Типы станков для резки металлических труб: Лазерная, пильная, плазменная, сравнительная

Many metal fabrication businesses struggle with outdated tube cutting methods, leading to inefficiency and high waste. Imagine the frustration of manual processes or limited machine capabilities. I’m here to guide you through advanced solutions that optimize production and transform your operations.

Metal tube cutting relies on laser, saw, and plasma technologies, each offering distinct characteristics for precision, speed, and material handling. Laser cutting provides high accuracy for various metals, while saws offer robust solutions for thick sections, and plasma excels in speed for conductive materials.

Choosing the right metal tube cutting machine is pivotal for any fabrication business aiming for efficiency and profitability. As Eric Liu from MZBNL, I understand these challenges firsthand. We've spent 25 years in this industry, observing countless operations, including those of clients like Ahmed in the UAE, who constantly seek superior technological solutions to elevate their production capabilities.

The landscape of metal tube cutting is incredibly diverse, yet many businesses still grapple with finding the optimal technology for their specific needs. From the precise, automated capabilities of modern laser systems1 to the brute force of traditional sawing and the rapid cutting of plasma, each method presents unique trade-offs in terms of capital investment, operational efficiency, and the quality of the final cut. I've witnessed companies, including some of our 4000+ global clients, transform their production lines by strategically adopting the right technology. This isn't just about cutting; it's about integrating processes, reducing waste, and empowering operators, echoing MZBNL's commitment to technological innovation and tailored solutions. Let's delve into these core technologies and see how they stack up.

What are the main characteristics of laser, saw, and plasma cutting machines for metal tubes?

Are you struggling to achieve consistent quality or high throughput with your current tube cutting methods? Inaccurate cuts and slow production can severely impact your bottom line. Discover the defining features of laser, saw, and plasma cutting technologies to identify the right solution for your unique fabrication challenges.

Laser tube cutters offer high precision for complex geometries and various metals. Saw cutting excels in speed for thick, large-diameter tubes. Plasma cutting provides rapid, cost-effective processing for conductive metals, albeit with less precision than laser.

Understanding the fundamental characteristics of each cutting method is the first step toward informed decision-making. I've seen firsthand how crucial this knowledge is, especially for discerning clients like Ahmed, who scrutinize every detail to ensure their investment aligns perfectly with their expanding business in architectural metalwork and vehicle parts. For him, a machine's ability to deliver consistent, high-quality output while integrating seamlessly into existing workflows is paramount. My goal here is to give you the clarity you need, moving beyond general descriptions to highlight the specific nuances that truly differentiate these technologies in real-world applications and how they can address pain points like the need for skilled CAD operators or high operator turnover.

Laser Cutting: Precision, Versatility, and Automation

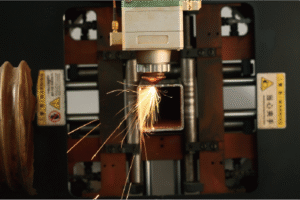

Laser cutting for metal tubes represents the pinnacle of precision and versatility in modern fabrication. Utilizing a focused high-power laser beam, typically CO2 or fiber laser, these machines melt or vaporize material along the cutting path, resulting in extremely clean edges with minimal heat-affected zones (HAZ). One of the most significant advantages is their ability to cut complex shapes, intricate patterns, and precise holes in various metals, including stainless steel, carbon steel, aluminum, and even copper alloys, with exceptional accuracy—often within ±0.05 mm. This level of precision is critical for industries like automotive, medical equipment, and high-end furniture, where fit and finish are paramount. The non-contact nature of the process means there is no tool wear, which significantly contributes to consistent quality over long production cycles and reduces consumable costs associated with physical blades.

Furthermore, modern laser tube cutting machines are highly automated, often featuring automatic loading and unloading systems, intelligent nesting software, and sophisticated control interfaces. At MZBNL, we've pushed this automation further with our patented No-CAD Operating System. I remember a client, much like Ahmed, who initially struggled with the extensive CAD training required for their legacy machines. With our system, operators can process standard tube types and hole patterns by simply entering parameters, eliminating the need for complex 3D drawings. This innovation dramatically reduces the skill threshold and setup time, bringing operator training down from 15 days at the equipment factory to just one day on-site, directly addressing a common pain point of high operator turnover and retraining burdens. This digitalized approach transforms traditional workflows, making advanced technology accessible even to small-to-mid-sized operations.

The versatility extends beyond material type to tube shapes, including round, square, rectangular, oval, and even irregular profiles. The ability to perform multi-process integration—cutting, punching, and notching—in a single setup streamlines production, reducing the need for multiple machines and manual repositioning. While the initial investment in a high-quality laser tube cutting machine can be substantial, its long-term cost-effectiveness is realized through material savings (especially with innovations like MZBNL's Zero-Waste Tail Material system, which maximizes utilization by cutting from the rear chuck), reduced post-processing, and superior output quality. This technology is ideal for high-volume, high-precision manufacturing environments where customization and flexibility are key, offering a competitive edge for companies like Ahmed's that are expanding into diverse sectors like architectural metalwork and vehicle parts.

Saw Cutting: Robustness and Material Thickness

Saw cutting, encompassing technologies like cold saws, band saws, and friction saws, offers a robust and often more economical solution for processing metal tubes, particularly for thicker wall sections and larger diameters. Cold saws, using solid carbide or HSS blades, provide clean, burr-free cuts with minimal heat generation, making them suitable for high-quality finished products without extensive secondary operations. Band saws, on the other hand, are versatile for cutting a wide range of materials and profiles, often at a lower initial cost, albeit with slower cutting speeds and potentially more burr. Friction saws, utilizing high-speed abrasive blades, are effective for rapid cutting of very thick materials, though they generate significant heat and leave a rougher edge, often necessitating secondary finishing.

The primary characteristic of saw cutting is its mechanical nature, involving direct contact between the blade and the material. This makes it highly effective for thick-walled tubes and solid bars where laser power might be insufficient or too slow, and plasma precision inadequate. For instance, in structural applications, heavy machinery parts, or the initial processing of raw stock, saw cutting remains a staple. While not as precise as laser cutting for intricate designs or small holes, modern CNC saw machines can achieve respectable accuracy for straight cuts and angled cuts, often within ±0.2 mm. The initial capital outlay for a saw machine is generally lower than for a laser system, making it an attractive option for businesses with limited budgets or specific demands for heavy-duty material processing that prioritize raw cutting power over intricate detail.

