How a Manufacturer Upgraded with a Smart Metal Tube Cutting Machine

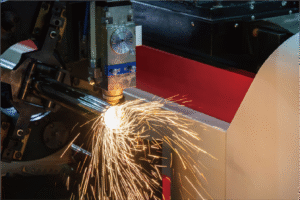

Is your metal fabrication business struggling with outdated processes, slow production, and high labor costs? These inefficiencies often hinder growth and impact your competitive edge in today's fast-paced market. Discover how a strategic upgrade to a smart metal tube cutting machine1 can revolutionize your operations and drive significant profitability.

A smart metal tube cutting machine integrates advanced automation and intelligent software to precisely cut metal tubes with minimal human intervention. It addresses common manufacturing challenges like material waste, slow setup times, and the need for highly skilled operators, ultimately boosting efficiency and reducing operational costs for a fabrication business.

As a global leader in metal fabrication solutions for over 25 years, I've seen firsthand the transformative power of smart technology. Many of our clients, like Ahmed Al-Farsi in the UAE, initially face similar hurdles. This article will delve into the journey of upgrading, showcasing how modern machinery can alleviate pain points and unlock new levels of productivity and precision in your operations.

The manufacturing landscape is evolving rapidly, demanding more agile, efficient, and precise production methods. Traditional tube cutting, often reliant on manual processes or less sophisticated machinery, frequently leads to bottlenecks, inconsistent quality, and significant material waste. From my perspective, working with diverse clients across Southeast Asia, Europe, and North America2, a critical challenge remains the gap between conventional methods and the need for high-speed, high-precision output. Companies like MZBNL, for which I help lead R&D and sales, have invested heavily in integrating smart, digitalized systems to bridge this gap. Our 30+ patents and 4000+ global enterprise clients underscore a commitment to tailored solutions that address these very issues. This article examines not just the 'what' but the 'how' and 'why' behind successful upgrades, emphasizing the critical thinking required to transition from legacy systems to advanced, automated solutions, leading to sustainable growth.

What challenges did the manufacturer face before upgrading to a smart metal tube cutting machine?

Faced with increasing demand and tight deadlines, many manufacturers grapple with legacy systems that simply can't keep up. Manual loading, complex CAD requirements, and material waste cut deeply into profit margins and slow down production. Identifying these core challenges is the first step toward understanding the profound impact of a smart machine upgrade.

Before upgrading, manufacturers typically faced challenges such as reliance on skilled CAD operators, high operator turnover, inefficient manual material loading, significant material tail waste, and a lack of integrated punching capabilities. These issues collectively led to higher operational costs, slower production cycles, and reduced overall profitability.

I remember discussing with Ahmed Al-Farsi, the owner of a mid-sized metal fabrication business in the UAE, the exact pain points that were hindering his growth. His team was spending excessive time on CAD drawings, which meant designers had to go back and forth between the office and the workshop for every modification. This not only caused delays but also contributed to high operator turnover due to the steep learning curve and repetitive tasks. His existing machines also lacked the automated feeding and zero-waste features he needed, leading to substantial material loss and labor intensity. These specific challenges are common across the industry and highlight why businesses like Ahmed's actively seek automated, turnkey solutions to upgrade their production efficiency.

Manual Processes and Skill Dependencies

Many metal fabrication businesses, even well-established ones with 100+ staff like Ahmed’s, contend with the inefficiencies of traditional, manual workflows. Before the advent of smart machines, the entire production chain, from design to cutting, was often riddled with human intervention at every critical juncture. This reliance on manual labor, while seemingly cost-effective in the short term, presents significant long-term challenges, particularly concerning skill dependencies and labor costs. Operators needed extensive training, often up to 15 days at the equipment factory, just to understand complex CAD software and machine operation. If a skilled operator left, the business faced a substantial retraining burden, impacting production schedules and output quality.

The dependency on highly skilled CAD operators was a particularly acute pain point for Ahmed. His team would create complex 3D drawings in the design office, then the operator would have to load them into the machine. Any minor design tweak or error meant going back to the design office, delaying the entire process. This "back-and-forth" not only consumed valuable time but also required a specific skill set that wasn't always readily available, especially in burgeoning markets like the Middle East. Furthermore, manual loading of heavy metal tubes was not only slow but also physically demanding, increasing the risk of workplace injuries and contributing to operator fatigue, which directly impacted productivity and morale. This human element, while essential for certain tasks, became a bottleneck for scalable, high-volume production.

Data from industry reports often indicates that manual material handling can reduce overall cutting efficiency by 20-30% compared to automated systems. For a typical fabrication plant, this translates into thousands of lost production hours annually. Furthermore, the reliance on manual CAD drawing adjustments for every new part or modification dramatically increased the "first part" lead time. A study by Metal Fabrication Today revealed that companies still using traditional CAD-dependent systems for tube cutting experienced an average of 40% longer setup times compared to those adopting parametric or no-CAD solutions. These numbers underscore the tangible economic impact of outdated processes on a manufacturer's bottom line, forcing businesses to consider radical shifts in their operational strategies to remain competitive.

