Strategies to Overcome Limitations of Traditional Cutting Techniques

Your production line is bottlenecked by slow, wasteful cutting methods. This inefficiency eats into your profits and competitive edge. Modern strategies integrating smart technology offer a clear path to higher productivity.

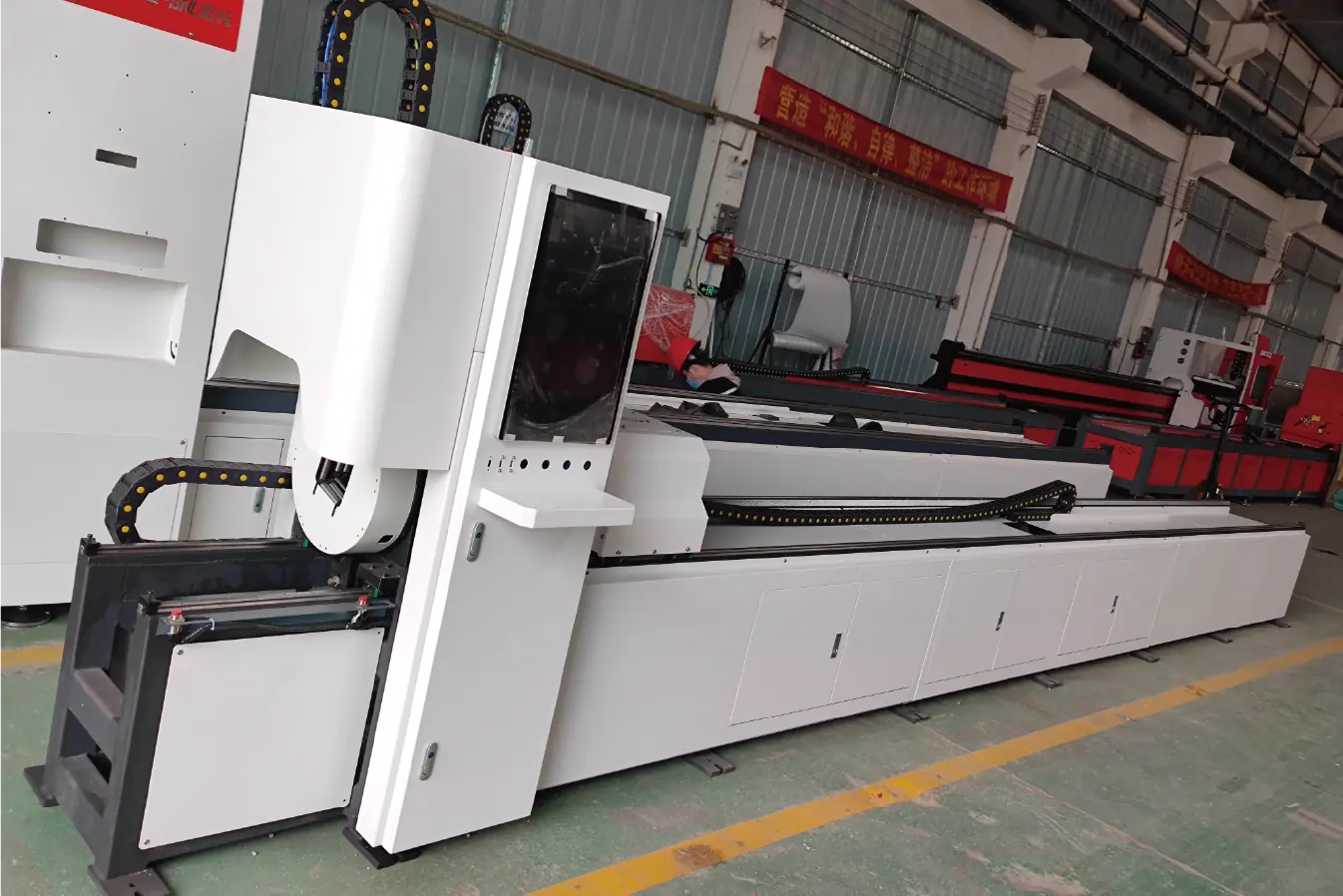

The most effective way to overcome traditional cutting limitations is by adopting advanced laser tube cutting machines. These solutions integrate automation, simplify operations with systems like our No-CAD interface, and eliminate material waste, directly boosting efficiency, quality, and profitability for your manufacturing business.

