Revolutionizing Medical Equipment Manufacturing with Tube Laser Cutting Machines

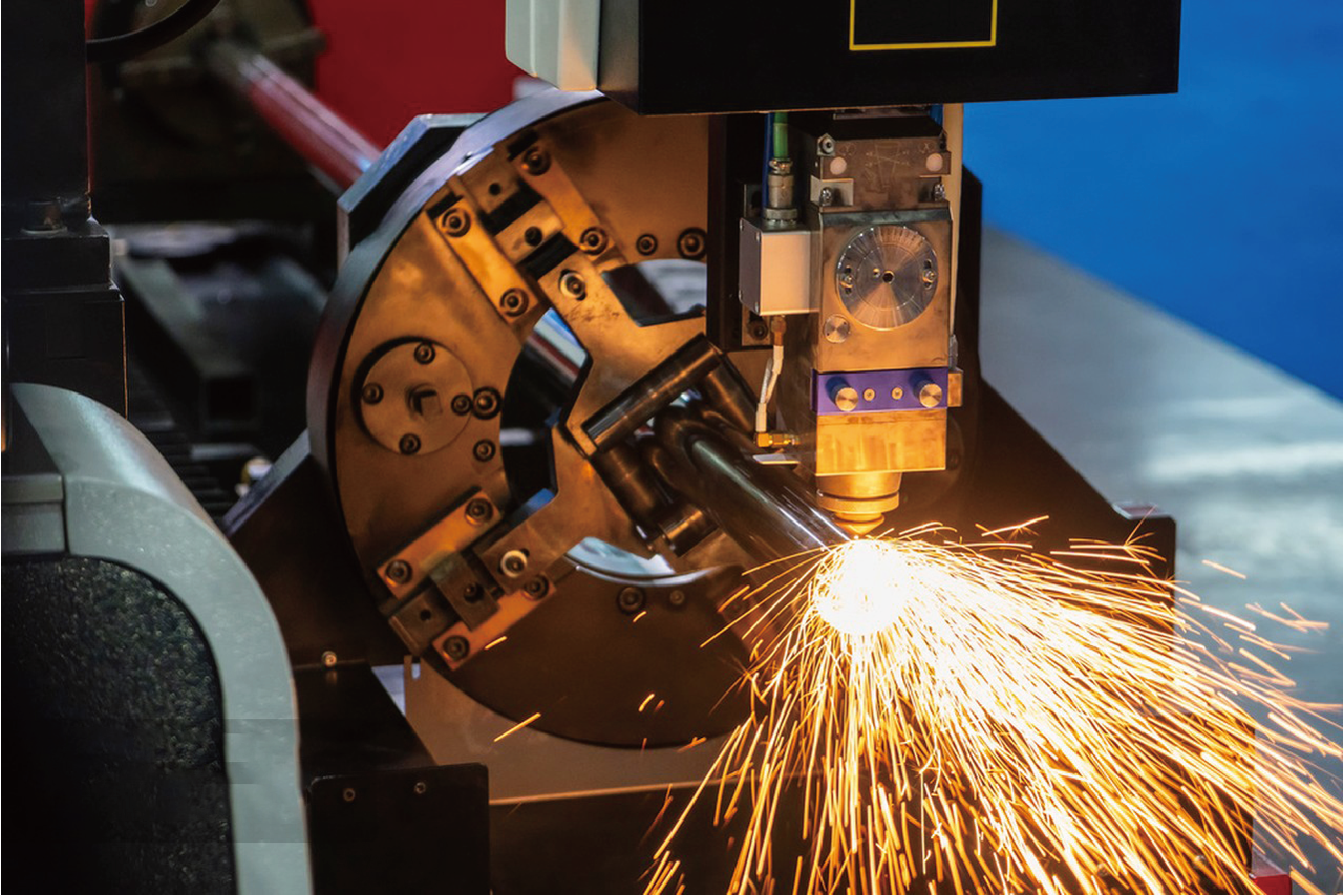

The medical equipment sector demands extreme precision, yet traditional manufacturing methods often fall short. This gap frequently leads to inefficiencies and compromises. Tube laser cutting offers a groundbreaking solution to these persistent challenges.