However, saw cutting does have operational considerations. Blade wear is a continuous factor, requiring regular replacement and resharpening, which adds to recurring costs and downtime. The mechanical nature can also induce vibrations, potentially affecting cut quality if the machine is not robustly designed or properly maintained. From my discussions with clients, particularly those in large-scale construction or raw material supply, saw cutting forms the backbone of their initial tube processing due to its cost-effectiveness for straightforward cuts. Despite its limitations in complexity and the need for more post-processing compared to laser, its reliability for high-volume, straightforward cuts in demanding materials ensures its continued relevance in the industry, particularly where precision tolerances are not as strict as those required for automotive or medical components.

Plasma Cutting: Speed and Cost-Effectiveness for Conductive Metals

Plasma cutting utilizes a superheated, electrically ionized gas (plasma) to melt and expel molten material, making it an incredibly fast and cost-effective method for cutting any electrically conductive metal, including steel, stainless steel, aluminum, brass, and copper. The process involves creating an electrical arc between an electrode and the workpiece, which superheats gas (like compressed air, oxygen, or nitrogen) to temperatures exceeding 20,000°C. This high-velocity plasma stream quickly slices through metal, making it particularly efficient for rapid material breakdown and initial profiling where extreme precision isn't the highest priority. The speed of plasma cutting can be significantly higher than mechanical cutting for certain thicknesses, allowing for greater throughput in high-volume production environments.

Its key characteristic is speed, especially on medium to thick materials where laser cutting would be slower and more energy-intensive. Plasma cutting machines are less expensive to acquire than laser systems, and their running costs can be lower for certain applications due to less expensive consumables (electrodes and nozzles compared to laser optics), making them a popular choice for job shops, fabrication facilities, and businesses like Ahmed's, which might need to process large volumes of material quickly for architectural elements or vehicle frames where rougher edges are acceptable. While the cut quality is generally rougher than laser, with a wider kerf and more significant HAZ (Heat Affected Zone), modern plasma systems with high-definition plasma technology have significantly improved edge quality and angularity, reducing the need for extensive post-processing in many applications, bridging the gap between conventional plasma and laser quality.

One challenge with plasma cutting is the potential for dross and slag, which may require secondary cleanup operations, especially for aesthetic or precise assembly applications. Ventilation systems are also critical due to the fumes generated and noise levels can be considerable. Despite these, for high-speed cutting of large-diameter tubes or thick plates where intricate details are less crucial than throughput, plasma cutting offers an unparalleled balance of speed and cost-efficiency. I've observed companies using plasma primarily for initial breakdowns before more precise operations, or for structural components where slight imperfections are acceptable. It stands as a vital tool in the metal fabrication arsenal, bridging the gap between the ultra-precision of laser and the robust capacity of sawing, providing a middle ground for businesses seeking rapid production without the higher capital outlay of a laser system.

| Характеристика | Laser Cutting | Saw Cutting | Plasma Cutting |

|---|---|---|---|

| Точность | Excellent (±0.05 mm typical) | Good to Fair (±0.2 mm typical) | Fair to Good (±0.5 mm typical) |

| Скорость | High (especially for thin-medium materials) | Moderate to High (for thick materials) | Very High (for conductive materials) |

| Материал | Wide range (carbon steel, stainless, aluminum, copper, brass) | Wide range (ferrous & non-ferrous, solid/hollow) | Conductive metals (steel, stainless, aluminum, etc.) |

| Edge Quality | Very clean, minimal HAZ, smooth | Clean (cold saw), rougher (friction saw) | Rougher, dross, significant HAZ |

| Сложность | High (intricate shapes, holes, 3D cuts) | Limited (straight, angled cuts, basic profiles) | Moderate (can cut complex shapes, holes) |

| Первоначальная стоимость | High (e.g., $150,000 - $1,000,000+) | Low to Moderate (e.g., $5,000 - $100,000+) | Moderate (e.g., $30,000 - $200,000+) |

| Операционные расходы | Moderate (gas, electricity, optics) | Moderate (blades, power, lubrication) | Moderate (consumables, power, gas) |

| Автоматизация | High (auto loading, nesting, No-CAD systems) | Moderate (CNC available, semi-auto loading) | Moderate (CNC available, auto torch height) |

Laser cutting offers highest precisionПравда

Laser cutting achieves ±0.05 mm accuracy, superior to saw and plasma methods, making it ideal for intricate designs.

Saw cutting requires no consumablesЛожь

Saw blades wear out and require regular replacement, unlike laser systems which have non-contact cutting.

How do efficiency and cost compare among laser, saw, and plasma tube cutters?

Are spiraling production costs and sluggish output hindering your metal fabrication business? Inefficient tube cutting can directly impact your profitability and project timelines. Let’s unravel the efficiency and cost dynamics of laser, saw, and plasma technologies to reveal where true value lies.

Laser cutting offers superior material utilization and reduced post-processing, yielding higher overall efficiency despite higher initial costs. Saw cutting is cost-effective for large, simple cuts. Plasma provides rapid throughput for conductive materials at a lower per-cut cost for specific applications.

Beyond the technical characteristics, the true measure of a cutting machine's worth lies in its operational efficiency and overall cost-effectiveness. This is a critical discussion point I often have with clients like Ahmed, who continually evaluate their capital expenditures against long-term gains. He seeks solutions that not only cut well but also reduce labor intensity, minimize material waste, and integrate seamlessly with automation goals. My experience at MZBNL, developing systems like our Front-Feeding innovation that boosts efficiency by 40% and reduces labor by 40%, has shown me that true cost savings come from optimizing the entire production chain, not just the per-cut cost. Let's examine how these technologies stack up in terms of both direct and indirect costs.