I've walked through countless factories over the years and seen the same struggles time and again: skilled operators spending hours on setup, piles of wasted material, and production schedules constantly at risk. It’s a frustrating cycle. But I've also seen the incredible transformation that happens when a business decides to move beyond these outdated methods. The shift isn't just about a new machine; it's about a new way of thinking. Let’s dive into the specific limitations of the old ways and explore the powerful strategies available to you today.

What are the historical limitations of traditional cutting techniques?

Manual saws and punches were once the industry standard. But they were slow, often inaccurate, and demanded highly skilled operators. Understanding these historical flaws highlights why today's technological evolution is so necessary.

Historically, traditional cutting techniques like sawing, drilling, and punching were severely limited by low precision, slow processing speeds, significant material waste from burrs and tailings, and a heavy reliance on highly skilled operators for every task.

When I first entered this industry, the sound of the workshop was defined by manual labor. We relied on band saws, drills, and mechanical punch presses. Each step was a separate, time-consuming process that introduced a new opportunity for error. An operator had to manually measure and mark a tube, carry it to the saw, make the cut, then move it again to a drill press for holes, and finally to a grinding station to remove the sharp burrs. This multi-stage workflow was not only slow but also physically demanding. The quality of the final product depended entirely on the operator's experience and focus on that particular day. A slight miscalculation in measurement or an unsteady hand could result in a scrapped part, wasting both valuable material and precious time. Furthermore, the skill required to operate these machines effectively was developed over years, creating a knowledge gap that was difficult and expensive to fill. These historical constraints—the reliance on manual skill, the inherent imprecision, and the fragmented workflow—are the very problems we at MZBNL set out to solve from day one.

How do traditional cutting techniques impact production efficiency today?

Is your production line constantly bottlenecked by the cutting station? These delays lead to missed deadlines and lost contracts. Identifying how old methods slow you down is the first step to a solution.

Today, traditional cutting techniques cripple efficiency by creating production bottlenecks, inflating labor costs due to manual handling and multi-step processes, and causing significant downtime for tool changes, directly reducing overall output and profitability.

The impact of these outdated methods on a modern production floor is profound. Think about the total time it takes to get a finished part. With traditional techniques, you're not just measuring the cutting time; you're measuring the time spent loading heavy tubes, clamping them, changing saw blades or punch dies for different jobs, and moving semi-finished parts between workstations. Each of these steps is a non-value-added activity that halts production flow. I once consulted for a furniture manufacturer who was struggling to meet a large order. We discovered their cutting department was the primary bottleneck. Operators spent nearly 40% of their time just loading and unloading material from their old side-loading machines. This is precisely why we developed our Front-Feeding Innovation. By automating the loading process from the front, we reduce operator labor intensity by about 40% and increase feeding efficiency by a similar margin. This turns a major time sink into a smooth, continuous operation, effectively breaking the bottleneck and allowing the rest of the production line to run at its full potential. It proves that efficiency isn't just about cutting faster; it's about working smarter.

What challenges do manufacturers face with outdated cutting methods?

Finding and retaining skilled labor is harder than ever. Relying on outdated methods that require deep expertise makes your business vulnerable to workforce shortages. Modern systems reduce this dependency and empower your team.

Manufacturers using outdated methods face critical challenges, including a severe shortage of skilled operators, high material waste that inflates costs, inconsistent quality control, and an inability to quickly adapt to custom orders or complex designs.

In my conversations with factory owners around the world, from Southeast Asia to North America, the same challenges with old technology come up again and again. These aren't minor inconveniences; they are fundamental threats to a business's viability in a competitive market.

The Skilled Labor and Training Gap

The biggest challenge I hear about is the struggle to find operators who can read complex technical drawings and program machines. When you rely on traditional methods, you're not just buying a machine; you're committing to finding, training, and retaining a highly specialized employee. This is why we pioneered our No-CAD System. We wanted to break the dependency on specialized skills. Our system allows an operator to process standard tubes simply by inputting parameters like length and hole position directly into the interface. This transforms a 15-day training process for a CAD-based machine into a single day of learning. It empowers any member of your team to become a productive operator almost immediately.