Tube laser cutting machines play a pivotal role in medical equipment manufacturing by delivering high precision, intricate designs, and sterile components. They significantly enhance production efficiency and ensure compliance with stringent industry standards, addressing the unique challenges of complex medical device fabrication.

Having spent over 25 years immersed in the metal fabrication industry, I’ve witnessed firsthand the relentless pursuit of perfection, particularly in critical sectors like medical equipment. The evolution from manual processes to advanced automation has been transformative, underscoring the vital role technology plays in meeting escalating demands for precision and safety.

[Insert personal story here about seeing demand for precision or a specific observation on automation, e.g., "I recall a conversation with a client, a seasoned engineer, who expressed his frustration over the limitations of traditional manufacturing in producing intricate medical components. He emphasized that even a millimeter of error could have severe consequences. This deeply resonated with me, reinforcing MZBNL's commitment to pushing the boundaries of precision."] The medical device industry, unlike almost any other, operates under a microscope of stringent quality controls and regulatory requirements. Every component, from a tiny surgical pin to a complex implant1, must adhere to exact specifications to ensure patient safety and product efficacy. Traditional methods, often limited by tooling, material stress, and manual intervention, struggle to consistently deliver the micron-level accuracy and smooth finishes demanded. This is precisely where advanced technologies like tube laser cutting machines step in. They not only meet but exceed these rigorous demands, enabling the creation of previously impossible designs and significantly streamlining the production workflow. This shift is not just about adopting new machinery; it’s about embracing a paradigm where technological innovation directly translates into enhanced patient outcomes and market competitiveness. At MZBNL, our integrated R&D and manufacturing approach ensures we are constantly evolving our solutions to meet these critical sector needs.

What role do tube laser cutting machines play in medical equipment manufacturing?

Medical devices demand unparalleled accuracy, with patient safety hanging in the balance. Traditional fabrication methods frequently introduce errors and inconsistencies. Tube laser cutting offers a precision-driven solution, revolutionizing the production of critical components.

Tube laser cutting machines are crucial for producing intricate, high-precision medical components such as surgical instruments, implants, and diagnostic equipment. They enable complex geometries, smooth finishes, and consistent quality essential for healthcare applications, significantly impacting device performance and patient safety.

The importance of precision in medical equipment cannot be overstated. From life-saving implants to diagnostic tools, every piece must function flawlessly. I’ve seen how even the slightest deviation can have profound implications, making reliable and precise manufacturing absolutely non-negotiable. This drive for perfection mirrors the ambition I often see in clients like Ahmed Al-Farsi, who, despite operating in architectural metalwork and vehicle parts, values high cost-performance ratio and proven technology over mere low price. He understands that investing in advanced solutions like our laser tube cutting machines ensures consistent, high-quality output—a principle magnified tenfold in the medical sector. Just as Ahmed seeks turnkey solutions for his production, medical manufacturers require machines that deliver uncompromising quality with minimal operational complexity. The transition from concept to precise reality in medical device production is where laser cutting machines truly shine, setting the standard for what’s possible. They don't just cut; they craft with unparalleled exactitude, fulfilling the critical demands of a sector where error is not an option. This is about ensuring every component is a perfect fit, a principle that MZBNL champions through its cutting-edge machinery and tailored solutions.

Unparalleled Precision and Material Integrity for Critical Applications

In medical equipment manufacturing, precision isn't merely a desirable trait; it's a fundamental requirement. Tube laser cutting machines achieve micron-level accuracy, delivering clean, burr-free cuts that are essential for components like surgical instruments, implants, and diagnostic probes. Unlike traditional methods such as stamping or milling, laser cutting uses a non-contact process, which minimizes material distortion and heat-affected zones, preserving the structural integrity and biocompatibility of delicate materials like medical-grade stainless steel, titanium, and nitinol2. For instance, creating a precise lumen in a catheter or an exact hole pattern on an orthopedic implant demands this level of control to ensure functionality and prevent contamination. MZBNL's laser tube cutting machines are engineered for this exact purpose, offering not just high-speed but also high-precision cutting that is paramount for patient safety and device performance. The ability to precisely control the beam's energy and focal point means that intricate details can be carved into complex geometries, ensuring that each part adheres to the most rigorous standards. This is particularly crucial for devices that are implanted in the human body, where any surface imperfection could lead to adverse reactions or device failure.