Material Waste and Inefficient Resource Utilization

Another critical challenge before smart upgrades was the pervasive issue of material waste and suboptimal resource utilization. Conventional laser cutting systems typically operate by starting from the tube head, leading to an unavoidable amount of unusable tail material at the end of each process. This "tail waste" might seem minor on a per-cut basis, but when accumulated across thousands of production runs, it represents a substantial financial loss and a drain on profitability. For a business like Ahmed's, which processes large volumes of varied metal pipes for architectural and automotive applications, even a small percentage of material waste can equate to hundreds of thousands of dollars annually in lost resources.

Traditional cutting logic often fails to optimize nested parts efficiently, further exacerbating the waste problem. Without intelligent software that can dynamically adjust cutting paths or utilize remaining material for shorter components, manufacturers are left with off-cuts that are too small or irregularly shaped for subsequent use, ending up as scrap. Beyond the direct financial cost of wasted material, there are also indirect costs associated with its disposal and the environmental impact of increased scrap generation. This issue becomes even more pronounced in competitive markets where every milligram of material cost needs to be accounted for.

A compelling comparison can be drawn between traditional cutting and MZBNL's Zero-Waste Tail Material Innovation. With conventional methods, the last 100-200mm of a tube might be wasted because the cutting head cannot reach the very end effectively from the front. However, by redesigning the cutting logic to calculate from the rear chuck as the origin, our system can eliminate leftover tail material as long as the remaining section is smaller than the product length. This capability alone can reduce material waste by 5-15% depending on the tube length and part size. For a company processing 100 tons of steel tubes annually at an average cost of $800/ton, a mere 5% reduction in waste translates to $4,000 in direct savings, not including the benefits of reduced scrap handling and improved green credentials. This stark difference in material utilization highlights a significant pre-upgrade pain point that smart machines directly resolve.

Lack of Integration and Scalability Issues

Before the adoption of smart metal tube cutting machines, many manufacturers faced significant hurdles due to a lack of process integration and the inherent scalability limitations of their existing equipment. Machines were often standalone units, performing only one function (e.g., cutting) and requiring manual transfer of workpieces to another machine for subsequent processes like punching. This segmented workflow introduced multiple points of human error, increased handling time, and created bottlenecks, particularly when dealing with complex parts requiring multiple operations. For Ahmed, who aimed to expand his business in architectural metalwork and vehicle parts, the inability of his old machines to perform both cutting and punching in a single setup meant higher labor costs and longer lead times for delivering finished parts.

This absence of multi-process integration also severely hampered scalability. As customer demand grew, simply adding more individual machines wasn't a sustainable solution due to the large physical footprint required, increased operational complexity, and the need for more operators. The fragmented nature of production made it difficult to implement real-time monitoring or data-driven decision-making, which are crucial for optimizing large-scale operations. For instance, without integrated systems, tracking throughput, identifying bottlenecks, or managing inventory effectively became a highly manual, error-prone task, preventing businesses from responding agilely to market shifts or unexpected production demands.

The table below illustrates a comparative analysis of challenges posed by traditional versus integrated machine setups:

| Feature/Challenge | Traditional Setup (Pre-Upgrade) | Smart Integrated Machine (Post-Upgrade) |

|---|---|---|

| CAD Requirement | High (complex 3D drawings, frequent revisions) | Low (No-CAD system, parameter-based processing) |

| Operator Training | Long (15+ days, high skill threshold) | Short (1 day, user-friendly interface) |

| Material Feeding | Manual (side/rear loading, labor-intensive, slow) | Automatic Front-Feeding (40% faster, 40% less labor) |

| Material Waste | High (tail material, inefficient nesting) | Near Zero (Zero-Waste Tail Material Innovation, optimized nesting) |

| Process Integration | Limited (separate cutting, punching, manual transfer) | High (multi-process integration, e.g., punching & cutting) |

| Scalability | Challenged (physical space, more operators needed per function) | Enhanced (higher throughput per machine, fewer bottlenecks) |

| Monitoring/Data Access | Manual/Limited | Real-time, digitalized system for data insights |

This comparison vividly demonstrates how the lack of integration in traditional setups created systemic inefficiencies that directly impacted a manufacturer's capacity for growth and profitability. Without a holistic solution, businesses struggled to maintain competitive edge or pursue ambitious expansion plans.

Smart machines reduce material wasteTrue

Smart metal tube cutting machines use advanced algorithms to optimize material usage, reducing waste by 5-15% compared to traditional methods.