Operational Efficiency: Speed, Automation, and Throughput

Operational efficiency is the cornerstone of profitability in metal fabrication. For laser tube cutting machines, high efficiency stems from their cutting speed, particularly for complex geometries2 and smaller diameters, coupled with advanced automation features. For example, a modern fiber laser can cut stainless steel tube at speeds significantly faster than traditional methods, often achieving up to 60 meters per minute for thinner walls. Beyond sheer speed, intelligent nesting software optimizes material usage, reducing scrap rates to near zero, especially when combined with MZBNL's Zero-Waste Tail Material innovation, which maximizes every inch of tubing by calculating from the rear chuck. This minimizes material expenditure, a significant cost factor. Furthermore, features like automatic bundle loaders, automatic clamping, and our BNL Front-Feeding mechanism, which boosts feeding efficiency by approximately 40%, drastically reduce idle time and operator intervention. The cumulative effect of these efficiencies means higher throughput per shift, allowing businesses to take on more projects and meet tighter deadlines, directly impacting their revenue.

In contrast, saw cutting machines, while robust for heavy-duty applications, often operate at slower speeds, particularly for thicker materials where multiple passes or slower feed rates are required. While some saw systems incorporate automatic feeding, their overall automation capabilities and ability to perform complex cuts are limited compared to laser. This means more manual handling, longer cycle times per part, and a greater reliance on human operators for setup and material management. This can lead to bottlenecks in high-volume production environments. However, for specialized applications like cutting large structural pipes for building frames, where the primary need is robust cutting capacity for thick walls rather than intricate designs, their efficiency is perfectly adequate. The simplicity of their operation can also be seen as an efficiency, requiring less specialized training for basic cuts, though for precise or complex angles, skilled operators are still essential.

Plasma cutting shines in speed, especially for rapid breakdown of thick, conductive materials where absolute precision isn't paramount. Its ability to quickly slice through various metals makes it highly efficient for initial processing or for components that will undergo further machining. While not as precise as laser, the rapid cutting speed means high throughput for simple cuts. However, its efficiency can be hampered by the need for secondary operations to clean up dross and achieve a smoother edge, which adds to overall production time and labor costs. Automated plasma systems, with features like automatic torch height control and CNC programming, do enhance efficiency, reducing manual adjustments. For clients like Ahmed, who balance volume with quality, plasma could be an efficient choice for large, less critical parts, while laser handles high-precision components, demonstrating that efficiency often requires a multi-technology approach rather than a one-size-fits-all solution.

Cost Structure: Initial Investment vs. Long-Term Value

The initial investment is a significant hurdle for many businesses, and here, a clear hierarchy emerges. Saw cutting machines generally represent the lowest capital outlay, with basic models costing as little as a few thousand dollars, making them accessible to small shops or as supplementary equipment. Plasma cutting machines sit in the mid-range, with advanced systems costing tens of thousands to hundreds of thousands of dollars. Laser tube cutting machines, particularly high-power fiber lasers with advanced automation, represent the highest initial investment, often ranging from hundreds of thousands to over a million dollars. For a business like Ahmed's, planning to automate existing manual workflows, this initial cost is heavily weighed against the long-term benefits and potential for business expansion, rather than just choosing the cheapest option.

However, focusing solely on initial purchase price can be misleading. Long-term value assessment must consider operating costs, maintenance, material utilization, and potential for increased revenue. Saw machines have lower initial costs but incur recurring expenses for blades, coolants, and more frequent maintenance due to wear and tear. Plasma systems require consumables like electrodes and nozzles, and electricity costs can be substantial, especially for higher power units, but these are generally less costly than laser optics. Laser cutting, while having a high upfront cost, offers remarkable long-term cost-effectiveness. Its precise cuts reduce material waste significantly (as demonstrated by MZBNL's Zero-Waste Tail Material innovation), and minimal HAZ often means less post-processing, saving labor and additional machinery costs. Furthermore, the longevity and reliability of well-maintained laser systems lead to lower total cost of ownership over their operational lifespan.

Considering the total cost of ownership (TCO), laser machines, despite their high initial price tag, often prove more economical in the long run for high-volume, high-precision applications. A study by a leading industry analyst suggested that over a five-year period, the TCO for a laser cutter in a high-production environment could be comparable to or even lower than alternative methods due to savings in material, labor (especially with reduced training thanks to systems like MZBNL's No-CAD), and post-processing. For a client like Ahmed, prioritizing high cost-performance ratio over low price, the ability to produce superior quality products more efficiently, expand into new markets (like vehicle parts supply), and potentially become a regional distributor with reliable technology makes the higher initial investment in a laser machine a strategic business decision, not merely an expense.

Return on Investment (ROI) and Market Competitiveness

The return on investment (ROI) for each cutting technology is deeply tied to the specific application and market demands. For businesses dealing with high volumes of standard, thick-walled tubing, a well-selected saw cutting machine can deliver a strong ROI relatively quickly due to its low initial cost and robust performance for its specific niche. Its value proposition is straightforward: reliable cutting of common profiles with minimal fuss. However, its market competitiveness can be limited if client demands shift towards intricate designs or higher precision. This might force companies to outsource specialized work, eroding profit margins and delaying project delivery, which was a pain point for Ahmed with long machine lead times.

Plasma cutting offers a compelling ROI for shops needing high-speed processing of conductive metals without the stringent precision requirements of aerospace or medical components. Its relatively lower capital cost compared to laser, combined with high throughput for specific tasks, allows for rapid payback periods. Companies specializing in general fabrication, structural steel, or large-scale architectural elements often find plasma to be an excellent investment. The ability to quickly process large sheets or tubes can significantly reduce turnaround times for contract-based fabrication services, directly contributing to increased profit models. However, its ROI can be diminished if post-processing for dross removal becomes excessive, adding hidden labor costs.