The table below illustrates the critical differences in output quality for medical components between traditional and laser cutting methods:

| Feature/Method | Traditional Cutting (Sawing/Stamping/Milling) | Tube Laser Cutting (BNL) |

|---|---|---|

| Precision | Millimeter-level; less consistent | Micron-level; highly consistent |

| Edge Finish | Burrs, rough edges, often requires post-processing | Clean, smooth, minimal post-processing |

| Heat Affected Zone | Larger, potential material distortion | Minimal, controlled, preserves material integrity |

| Design Complexity | Limited, requires specific tooling | High, intricate geometries, no tooling needed |

| Material Waste | Significant, especially with complex shapes | Minimal, optimized material utilization |

| Process Sterility | Higher risk of contamination | Cleaner, non-contact, less particulate generation |

Enabling Complex Geometries and Miniaturization for Innovation

The medical device industry is constantly pushing the boundaries of innovation, leading to smaller, more complex, and multi-functional devices. Traditional cutting methods are often bottlenecks in this evolution, as they struggle with intricate geometries, very small diameters, and thin-walled tubes. Tube laser cutting machines, however, excel in this domain. They can effortlessly create elaborate patterns, precise perforations, and complex contours on tubes used in everything from endoscopic tools to cardiovascular stents. For example, the fabrication of a custom stent requires thousands3 of microscopic cuts on a tube to form an intricate mesh structure that can expand and contract. This level of detail is simply unachievable with mechanical cutting tools. Furthermore, our pioneering No-CAD Operating System significantly enhances this capability. While I've seen many operators struggle with complex 3D drawings for days or even weeks, our system allows for the processing of standard tube types and hole patterns simply by entering parameters. This dramatically reduces setup time and lowers the skill threshold, meaning an operator only needs 1 day of on-site training instead of 15 days at the equipment factory, accelerating the prototyping and production of new, innovative medical devices. This freedom in design is critical for researchers and developers to bring next-generation medical solutions to market faster.

Optimizing Efficiency and Cost-Effectiveness in Production

Beyond precision, tube laser cutting machines offer substantial improvements in operational efficiency and cost-effectiveness for medical equipment manufacturers. The high-speed nature of laser cutting significantly reduces cycle times compared to slower, mechanical processes. Our proprietary Front-Feeding Innovation is a prime example of this optimization. Traditional machines often rely on cumbersome manual loading from the side or rear, but our automated front-feeding mechanism pulls the tube in seamlessly. This design increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%, directly translating into higher throughput and lower labor costs. Moreover, material utilization is a critical factor, especially with costly medical-grade alloys. Our Zero-Waste Tail Material Innovation addresses this directly. Conventional systems typically generate unusable tail material at the end of the process. MZBNL redesigned the cutting logic to calculate from the rear chuck as the origin, allowing the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This maximizes material utilization, significantly reducing waste and boosting overall cutting efficiency, directly impacting the bottom line for manufacturers. These combined innovations make our laser tube cutting machines not just a precision tool, but a comprehensive solution for profitable, high-volume medical equipment production.

Laser cutting enables micron-level precisionTrue

Tube laser cutting achieves micron-level accuracy crucial for medical components, far surpassing traditional methods' millimeter-level precision.

Traditional methods produce cleaner edgesFalse

Laser cutting creates cleaner, burr-free edges while traditional methods often require post-processing to achieve smooth finishes.

What is the current state of the medical equipment industry regarding laser cutting technology?

The medical equipment industry is constantly evolving, demanding manufacturing solutions that keep pace. Traditional methods often create bottlenecks, hindering innovation and efficiency. Laser cutting technology is emerging as a cornerstone for modern production.

The medical equipment industry increasingly adopts laser cutting for precision, automation, and advanced materials processing. This shift is driven by demands for miniaturization, rapid prototyping, and stricter regulatory compliance, making it a standard for modern production workflows worldwide.

