The Future of Tube Laser Cutting Machines in Smart Manufacturing

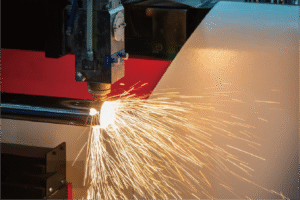

Are you struggling to keep up with the demands of modern manufacturing, facing inefficiencies and high labor costs? Traditional processes often hinder agility and digital integration, leaving your operations behind. Discover how advanced tube laser cutting machines are not just tools, but cornerstones of smart manufacturing's future, transforming your productivity.

Tube laser cutting machines are pivotal in smart manufacturing, providing automated, precise, and integrated solutions for metal fabrication. They enable seamless data flow, remote operation, and enhanced material utilization, significantly boosting efficiency and paving the way for truly intelligent production lines.

As the global manufacturing landscape continues its rapid evolution towards digitalization and automation, the role of core machinery like tube laser cutters becomes increasingly critical. I invite you to delve deeper into how these cutting-edge systems are not just adapting but actively shaping the future of smart factories, offering unparalleled precision and efficiency for businesses worldwide.

My journey at MZBNL, spanning 25 years in metal fabrication, has shown me firsthand the transformative power of technological innovation. The shift towards smart manufacturing isn't just a trend; it's a fundamental change in how we approach production, driven by the need for greater efficiency, flexibility, and sustainability. For example, our clients in Southeast Asia and North America are constantly seeking integrated solutions that reduce manual intervention and optimize material usage. This often involves critical evaluation of existing workflows, challenging the status quo, and investing in systems that offer more than just cutting—they offer intelligence, data, and unparalleled performance.

What is the current role of tube laser cutting machines in smart manufacturing?

Are your current cutting methods bottlenecks in your smart factory vision? Manual processes and disconnected machines often limit real-time data flow and overall system intelligence. Learn how advanced tube laser cutting machines are already central to smart manufacturing, delivering precision, automation, and seamless integration.

Tube laser cutting machines currently serve as critical automated nodes in smart manufacturing, enabling high-precision, high-speed, and complex geometry processing. They integrate with MES/ERP systems for real-time data exchange, reducing human error, optimizing material flow, and facilitating lights-out production in modern factories.

From my perspective at MZBNL, having seen countless factories transition from traditional setups to digitally integrated environments, the evolution of tube laser cutting machines has been remarkable. These aren't just standalone tools anymore; they are intelligent components of a larger, interconnected ecosystem. Imagine Ahmed Al-Farsi's metal fabrication business in the UAE, moving from labor-intensive manual processes to a streamlined, automated workflow where every cut is precise, and every data point is captured for analysis. This isn't just about speed; it's about transforming the fundamental way production lines operate, ensuring seamless interaction between design, execution, and quality control. This connectivity allows for dynamic adjustments, predictive maintenance, and unparalleled efficiency across the entire production chain, enabling businesses to meet the stringent demands of modern markets, from architectural metalwork to specialized vehicle parts.

Tube laser cutting machines are no longer isolated workhorses; they are sophisticated components within complex automated production lines. Their ability to handle various tube profiles and intricate designs with extreme precision makes them indispensable. Unlike traditional saws or punching machines, laser cutters offer unparalleled versatility, performing multiple operations (cutting, hole punching, intricate patterns) on a single machine. This multi-process integration is a cornerstone of smart manufacturing, as it reduces material handling, minimizes errors, and shortens lead times, crucial for rapid prototyping and mass production alike.

In my experience, working with clients like Ahmed Al-Farsi, a common pain point was the need for highly skilled CAD operators and manual loading processes, which often led to high operator turnover and retraining burdens. Our MZBNL machines address this directly. For instance, our No-CAD Operating System allows operators to process standard tube types and hole patterns by simply entering parameters, reducing training time from 15 days at the equipment factory to just 1 day of on-site training. This dramatically lowers the skill threshold and integration complexity, making automation accessible even for businesses without extensive in-house engineering teams. Data shows that companies adopting such user-friendly systems can achieve a 30-40% reduction in setup times, directly impacting project delivery schedules.

