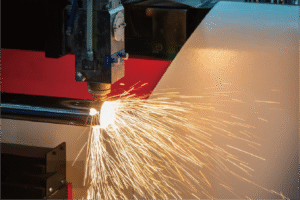

Steel Tube Laser Cutting Machine: Why It's a Must-Have

Struggling with slow, inaccurate metal tube cutting? Old methods waste material and require highly skilled operators, hurting your bottom line and production speed in a competitive market.

A steel tube laser cutting machine is a must-have because it delivers unmatched precision, speed, and automation. It drastically reduces material waste, lowers labor costs, and integrates multiple processes, providing a significant competitive advantage in modern manufacturing for industries from automotive to furniture production.

I've been in this industry for a long time, and I've seen countless workshops transform their operations almost overnight. The shift from traditional saws and drills to advanced laser cutting isn't just an equipment upgrade; it's a fundamental change in how you approach production. It’s about moving faster, smarter, and more profitably. Let's dive into exactly why this technology has become so essential for any modern metal processing factory.

What Are the Key Benefits of Using a Steel Tube Laser Cutting Machine?

Are production bottlenecks and material waste eating into your profits? Traditional cutting methods are often slow, imprecise, and costly, limiting your factory's true potential and growth.

The key benefits are superior precision, high-speed processing, and significant material savings. It automates complex cuts, reduces the need for secondary finishing, and enables design flexibility, leading to higher quality products and a more efficient, cost-effective production line.