In my decades of experience in the metal fabrication industry, I've observed a distinct trend: the relentless pursuit of automation and integration. This trend is nowhere more pronounced than in the medical sector, where quality and efficiency are paramount. Just as my client, Ahmed Al-Farsi, is strategically planning to automate his existing manual workflows in the UAE, medical manufacturers globally are making similar pivotal shifts. They recognize that relying solely on traditional methods is a recipe for stagnation in a rapidly advancing field. MZBNL’s integrated R&D, manufacturing, sales, and service model4 stands at the forefront of this technological revolution. We've dedicated ourselves to developing smart, digitalized systems and multi-process integration capabilities, recognizing that modern manufacturers require more than just a cutting tool; they need a comprehensive solution that streamlines their entire production line. The current state of the medical equipment industry reflects a strong pull towards these advanced, automated systems, driven by a need for faster market entry, higher precision for complex designs, and robust compliance with ever-tightening regulatory standards. This is about staying competitive and, more importantly, ensuring the highest standards of safety and efficacy for medical devices worldwide.

Widespread Adoption and Accelerating Market Penetration

The medical equipment industry is rapidly embracing laser cutting technology, moving beyond niche applications to becoming a mainstream manufacturing process. Data from various industry reports indicate a significant Compound Annual Growth Rate (CAGR) for laser processing in medical devices, often exceeding 7-8% annually. This growth is primarily fueled by the increasing demand for minimally invasive surgical tools, sophisticated implants, and miniaturized diagnostic equipment, all of which benefit immensely from the precision and flexibility of laser technology. Geographically, regions with strong R&D infrastructure and high healthcare spending, such as North America and Europe (key export markets for MZBNL5), are leading this adoption. For instance, the demand for precise micro-components in cardiovascular devices or neurological implants has driven many manufacturers in these regions to upgrade their traditional machinery to advanced laser systems. This widespread adoption reflects a broader industry recognition that laser cutting is no longer an emerging technology but a proven, indispensable tool for modern medical manufacturing, especially as product lifecycles shorten and customization becomes more prevalent.

The Rise of Automation, AI, and Integrated Solutions

The current landscape of medical equipment manufacturing is characterized by a strong push towards automation and digitalization, with laser cutting technology at its core. Manufacturers are not just looking for standalone machines but integrated solutions that can communicate with existing systems, optimize workflows, and minimize human intervention. This is where the concept of "smart factories" and Industry 4.0 principles, applied to medical production, becomes highly relevant. MZBNL's focus on smart and digitalized systems aligns perfectly with this trend. Our machines offer features like automatic feeding (Front-Feeding Innovation), remote diagnostics, and data analytics capabilities, allowing manufacturers to monitor production in real-time, predict maintenance needs, and optimize material flow. For a client like Ahmed, who seeks to automate his manual workflows, the appeal of a turnkey solution with easy-to-operate and maintain smart systems is immense. The integration of artificial intelligence, particularly in areas like defect detection and process optimization, is further enhancing the capabilities of laser cutting, allowing for unprecedented levels of quality control and efficiency, critical in a sector with zero tolerance for error. This shift represents a move towards more resilient, efficient, and intelligent manufacturing ecosystems.

Advancements in Material Versatility and Advanced Applications

The medical equipment industry continuously explores new materials for enhanced device performance, and laser cutting technology is evolving to process these diverse and often challenging substrates. Beyond traditional stainless steel and titanium, modern medical devices utilize a range of materials including nitinol (for its superelasticity and shape memory), various bio-absorbable polymers (for dissolving implants), and advanced ceramics. Laser cutting's non-contact nature makes it ideal for processing these materials without compromising their unique properties. For example, cutting nitinol for stents requires precise control to avoid thermal damage that could alter its crucial properties, a feat where laser technology excels. Additionally, advanced applications are emerging, such as the direct manufacturing of medical device components through laser additive manufacturing (3D printing with lasers) for highly customized implants or prosthetics. While MZBNL primarily focuses on laser tube cutting, our machines are designed with the versatility to handle a broad spectrum of materials and geometries, making them future-proof for evolving medical material science. This capability ensures that manufacturers can innovate with confidence, knowing their production machinery can keep pace with breakthroughs in material science and device design, further solidifying laser cutting's indispensable role in the industry.