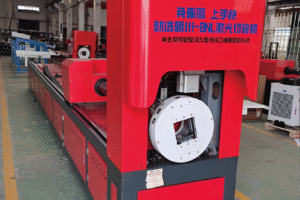

Furthermore, the integration of automation extends to material handling, a critical bottleneck in many traditional setups. Older methods often involved manual loading and unloading, which is not only labor-intensive and slow but also prone to human error and potential safety risks. Modern tube laser cutters, like those featuring MZBNL's optimized Front-Feeding Innovation, automatically pull the tube from the front, boosting feeding efficiency by approximately 40% and cutting operator labor intensity by 40%. This enhancement not only accelerates production cycles but also significantly improves workplace ergonomics and safety, creating a more sustainable operational environment for factory staff.

The "smart" in smart manufacturing comes from data. Tube laser cutting machines generate vast amounts of data—from cutting parameters and material consumption to machine performance and error logs. This data, when integrated with Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) systems, provides real-time insights into production processes. This level of transparency was previously unimaginable with older technologies, which relied on manual tracking and periodic reports, often leading to delayed problem identification and reactive problem-solving. The ability to instantly access performance metrics empowers manufacturers to make informed decisions swiftly.

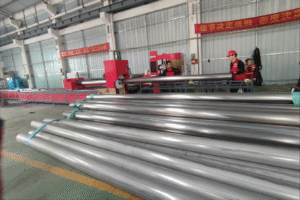

For example, a furniture manufacturer, one of our typical clients, might use this real-time data to identify bottlenecks in their production of metal chair frames or display racks. By continuously monitoring cutting speeds, material waste, and machine uptime, they can optimize nesting patterns or adjust laser power for different alloys, ensuring maximum material utilization and consistent output quality. Our Zero-Waste Tail Material Innovation, which recalculates the cutting logic from the rear chuck, directly addresses material waste, allowing companies to virtually eliminate unusable tail material as long as the remaining section is smaller than the product length. This translates to significant cost savings, often reducing material waste by 10-15% compared to conventional systems.

A comparative analysis highlights the advantages of integrated laser cutting systems:

| Feature | Traditional Punching/Sawing | MZBNL Laser Tube Cutting | Impact |

|---|---|---|---|

| Setup Time | High (tool changes, manual) | Low (No-CAD, parameter input) | Reduced downtime, faster project starts |

| Material Waste | Significant (fixed cuts) | Minimal (Zero-Waste Tail) | 10-15% material cost savings, sustainability |

| Design Flexibility | Limited (fixed dies) | High (complex geometries) | Customization, product innovation |

| Data Integration | Manual/Limited | Seamless (MES/ERP ready) | Real-time insights, predictive maintenance |

| Labor Intensity | High (manual feeding, skilled op) | Reduced (Automated Front-Feeding) | 40% less labor, improved ergonomics |

This comprehensive data integration allows for predictive maintenance, where machine sensors detect potential issues before they lead to costly downtime, a critical concern for businesses that cannot afford production interruptions. A recent study by Deloitte found that predictive maintenance can reduce maintenance costs by 5-10% and increase machine uptime by 10-20%. This proactive approach is vital for ensuring consistent production schedules and meeting client deadlines, something critical for businesses like Ahmed's, who prioritize consistent project delivery and value turnkey solutions that are easy to maintain.

One of the most significant roles of tube laser cutting machines in smart manufacturing is their ability to facilitate high levels of customization and on-demand production, a key differentiator in today's competitive market. In an era where consumers and businesses demand personalized products and rapid turnaround, the flexibility and precision of laser cutting are unmatched. Whether it's unique display racks for a retail client, bespoke medical equipment components, or custom automotive parts, these machines can adapt quickly to new designs without extensive physical retooling or complex die changes, enabling agile manufacturing.