Laser tube cutting machines, while demanding a higher initial outlay, typically offer the most substantial long-term ROI for businesses focused on precision, versatility, and advanced fabrication. The capacity to produce highly complex, finished components with superior edge quality often commands higher prices and opens doors to more lucrative markets. For MZBNL's clients, including those in automotive or medical sectors, the ability to cut complex geometries, integrate multiple processes (like automatic punching), and ensure part consistency (a hallmark of our high-speed and high-precision cutting) means they can outbid competitors on complex projects, reduce rework, and build a reputation for quality. The ROI for a laser machine is not just measured in parts per hour, but in enhanced market competitiveness, client satisfaction from tailored solutions, and the potential for becoming an industry leader—something Ahmed considers when thinking about exclusive distribution rights. This comprehensive perspective on efficiency and cost is crucial for making a truly informed decision.

| Cost/Efficiency Factor | Laser Cutting | Saw Cutting | Plasma Cutting |

|---|---|---|---|

| Использование материалов | Excellent (minimal scrap, Zero-Waste Tail) | Good (can have more scrap for complex cuts) | Good (can have wider kerf, some waste) |

| Post-Processing Need | Low (clean cuts, minimal HAZ) | Moderate to High (burr, rough edges depending on type) | Moderate to High (dross, slag, HAZ) |

| Интенсивность труда | Low (high automation, No-CAD reduces skill needs) | Moderate (more manual handling, blade changes) | Moderate (some manual clean-up, consumables) |

| Consumables Cost | Moderate (optics, gas) | Moderate (blades, coolant) | Moderate (electrodes, nozzles, gas) |

| Потребление энергии | Moderate to High (power for laser) | От низкого до умеренного | High (power for plasma generation) |

| Частота технического обслуживания | Low to Moderate (precision components) | Moderate to High (blade wear, mechanical parts) | Moderate (torch/consumable replacement) |

| Revenue Potential | High (precision, complex parts, new markets) | Moderate (standard parts, high volume) | Moderate (fast production, specific applications) |

Лазерная резка уменьшает количество отходов материалаПравда

Laser cutting's precision and nesting software minimize scrap rates, especially when combined with innovations like Zero-Waste Tail Material.

Saw cutting is always cheaper than laserЛожь

While saw cutting has lower initial costs, laser cutting often proves more cost-effective long-term due to material savings, reduced labor, and higher throughput.

What are the advantages and disadvantages of using laser, saw, and plasma cutting machines?

Facing a dilemma in choosing the right metal tube cutting technology? Each option comes with its own set of benefits and drawbacks that directly impact your operations. Let's weigh the pros and cons of laser, saw, and plasma systems to simplify your decision-making process.

Laser cutting offers unmatched precision and versatility but at a higher cost. Saw cutting is cost-effective and robust for thick materials, yet lacks intricate capability. Plasma provides high-speed cutting for conductive metals but with lower precision and more dross.

Understanding the characteristics and comparing efficiency and cost is one thing; truly grasping the advantages and disadvantages for your specific business is another. This is where the rubber meets the road, impacting everything from your production lead times to your ability to take on diverse contracts. I’ve personally guided businesses, much like Ahmed’s in the UAE, through this very deliberation. He values a turnkey solution that's easy to install and operate, alongside robust after-sales support and customization. Weighing the pros and cons of each technology against these practical considerations is essential to avoid future pain points, such as the need for skilled CAD operators or the lack of local service support.

Laser Cutting: Precision, Versatility, and Cost

The advantages of станки для лазерной резки труб3 are numerous and compelling, making them a preferred choice for high-end fabrication. Foremost is their unparalleled precision. Modern fiber lasers can achieve cut tolerances of ±0.05 mm, producing extremely clean and accurate cuts with minimal burr or distortion. This precision is vital for industries where parts must fit together perfectly, such as in the assembly of furniture, automotive components, or medical devices. Furthermore, laser cutting offers exceptional versatility in terms of material type and thickness, capable of cutting carbon steel, stainless steel, aluminum, brass, copper, and even galvanized pipes, with consistent quality. The ability to cut complex geometries, intricate patterns, and fine details, including various hole shapes and slotting, in a single setup significantly expands design possibilities and product capabilities. For a client like Ahmed, expanding into architectural metalwork and vehicle parts, this versatility means he can meet diverse client demands without investing in multiple specialized machines.

However, laser cutting does come with notable disadvantages. The most significant is the high initial capital investment. A high-quality laser tube cutting machine with automated features can cost several hundred thousand to over a million US dollars, making it a substantial financial commitment for any business. While running costs can be optimized through efficient operations, the consumption of assist gases (like oxygen, nitrogen) and electricity, along with the eventual replacement of optics, can add up. Another potential drawback for some users is the perceived complexity of operation; while MZBNL has mitigated this with our No-CAD system4, traditional laser systems often require highly skilled operators trained in CAD/CAM software. The learning curve for optimizing cut parameters for various materials and thicknesses can also be steep. Moreover, laser cutting speed can decrease significantly for very thick materials, making it less efficient than saw or plasma for certain heavy-duty applications.

Despite these disadvantages, the long-term benefits often outweigh the initial hurdles, particularly for businesses focused on growth and quality. The elimination of secondary finishing operations due to clean cuts, the dramatic reduction in material waste (especially with our Zero-Waste Tail Material innovation), and the ability to automate processes like loading (our Front-Feeding system) and punching, lead to significant labor and material cost savings over time. For a business seeking to upgrade production efficiency and secure a competitive edge through high-quality, complex output, the laser tube cutting machine, despite its cost, represents a strategic investment that unlocks new opportunities and enhances overall profitability, enabling a higher cost-performance ratio that Ahmed seeks.

Saw Cutting: Accessibility, Robustness, and Limitations

The primary advantages of saw cutting machines for metal tubes are their relatively low initial cost and robust performance for straightforward, heavy-duty applications. For businesses with limited budgets or those primarily dealing with large volumes of thick-walled, standard-profile tubing, a saw machine provides an accessible entry point into automated cutting. Basic models can be acquired for a fraction of the cost of a laser or even advanced plasma system, making them a viable option for startups or small workshops. Their mechanical nature means they excel at cutting very thick materials, solid bars, and large-diameter pipes where the power requirements for laser or plasma might be excessive or inefficient. Saw cuts are often clean and precise for straight cuts, especially with cold saws, minimizing the need for extensive deburring in some cases.

However, saw cutting machines are not without their significant disadvantages. Their versatility for complex shapes and intricate designs is severely limited. They are primarily designed for straight or angled cuts, and cannot produce holes, slots, or intricate patterns in a single operation, requiring additional machinery (like an automatic punching machine) or manual processes for such features. This multi-step process adds to labor, increases potential for error, and extends production time. Blade wear is a constant concern, necessitating frequent blade changes or resharpening, which incurs ongoing consumable costs and causes machine downtime. The generation of chips and burrs, particularly with friction saws, often requires secondary cleanup operations, adding another layer of cost and labor.