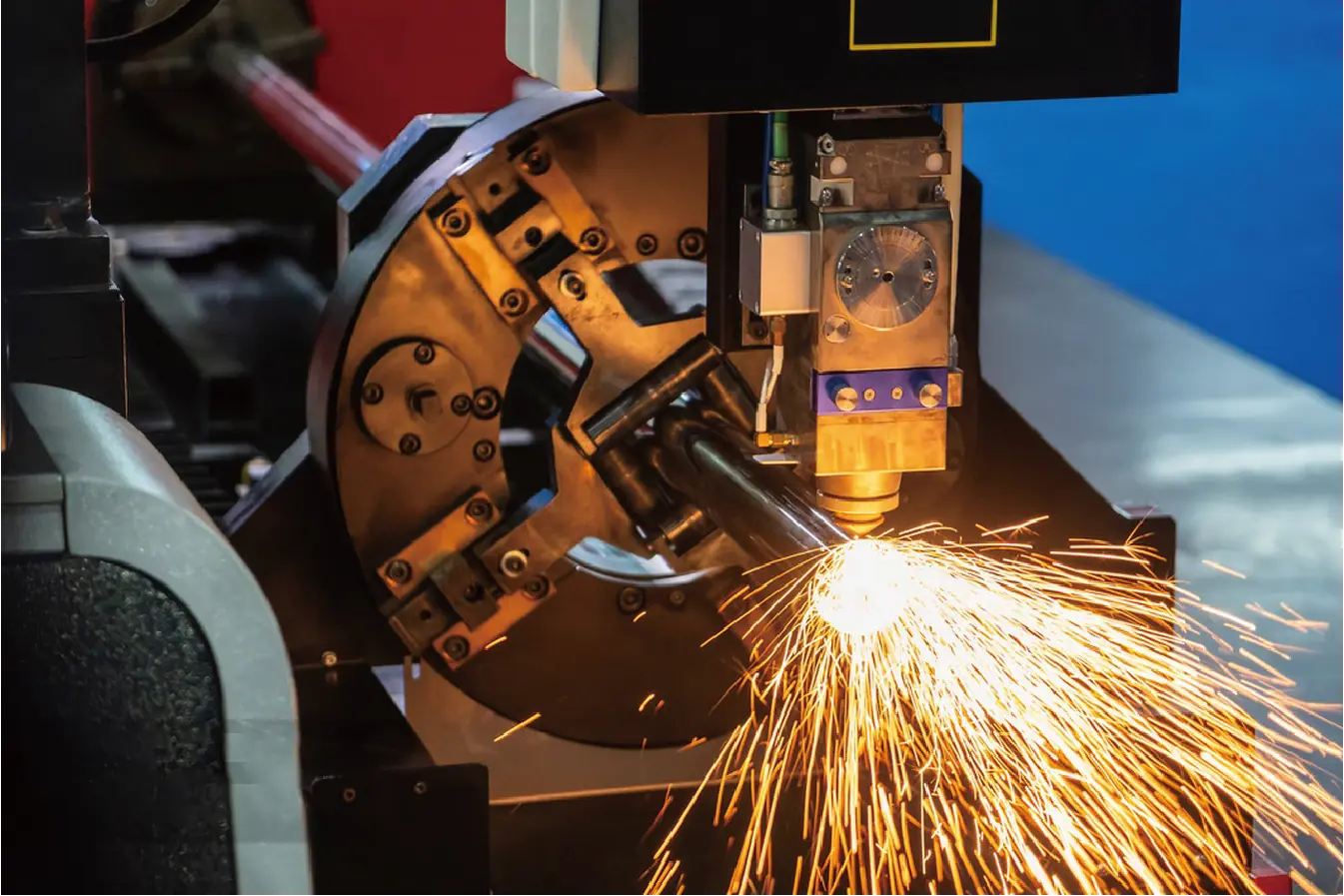

A New Standard for Quality and Efficiency

When I talk to factory owners, their core challenges are almost always the same: cost, quality, and speed. A steel tube laser cutter directly addresses all three. The benefits aren't just marginal improvements; they represent a complete overhaul of what's possible on the production floor. Let's break down the most impactful advantages I've seen our clients experience.

- Unmatched Precision and Quality: A laser beam doesn't wear down like a saw blade. It delivers perfect, clean cuts every single time, with tolerances that are impossible to achieve manually. This means less scrap, fewer rejected parts, and a higher quality end-product, which is critical for sectors like medical equipment and automotive parts.

- Incredible Speed: A laser cutting machine can cut, drill, and notch a complex part in the time it would take a worker to simply set up for a single cut on a traditional saw. This massive increase in throughput means you can take on more jobs and deliver them faster.

- Drastic Material Savings: This is where we at MZBNL have focused our innovation. Traditional cutting often leaves a significant piece of "tail material" that gets thrown away. Our Zero-Waste Tail Material innovation redesigns the cutting logic. By having the chucks work together to start the cut from the rear, we can process the entire length of the tube. For our clients, this translates to thousands of dollars in saved material costs each year. It’s a simple change in logic with a huge financial impact.

What Challenges Do Manufacturers Face Without a Steel Tube Laser Cutting Machine?

Facing inconsistent quality and high labor costs? Depending on manual cutting and multiple machines creates production delays, drives up expenses, and makes it hard to stay competitive.

Without a laser cutter, manufacturers face high material waste from inaccurate cuts, significant labor costs due to manual processes, and production bottlenecks from slow, multi-step operations. They also struggle with design limitations, inconsistent quality, and a long time-to-market.

The Hidden Costs of Outdated Methods

Before adopting modern technology, many factories are fighting an uphill battle they don't even fully recognize. The costs of "the old way" are often hidden in wasted time, wasted material, and the constant search for skilled workers. From my experience visiting hundreds of facilities, the challenges are severe and systemic.

First, there's the skilled labor dependency. Finding, training, and retaining an operator who can accurately read complex drawings and manually set up a machine is incredibly difficult and expensive. This is the single biggest bottleneck I hear about. To solve this, we developed our No-CAD System. Instead of needing a highly trained engineer to create 3D drawings, an operator can simply input parameters like length and hole position directly into the machine for standard tubes. We've reduced on-site training from 15 days to just one. This empowers the existing workforce and solves the skilled labor shortage head-on.

Second is the problem of process inefficiency. A typical workflow involves cutting a tube on a saw, moving it to a drill press for holes, then to a deburring station. That's three machines, three setups, and a lot of manual handling. This multi-step process is slow, introduces opportunities for error at each stage, and clutters the workshop. A laser tube cutter consolidates all these steps into one seamless, automated operation.

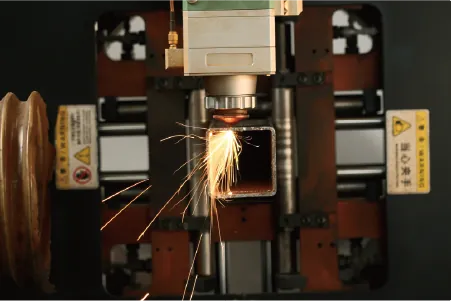

How Does a Steel Tube Laser Cutting Machine Improve Production Efficiency?

Are slow cycle times and excessive manual labor holding your factory back? Relying on outdated processes means you're not meeting demand or maximizing your operational capacity effectively.

A steel tube laser cutter boosts efficiency by integrating multiple steps—like cutting, drilling, and marking—into one automated process. This drastically reduces cycle times, minimizes material handling, and allows for continuous operation, directly increasing throughput and factory output.