Consider the automotive parts producers, another key client identity for MZBNL. They often require small batches of specialized parts with complex geometries and stringent quality requirements. Our machines, with their high precision and ability to cut without CAD drawings for standard shapes, allow them to shift from mass production of identical parts to agile, customized manufacturing. This capability is crucial for supporting just-in-time inventory strategies, reducing warehousing costs, and responding swiftly to market changes and evolving design requirements. For instance, a client recently used our machine to produce a limited run of bespoke exhaust systems for a luxury car brand, completing the order in a fraction of the time it would have taken with traditional methods, significantly enhancing their competitive edge and reputation for rapid delivery.

The demand for customization is growing exponentially, with reports indicating a significant increase in custom product orders across various industries, from furniture to construction. Tube laser cutting machines, by virtue of their digital control and precise cutting capabilities, are perfectly positioned to meet this demand, turning complex digital designs into physical products with minimal human intervention and exceptional accuracy. This flexibility empowers businesses like Ahmed's to take on more diverse projects, expanding their market reach into high-value, niche segments and ultimately boosting their revenue streams. It transforms them from simple parts suppliers to sophisticated solution providers.

Tube laser cutters reduce material wasteTrue

Advanced nesting algorithms and Zero-Waste Tail Innovation can reduce material waste by 10-15% compared to traditional methods.

Laser cutting requires extensive CAD skillsFalse

Modern No-CAD systems allow operators to process standard tube types with simple parameter inputs, reducing training time from weeks to days.

How are tube laser cutting technologies integrated into existing smart manufacturing systems?

Are your current manufacturing processes isolated, hindering true automation and data synergy? The challenge of bridging legacy systems with new technology can seem daunting, limiting your smart factory's potential. Discover how tube laser cutting machines seamlessly integrate, becoming vital components of a fully interconnected and intelligent production ecosystem.

Tube laser cutting technologies are integrated into smart manufacturing systems primarily through standardized communication protocols (e.g., OPC UA, MQTT and robust software platforms (MES, ERP). This enables real-time data exchange, remote monitoring, automated job scheduling, and comprehensive production analysis, ensuring seamless operational flow from design to finished product.

In my role at MZBNL, I frequently engage with clients seeking to upgrade their operations, and a recurring theme is the desire for seamless integration—not just standalone machines, but entire production lines that "talk" to each other. For a business like Ahmed Al-Farsi's, already stable and planning to automate existing manual workflows, the ease of integration is as crucial as the machine's performance. He prefers turnkey solutions and expects customization. This involves ensuring our machines can easily connect with his existing ERP and MES systems, allowing for automated work orders, material tracking, and quality control from a central dashboard. This level of interconnectedness is what truly transforms a collection of machines into a smart factory, optimizing resource allocation, reducing human error, and accelerating the entire manufacturing cycle.

The foundation of integration lies in robust data exchange. Modern tube laser cutting machines are equipped with advanced sensors and control systems that generate a wealth of operational data, from power consumption and cutting speeds to material usage and machine diagnostics. To integrate into a smart manufacturing ecosystem, this data must be effectively communicated to higher-level systems such as Manufacturing Execution Systems (MES)1 or Enterprise Resource Planning (ERP) systems. This is achieved through industry-standard communication protocols like OPC UA (Open Platform Communications Unified Architecture) or MQTT (Message Queuing Telemetry Transport), which provide a common language for machines and software to interact.

For example, when Ahmed Al-Farsi's team submits a new batch of orders for railing components, his ERP system can automatically generate work orders that are sent directly to the laser cutting machine's control system. This eliminates manual data entry, reducing human error and accelerating job setup. The machine then reports back real-time progress, material consumption, and any anomalies, allowing his MES to monitor production against schedule and adjust upstream or downstream processes as needed. This bidirectional data flow is critical; it’s not just about pushing instructions to the machine, but also about the machine feeding back valuable operational intelligence. This holistic data flow helps manage inventory and optimize production, ensuring that parts are delivered to builders and OEMs precisely when needed, overcoming previous pain points of long machine lead times affecting project delivery.