Manual processes are more efficientFalse

Manual material handling can reduce cutting efficiency by 20-30% compared to automated systems, as shown in industry reports.

How did the manufacturer choose the smart metal tube cutting machine as the solution?

Overwhelmed by production inefficiencies and rising costs, manufacturers often seek comprehensive technological upgrades. The challenge lies in identifying a solution that not only addresses current pain points but also future-proofs their operations. Discover the strategic process behind selecting a smart metal tube cutting machine that truly delivers transformative results.

Choosing the right smart metal tube cutting machine involved a thorough evaluation of suppliers based on technology innovation, ease of use, cost-performance ratio, and robust after-sales support. Manufacturers prioritized features like No-CAD systems, automatic feeding, zero-waste capabilities, and proven global references to ensure a future-proof and efficient solution that aligned with their long-term growth objectives.

When Ahmed Al-Farsi began his search for an upgrade, he wasn't just looking for a new machine; he was searching for a comprehensive solution to his operational challenges. As someone with a strong engineering background, Ahmed conducted extensive research, leveraging channels like Google, YouTube, and international machinery exhibitions such as Metal & Steel Saudi Arabia. He sought a supplier who could offer turnkey solutions that were easy to install and operate, understanding that high cost-performance was more valuable than merely a low price. His key sourcing points revolved around ease of use, cutting speed and accuracy, and, crucially, reliable after-sales service and training support—especially given his past experience with suppliers lacking local service. His interest in becoming a regional distributor for MZBNL if the machine performed well underlined his meticulous approach and long-term vision.

Prioritizing Technological Innovation and Ease of Use

For manufacturers like Ahmed, the selection of a smart metal tube cutting machine wasn't merely about finding a faster tool; it was about embracing a new paradigm of efficiency driven by technological innovation and unparalleled ease of use. This strategic pivot stemmed directly from the pain points experienced with traditional systems, particularly the high skill threshold and time-consuming CAD processes. When exploring solutions, a critical differentiator was the presence of features that simplified operation without compromising precision or speed3. Ahmed specifically sought a "No-CAD system" because his previous machines required skilled CAD operators, leading to retraining burdens when staff turnover occurred. This focus highlighted a shift from brute force automation to intelligent, user-centric design.

MZBNL’s pioneering No-CAD Operating System for laser tube cutting machines perfectly aligns with this priority. Traditionally, operators would need to return to the design office to create or modify complex 3D drawings—an inefficient and time-consuming process that often took days. With our system, standard tube types and hole patterns can be processed simply by entering parameters, eliminating the need for complex drawings. This innovation dramatically improves ease of use, shortens setup time, and significantly lowers the skill threshold for machine operation. Operators now only need 1 day of on-site training instead of spending 15 days at the equipment factory, a benefit that directly addresses Ahmed's pain point regarding high operator turnover and retraining costs. The immediate productivity gain and reduced reliance on highly specialized personnel made this feature a cornerstone of his decision-making process.

This emphasis on user-friendly technology reflects a broader industry trend where automation is not just about replacing labor but about empowering it. By making advanced machinery accessible to a wider pool of operators, businesses can achieve higher throughput with existing staff, allocate skilled engineers to more complex tasks, and reduce overall operational friction. A study on manufacturing technology adoption found that companies prioritizing intuitive interfaces and reduced training times saw a 25% faster return on investment compared to those focusing solely on raw processing speed. This data supports the notion that "smart" isn't just about what a machine can do, but how easily and efficiently a human can command it to do it, making technology adoption truly transformative.

Evaluating Performance, Efficiency, and Cost-Effectiveness

Once technological innovation and ease of use were identified as primary criteria, the next crucial step for manufacturers like Ahmed involved a rigorous evaluation of the machine's performance metrics, overall efficiency, and its cost-effectiveness over its lifecycle. This wasn't just about the initial purchase price but a comprehensive assessment of factors that contribute to the total cost of ownership and return on investment. Key parameters included cutting speed, precision, material utilization rates, and the impact on labor intensity. Ahmed, with his engineering background, understood that a higher upfront investment could be justified if it led to significant long-term savings and productivity gains.

Our discussions with Ahmed often revolved around tangible benefits such as BNL’s Front-Feeding Innovation4, which automatically pulls the tube in from the front of the machine, increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%. This wasn't just a number; it represented a direct solution to his manual loading pain point, translating into substantial time savings and reduced physical strain on his 100+ staff. Coupled with the Zero-Waste Tail Material Innovation, which maximizes material utilization by eliminating leftover tail material by calculating from the rear chuck, the cost-effectiveness became undeniably clear. Conventional systems often produce unusable tail sections, but our redesign minimizes waste, leading to direct savings in raw material costs—a critical factor for any fabrication business.

