystem around the machine still benefits from technically adept staff. Training existing employees can be time-consuming and takes them away from current production. Hiring new, skilled personnel can be competitive. Therefore, businesses must invest in comprehensive training programs, either from the machine supplier or third-party providers, and foster a culture of continuous learning to keep up with technological advancements. Supplier support in terms of initial and ongoing training is crucial, a factor Ahmed rightly prioritizes.

Integration with Existing Workflows and Systems

Integrating a new, highly automated tube laser cutting machine into an existing manufacturing environment often presents significant operational and logistical challenges. Many fabrication shops have established workflows, material handling processes, and production scheduling systems that may not be immediately compatible with the capabilities and demands of a high-speed laser cutter. For example, the sheer output capacity of a modern tube laser cutter might outpace downstream processes like welding, bending, or assembly if these are not also upgraded or reconfigured. This can lead to bottlenecks shifting rather than being eliminated. I've consulted with businesses that installed a state-of-the-art machine only to find their material flow couldn't keep up, or their job scheduling wasn't optimized to leverage the machine's quick changeover capabilities. Furthermore, data integration can be a hurdle. Connecting the new machine to existing ERP (Enterprise Resource Planning) or MES (Manufacturing Execution Systems)6 for seamless job tracking, inventory management, and performance monitoring requires technical expertise and may involve custom software development or middleware. This is where turnkey solutions, which Ahmed prefers, and thorough pre-installation planning with the supplier become invaluable. Successfully navigating this requires a holistic view of the entire production process, not just the cutting operation itself, and a willingness to adapt existing practices. Companies like MZBNL often provide consultation on how best to integrate their machines, recognizing that the machine's success is tied to the overall efficiency of the client's operations.

High initial investment is a major challengeTrue

Tube laser cutting machines require significant upfront costs ranging from tens of thousands to over a million dollars, making ROI justification crucial.

No training is required for operatorsFalse

Even with user-friendly innovations, operators still need training in machine setup, troubleshooting, and maintenance to effectively use tube laser cutters.

What solutions address the challenges in tube laser cutting machine usage?

Facing high costs, skill gaps, and integration issues can make adopting tube laser cutters seem daunting. Businesses often worry if the investment will truly pay off or if they'll get bogged down by operational complexities. This uncertainty can paralyze decision-making, delaying much-needed modernization.

Solutions include user-friendly interfaces like No-CAD systems, comprehensive training from suppliers, modular machine designs for phased investment, robust after-sales support with remote diagnostics, and innovations that boost efficiency and reduce operational costs, such as automated feeding and zero-waste cutting.

At MZBNL, we've dedicated ourselves to tackling these challenges head-on. For instance, our No-CAD Operating System directly counters the skill gap, enabling operators to be productive with minimal training. Ahmed's preference for turnkey solutions that are easy to install and operate, along with his emphasis on after-sales training and support, reflects the market's need for practical solutions. We also address cost concerns through innovations like our Front-Feeding mechanism, enhancing efficiency by about 40%, and Zero-Waste Tail Material design, maximizing material use. These aren't just features; they are direct answers to the real-world problems our clients face, ensuring that the adoption of advanced technology is smooth and profitable.

The challenges associated with adopting tube laser cutting machines, while significant, are not insurmountable. Machine manufacturers and industry partners have developed a range of solutions aimed at mitigating these hurdles, making the technology more accessible, cost-effective, and easier to integrate. These solutions span technological innovations, service offerings, and strategic approaches to implementation. For businesses like Ahmed Al-Farsi's, which prioritize ease of use, high cost-performance ratios, and reliable support, these advancements are critical. The goal is to lower the barriers to entry and maximize the return on investment for companies looking to modernize their fabrication processes. At MZBNL, our focus has always been on practical innovation that directly addresses customer pain points, such as the complexity of operation or the inefficiency of traditional processes. By understanding these solutions, businesses can approach the adoption of tube laser cutting technology with greater confidence and a clearer path to success, transforming potential challenges into opportunities for growth and enhanced competitiveness.

Technological Innovations for Ease of Use and Efficiency

A primary solution to the skill gap and operational complexity lies in technological advancements that simplify machine operation and boost overall efficiency. One standout example from our work at MZBNL is the No-CAD System Innovation. Traditionally, as Ahmed experienced, creating or modifying 3D drawings for tube cutting was a time-consuming process requiring skilled CAD operators in a separate office. Our No-CAD system allows standard tube types and hole patterns to be processed simply by entering parameters directly at the machine. This dramatically improves ease of use, slashes setup time, and significantly lowers the skill threshold, reducing on-site training from a typical 15 days to just 1 day. Another crucial innovation is in material handling. Our Front-Feeding Innovation optimizes the loading process by automatically pulling the tube from the front, increasing feeding efficiency by approximately 40% and reducing operator labor intensity by a similar margin. This directly translates to higher productivity. Furthermore, material waste is a major cost factor. MZBNL's Zero-Waste Tail Material Innovation redesigns the cutting logic to calculate from the rear chuck, effectively eliminating leftover tail material as long as the remaining section is smaller than the product length. This maximizes material utilization and boosts cutting efficiency. These types of innovations make the machines more accessible to a wider range of users and improve the financial viability of the investment by directly impacting operational costs and throughput.