Laser cutting enables miniaturizationTrue

The precision of laser cutting is crucial for creating smaller, more complex medical devices like minimally invasive surgical tools.

Traditional methods are sufficientFalse

Traditional manufacturing methods cannot meet the demands for precision, speed, and material versatility required by modern medical devices.

What challenges are faced by medical equipment manufacturers when using traditional cutting methods?

Medical device production demands uncompromising quality, yet conventional cutting methods present significant hurdles. These challenges directly impact efficiency, cost, and the ability to innovate. They often force compromises where none should exist.

Medical equipment manufacturers using traditional cutting face challenges like low precision and significant material waste, extended production times, and the inability to create complex designs. These methods often require extensive post-processing, struggle with high-volume demands, and rely heavily on costly skilled labor.

From my perspective, having worked with countless metal fabrication businesses over the years, the "pain points" experienced by manufacturers using outdated methods are remarkably consistent, regardless of the industry. My client, Ahmed Al-Farsi, perfectly articulates many of these, including the need for skilled CAD operators, the burdens of high operator turnover, and the lack of reliable local service support from some suppliers. In the medical equipment sector, these challenges are amplified by the critical nature of the products. Imagine if a surgical instrument had imprecise dimensions due to outdated cutting. The consequences could be dire. Traditional methods like stamping, sawing, or milling, while perhaps suitable for simpler, less critical parts, fall short in areas where micron-level accuracy and intricate geometries are paramount. They often lead to excessive material waste, increased post-processing requirements, and significant bottlenecks in the production cycle. This not only inflates manufacturing costs but also hinders innovation, preventing the rapid development and deployment of next-generation medical devices. It's a constant struggle between maintaining quality and battling the inherent limitations of old technology, a struggle that newer, integrated solutions aim to resolve definitively.

Inherent Limitations in Precision and Significant Material Waste

Traditional cutting methods, such as stamping, sawing, or abrasive waterjet cutting, inherently struggle to achieve the ultra-high precision required for medical devices6. Stamping can introduce burrs and material deformation, necessitating time-consuming and costly secondary finishing operations to meet medical standards. For example, when creating tiny components for an endoscope, a traditional punch press might leave uneven edges that could compromise the device's function or sterility. Moreover, these methods are often highly inefficient in terms of material utilization. They typically involve removing large sections of material or are designed for specific, non-flexible shapes, leading to considerable scrap, especially with expensive medical-grade alloys like titanium or specialized stainless steels. This material waste directly impacts production costs, a significant concern for manufacturers. In contrast, MZBNL's Zero-Waste Tail Material Innovation addresses this pain point head-on by optimizing material usage, which is crucial for reducing overhead in sectors that use high-value materials. The limitations in precision also contribute to higher rejection rates, further compounding material loss and slowing down overall production.

Restricted Design Complexity and Protracted Prototyping Cycles

One of the most significant challenges traditional cutting methods pose is their inability to produce highly complex or miniaturized geometries, which are increasingly common in modern medical devices. Mechanical cutting often requires specialized tooling for each new design, making it expensive and time-consuming to adapt to design changes or prototype new products. Imagine trying to create the intricate mesh pattern of a cardiovascular stent using a traditional milling machine; it would be virtually impossible or prohibitively expensive and slow. This limitation stifles innovation, as designers are forced to compromise on their vision to fit the constraints of manufacturing capabilities. Furthermore, the prototyping phase for new medical devices becomes excessively long due. Each design iteration might require new molds or tooling, adding weeks or months to the development cycle. This delay can mean missing market opportunities or lagging behind competitors in bringing life-saving technologies to patients. My observations suggest that manufacturers need agility to succeed, and traditional methods simply don't provide that.