Furthermore, while saw machines can be automated with CNC controls for feeding and positioning, their overall automation capability for lights-out manufacturing is generally less advanced than laser systems. They typically require more manual intervention for material loading and unloading, impacting labor intensity and overall throughput compared to highly integrated laser systems. For a customer like Ahmed, who is planning to automate existing manual workflows and desires multi-process integration, the limitations of saw cutting in terms of complexity and automation would mean he'd still face challenges with high operator turnover and the need for multiple machines, despite its lower initial price. Therefore, while saw cutting offers a cost-effective solution for simple, heavy cuts, its drawbacks in precision, versatility, and advanced automation can limit its long-term scalability and competitiveness for modern fabrication demands.

Plasma Cutting: Speed, Cost-Effectiveness, and Quality Trade-offs

Plasma cutting machines offer compelling advantages, primarily their high cutting speed and cost-effectiveness for processing a wide range of electrically conductive metals. They can cut through thick materials much faster than laser cutters and often at a lower operating cost per linear foot for specific applications, especially for metals like carbon steel and aluminum. The capital investment for a plasma system is generally lower than a laser machine, making it a more accessible option for many mid-sized fabrication shops or those focused on high-volume production of components where extreme precision is not the paramount concern. Their ability to handle various material thicknesses and types makes them versatile for general fabrication, structural steelwork, and initial material breakdown.

However, plasma cutting also comes with distinct disadvantages, mainly concerning cut quality and post-processing requirements. The cuts produced by plasma are typically rougher than those from a laser, with a wider kerf and a more pronounced Heat Affected Zone (HAZ). This often results in the need for secondary operations like grinding or deburring to remove dross and slag, adding labor, time, and cost to the overall production process. While high-definition plasma systems have improved quality, they still do not match the precision and smooth edge finish of laser cuts. Another drawback is the generation of significant fumes and noise during operation, necessitating robust ventilation systems and hearing protection for operators, which are additional operational considerations and costs.

Furthermore, plasma cutting is limited to electrically conductive materials, unlike laser, which can cut some non-metals (though not for the purpose of this blog post on metal tubes). The precision for intricate details, small holes, and complex contours is also lower compared to laser, which can be a critical limitation for industries requiring tight tolerances or aesthetic finishes, such as furniture or precision automotive parts. For a business like Ahmed's, which seeks high cost-performance and requires specific capabilities like automatic punching, a standalone plasma cutter might not offer the full turnkey solution he desires. While effective for rapid, rough cuts, the trade-off in quality and the need for subsequent operations mean that plasma cutting often serves as a complementary technology rather than a sole solution for diversified fabrication needs.

| Comparison Point | Laser Cutting (Advantages) | Laser Cutting (Disadvantages) | Saw Cutting (Advantages) | Saw Cutting (Disadvantages) | Plasma Cutting (Advantages) | Plasma Cutting (Disadvantages) |

|---|---|---|---|---|---|---|

| Точность | Unmatched accuracy (±0.05mm) | - | Cost-effective for straight cuts | Low for complex shapes, rougher burr | Fast for conductive metals | Lower precision, wide kerf |

| Универсальность | Cuts diverse materials, complex shapes | Slower for very thick materials | Robust for very thick, large materials | Limited to basic straight/angle cuts | Good for range of conductive metals | Limited to conductive materials |

| Автоматизация | High (auto loading, No-CAD, multi-process) | High initial cost | Lower initial cost | Lower automation compared to laser | High speed, good for rough cuts | Requires extensive post-processing (dross) |

| Cost | Low operating cost long-term (material savings) | - | Simplicity, ease of operation | High recurring costs (blades, maintenance) | Lower capital cost vs. laser | Higher operating costs (consumables, power) |

| Cut Quality | Clean, minimal HAZ, no post-processing | Potential for thermal distortion on thin tubes | - | Significant chip/burr generation | - | Significant HAZ, potential for material warping |

| Мастерство оператора | No-CAD system reduces skill threshold | Traditionally required skilled CAD operators | Relatively easy for basic operation | Requires blade changes, alignment | Relatively easy to operate | Requires consumable replacement, higher power consumption |

Laser cutting offers highest precisionПравда

Modern fiber lasers achieve ±0.05mm tolerances, making them ideal for precision components.

Saw cutting handles all material thicknesses equallyЛожь

While robust for thick materials, saw cutting becomes inefficient for very thin-walled tubes.

What factors should be considered when choosing between laser, saw, and plasma cutting technologies?

Feeling overwhelmed by the array of metal tube cutting technologies? Selecting the right machine isn't just about features; it's about aligning with your business goals and operational realities. Let's explore the critical factors you must consider to make an informed decision for long-term success.

Key factors include material type and thickness, desired cut precision and complexity, production volume, budget, and integration with existing workflows. Post-processing needs, operator skill requirements, and supplier support are also critical for an optimal choice.

Navigating the choices between laser, saw, and plasma technologies5 can feel like a complex puzzle, especially when your investment directly impacts your company's future growth and profitability. This is precisely the kind of strategic decision-making that clients like Ahmed Al-Farsi excel at, given his strong engineering background and hands-on approach. He's not just buying a machine; he's investing in a solution that must offer a high cost-performance ratio, integrate with his automation plans, and come with reliable post-sales training and support. My role, as Eric Liu from MZBNL, is to help you dissect these factors, drawing from our 25 years of experience in metal fabrication, to ensure your chosen technology doesn't just meet today's needs but also secures your competitive advantage for tomorrow.

Material Characteristics and Cut Specifications

The first and perhaps most fundamental factor in choosing a metal tube cutting machine is the specific characteristics of the materials you intend to process and the desired cut specifications. Different metals react uniquely to various cutting methods. For instance, carbon steel, stainless steel, aluminum, brass, and copper are all commonly cut, but their thermal and conductive properties dictate which technology is most efficient and produces the best quality. For high precision, complex cuts, and intricate designs on a wide range of materials (especially stainless steel and aluminum where thermal distortion is a concern), a laser tube cutting machine is often the superior choice. Its focused beam minimizes HAZ and produces exceptionally clean edges, essential for industries like furniture, sanitary ware, and medical equipment6 where aesthetic finish and tight tolerances are critical. Laser is also highly versatile for cutting different tube shapes—round, square, rectangular, oval—in varying wall thicknesses.