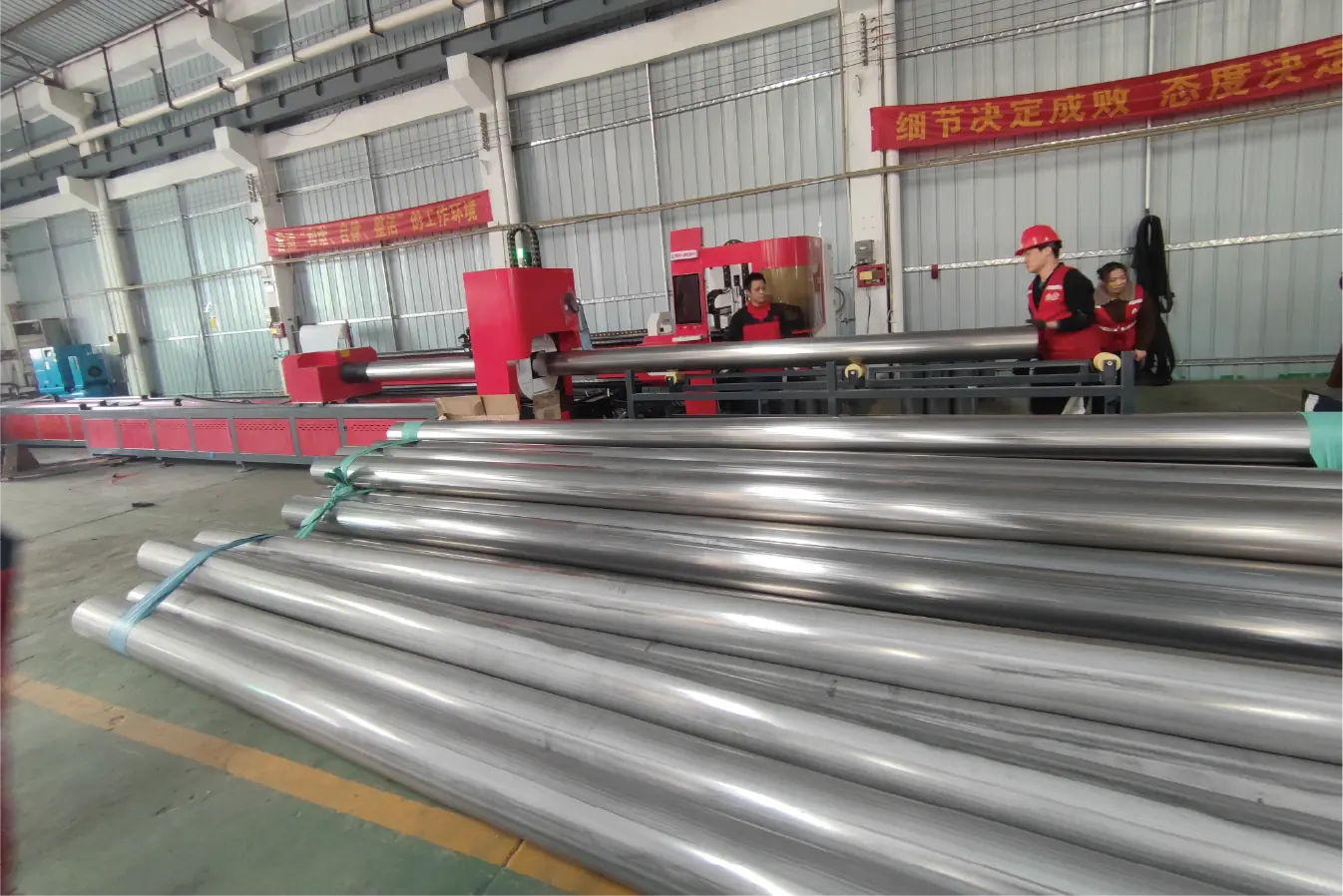

The Unacceptable Cost of Material Waste

Material is one of the largest costs in metal processing. Traditional cutting, especially with saws, inherently creates waste. The biggest culprit is often the "tail material"—the last unusable piece of the tube held by the chuck. For many businesses, this adds up to thousands of dollars in scrapped material each year. Our Zero-Waste Tail Material technology directly solves this. By redesigning the machine's logic to allow the front chuck to pass through the rear chuck, we can cut the entire length of the tube. We effectively turn that final piece from scrap into a usable part, maximizing material utilization and directly boosting your bottom line.