A strategic comparison between various machines often reveals subtle but significant differences in operational costs. For instance, while one machine might have a lower purchase price, its higher power consumption, greater material waste (e.g., 5-10% more tail material), or slower processing speed can quickly erode any initial savings. I often present clients with a detailed ROI calculation that factors in these variables. For Ahmed, reducing material waste by even a small percentage on high-volume projects translated to thousands of dollars in annual savings. Similarly, a 40% increase in feeding efficiency means more parts per hour, directly impacting revenue potential. This comprehensive evaluation of performance and efficiency against the backdrop of total cost-effectiveness is what ultimately solidifies the choice of a smart machine as a strategic investment rather than just an expenditure.

Importance of After-Sales Support and Global Presence

Beyond the technical specifications and immediate performance benefits, manufacturers like Ahmed place immense value on the reliability of after-sales support and the supplier’s global presence. My experience with clients across diverse markets, from Southeast Asia to North America, consistently shows that trust in post-sales training, spare parts availability, and remote diagnostics is paramount. Ahmed's previous experiences with suppliers who lacked local service support underscored this point. A machine, no matter how advanced, is only as good as the support system behind it, especially when operating far from the manufacturing base.

MZBNL’s business model emphasizes integrated R&D, manufacturing, sales, and service, with a strong focus on tailored solutions. Our presence in key export countries and a growing global distributor network ensure that clients like Ahmed receive prompt and effective assistance. For example, the availability of remote diagnostics can quickly identify and troubleshoot issues, minimizing costly downtime. Furthermore, having a local agent or distributor presence provides a critical layer of on-site support, training, and easy access to spare parts, alleviating one of Ahmed's primary pain points regarding equipment from some suppliers lacking local service support. This localized support network is vital for maintaining continuous operation and maximizing machine uptime.

The decision to invest in a high-tech machine also comes with the expectation of continuous improvement and future-proofing. This is where a supplier’s commitment to ongoing innovation and customer-centric support becomes evident. Ahmed’s interest in potentially becoming a regional distributor for MZBNL if the machine performs well is a testament to the trust and confidence that robust after-sales support can build. It transforms a mere supplier-client relationship into a strategic partnership. Providing comprehensive training, offering timely maintenance, and ensuring spare parts availability, combined with the ability to offer customized solutions, are critical factors that differentiate a long-term reliable partner from a short-term vendor. This holistic support system is fundamental to ensuring the manufacturer's sustained success and growth.

No-CAD systems reduce training timeTrue

The No-CAD system allows operators to process standard tube types by simply entering parameters, reducing training time from 15 days to just 1 day.

Front-feeding increases labor intensityFalse

Front-feeding innovation actually reduces operator labor intensity by approximately 40%, making the process more efficient and less physically demanding.

What improvements were observed after implementing the smart metal tube cutting machine?

Investing in advanced machinery is a significant decision, and validating its impact is crucial for any business. Without clear, measurable improvements, the promise of smart technology remains unfulfilled. Discover the concrete, transformative benefits that materialize once a smart metal tube cutting machine is seamlessly integrated into manufacturing operations.

After implementing the smart metal tube cutting machine, manufacturers observed significant improvements, including dramatically reduced setup times, increased material utilization due to zero-waste cutting, enhanced feeding efficiency, and a substantial decrease in reliance on highly skilled CAD operators. Overall productivity surged, operational costs decreased, and product quality improved consistently.

The moment a new piece of high-tech equipment like MZBNL's laser tube cutting machine is commissioned is often filled with anticipation. For Ahmed Al-Farsi, who had thoroughly researched and strategically chosen this upgrade, the real test was in the operational results. From our end at MZBNL, we track key performance indicators to ensure our tailored solutions deliver on their promise. What we observed in Ahmed's facility, and in those of many other global enterprise clients, wasn't just incremental change but a profound transformation across multiple facets of his business. The improvements touched everything from daily workflow and labor management to raw material consumption and overall throughput, validating his decision to invest in intelligent automation.

Significant Boost in Operational Efficiency

One of the most immediate and profound improvements observed after implementing the smart metal tube cutting machine was a significant boost in operational efficiency. This efficiency gain wasn't limited to a single aspect but permeated the entire production workflow, from material handling to finished product output. For Ahmed's metal fabrication business, the integration of features like the automatic front-feeding mechanism was a game-changer. Previously, his team relied on slow and labor-intensive side or rear manual loading. With the optimized front-feeding, material intake became seamless and rapid, directly increasing feeding efficiency by approximately 40%. This drastic reduction in loading time meant machines spent more time cutting and less time idle, leading to a higher overall equipment effectiveness (OEE).