Comprehensive Training, Support, and Turnkey Solutions

Addressing the challenges of skill gaps and maintenance requires robust support from the machine supplier. This is an area where businesses like Ahmed's place high importance, looking for suppliers with proven technology and global references. Comprehensive training programs are essential. At MZBNL, we provide on-site training tailored to the customer's specific needs, ensuring their operators are confident and competent. This includes not just basic operation but also routine maintenance and troubleshooting. Post-sales support is equally critical. This encompasses readily available spare parts, remote diagnostics capabilities7 to quickly identify and resolve issues, and, where feasible, local agent or distributor presence for faster on-site assistance. Ahmed specifically looks for this when sourcing suppliers. Many manufacturers now offer "turnkey solutions8," which means they provide not just the machine but also assistance with installation, initial setup, software integration, and operator training as a complete package. This approach simplifies the adoption process for the customer, as they have a single point of responsibility. Service level agreements (SLAs) can also provide peace of mind, guaranteeing response times for service calls and ensuring preventative maintenance schedules are adhered to, minimizing unexpected downtime. This holistic approach to customer support is vital for ensuring the long-term success and reliability of the tube laser cutting investment.

Phased Implementation and Financial Options

For businesses concerned about the high initial investment, a phased implementation approach and flexible financial options can provide a viable path forward. Instead of investing in the largest, most automated system immediately, a company might start with a more basic machine that meets their current core needs and then add automation modules—like automatic loaders/unloaders or advanced software features—as their business grows and they become more familiar with the technology. This allows for a more manageable initial outlay and a quicker ROI on the initial investment phase. Suppliers are increasingly offering modular machine designs that facilitate such upgrades. In terms of financing, beyond traditional bank loans, many equipment manufacturers offer their own financing or leasing programs. Leasing can be an attractive option as it often requires a lower upfront payment and can offer tax advantages. It also allows businesses to upgrade to newer technology more easily at the end of the lease term. Some suppliers might also offer performance-based contracts or even pay-per-use models, although these are less common for large capital equipment. Exploring government incentives or grants for investing in advanced manufacturing technology9 can also help offset costs. For instance, many countries have programs to support SMEs in adopting digital technologies. Careful financial planning, coupled with discussions with suppliers about flexible purchasing or leasing options, can make advanced tube laser cutting technology accessible even for businesses with tighter capital budgets.

No-CAD reduces training timeTrue

The No-CAD system cuts operator training from 15 days to just 1 day by eliminating complex CAD requirements.

Front-feeding decreases efficiencyFalse

Front-feeding innovation actually increases loading efficiency by 40% by optimizing tube handling.

How can tube laser cutting machines transform manufacturing processes today?

Many manufacturers are stuck with outdated, multi-step tube processing methods that are slow, prone to error, and limit design freedom. This inefficiency eats into profits and hinders competitiveness. They dream of a streamlined workflow that boosts quality and unlocks new market opportunities.

Tube laser cutting machines transform manufacturing by consolidating multiple processes into one, enabling complex geometries with high precision, drastically reducing lead times and material waste, and facilitating mass customization and automation for enhanced productivity and innovation.

I've seen this transformation firsthand at MZBNL, where our clients, including those in demanding sectors like automotive parts and architectural decoration, have revolutionized their operations. Imagine taking a complex tube component that previously required sawing, drilling, milling, and deburring—each a separate setup with potential for error—and producing it in a single, automated step. This is the power tube laser cutters bring. For businesses like Ahmed Al-Farsi's, looking to automate and upgrade, this technology means not just improved efficiency but the ability to take on more sophisticated projects, respond faster to customer demands, and ultimately, achieve significant growth and a stronger market position.

Tube laser cutting machines are not just an incremental improvement over traditional methods; they are a disruptive technology that fundamentally redefines how tubular components are designed, processed, and integrated into final products. Their impact extends across the entire manufacturing value chain, from initial design concepts to final assembly, offering a multitude of benefits that can collectively transform a business's operational efficiency, product quality, and innovative capacity. For my clients at MZBNL, whether they are furniture manufacturers, automotive suppliers, or architectural firms, the adoption of this technology has consistently led to remarkable improvements. This transformation is driven by the machine's inherent capabilities in precision, speed, flexibility, and automation. It's about shifting from a reactive mode of production, constrained by older technologies, to a proactive, agile approach that can readily meet the dynamic demands of modern markets. The ability to integrate multiple processes, handle complex designs with ease, and reduce waste significantly alters the manufacturing landscape for any company working with tubes.