What innovative strategies can address these challenges?

You know you need to innovate to stay competitive. But choosing the right strategy can feel overwhelming. The solution is to focus on three key areas: simplifying process, automating handling, and optimizing material.

Innovative strategies include adopting integrated machines to consolidate process steps, implementing user-friendly systems that lower the skill barrier, and utilizing smart automation for material handling and cutting logic to maximize both efficiency and yield.

Overcoming these challenges requires more than just a faster machine; it demands a holistic strategy. At MZBNL, we've built our entire philosophy around providing a complete solution that addresses the core weaknesses of traditional manufacturing. It’s a three-pronged approach that I've seen deliver transformative results for our 4000+ clients.

-

Strategy 1: Radically Simplify the Workflow. The first step is to remove unnecessary complexity. The traditional process of taking a design from an engineer's desk to the shop floor is slow and prone to error. Our No-CAD System is the cornerstone of this simplification. It empowers the operator on the floor to execute standard jobs without ever needing a 3D drawing. This accelerates production, reduces the chance of misinterpreting drawings, and makes your operation far more agile.

-

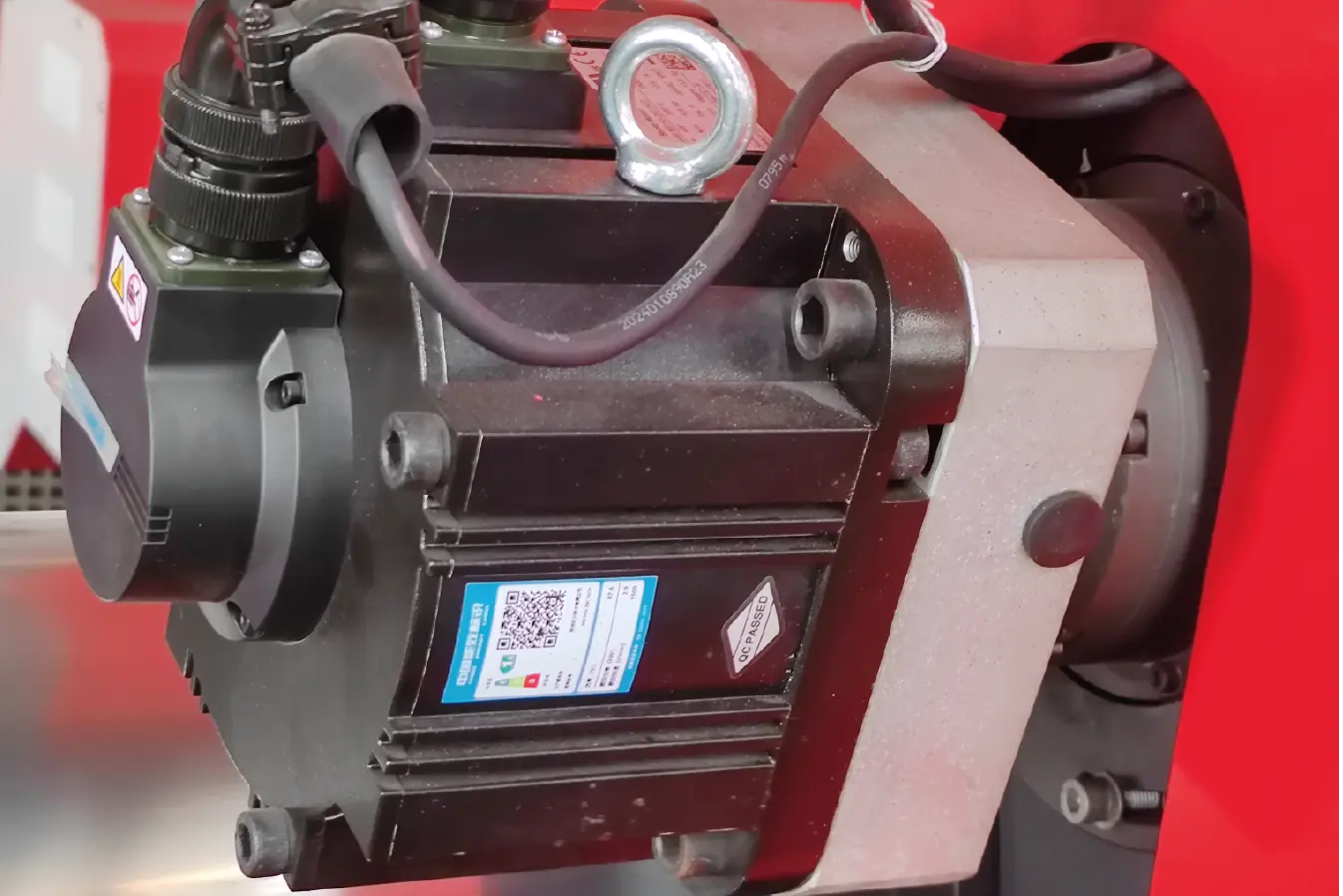

Strategy 2: Automate Repetitive and Labor-Intensive Tasks. Manual material handling is inefficient, unsafe, and a major source of operator fatigue. Our Front-Feeding Innovation is a strategic move to automate this crucial step. Instead of operators wrestling with long, heavy tubes, the system does the work. This not only speeds up the cycle time but also creates a safer, more ergonomic work environment, which helps with employee retention.

-

Strategy 3: Engineer Waste Out of the Process. Waste is a direct drain on profitability. The most effective strategy is to design processes where waste is minimized or eliminated by default. Our Zero-Waste Tail Material technology is the perfect example. It's not an afterthought; it's a core part of the machine's design, ensuring that you get the most out of every single tube you purchase.

How can technology advancements improve cutting processes?