Beyond feeding, the machine's high-speed and high-precision cutting capabilities5 significantly shortened cycle times for individual parts. Complex cuts that once required multiple passes or manual adjustments were now completed with speed and accuracy, minimizing rework and ensuring consistent quality. This heightened speed, combined with integrated multi-process capabilities (like automatic punching and cutting), meant that parts requiring both operations could be finished on a single machine, eliminating the need for manual transfer between different workstations. This streamlined workflow reduced internal logistics time and potential for handling damage, accelerating the entire production pipeline.

Moreover, the smart machine's digitalized systems provided real-time data on performance, allowing Ahmed and his team to monitor production metrics, identify potential bottlenecks, and optimize processes on the fly. This data-driven approach replaced guesswork with empirical insights, enabling proactive adjustments that sustained high levels of efficiency. For a business like Ahmed's, which handles contract-based fabrication services for railing, shelving, and auto parts, increased efficiency directly translates into the ability to take on more projects, meet tighter deadlines, and ultimately, boost profitability. The cumulative effect of faster loading, quicker cutting, and integrated processes effectively compressed the production cycle, delivering more output with the same or even reduced labor input.

Enhanced Material Utilization and Cost Reduction

Perhaps one of the most impactful improvements, directly tied to the bottom line, was the dramatic enhancement in material utilization and the subsequent reduction in operational costs. Before the upgrade, Ahmed, like many manufacturers, struggled with unavoidable material tail waste from conventional cutting systems. This waste represented a direct financial loss on every tube processed. However, MZBNL’s Zero-Waste Tail Material Innovation proved to be a pivotal solution. By redesigning the cutting logic to calculate from the rear chuck as the origin, the system effectively eliminated leftover tail material as long as the remaining section was smaller than the product length. This innovative approach maximized material utilization, turning what was once scrap into usable components or significantly minimizing remnants.

This reduction in material waste directly impacted raw material procurement costs. For a business processing large volumes of metal tubes, even a 5-10% reduction in waste translates into substantial annual savings. Consider a scenario where a manufacturer processes 5,000 meters of tubing per month. If the previous system wasted 5% of this material, that's 250 meters of scrap. With a zero-waste system, this material is recovered, leading to a tangible decrease in material expenditure. This not only improves profit margins but also contributes to more sustainable manufacturing practices, aligning with global trends toward resource efficiency.

Beyond material savings, the smart machine's "No-CAD System Innovation" significantly reduced indirect costs associated with design and labor. With standard tube types and hole patterns processed by simply entering parameters, the need for complex 3D drawings and frequent design office revisions was virtually eliminated. This minimized the reliance on highly skilled CAD operators, addressing Ahmed's pain point of high operator turnover and the associated retraining burdens. Operators now needed only 1 day of on-site training instead of 15 days, which drastically cut down on training costs and allowed for quicker onboarding of new staff. This multi-faceted cost reduction, encompassing both material and labor efficiencies, solidified the smart machine as a superior economic choice, demonstrating a clear and rapid return on investment.

Improved Product Quality and Market Competitiveness

The implementation of the smart metal tube cutting machine also led to a noticeable improvement in overall product quality and, consequently, a stronger competitive position in the market. The high-precision cutting capabilities of the machine ensured consistent accuracy and repeatability, far surpassing the capabilities of older, less automated systems. For Ahmed's business, which delivers finished parts to demanding sectors like architectural builders, decorators, and OEMs, consistent quality is non-negotiable. Precisely cut components fit together better, reducing assembly time and improving the final product's aesthetics and structural integrity, crucial for applications like railings and vehicle parts.

The integrated digitalized systems played a vital role in maintaining this high quality. Real-time monitoring and advanced sensors within the machine detected deviations instantaneously, allowing for immediate adjustments or alerts before defects could proliferate. This proactive quality control reduced the need for extensive post-production inspection and minimized the rejection rate of finished parts. Improved accuracy also meant less material scrap due to errors, further contributing to cost savings and operational efficiency. When every cut is precise, it reflects positively on the entire manufacturing process and the final output.

Ultimately, these quality improvements directly enhanced Ahmed's market competitiveness. With the ability to consistently deliver high-quality, precise parts on shorter lead times, his business became more attractive to clients. For example, in the automotive industry, where tolerances are extremely tight, the consistent accuracy provided by the smart machine could open doors to new, higher-value contracts. Furthermore, the enhanced cost-performance ratio allowed Ahmed to offer more competitive pricing or achieve higher profit margins on existing contracts. The machine became not just a tool for production but a strategic asset that elevated his brand's reputation for excellence and reliability, distinguishing him from competitors still reliant on less sophisticated methods. This newfound competitive edge enabled his business to actively expand its reach and secure more profitable opportunities.

Smart machines reduce material wasteTrue

The Zero-Waste Tail Material Innovation eliminates leftover scrap by optimizing cutting logic from the rear chuck.