Another critical aspect of integration is the ability to achieve full automation, often referred to as "lights-out manufacturing" in some advanced scenarios. This involves seamlessly connecting the tube laser cutting machine with automated material handling systems, such as robotic loaders and unloaders, automated guided vehicles (AGVs)2, and automated storage and retrieval systems (AS/RS). This end-to-end automation reduces the need for human intervention, especially during repetitive or hazardous tasks, enhancing safety and allowing operators to focus on higher-value activities like quality control or system optimization.

For instance, after a batch of parts is cut on an MZBNL machine, a robotic arm can automatically pick and sort the finished parts, placing them onto an AGV that transports them to the next workstation or directly to a storage unit. This significantly reduces manual labor and the potential for damage during handling, which is a major concern for delicate or precisely fabricated components. Our Front-Feeding Innovation, which automatically pulls tubes from the front, further enhances this automated workflow by streamlining the initial material loading process, which traditionally required significant manual effort and time. This holistic approach to automation ensures material flow is continuous and optimized, leading to a substantial increase in overall productivity and a reduction in operational costs.

The benefits of fully integrated automation extend beyond just speed and labor reduction; they also contribute to higher quality and consistency. By minimizing human contact with materials and parts, the risk of errors, contamination, or damage is significantly reduced. This is particularly important for industries like medical equipment or automotive parts, where precision and flawless surfaces are paramount.

Furthermore, integrating tube laser cutting machines into smart manufacturing systems extends beyond physical processes to include predictive maintenance and remote diagnostics. Modern machines are equipped with sensors that continuously monitor critical components, from laser power and gas consumption to motor temperatures and vibration levels. This data is then analyzed by AI-powered software, which can detect subtle anomalies that indicate impending failures. Instead of waiting for a machine to break down, which leads to costly unplanned downtime, maintenance can be scheduled proactively during non-production hours.

For Ahmed Al-Farsi, who values reliable post-sales support and spare parts availability, this capability is invaluable. Our MZBNL machines are designed with smart diagnostics, allowing our service teams to remotely access machine data and identify issues, often before Ahmed's team even notices a problem. This significantly reduces troubleshooting time and enables faster resolution, minimizing disruption to his contract-based fabrication services. This remote support capability is particularly important for international clients, ensuring that geographical distance does not compromise service quality. Studies indicate that predictive maintenance can decrease maintenance costs by 25-30% and reduce breakdowns by up to 70-75%, offering a significant return on investment for businesses investing in smart machinery. This level of proactive support is what helps MZBNL maintain its reputation with 4000+ global enterprise clients.

OPC UA enables machine communicationTrue

OPC UA is an industry-standard protocol that allows tube laser cutting machines to communicate with MES/ERP systems for bidirectional data exchange.

Lights-out manufacturing requires humansFalse

Lights-out manufacturing refers to fully automated production without human intervention, enabled by integrated material handling systems.

What challenges do manufacturers face when incorporating tube laser cutting machines in smart factories?

Are you struggling to connect your advanced machinery into a unified smart factory system? The complexity of integrating new technologies with existing infrastructure can create significant hurdles, leading to operational inefficiencies. Discover the common challenges manufacturers encounter and how strategic planning can overcome them to unlock the full potential of smart manufacturing.

Manufacturers face challenges such as high initial investment, data interoperability issues between diverse systems, a shortage of skilled labor for advanced machine operation and maintenance, and cybersecurity risks. Overcoming these requires modular integration, comprehensive training, strategic partnerships, and robust data security protocols to ensure seamless adoption.

While the benefits of integrating tube laser cutting machines into smart factories are clear, the path to full implementation is not without its obstacles. From my vantage point at MZBNL, I’ve seen companies, large and small, grapple with various issues during their digital transformation journeys. For a forward-thinking owner like Ahmed Al-Farsi, the challenge isn't just about purchasing the machine; it's about making sure it fits seamlessly into his entire operational ecosystem, that his team can use it effectively, and that it addresses his existing pain points like the need for skilled CAD operators or the lack of local service support from previous suppliers. Understanding these challenges is the first step toward developing effective strategies for their mitigation.