Technology is evolving at an incredible pace. Falling behind means losing your competitive edge. Embracing smart, digitalized cutting systems is the key to future-proofing your operations and unlocking new levels of performance.

Technology advancements, particularly in fiber laser cutting and smart digitalization, improve processes by delivering unparalleled precision, enabling high-speed production, integrating multiple operations into one machine, and providing data-driven insights for continuous optimization.

The leap from traditional cutting to modern laser technology is not just an incremental improvement; it's a complete paradigm shift. Advanced fiber laser systems offer a level of speed and precision that is simply unattainable with mechanical saws or punches. The laser beam cuts with no physical contact, which means there is no tool wear, no blade changes, and a perfectly clean, burr-free edge every time. This eliminates entire downstream processes like deburring, saving both time and labor. But the hardware is only half the story. The real revolution is in the smart, digitalized systems that control the process. These systems integrate all our innovations—No-CAD, Front-Feeding, and Zero-Waste—into a single, cohesive workflow. The difference is stark when you compare the old way with the new.

| Feature | Traditional Cutting Method | MZBNL's Modern Laser Cutting |

|---|---|---|

| Precision | Low to Medium (Operator dependent) | High (Micron-level accuracy) |

| Speed | Slow (Multiple manual steps) | Very High (Integrated, automated process) |

| Material Waste | High (Tailings, burrs, errors) | Near-Zero (Optimized cutting logic) |

| Skill Requirement | High (Years of experience needed) | Low (1 day of training) |

| Flexibility | Low (Long setup for new jobs) | High (Instant changeover for custom parts) |

This table clearly illustrates the technological advantage. By embracing these advancements, you are not just buying a machine; you are investing in a more agile, efficient, and profitable future for your business.

Conclusion

Moving beyond traditional cutting is a critical strategic decision. By focusing on simplifying operations with No-CAD systems, automating material handling, and engineering waste out of the process, you can build a more resilient, competitive, and profitable manufacturing business for the future.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.