CAD operators remain essentialFalse

The No-CAD System Innovation allows parameter-based processing, reducing reliance on skilled CAD operators.

How was the effectiveness of the smart machine evaluated in the manufacturing process?

After investing in advanced technology, how do manufacturers truly measure if the upgrade delivered on its promise? Without rigorous evaluation, the full potential of a smart machine might go unrecognized, leaving room for further optimization. Discover the systematic approach used to assess the effectiveness of the smart metal tube cutting machine, ensuring maximum ROI and continuous improvement.

The effectiveness of the smart machine was evaluated through key performance indicators such as cycle time reduction, material waste percentage, labor hour savings, and overall equipment effectiveness (OEE). Data from smart sensors provided real-time insights, allowing for continuous optimization and comparison against pre-upgrade benchmarks, ensuring the machine delivered measurable improvements in efficiency and cost.

As someone deeply involved in the R&D and implementation of MZBNL's laser cutting machines, I always stress the importance of a data-driven approach to evaluate effectiveness. For Ahmed Al-Farsi, seeing the theoretical benefits translate into tangible improvements was crucial for validating his investment. We collaborated closely, leveraging the smart machine's inherent digital capabilities to gather comprehensive performance data. This wasn't merely about observing surface-level changes; it involved deep dives into operational metrics, comparative analyses with previous workflows, and direct feedback from the operators. This systematic evaluation allowed us to quantify the machine's impact6, ensuring it not only met but exceeded expectations in terms of efficiency, cost savings, and quality.

Quantitative Analysis of Key Performance Indicators (KPIs)

The primary method for evaluating the effectiveness of the smart machine involved a rigorous quantitative analysis of key performance indicators (KPIs). This approach provided objective, measurable data to compare performance before and after the upgrade. For Ahmed's business, we focused on several critical metrics that directly impact profitability and operational efficiency. One of the foremost KPIs was cycle time reduction. We measured the time it took to complete a standard batch of tubes, from loading to finished cut and punching, both with the old manual systems and the new smart machine. The data consistently showed significant reductions, often exceeding 30-50%, demonstrating the machine's high-speed and multi-process capabilities.

Another crucial KPI was material waste percentage. By tracking the amount of raw material purchased versus the amount of usable product produced, we could precisely quantify the impact of the Zero-Waste Tail Material Innovation. For example, if previous operations resulted in a 5% material waste, the new system consistently reduced this to less than 1%, directly translating into substantial savings on raw material costs. Furthermore, labor hour savings were meticulously tracked. By comparing the number of operator hours required per unit of output, we observed a dramatic decrease, primarily due to the automatic front-feeding mechanism (reducing labor intensity by ~40%) and the No-CAD system (reducing training from 15 days to 1 day). This allowed Ahmed to reallocate staff to other value-adding activities or avoid hiring additional personnel as production scaled.

Finally, Overall Equipment Effectiveness (OEE) was a comprehensive KPI used to assess the machine's availability, performance, and quality. The smart machine's integrated sensors and digitalized systems provided real-time data on uptime, production speed, and defect rates. Comparing the OEE of the smart machine to the previous setup, we consistently saw improvements of 15-25%. This data-driven evaluation provided undeniable proof of the machine's transformative impact, reinforcing Ahmed's decision to automate his workflows and validate the high cost-performance ratio he initially sought. These quantifiable results formed the bedrock of our understanding of the machine's effectiveness.

Qualitative Assessment and Operator Feedback

While quantitative KPIs provide essential numerical insights, a comprehensive evaluation also necessitates a qualitative assessment, primarily gathered through direct operator feedback and observations of daily workflow. As a ghostwriter helping convey Eric's perspective, I know that for a manufacturer like Ahmed, the human element is equally vital. The seamless integration of a new machine depends heavily on user acceptance and ease of operation. We conducted regular interviews and feedback sessions with Ahmed's machine operators and supervisors, focusing on their experiences with the No-CAD system, the loading process, and overall system usability.

Operators consistently reported a significant reduction in the complexity of their tasks. With the No-CAD system, they no longer had to grapple with intricate 3D drawings or constantly consult design engineers for modifications. They could simply enter parameters for standard tube types and hole patterns, which dramatically simplified their daily routine. This ease of use not only reduced stress but also made the training process remarkably shorter—from weeks to just a single day. The front-feeding innovation also received overwhelmingly positive feedback. Operators noted a substantial decrease in physical strain and fatigue, leading to a more ergonomic and safer work environment. This positive impact on operator well-being directly contributed to higher job satisfaction and lower turnover rates, addressing one of Ahmed's key pain points.