The initial investment required for high-precision tube laser cutting machines3 and their integration into a smart factory ecosystem can be substantial. This includes not only the cost of the machinery itself but also expenses related to software licenses (MES, ERP, CAD/CAM), sensor implementation, network infrastructure upgrades, and potentially new automation components like robotics or AGVs. For mid-sized metal fabrication businesses, this capital outlay can be a significant barrier. Unlike a simple machine purchase, smart factory integration is an enterprise-wide project that requires careful financial planning and a clear return on investment (ROI) projection.

For a business owner like Ahmed Al-Farsi, who considers a high cost-performance ratio over low price, the challenge isn't necessarily finding the cheapest machine but rather justifying the comprehensive investment. He needs to see a clear path to increased productivity, reduced labor costs, and improved material utilization that offsets the initial expenditure. This means suppliers must articulate the long-term benefits compellingly, perhaps by demonstrating how MZBNL's No-CAD system dramatically reduces training costs and operator skill requirements, or how the Zero-Waste Tail Material Innovation provides substantial material savings. While the upfront cost is high, the long-term operational savings and enhanced competitiveness often prove to be a compelling case for investment.

Another significant challenge is ensuring data interoperability between disparate systems and machines. Factories often have a mix of legacy equipment, different brands of new machinery, and various software platforms (CAD, CAM, ERP, MES, CRM). Getting these systems to "talk" to each other seamlessly can be incredibly complex. Different proprietary protocols, data formats, and communication standards can create data silos, preventing the real-time, holistic view essential for smart manufacturing. This fragmented data environment undermines the very promise of integrated operations, leading to manual data transfer, errors, and delays.

For instance, Ahmed might have an existing ERP system that manages his orders and inventory, but his previous cutting machines might not have been able to automatically report production data back to it. This creates a disconnect, requiring manual updates and delaying real-time decision-making. Overcoming this requires robust integration strategies, often leveraging middleware or standardized protocols like OPC UA. At MZBNL, we prioritize systems designed for broad compatibility, allowing our machines to communicate effectively with diverse enterprise software. Our goal is to provide a turnkey solution that minimizes integration headaches for our clients, ensuring that crucial production data, such as cutting speed, material consumption, and job completion status, flows seamlessly into their existing management systems. This focus on connectivity helps mitigate the pain point of machines lacking local service support by enabling remote diagnostics and preventative maintenance through integrated data.

The transition to smart manufacturing and the operation of advanced machinery like tube laser cutters demand a workforce with new skills. There's a growing shortage of skilled labor proficient in operating digitalized systems, performing complex programming, and conducting advanced maintenance. Traditional manufacturing roles often do not equip workers with the necessary expertise in data analytics, cybersecurity, or advanced robotics. This skills gap can lead to underutilized machinery, operational inefficiencies, and an increased reliance on external technical support.

Ahmed Al-Farsi's concern about high operator turnover causing retraining burdens is a perfect illustration of this challenge. Investing in a sophisticated laser cutting machine only makes sense if there are operators who can maximize its potential. Our MZBNL solution directly addresses this with our No-CAD Operating System, which dramatically lowers the skill threshold for machine operation. Operators only need 1 day of on-site training instead of spending 15 days at the equipment factory. This significantly reduces the training burden and makes it easier for businesses to onboard new staff. Furthermore, we offer comprehensive post-sales training and support, including remote diagnostics and spare parts availability, ensuring that our clients are never left without the necessary expertise. This holistic approach to training and support is crucial for bridging the skills gap and empowering the workforce to fully leverage the capabilities of smart machinery.

High initial investment is a challengeTrue

The text clearly states that integrating tube laser cutting machines requires substantial investment in machinery, software, and infrastructure upgrades.