High Labor Dependency and Skill Thresholds

Traditional cutting methods frequently demand a high level of manual intervention and rely heavily on skilled operators. For instance, operating a complex milling machine for intricate medical parts requires extensive training and experience. The problem, as highlighted by clients like Ahmed Al-Farsi, is the high operator turnover and the subsequent burden of retraining. When a skilled CAD operator leaves, it can create a significant bottleneck in production until a new one is adequately trained, which could take weeks or even months. This dependency on highly specialized labor not only drives up operational costs but also introduces variability in product quality due to human error. Manual loading processes, common in older systems, further exacerbate labor intensity and reduce overall efficiency. MZBNL's Front-Feeding Innovation, which automates tube loading and reduces labor intensity by approximately 40%, directly counters this. Similarly, our No-CAD Operating System dramatically lowers the skill threshold, requiring only 1 day of training compared to 15 days, directly addressing the pain points of operator dependency and retraining burdens that many manufacturers face. These challenges collectively demonstrate the urgent need for more automated, user-friendly, and precise cutting solutions in the medical equipment sector.

Traditional cutting causes material wasteTrue

Methods like stamping remove large material sections, creating significant scrap with expensive medical alloys.

Milling creates perfect stent meshesFalse

Traditional milling struggles with intricate stent geometries, often making them impossible or prohibitively expensive to produce.

How can tube laser cutting machines address these challenges effectively?

Traditional manufacturing bottlenecks hinder medical innovation, but there’s a powerful solution at hand. Tube laser cutting machines offer a robust answer to these pervasive industry pain points. They directly tackle issues of precision, waste, and labor.

Tube laser cutting machines effectively address medical manufacturing challenges by providing ultra-high precision, minimal material waste, rapid prototyping and complex geometry capabilities. Their automation features also reduce labor dependency, improve throughput, and ensure compliance with stringent quality standards.

When I discuss the capabilities of our tube laser cutting machines with potential clients, I often see a sense of relief. The challenges faced by medical equipment manufacturers—the constant pressure for precision, the high cost of material waste, and the difficulty in securing and retaining skilled labor—are deeply understood at MZBNL. This understanding is built into the very innovations we’ve pioneered. I often think of Ahmed Al-Farsi’s strong emphasis on needing easy-to-install and operate turnkey solutions. His preference for proven technology and global references stems from a desire for reliability and problem-solving, not just a purchase. Our machines are designed to be precisely that: a comprehensive solution that directly combats the pain points of older methods. Our No-CAD system tackles the skilled operator dilemma, our Front-Feeding innovation boosts efficiency and cuts labor intensity, and our Zero-Waste Tail Material feature maximizes precious resources. These aren't just features; they are direct responses to the critical needs of an industry that demands unwavering precision and efficiency, fundamentally transforming how medical components are produced.

Unrivaled Precision and Material Efficiency for Cost Savings

Tube laser cutting machines stand out for their ability to deliver exceptional precision, a non-negotiable requirement in medical equipment manufacturing. They achieve micron-level accuracy, creating clean, burr-free cuts that eliminate the need for extensive post-processing, a common and costly step with traditional methods. This unparalleled precision ensures that components like tiny stents, hypodermic needles, or bone screws meet exact specifications, directly impacting their performance and safety. Furthermore, laser cutting significantly minimizes material waste, a critical advantage given the high cost of medical-grade alloys such as titanium, nitinol, and specialized stainless steels. At MZBNL, our Zero-Waste Tail Material Innovation is a game-changer in this regard. Unlike conventional systems that leave unusable remnants, our redesigned cutting logic maximizes utilization by calculating from the rear chuck as the origin. This ensures that as long as the remaining section is larger than the product length, it can be fully utilized, leading to substantial cost savings. For example, if a traditional machine produces 50mm of waste on every 6-meter tube, over thousands of tubes annually, this adds up to tons of wasted expensive material; our innovation effectively eliminates this. This combination of precision and efficiency ensures that manufacturers can produce higher quality parts with lower material overhead.