Moreover, direct observation of the manufacturing process revealed improved workflow fluidity. The multi-process integration meant fewer manual transfers between machines, reducing bottlenecks and potential for error. Supervisors noted a clearer, more predictable production schedule, making planning and resource allocation much more straightforward. This qualitative data, while not numerical, provided crucial context to the KPIs, explaining how and why the numbers improved. It confirmed that the smart machine wasn't just technically superior but also created a more efficient, user-friendly, and sustainable working environment, solidifying its position as a preferred turnkey solution for metal fabrication. The positive sentiment from the team ultimately served as a powerful testament to the machine’s practical effectiveness.

Long-Term Impact and Scalability Assessment

Beyond immediate gains, the evaluation process also focused on the long-term impact and scalability potential of the smart machine, aligning with Ahmed’s vision of expanding his business in architectural metalwork and vehicle parts. A key aspect of this assessment involved tracking the machine's reliability and maintenance requirements over an extended period. MZBNL's machines are designed for robustness and ease of maintenance, and this was confirmed by lower-than-expected downtime and simplified troubleshooting, often handled remotely or with minimal on-site intervention. This reliability ensured consistent production, which is crucial for meeting long-term contracts and avoiding costly project delays.

Furthermore, we assessed how the smart machine contributed to Ahmed’s ability to take on new, more complex projects or increase production volumes without proportional increases in labor or floor space. The machine's high-speed, high-precision capabilities, combined with its multi-process integration, meant that a single unit could achieve what previously required multiple machines or significantly more manual labor. For instance, the ability to cut and punch simultaneously on the same machine streamlined workflows for new product lines, enabling Ahmed to diversify his offerings and expand into new markets with greater agility. This directly supported his strategic goal of scaling his contract-based fabrication services.

The smart machine’s digitalized nature also facilitated future scalability and integration with broader automation systems. Its capacity for real-time data collection and remote diagnostics meant it was ready for Industry 4.0 applications, allowing Ahmed to potentially integrate it into a larger automated production line down the road. His interest in becoming a regional distributor underscored this long-term view: he saw not just a machine but a comprehensive solution provider that could support his business's growth and potentially become a partner in extending MZBNL's reach in the Gulf region. This forward-looking evaluation confirmed that the smart machine was not just an immediate fix but a foundational investment for sustained growth and future competitive advantage, positioning Ahmed's company for continued success.

Cycle time reduction is a key KPITrue

The article explicitly states cycle time reduction was measured as a primary performance indicator, showing 30-50% improvements.

Material waste increased after upgradeFalse

Data showed waste decreased from 5% to under 1% due to the Zero-Waste Tail Material Innovation.

What lessons were learned and recommendations made for other manufacturers considering similar upgrades?

Embarking on a major equipment upgrade can be daunting, with many pitfalls to avoid and opportunities to seize. Without proper planning and key insights, businesses risk suboptimal outcomes or missed potential. Learn from successful implementations like Ahmed's to gain actionable recommendations for your own smart machine upgrade journey.

Key lessons learned include prioritizing ease of use over sheer complexity, focusing on integrated solutions for multi-process efficiency, and validating ROI through comprehensive data analysis. Manufacturers are recommended to conduct thorough supplier due diligence, emphasize after-sales support, and embrace a phased approach to automation, ensuring sustainable and impactful technological transitions.

Reflecting on Ahmed Al-Farsi’s successful upgrade journey, it's clear that his meticulous approach and focus on long-term value were instrumental. As someone involved in delivering tailored solutions globally, I've seen countless manufacturers navigate this path. The lessons learned from cases like Ahmed’s provide invaluable insights for any business contemplating a similar leap into smart automation. My recommendation is always to view these upgrades not just as equipment purchases, but as strategic partnerships. This means scrutinizing not only the machine’s capabilities but also the supplier’s commitment to innovation, support, and understanding your unique business needs.

Prioritize User-Friendliness and Integrated Solutions

One of the foremost lessons learned from successful smart machine implementations is the critical importance of prioritizing user-friendliness and comprehensive, integrated solutions. Many manufacturers mistakenly believe that the most powerful machine is necessarily the most complex. However, as seen with Ahmed's experience, the immediate and tangible benefits came from systems that drastically lowered the skill threshold and simplified operational procedures. MZBNL's No-CAD System Innovation, which allowed operators to process standard tube types and hole patterns by simply entering parameters rather than requiring complex 3D drawings, was a pivotal factor. This innovation reduced training time from 15 days to just 1 day, directly addressing the pain point of high operator turnover and retraining burdens.

For other manufacturers, this means looking beyond raw cutting speed and focusing on features that genuinely empower their existing workforce. An intuitive interface, simplified programming, and reduced manual intervention are paramount. The Front-Feeding Innovation7, which increased feeding efficiency by 40% and reduced operator labor intensity by 40%, further exemplifies this. It's not just about automation; it's about smart automation that makes the operator's job easier, safer, and more productive. This approach minimizes resistance to new technology adoption and accelerates the time to full operational efficiency.