Legacy systems integrate easilyFalse

The text explains that data interoperability between legacy equipment and new systems is a significant challenge due to different protocols and standards.

How can the integration of tube laser cutting machines in smart manufacturing be optimized for future advancements?

Are you wondering how to future-proof your smart manufacturing investments? The rapidly evolving technological landscape demands strategies for continuous optimization and seamless integration of emerging advancements. Discover effective approaches to refine your tube laser cutting machine integration, ensuring adaptability and maximizing long-term efficiency in your smart factory.

Optimizing tube laser cutting machine integration involves prioritizing modular, open-architecture systems, investing in continuous workforce training, implementing robust data analytics for performance insights, and embracing cybersecurity best practices. Leveraging AI/ML for predictive maintenance and dynamic scheduling also enhances adaptability for future advancements.

From my perspective at MZBNL, optimizing the integration of tube laser cutting machines isn't a one-time task; it's a continuous process of refinement and adaptation. For a client like Ahmed Al-Farsi, whose business thrives on efficiency and reliability, ensuring that his investment in our Laser Tube Cutting Machine remains cutting-edge is paramount. This isn't just about the machine's initial performance; it's about its capacity to evolve with new technologies, to seamlessly integrate with future software upgrades, and to continue delivering optimal results for years to come. It requires a forward-thinking approach that focuses on flexibility, data leverage, and human-machine collaboration.

One of the most effective strategies for optimizing integration is to prioritize modular and open-architecture systems. Unlike proprietary, closed systems that limit compatibility and future upgrades, open architectures allow for easier integration of new technologies, software, and third-party solutions. This modularity means that specific components or software modules can be updated or replaced without overhauling the entire system, offering greater flexibility and longevity for your investment. It ensures that your smart factory is not locked into a single vendor's ecosystem, allowing you to incorporate the best available technologies as they emerge.

For example, when MZBNL designs its laser cutting machines, we ensure they are built with compatibility in mind, leveraging industry standards for data exchange like OPC UA. This means that if Ahmed Al-Farsi wants to integrate a new type of robotic arm for automated part sorting or a more advanced MES system in the future, our machine will be able to communicate with it without extensive custom programming or costly workarounds. This "plug-and-play" capability, even if not fully literal, significantly reduces the complexity and cost of future upgrades, making the initial investment more sustainable and adaptable. This approach contrasts sharply with older, closed systems that often necessitated a complete equipment replacement just to keep pace with technological advancements, thereby providing a more cost-effective and flexible pathway for continuous optimization.

A critical aspect of optimization involves continuous investment in workforce training and development. While smart machines like MZBNL's No-CAD system simplify operations, the evolving nature of smart manufacturing demands new skills from operators, maintenance technicians, and even management. Training should go beyond basic machine operation to include data interpretation, troubleshooting automated systems, understanding cybersecurity protocols, and leveraging analytical tools to optimize production workflows. This ongoing education ensures that the human element of the smart factory remains competent and adaptable.

For Ahmed, whose pain points include high operator turnover and retraining burdens, our focus on user-friendly design with minimal training requirements is a direct solution. However, to truly optimize, his team should also be trained on interpreting the data generated by the machine, identifying efficiency improvements, and performing predictive maintenance. This proactive approach ensures that the human workforce evolves alongside the technology. MZBNL offers comprehensive post-sales training and support, including remote diagnostics, which empowers local teams to troubleshoot minor issues and leverage advanced features, ultimately reducing reliance on external support and increasing operational autonomy. This investment in human capital ensures that the technology's full potential is consistently harnessed, translating directly into improved productivity and a stronger competitive edge.

To truly optimize the integration of tube laser cutting machines within a smart factory, manufacturers must embrace data analytics and artificial intelligence (AI) beyond simple monitoring. This involves leveraging machine learning algorithms to identify complex patterns in operational data, predict potential machine failures before they occur (predictive maintenance), and dynamically optimize cutting parameters for various materials and geometries. AI can also be used for advanced scheduling, automatically adjusting production plans based on real-time factors like raw material availability, machine load, and urgent customer orders.