Conversely, for very thick-walled tubes, large diameters, or solid bars, saw cutting might be the most practical and cost-effective solution. While it lacks the intricate cutting capabilities of laser, its mechanical force excels at brute force cutting of heavy gauges. For instance, in structural applications or the initial breakdown of raw stock, a cold saw can provide clean, straight cuts without the immense power requirements of a laser for such thicknesses. On the other hand, if your primary need is high-speed processing of electrically conductive metals, particularly for larger volumes and less critical precision, plasma cutting becomes a strong contender. Plasma thrives on speed for materials like mild steel or aluminum, where surface finish is not the top priority or where secondary processing is acceptable. Understanding these nuances – material type, wall thickness (e.g., 2mm aluminum vs. 10mm steel), and the required edge quality (smooth vs. rough with dross) – is paramount. This initial assessment guides whether you lean towards the surgical precision of laser, the raw power of a saw, or the rapid efficiency of plasma for your specific applications, ensuring the technology aligns with the physical demands of your product line.

Ultimately, the desired cut precision and complexity are pivotal. If your projects demand extremely tight tolerances (e.g., ±0.05 mm), small intricate holes, or complex contours that integrate multiple features onto a single tube (like punching and notching), a laser tube cutting machine is indispensable. Our MZBNL laser tube cutting machines are designed for high-speed and high-precision cutting, offering the ability to integrate multi-process capabilities. This level of detail and quality is often required for high-value products or components that will undergo automated assembly. In contrast, if your parts are less complex—primarily straight cuts, simple angles, or basic shapes—and a tolerance of ±0.2mm or ±0.5mm is acceptable, then saw or plasma cutting might suffice. For example, for producing simple fence railings or basic display rack components, a robust saw or fast plasma cutter might be perfectly adequate. Critically evaluating the 'fit for purpose' of each technology against your product's technical specifications prevents overspending on unnecessary features or under-investing in crucial capabilities. This careful match between product requirement and machine capability is a hallmark of tailored solutions.

Production Volume, Budget, and Operational Integration

Beyond material and cut specifics, your anticipated production volume, available budget, and how the new machine integrates into your existing operational workflow are paramount. For high-volume production of complex parts that demand precision, a laser tube cutting machine often offers the best long-term ROI. While the initial investment is higher, its speed, automation capabilities (like automatic loading, intelligent nesting, and MZBNL's Front-Feeding system that increases feeding efficiency by 40%), and minimal post-processing needs translate into lower per-part costs and higher overall throughput. This efficiency is critical for meeting the demands of large enterprise clients and allows for rapid scalability. Conversely, if your production volume is low to moderate, or if you primarily handle simple, high-volume cuts of standard profiles, a saw machine might be a more budget-friendly and operationally appropriate choice, especially if manual labor is readily available and direct labor costs are low.

Budget allocation is not just about the purchase price but also includes installation, training, maintenance, consumables, and potential upgrades. A saw machine has the lowest initial cost, but consider the ongoing cost of blades, maintenance, and potential bottlenecks if demand for complex parts increases. Plasma cutting offers a middle-ground in terms of capital expenditure and can be highly cost-effective for rapid cuts where quality is not ultra-critical. However, consider the costs associated with dross removal and potential energy consumption. For laser machines, while the upfront cost is substantial, the long-term savings from reduced material waste (e.g., MZBNL's Zero-Waste Tail Material innovation), lower labor requirements due to automation (e.g., 1-day training with No-CAD system), and minimal post-processing often make the total cost of ownership more favorable over time, especially for high-value production. For Ahmed, who prioritizes a high cost-performance ratio and automation, this TCO analysis is crucial.

Finally, consider how the new machine will integrate into your existing workflow and the capabilities of your current staff. A key pain point Ahmed experienced was the need for skilled CAD operators and high operator turnover. MZBNL addresses this directly with our No-CAD Operating System, which dramatically lowers the skill threshold and training time, making our advanced laser machines easy to operate and maintain. This significantly reduces retraining burdens and allows existing staff to quickly adapt. Evaluate the availability of local service support, spare parts, and remote diagnostics—all critical components of post-sales training and support that Ahmed values. Choosing a supplier with a strong global distributor network and proven technology, like MZBNL with 30+ patents and 25 years of experience, ensures that your investment is supported long-term. A turnkey solution that provides training and reliable service mitigates risks and maximizes uptime, ensuring seamless integration into your facility and continuous, profitable operation.

Supplier Reliability and Post-Sales Support

Choosing the right machine is only half the battle; selecting a reliable supplier with robust post-sales support is equally, if not more, critical for long-term success. A machine, no matter how advanced, is only as good as the support system behind it. Key considerations here include the supplier's reputation, their experience in the industry, and their commitment to customer service. For instance, MZBNL's 25 years of experience in metal fabrication and our status as a high-tech enterprise with 30+ patents provide a strong indicator of our proven technology and reliability. Clients like Ahmed, who consider becoming regional distributors, prioritize suppliers with global references and a track record of delivering stable, long-term business relationships. Researching a supplier's history, their client testimonials, and their technological innovation portfolio (like our No-CAD, Front-Feeding, and Zero-Waste systems) can provide invaluable insights into their trustworthiness and capabilities.

Furthermore, the availability and quality of after-sales service and training support are paramount. Even the most user-friendly machine will eventually require maintenance, troubleshooting, or part replacement. A supplier with strong local agent or distributor presence, remote diagnostics capabilities, and readily available spare parts can significantly reduce downtime, which directly impacts your project delivery schedules—a common pain point for businesses with long machine lead times. For Ahmed, who has experienced a lack of local service support from previous suppliers, MZBNL's extensive export to Southeast Asia, Middle East, Europe, and North America, supported by global distributor networks, offers the reassurance he seeks. He expects customization and post-sales training/support, particularly regarding the ease of use of a No-CAD system and rapid problem resolution, which MZBNL excels at.