Therefore, my strong recommendation is to seek out suppliers who offer multi-process integration (e.g., automatic punching and cutting in one machine) and user-centric designs. Avoid piecemeal solutions that require multiple machines and manual transfers between them, as these often create new bottlenecks. A truly smart machine should streamline the entire workflow, from loading to finished part, minimizing human error and maximizing throughput. Prioritize solutions that offer a clear path to simplifying complex tasks, reducing reliance on highly specialized labor, and ultimately making your production line more agile and resilient.

Emphasize Long-Term Support and Supplier Partnership

Another crucial lesson derived from successful upgrades is the profound importance of long-term support and viewing the supplier as a strategic partner rather than just a vendor. A high-tech machine is a significant investment, and its continued performance relies heavily on reliable after-sales service, technical assistance, and the availability of spare parts. Ahmed’s prior experience with suppliers who lacked local service support highlighted this vulnerability. A machine performing suboptimally or breaking down without prompt local assistance can quickly negate any initial efficiency gains and lead to costly downtime.

Manufacturers should conduct thorough due diligence on a potential supplier's global presence, service network, and reputation for post-sales support. In MZBNL, we pride ourselves on our integrated R&D, manufacturing, sales, and service model, which ensures tailored solutions and robust support across our main export countries, including Southeast Asia, the Middle East, Europe, and North America. This encompasses offering comprehensive training, remote diagnostics, and ensuring the availability of spare parts. The ability to troubleshoot issues remotely or have a local agent for on-site support is invaluable for minimizing production interruptions.

My recommendation for other manufacturers is to explicitly discuss service level agreements (SLAs), spare parts inventory, and training programs during the negotiation phase. Don't let a lower upfront price overshadow the potential for high operational costs due to inadequate support. Furthermore, explore opportunities for long-term collaboration, such as co-branding or exclusive distribution rights if your business model allows, as Ahmed considered. A supplier willing to engage in such partnerships often demonstrates a deeper commitment to your success. Choosing a partner with proven technology and global references, and a track record of supporting 4000+ global enterprise clients, will provide the peace of mind necessary for a sustainable technological upgrade.

Adopt a Data-Driven Evaluation and Phased Implementation

The final, crucial lesson is the necessity of adopting a data-driven evaluation approach coupled with a potentially phased implementation strategy. It’s not enough to simply install a new machine; its effectiveness must be rigorously measured against predefined KPIs. As we did with Ahmed, tracking metrics like cycle time reduction, material waste percentage, labor hour savings, and Overall Equipment Effectiveness (OEE) provides concrete proof of ROI and identifies areas for further optimization. The smart machine's digitalized systems and sensors are invaluable for collecting this real-time data, transforming guesswork into informed decision-making.

For manufacturers new to advanced automation, a phased implementation strategy can mitigate risks and ensure a smoother transition. Instead of overhauling an entire production line at once, consider upgrading one critical process or one product line first. This allows your team to gain familiarity with the new technology, refine workflows, and address unforeseen challenges in a controlled environment before rolling out broader changes. This approach also provides concrete internal case studies that can build confidence and secure buy-in from other departments or stakeholders.

My recommendation is to establish clear benchmarks before the upgrade and continuously monitor performance after implementation. Be prepared to adapt and optimize. While MZBNL machines are designed to be "easy to operate and maintain" and "smart and digitalized," successful integration still requires a commitment to continuous improvement from the manufacturer's side. Use the machine's data to drive decisions, identify new opportunities for efficiency, and fine-tune processes. This systematic approach ensures that your investment not only solves immediate pain points but also lays the groundwork for sustained growth, making your manufacturing operations truly future-proof and competitively robust.

User-friendliness boosts adoptionTrue

Simplified interfaces and reduced training time significantly improve operator acceptance and productivity.

Complex machines guarantee successFalse

Raw technical complexity often creates operational bottlenecks - integrated solutions with intuitive operation deliver better results.

Conclusion

Upgrading to a smart metal tube cutting machine dramatically enhances efficiency, reduces waste, and improves quality. Through MZBNL's innovations like No-CAD, front-feeding, and zero-waste, manufacturers like Ahmed Al-Farsi achieve significant cost savings and elevate market competitiveness, proving automation is key for modern metal fabrication.

-

Learn about automation benefits in metal tube cutting ↩

-

Explore key metal fabrication market insights across regions ↩

-

Find out the benefits of simplification in machine operations. ↩

-

Understand how this innovation improves efficiency and reduces labor intensity. ↩

-

Explore benefits of high-precision cutting technology in achieving consistent production quality. ↩

-

Understand methods to quantify improvements and calculate ROI in smart machinery ↩

-

Explore the benefits of Front-Feeding Innovation for cutting efficiency and labor reduction. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.