Accelerating Innovation with Unparalleled Design Freedom

One of the most significant advantages of tube laser cutting machines is the design freedom they offer, directly addressing the limitations of traditional methods. Unlike mechanical cutting, which often requires specific tooling for each unique design, laser cutting is tool-less. This means manufacturers can rapidly prototype and produce highly intricate geometries, complex patterns, and miniaturized components without incurring the costs and delays associated with mold or die creation. This capability is crucial for the fast-paced medical device industry, where rapid innovation and time-to-market are competitive advantages. Our pioneering No-CAD Operating System exemplifies this transformative power. Traditionally, operators had to spend days or even weeks creating or modifying complex 3D drawings before production could start. With MZBNL's system, standard tube types and hole patterns can be processed simply by entering parameters, eliminating the need for complex CAD drawings. This dramatically shortens setup time, lowers the skill threshold for machine operation (requiring only 1 day of on-site training instead of 15 days), and empowers designers to explore more complex and innovative concepts for new devices, accelerating the entire R&D and product launch cycle. This agility is vital for staying ahead in a market driven by continuous technological advancement.

Enhancing Productivity and Significantly Reducing Operational Costs

Tube laser cutting machines not only enhance precision and design freedom but also deliver substantial improvements in productivity and operational cost reduction, directly tackling pain points like high labor dependency and inconsistent output. The high-speed processing capability of lasers allows for significantly faster production cycles compared to traditional methods. Furthermore, the automation features embedded in modern laser cutting systems greatly reduce the need for manual intervention. Our Front-Feeding Innovation is a prime example: by automatically pulling the tube from the front, it increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%. This translates into higher throughput with fewer personnel, directly combating the issue of high labor costs and operator turnover that clients like Ahmed Al-Farsi experience. The smart and digitalized systems integrated into MZBNL machines further enhance this. They offer intuitive operation, minimal maintenance requirements, and multi-process integration (like automatic punching), consolidating several steps into one machine. This not only streamlines the workflow but also reduces the floor space, energy consumption, and overall operational complexity. By providing solutions that are easy to operate, precise, and highly automated, tube laser cutting machines effectively address the core challenges of medical equipment manufacturing, enabling greater efficiency, profitability, and compliance.

Laser cutting reduces material wasteTrue

Tube laser cutting machines minimize waste by maximizing material utilization, especially with innovations like Zero-Waste Tail Material.

Traditional cutting is faster than laserFalse

Laser cutting offers high-speed processing, significantly reducing production cycles compared to traditional methods.

What are the suggested best practices for implementing laser cutting in medical equipment production?

Implementing new technology requires strategic planning, especially for critical medical equipment manufacturing. Laser cutting integration needs careful consideration to maximize its benefits. Adopting proven best practices ensures optimal outcomes and seamless adoption.

Implementing laser cutting in medical equipment production requires careful material selection, thorough machine calibration, robust quality control, comprehensive operator training, and strict adherence to regulatory standards. These practices ensure precision, compliance, and efficiency throughout the manufacturing process, maximizing investment returns.

Based on my extensive experience guiding businesses through technological transitions, I can confidently say that merely acquiring a sophisticated machine isn't enough; strategic implementation is paramount. This insight is continually reinforced by discussions with forward-thinking clients like Ahmed Al-Farsi, who explicitly values turnkey solutions, comprehensive post-sales training, and reliable support. He understands that the true value of an investment like a laser tube cutting machine7 extends far beyond its initial purchase price, encompassing its entire lifecycle of operation, maintenance, and the support ecosystem surrounding it. For the medical equipment sector, where precision and compliance are non-negotiable, this meticulous approach to implementation becomes even more critical. It involves not just mastering the machine's capabilities but also integrating it seamlessly into existing workflows, ensuring strict adherence to regulatory bodies, and fostering a culture of continuous improvement and precise execution. This requires a partnership approach, where the supplier actively supports the client through training, troubleshooting, and ongoing service, much like MZBNL strives to do with its global network and dedicated support.

Strategic Machine Selection and Tailored Solution Integration

The first and most critical best practice is to conduct a thorough evaluation and strategically select a tube laser cutting machine8 that precisely aligns with the specific needs of medical equipment production. This involves assessing the types of materials to be processed (e.g., stainless steel, titanium, nitinol, polymers), the required cutting precision (micron-level accuracy), the complexity of designs (e.g., intricate holes, tiny diameters), and projected production volumes. Simply opting for the cheapest machine can lead to long-term inefficiencies and quality compromises. Instead, focus on a high cost-performance ratio, prioritizing machines that offer features crucial for medical applications, such as fine cutting capabilities, stable power output, and advanced control systems. MZBNL excels in providing cost-effective customized solutions, ensuring that manufacturers receive a system tailored to their unique demands. For instance, if a company is primarily producing high volumes of small, precise tubes for catheters, a machine optimized for micro-cutting and automated feeding would be ideal. My discussions with clients like Ahmed Al-Farsi underscore this: he actively seeks turnkey solutions and values customization, wanting a machine that fits his specific production needs rather than a generic off-the-shelf product. Partnering with suppliers like MZBNL, who offer integrated R&D, manufacturing, sales, and service, ensures access to expert guidance in selecting and integrating the optimal machine, ultimately leading to a more efficient and profitable production line.