Finally, consider the supplier's commitment to continuous innovation and tailored solutions. A company that integrates R&D, manufacturing, sales, and service, like MZBNL, is typically better positioned to offer customized solutions that precisely fit your unique needs. They are more likely to understand specific industry challenges and adapt their technology accordingly. This dedication to innovation also means your machine will likely benefit from future software updates or hardware improvements, ensuring it remains competitive for years to come. For Ahmed, who is interested in co-branding options or exclusive distribution rights, a supplier's willingness to build a partnership demonstrates their long-term vision and commitment to mutual success, moving beyond a transactional relationship to a strategic alliance.

| Фактор | Laser Cutting Considerations | Saw Cutting Considerations | Plasma Cutting Considerations |

|---|---|---|---|

| Material Types | Broad range, excels on thin-medium metals, precise on all | Best for thick, large tubes/solids, ferrous/non-ferrous | Conductive metals only, good for medium-thick |

| Cut Precision | Highest precision, intricate details, minimal HAZ | Good for straight cuts, less for complex shapes | Moderate precision, wider kerf, more HAZ |

| Объем производства | High volume, complex parts, automated lines | Moderate to high volume for simple cuts | High volume for rougher cuts, fast |

| Budget | High initial investment, lower TCO for high use | Low initial investment, higher TCO for heavy use (blades) | Moderate initial investment, balanced TCO |

| Integration/Automation | High automation (No-CAD, auto-feeding), multi-process | Moderate automation, requires more manual handling | Moderate automation, integrates well with simple CNC |

| Мастерство оператора | Reduced with No-CAD, traditionally higher skilled | Relatively lower skill for basic cuts | Moderate skill, awareness of dross/fumes |

| Постобработка | Minimal to none | Often required (deburring, cleaning) | Often required (dross removal, grinding) |

| Послепродажная поддержка | Critical for complex tech, requires robust global network | Important for blade sourcing, general maintenance | Important for consumables, troubleshooting |

Laser is best for thin materialsПравда

Laser cutting excels with thin to medium thickness materials where precision is critical, as it minimizes heat-affected zones.

Saw cutting requires no post-processingЛожь

Saw cutting often requires deburring and cleaning as post-processing steps to achieve acceptable edge quality.

What are the expert recommendations for selecting the best tube cutting machine for specific applications?

With numerous options available, making the final choice for a metal tube cutting machine can be daunting. My expert recommendations, refined over 25 years in metal fabrication, will guide you toward the optimal technology tailored to your specific application needs and long-term business goals.

Expert recommendations prioritize laser cutting for high-precision, complex tasks across diverse materials, especially where automation is key. Saw cutting is recommended for robust, thick-material applications. Plasma is ideal for high-speed cutting of conductive metals with less stringent precision demands.

Having explored the characteristics, costs, advantages, and disadvantages of laser, saw, and plasma tube cutting machines, the final step is to synthesize this knowledge into actionable recommendations. My experience at MZBNL, working with thousands of global clients like Ahmed, has taught me that the "best" machine is always the one that perfectly aligns with a client's unique needs, pain points, and strategic vision. It's about finding a tailored solution that maximizes efficiency, minimizes waste, and provides a tangible return on investment. I'll now offer specific guidance, considering various application scenarios and how our innovations at MZBNL can provide a distinct competitive advantage.

Precision-Driven Industries: Automotive, Medical, High-End Furniture

For industries where precision, intricate designs, and flawless finishes are non-negotiable, such as automotive parts, medical equipment, and high-end furniture manufacturing, the unanimous expert recommendation leans heavily towards laser tube cutting machines. In these sectors, even a fraction of a millimeter in inaccuracy can lead to costly rejections, assembly issues, or functional failures. Laser technology, with its sub-millimeter precision (typically ±0.05 mm), minimal heat-affected zones, and ability to create complex contours, slots, and holes in a single, automated pass, ensures component integrity and aesthetic quality. For example, in automotive manufacturing, precise fitment of exhaust pipes or structural chassis components is critical for safety and performance; laser cutting consistently delivers this. Similarly, for medical device tubing, cleanliness and burr-free edges are paramount to prevent contamination or obstruction.

Moreover, these industries often demand versatility in handling various metals—from thin-walled stainless steel for medical instruments to high-strength alloys for vehicle frames—and the ability to transition quickly between different part geometries. Laser tube cutters excel here, allowing for rapid reprogramming and execution of diverse designs without extensive retooling. This agility is a significant advantage in industries characterized by evolving product designs and customized orders. I’ve seen firsthand how a company investing in a high-precision laser system can significantly reduce post-processing steps like deburring or grinding, which saves substantial labor costs and improves overall throughput. This streamlines production, ensuring parts are "right the first time," a critical factor for maintaining tight production schedules and controlling costs.

From MZBNL's perspective, our innovations specifically cater to these precision-driven demands. Our high-speed and high-precision cutting capabilities ensure that the strict tolerances required by automotive or medical clients are consistently met. The Zero-Waste Tail Material innovation contributes to significant material savings, critical when working with expensive, high-grade metals. More importantly, our No-CAD Operating System simplifies the creation of complex designs, drastically reducing the skill threshold for operators. I’ve spoken with manufacturers who previously struggled with training new CAD operators for weeks; with our system, they can train a new operator in just one day. This not only mitigates pain points like high operator turnover but also ensures consistent quality across shifts, positioning companies to thrive in competitive markets demanding both speed and unwavering accuracy.

Heavy Fabrication and Structural Applications: Construction, Agriculture, Infrastructure

When the application shifts towards heavy fabrication, structural components, and industries like construction, agriculture, and infrastructure, where the primary focus is on robust cutting of thick materials and large diameters, saw cutting machines are often the most practical and cost-effective expert recommendation. These sectors typically work with substantial wall thicknesses (e.g., 5mm to 20mm+ steel pipes) and often require straightforward, strong connections rather than intricate aesthetic designs. While precision is still important for assembly, the requirements are generally less stringent than in automotive or medical, with tolerances often in the range of ±0.2mm to ±0.5mm being acceptable. Cold saws, in particular, provide clean, straight cuts suitable for welding and structural integration.