For instance, consider a scenario where MZBNL's laser cutting machine processes diverse metal pipes for different industries. An AI-powered system could analyze historical cutting data, material properties, and environmental conditions to suggest optimal laser power, speed, and gas pressures for each job, minimizing waste and maximizing efficiency. Our Zero-Waste Tail Material Innovation, which optimizes material utilization, can be further enhanced by AI that learns from cutting patterns to achieve even greater material savings over time. Such an AI-driven approach significantly outperforms static programming, as it adapts and learns from continuous operations. Data from industry reports suggests that AI integration in manufacturing can lead to a 20-30% improvement in overall equipment effectiveness (OEE).

| Optimization Strategy | Description | MZBNL Example | Impact on Smart Manufacturing |

|---|---|---|---|

| Open Architecture | Flexible systems allowing easy integration of new tech. | MZBNL's broad compatibility with MES/ERP systems | Future-proofing, reduced upgrade costs |

| Continuous Training | Upskilling workforce in data, AI, maintenance. | 1-day No-CAD training, ongoing remote support | Enhanced human-machine collaboration, reduced downtime |

| Advanced Analytics | AI/ML for predictive maintenance & process opt. | AI-enhanced material optimization (Zero-Waste) | Proactive maintenance, increased efficiency, cost savings |

| Cybersecurity | Protecting data and systems from threats. | Secure data protocols, network best practices | Data integrity, operational continuity |

Furthermore, the implementation of robust cybersecurity measures is paramount. As more machines become interconnected and data flows freely across networks, the attack surface for cyber threats expands significantly. A breach could lead to operational downtime, intellectual property theft, or compromise sensitive customer data. Therefore, optimizing integration also means ensuring that all communication channels are encrypted, access controls are stringent, and regular security audits are conducted. This builds a resilient and trustworthy smart factory environment, essential for protecting business assets and maintaining client confidence.

Open architecture enables future upgradesTrue

Modular systems allow component updates without full system replacement, ensuring long-term adaptability.

AI replaces human operators entirelyFalse

While AI enhances efficiency, human oversight remains crucial for data interpretation and strategic decision-making.

What future trends and technological advancements are expected for tube laser cutting machines in smart manufacturing?

Are you wondering what's next for tube laser cutting in the rapidly evolving world of smart manufacturing? The pace of innovation means yesterday's cutting-edge is today's standard. Discover the exciting future trends and technological advancements poised to redefine precision, efficiency, and intelligence in tube laser cutting machines.

Future trends for tube laser cutting machines include deeper AI/ML integration for autonomous operation and predictive quality, advanced sensor fusion for real-time process control, enhanced digital twin capabilities for virtual commissioning, and increased sustainability through optimized material usage. Expect greater human-robot collaboration and seamless cloud integration.

Looking ahead, my vision for MZBNL, and for the entire metal fabrication industry, is one of continuous innovation where tube laser cutting machines become even more intelligent, autonomous, and integrated. For a forward-thinking business like Ahmed Al-Farsi's, staying ahead of these trends isn't just about competitive advantage; it's about pioneering new possibilities for architectural metalwork and vehicle parts, offering services that others simply cannot match. The trajectory of these advancements points towards factories that are not only smarter but also more adaptable, sustainable, and capable of unprecedented levels of precision and efficiency.

One of the most significant advancements expected is the deeper integration of artificial intelligence (AI) and machine learning (ML) to enable increasingly autonomous operations and predictive quality control. Currently, AI assists with optimization; in the future, it will drive decisions. Machines will learn from vast datasets, not just of cutting parameters but also of material characteristics, environmental conditions, and real-time feedback from the cutting process itself. This will allow the laser cutter to adapt its settings dynamically, ensuring optimal performance and consistent quality even with variations in raw materials or machine wear.