Comprehensive Operator Training and Skill Development

Effective implementation of laser cutting technology hinges significantly on comprehensive operator training and ongoing skill development. While modern laser systems, like MZBNL's, are designed for ease of use, a foundational understanding of laser principles, machine operation, safety protocols, and troubleshooting is essential. The No-CAD Operating System of MZBNL's laser tube cutting machines dramatically simplifies this learning curve, requiring only 1 day of on-site training compared to the traditional 15 days needed for complex CAD-based systems. This significantly reduces the training burden and accelerates operator proficiency. However, training should extend beyond basic operation to include best practices for material handling, quality inspection, routine maintenance, and an understanding of how small adjustments can impact precision and material integrity. Regular refresher courses and access to technical support are also vital for continuous improvement and to address new challenges. Investing in well-trained personnel not only maximizes the machine's potential but also minimizes errors, reduces downtime, and ensures consistent quality output, which is paramount in the medical sector. This directly addresses the pain points of high operator turnover and retraining burdens, as proficient operators are more likely to perform effectively and safely.

Rigorous Quality Control and Unwavering Regulatory Compliance

In medical equipment manufacturing, quality control and regulatory compliance9 are non-negotiable. Implementing laser cutting must be accompanied by stringent quality assurance processes at every stage, from material inspection to final product verification. This includes meticulous machine calibration, regular preventative maintenance to ensure consistent cutting performance, and sophisticated in-process monitoring systems that can detect deviations in real-time. For example, using precision measurement tools and visual inspection protocols to verify cut quality, dimensions, and surface finish immediately after processing is crucial. Furthermore, all processes must strictly adhere to relevant medical industry standards and regulations, such as ISO 13485 (Medical devices – Quality management systems) and FDA requirements (for markets like North America). This involves detailed documentation of cutting parameters, material traceability, and robust validation of the laser cutting process. MZBNL's smart and digitalized systems can contribute to this by providing precise data logging and operational insights, aiding in compliance documentation. Prioritizing suppliers with proven technology and global references, like MZBNL's 4000+ global enterprise clients, also provides an assurance of established quality and reliability. By embedding rigorous quality control and maintaining unwavering regulatory compliance, medical equipment manufacturers can leverage laser cutting technology with confidence, ensuring the safety and efficacy of their life-saving products.

Material selection is crucialTrue

Medical laser cutting requires careful material selection to ensure biocompatibility and precision.

Cheapest machines are bestFalse

Medical production requires high-precision machines with specific features, not just low-cost options.

Conclusion

Tube laser cutting machines are transforming medical equipment manufacturing, offering unparalleled precision, design freedom, and efficiency. By addressing the limitations of traditional methods, these advanced systems enable complex geometries, minimize waste, and reduce labor costs, ensuring superior product quality and accelerating innovation in the critical healthcare sector.

-

Explore why exact specifications are crucial for medical equipment safety and efficacy ↩

-

Understand the importance of material integrity in medical devices and laser cutting's role ↩

-

Learn about the process and precision involved in laser cutting custom medical stents ↩

-

Learn about MZBNL’s innovations and comprehensive manufacturing solutions ↩

-

Understand geographical trends and adoption rates of laser systems ↩

-

Discover how precision levels impact the functionality and safety of medical devices. ↩

-

Learn how laser cutting enhances precision and efficiency in medical equipment manufacturing. ↩

-

Discover how to match laser cutting technology with specific medical equipment needs for optimal performance. ↩

-

Understand the importance of regulatory compliance in medical equipment production using laser cutting technology. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.