The advantages of saw cutting in these heavy-duty scenarios are rooted in their mechanical strength and lower operating costs for brute force cutting. A large-diameter band saw or cold saw can efficiently process thick-walled tubing or solid bars that would be prohibitively slow or require immense power from a laser. While not as automated as advanced laser systems for complex tasks, modern CNC saw machines can offer automated feeding and precise angular cutting, which is often sufficient for structural components like support beams, columns, or agricultural equipment frames. The lower initial investment compared to a laser machine also makes saw technology highly attractive for businesses in these sectors that operate on tighter capital expenditure budgets but require significant cutting capacity for large-scale projects.

However, it's crucial to acknowledge the limitations and plan accordingly. Sawing will not create complex holes or intricate patterns, meaning that if your structural components also require detailed features, you would need to integrate an additional machine like a CNC punching machine or drill press into your workflow. This is a common approach in the industry, where a robust saw handles the main cut-to-length operations, and other machines handle secondary features. For companies focused solely on cutting raw stock to size for subsequent fabrication steps, the saw remains an indispensable and highly recommended tool. Its reliability and cost-efficiency for its specific niche make it a strong contender for foundational metal processing, allowing businesses to efficiently prepare material for the next stage of manufacturing or construction.

High-Speed General Fabrication and Cost-Sensitive Production: Fences, Shelving, General Parts

For applications in high-speed general fabrication, particularly for components like fences, railings, display racks, and shelving, or for any production where speed and cost-effectiveness for conductive metals are paramount, plasma cutting machines emerge as a strong expert recommendation. These industries often deal with medium-thickness materials and prioritize throughput over absolute precision, provided the cut quality is acceptable for the end-use. Plasma's ability to rapidly slice through steel, stainless steel, and aluminum with high velocity makes it exceptionally efficient for batch processing and quick turnaround times, which are crucial for contract-based fabrication services like those offered by Ahmed. The relatively lower capital cost compared to laser also makes plasma a more accessible investment for many mid-sized fabrication shops.

While plasma cuts are generally rougher and have a wider kerf than laser cuts, modern high-definition plasma technology has significantly improved edge quality, reducing the amount of post-processing needed. For many functional applications such as fence posts or shelving brackets, a clean but not surgically precise edge is perfectly adequate. The speed advantage of plasma means that a company can produce a very high volume of parts quickly, leading to faster project completion and improved cash flow. For example, a business manufacturing thousands of display rack components might find plasma cutting to be the most efficient method for achieving its daily production targets. The lower initial investment combined with good operational speed makes it highly competitive for markets sensitive to both cost and delivery time.

However, the recommendation for plasma cutting comes with the caveat that businesses must be prepared for the inherent characteristics of the process, particularly the potential for dross and slag. While reduced with advanced systems, some level of post-processing will likely be required, which adds labor and time to the overall process. Adequate ventilation and safety measures for fumes and noise are also critical. Despite these considerations, for a business that needs to rapidly process large quantities of conductive metal tubes for applications where extreme precision is not the primary driver, plasma cutting offers an unparalleled balance of speed, versatility, and cost-effectiveness. It often bridges the gap between the simplicity of saw cutting and the high investment of laser, providing a highly viable option for a broad spectrum of general fabrication needs.

| Application/Industry | Recommended Technology | Key Reasons (Expert Insights) | MZBNL Product Relevance |

|---|---|---|---|

| Automotive/Aerospace | Laser Cutting | High precision (±0.05mm), complex geometries, clean cuts, diverse materials, high automation, minimal post-processing, superior finish. | Laser Tube Cutting Machine: High-speed & precision, Multi-process integration, No-CAD System, Zero-Waste Tail Material. |

| Medical/Fitness Equipment | Laser Cutting | Ultra-clean cuts, strict tolerances, sterile environments, small intricate parts, consistency, no tool contamination. | Laser Tube Cutting Machine: High-precision for small intricate parts, customized solutions, easy to operate. |

| High-End Furniture/Sanitary Ware | Laser Cutting | Aesthetic finish, complex designs, invisible joints, versatile material handling, high customization, reduced assembly effort. | Laser Tube Cutting Machine: Superior cut quality, enables complex designs, cost-effective customization. |

| Heavy Construction/Infrastructure | Saw Cutting | Robust for thick/large diameter tubes, lower initial cost, reliable for straight/angled cuts, suited for structural integrity. | Not a direct MZBNL product for cutting, but our automatic punching machines can complement saw cut pieces for complex features. |

| General Fabrication (Thick) | Plasma Cutting | High speed for thick conductive metals, lower cost than laser, suitable for rougher cuts where precision is less critical, high throughput. | (If MZBNL produced plasma cutters, this would apply) |

| Display Racks/Shelving (High Vol.) | Laser or Plasma | Laser: High precision, clean welds, multi-process for holes. Plasma: High speed, cost-effective for large volumes with acceptable finish. | Laser Tube Cutting Machine: Smart & digitalized, cost-effective customized solutions, high-speed for volume. |

| Fencing/Railings (High Vol.) | Plasma or Laser | Plasma: Fast, cost-effective for standard designs. Laser: Precision, complex patterns, multi-process integration for punching. | Laser Tube Cutting Machine: Multi-process integration (punching), easy to operate, high-speed. |

Laser is best for medical tubingПравда

Laser cutting provides the ultra-clean cuts and strict tolerances required for sterile medical applications.

Saw cutting creates complex holesЛожь

Saw cutting is limited to straight cuts and cannot create intricate patterns or holes like laser cutting can.

Заключение

Choosing the ideal metal tube cutting machine—laser, saw, or plasma—hinges on balancing material, precision, volume, and budget. Laser excels in precision and automation, saw in robustness for thick materials, and plasma in speed for conductive metals. MZBNL's innovative laser solutions, like No-CAD and Zero-Waste, offer superior efficiency, helping businesses like Ahmed's achieve high cost-performance and upgrade production for long-term success.

-

Explore advanced features of modern laser cutting systems for improved fabrication efficiency ↩

-

Discover how lasers handle intricate designs efficiently ↩

-

To understand the precision and versatility advantages of laser cutting technology ↩

-

Learn how MZBNL's No-CAD system simplifies laser machine operations ↩

-

Compare the unique advantages of different cutting technologies for metal fabrication. ↩

-

Learn about the importance of clean edges and minimal HAZ in precision industries. ↩

У вас есть вопросы или нужна дополнительная информация?

Свяжитесь с нами, чтобы получить индивидуальную помощь и квалифицированный совет.