Imagine a tube laser cutting machine that can self-diagnose minor issues before they escalate, automatically order spare parts, and even adjust its cutting path to compensate for slight material imperfections, all without human intervention. For instance, MZBNL's No-CAD system already simplifies operation, but future iterations will use AI to suggest optimal cutting sequences for complex parts, potentially even learning from user feedback and design variations. This level of autonomy will dramatically reduce the need for constant supervision, allowing skilled operators to oversee multiple machines or focus on more complex design and innovation tasks. This transition shifts the operator's role from manual control to strategic oversight, directly addressing the pain point of high operator turnover and the need for constant retraining by making the machines inherently "smarter" and easier to manage.

Another crucial future trend is the advancement of sensor fusion and real-time process control4. Future tube laser cutting machines will incorporate an even greater array of sophisticated sensors—thermal cameras, spectral analyzers, acoustic sensors, and more—to gather comprehensive data about the cutting process in real time. This sensor data will be fused and analyzed instantly by edge computing devices, allowing for micro-adjustments to laser power, gas pressure, and cutting speed at a millisecond level. This level of granular control will virtually eliminate defects and ensure unparalleled precision, especially for demanding applications in industries like aerospace or medical devices.

Consider the challenge of cutting thick or reflective materials, where precision is paramount. Current machines perform well, but future systems, enhanced with advanced sensor fusion, will be able to detect the slightest variations in material composition or surface finish and adjust accordingly, preventing issues like dross formation or heat distortion before they occur. This predictive quality control ensures that every part cut is within tolerance, reducing scrap rates and material waste significantly. Building upon MZBNL's Zero-Waste Tail Material Innovation, these advancements will contribute to even greater material efficiency, pushing towards near-zero waste production. This level of technological refinement will enhance the machine's capabilities for complex and demanding projects, crucial for clients producing intricate parts for automotive and sanitary ware sectors.

The concept of digital twins5 will become integral to the operation and optimization of tube laser cutting machines. A digital twin is a virtual replica of a physical machine, continuously updated with real-time data from its physical counterpart. This allows manufacturers to simulate production runs, test new cutting programs, or even troubleshoot issues in a virtual environment before implementing them on the actual machine. This capability will revolutionize R&D, maintenance, and training by providing a risk-free testing ground.

For example, Ahmed Al-Farsi could use a digital twin of his MZBNL laser tube cutting machine to virtually commission new product designs, optimizing cutting paths and material nesting without consuming actual raw materials or machine time. This "what-if" scenario planning helps identify potential bottlenecks or inefficiencies in the design phase, drastically reducing lead times and ensuring first-time-right production. Moreover, technicians could use the digital twin for training purposes, simulating various operational scenarios and troubleshooting exercises, which would significantly improve their skills and responsiveness. Industry reports project that digital twin technology can reduce product development cycles by 25-50% and decrease maintenance costs by 10-20%, making it a cornerstone of future smart manufacturing. MZBNL's commitment to technological innovation means we are actively exploring how digital twin capabilities can further empower our global clientele, delivering tailored solutions and unprecedented operational insights.

AI will enable autonomous tube laser cuttingTrue

Future tube laser cutting machines will use AI to make autonomous decisions about cutting parameters and quality control without human intervention.

Digital twins require physical machine operationFalse

Digital twins allow virtual testing and optimization without needing to operate the physical machine, saving materials and time.

Conclusion

The future of tube laser cutting machines in smart manufacturing is bright, marked by deeper integration, autonomous capabilities, and unparalleled precision. These intelligent systems, like MZBNL's innovative solutions, are critical for optimizing efficiency, reducing waste, and enabling flexible, data-driven production in factories worldwide, meeting the evolving demands of industries.

-

Understand MES's role in optimizing production and improving efficiency in smart factories ↩

-

Discover how AGVs can automate material transport and improve operational efficiency ↩

-

Learn about the advantages and applications of precision laser cutting in modern manufacturing. ↩

-

Discover how sensor advances optimise precision and control during cutting processes ↩

-

Explore the advantages of virtual simulations for cutting machine operation and optimization ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.