From Manual Labor to Automated Throughput

Efficiency isn't just about cutting faster; it's about optimizing the entire workflow from raw material to finished part. This is where automation becomes a game-changer. A laser tube cutter is the heart of an efficient production line, but the real magic happens when you automate the processes around it, especially material handling.

I remember visiting a client in the furniture industry who was struggling to keep up with orders. Their cutters were fast, but the operators spent most of their time loading heavy bundles of tubes. It was slow, exhausting, and a major safety concern. This is why we pioneered our Front-Feeding Innovation. Instead of traditional side or rear loading, which is cumbersome, our system automatically loads tubes from the front. It’s a seemingly small change, but the impact is massive. We've measured a ~40% increase in feeding efficiency and a ~40% reduction in operator labor intensity. One operator can now comfortably manage multiple machines, because the machine does the heavy lifting. This doesn't just speed up production; it creates a safer, less strenuous work environment and allows you to reallocate your valuable human resources to more complex tasks.

What Solutions Does a Steel Tube Laser Cutting Machine Offer for Common Manufacturing Issues?

Worried about product quality, high costs, and slow turnarounds? These common manufacturing headaches can damage your reputation and profitability in a very competitive global market.

It solves issues by ensuring perfect repeatability for high-quality consistency, minimizing scrap with precise cuts to lower material costs, and enabling rapid prototyping and production to shorten lead times. It directly addresses the core problems of waste, inconsistency, and inefficiency.

Solving Problems at Their Core

A laser tube cutter isn't just a piece of equipment; it's a problem-solving tool. It provides direct, technological solutions to the most persistent issues that plague metal fabrication shops. Let's look at a few common problems and how this technology provides the answer.

| Common Manufacturing Issue | How a Laser Tube Cutter Solves It |

|---|---|

| Inconsistent Product Quality | The process is digitally controlled. Every cut is identical to the last, ensuring perfect repeatability. This is vital for industries like automotive or medical equipment where tolerances are non-negotiable. |

| High Material Costs | Our Zero-Waste Tail Material innovation is the perfect example. By eliminating the tail end scrap, it directly cuts down on raw material expenses. The precision of the laser also allows for tighter nesting of parts, further reducing waste. |

| Long Lead Times | Changing a design on a laser cutter is as simple as loading a new file. There are no physical tools or jigs to reconfigure. This allows for rapid prototyping and quick pivots in production, enabling you to respond to customer demands with incredible agility. |

| High Labor Costs | With our No-CAD System, you no longer need to hire expensive CAD specialists for every job. With our Front-Feeding Mechanism, one operator can do the work of several. The technology reduces your reliance on both skilled and manual labor. |

What Are the Best Practices for Integrating a Steel Tube Laser Cutting Machine Into Your Production Line?

Ready to upgrade but unsure how to start? Integrating new technology can seem daunting, and a poor transition can disrupt your entire workflow and negate the intended benefits.

Best practices include analyzing your current workflow to identify bottlenecks, choosing a machine with user-friendly software like a No-CAD system, and planning for automated material handling. Proper operator training and a phased integration approach are crucial for a smooth transition.

A Roadmap for Successful Integration

Bringing a laser tube cutter into your facility is a major step, and doing it right is key to maximizing your return on investment. Over the years, I've helped over 4,000 clients with this process, and I've learned that a successful integration follows a clear path.

Step 1: Analyze Your Current Workflow

Before you even look at machines, map out your existing production process. Where are the delays? Is it in the cutting, the material handling, or the secondary processing? Understanding your specific bottlenecks will help you choose a machine with the right features to solve your biggest problems.

Step 2: Prioritize Simplicity and Ease-of-Use

The most advanced machine in the world is useless if your team can't operate it efficiently. This is why a key "best practice" is to invest in technology that empowers your current staff. Our No-CAD System is a perfect example. By allowing operators to cut standard tubes just by entering parameters, it dramatically lowers the learning curve and makes your team productive from day one.

Step 3: Plan for Full Automation

Don't just think about the cutting machine in isolation. Think about the entire flow of material. How will tubes get to the machine? How will finished parts be removed? Planning for an automated system like our Front-Feeding Mechanism from the start will ensure your new machine is never waiting for material. A well-planned layout is essential for unlocking maximum efficiency.

Conclusion

A steel tube laser cutting machine is no longer a luxury; it's a necessity for competitive manufacturing. It boosts precision, efficiency, and material savings. By embracing innovations like No-CAD systems, automated feeding, and zero-waste cutting, you secure a powerful competitive edge for your business.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.