Unlocking Design Freedom and Product Innovation

One of the most profound transformations brought by tube laser cutting machines is the unprecedented design freedom they offer engineers and product designers. Traditional methods often impose severe limitations on the complexity of cuts, hole shapes, and joint types that can be practically and economically produced. Tube lasers, controlled by sophisticated CAD/CAM software10, can execute intricate patterns, precise contours, self-locating tabs and slots for easy assembly, bevel cuts for weld preparation, and complex intersections with remarkable accuracy and repeatability. This empowers designers to create components that are not only more aesthetically pleasing but also functionally superior – for example, lighter yet stronger structures, or parts designed for easier, error-proof assembly. I've worked with furniture designers who used our MZBNL machines to create stunning, previously impossible geometric forms, and automotive clients who developed more efficient and compact exhaust systems. This capability allows companies to differentiate their products, respond to demands for customization, and innovate faster. The ability to quickly prototype and iterate designs on the same machine further accelerates the product development cycle, enabling businesses like Ahmed's to explore new opportunities in markets like architectural metalwork, where unique designs are highly valued. This newfound design latitude can be a significant competitive advantage, opening doors to new markets and customer segments.

Drastic Improvements in Efficiency and Productivity

The impact on production efficiency and productivity is perhaps the most immediate and quantifiable transformation. Tube laser cutting machines consolidate multiple conventional operations—such as sawing, drilling, milling, punching, and deburring—into a single, automated process11. This drastically reduces material handling, setup times, and the number of machines and operators required. For instance, a complex part that might have taken several hours and multiple setups using traditional methods can often be produced in minutes on a tube laser cutter. Our MZBNL front-feeding innovation, which boosts loading efficiency by around 40%, and the No-CAD system, which shortens setup time by allowing parameter-based programming, contribute directly to this increased throughput. Consider a typical client processing display racks; they might have previously cut tubes to length on a saw, then moved them to a drill press for holes, and then to a manual deburring station. A tube laser can perform all these operations in one continuous flow, significantly reducing lead times from days to hours. This enhanced speed and efficiency allow businesses to handle larger order volumes, offer quicker turnaround times to customers, and reduce work-in-progress inventory. The result is a leaner, more agile manufacturing operation capable of responding rapidly to market changes. This is crucial for businesses like Ahmed's looking to automate existing manual workflows and scale up production.

Enhanced Material Utilization and Cost Reduction

Beyond speed and design, tube laser cutting machines offer significant advantages in material utilization and overall cost reduction. The precision of the laser kerf (the width of the material removed by the laser) is very small, minimizing scrap between parts. Advanced nesting software12 can optimize the placement of multiple parts on a single tube length to maximize yield. A key innovation from MZBNL in this area is our Zero-Waste Tail Material design. Conventional systems often leave an unusable piece of tail material at the end of each tube. By redesigning the cutting logic to calculate from the rear chuck as the origin, our system can eliminate this leftover tail material as long as the remaining section is smaller than the product length. This maximizes material utilization and can lead to substantial savings, especially when working with expensive materials. Furthermore, the reduction in manual labor, elimination of errors that lead to rework or scrap, lower tooling costs (as lasers don't wear out like physical tools), and reduced energy consumption per part (especially with efficient fiber lasers) all contribute to a lower cost per piece. These savings, compounded over thousands of parts, can significantly improve a company's profitability. For Ahmed, who values a high cost-performance ratio, these aspects are critical in justifying the investment and achieving a competitive edge in contract-based fabrication services. The ability to deliver finished parts more economically strengthens his position with builders, decorators, and OEMs.

Tube lasers enable complex geometriesTrue

Tube laser cutting machines can create intricate patterns and precise contours that traditional methods cannot achieve.

Tube lasers increase material wasteFalse

Advanced nesting software and precise laser kerf actually minimize scrap and maximize material utilization.

Conclusion

Tube laser cutting machines are revolutionizing manufacturing by offering unparalleled precision, speed, and design flexibility. They consolidate processes, reduce waste, and empower businesses like yours to innovate and achieve significant operational efficiencies, transforming production capabilities and boosting competitiveness in today's demanding market.

-

See data on the laser cutting market size, confirming widespread technology adoption. ↩

-

Learn about fiber laser benefits like efficiency, speed, and material versatility. ↩

-

Learn about the fourth industrial revolution's impact on manufacturing and smart factory concepts. ↩

-

Discover how MES optimizes production, integrates machinery, and enhances factory-wide operational visibility. ↩

-

Explore detailed market data, trends, and growth forecasts for the laser cutting industry. ↩

-

Understand ERP/MES systems and how they help integrate new machinery into existing production workflows. ↩

-

Learn how remote diagnostics improve machine uptime and reduce maintenance costs for industrial equipment. ↩

-

Understand what's included in a turnkey solution and its benefits for simplifying equipment deployment. ↩

-

Explore potential financial support options for acquiring advanced manufacturing technologies. ↩

-

Learn how CAD/CAM software unlocks intricate designs and precision in modern tube laser cutting. ↩

-

Understand how laser cutting streamlines production by replacing multiple traditional tube processing steps. ↩

-

Discover how nesting software optimizes material use and reduces scrap in tube cutting operations. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.