NY-High-Speed 3D Laser Pipe Cutting Machine

Fast, Precise, Effortless

Advantages and Features

Advanced technology and innovative design features that set our laser cutting machine apart from the competition

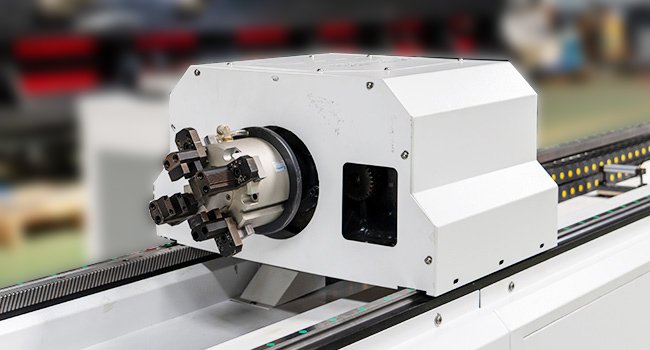

Front Chuck Movable Cutting

Reduces tail material to as short as 35MM or achieves "zero" tail design, significantly improving material utilization and saving resources.

Semi-Automatic Key Strip Loading System

Easier and more efficient loading, allowing for 5-12 pipes to be loaded at once.

No-Drawing Pipe Cutting System

Regular operators can quickly get started without the need for traditional 3D drawing for standard pipes and hole types.

Bus Control System

Multi-axis linkage with leapfrog and flying cut processes, improving efficiency by about 30% compared to traditional pulse systems.

Full-Stroke Chuck

Automatically centers and accommodates multi-material and multi-shape pipes without needing fixture changes.

Rear Chuck Auto Air Blow

Prevents jaw jamming, keeping pipe walls cleaner during operation.

Left/Right Machine Customization

Adapts to factory layout, facilitating operator handling, saving space and manpower.

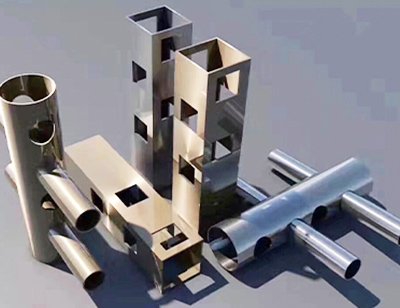

Versatile Cutting Types

Compatible with any pipe, including square pipe, round pipe, oval pipe, channel steel, angle iron, and I-beam.

Versatile Application

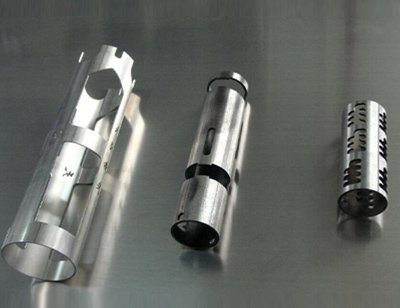

Efficiently performs 3D cutting on various types of small to medium-sized pipes, making it a star product in the hardware furniture industry!

Product Details

Explore the advanced features and precision engineering of our laser cutting machine

Technical Specifications

Detailed technical specifications and capabilities for our NY series laser cutting machines

| Feature | NY12 | NY16 | NY23 |

|---|---|---|---|

| Model | NY12 | NY16 | NY23 |

| Laser Power (W) | 1500-6000 | 1500-6000 | 1500-6000 |

| Processing Range |

Round Pipe: φ8mm-φ120mm

(Compliant with GB/T17395-1998)

Rectangular Pipe: External circle ≤ φ120mm

(Compliant with GB/T6728-1986)

Special-Shaped Pipe: External circle ≤ φ120mm

(Please consult our technical staff)

|

Round Pipe: φ10mm-φ160mm

(Compliant with GB/T17395-1998)

Rectangular Pipe: External circle ≤ φ160mm

(Compliant with GB/T6728-1986)

Special-Shaped Pipe: External circle ≤ φ160mm

(Please consult our technical staff)

|

Round Pipe: φ15mm-φ230mm

(Compliant with GB/T17395-1998)

Rectangular Pipe: External circle ≤ φ230mm

(Compliant with GB/T6728-1986)

Special-Shaped Pipe: External circle ≤ φ230mm

(Please consult our technical staff)

|

| Single Pipe Weight | Maximum combined load capacity of both chucks: 100kg | Maximum combined load capacity of both chucks: 140kg | Maximum combined load capacity of both chucks: 300kg |

| Repeat Positioning Accuracy (MM) | ±0.02 | ±0.02 | ±0.02 |

| Pipe Processing Range (MM) | ≈6250 | ≈6250 | ≈6250 |

| Machine Dimension (L×W×H MM) | 8856×1365×2172 | 8856×1365×2172 | 8856×1365×2172 |

| Machine Weight (T) | ≈3.5 | ≈3.5 | ≈3.5 |

| Maximum Acceleration (G) | ≈1.6 | ≈1.3 | ≈1.0 |

| Tail Material Length (MM) | ≈60 | ≈80 | ≈100 |

Notes

Standard laser power is 1500W; other powers can be customized. The 1500W laser cooler is horizontally configured, placed inside the machine body for lower noise and smaller footprint. Other power levels use a vertical, external cooler.

Appearance

Standard: Gray frame + red sheet metal

Optional: Blue frame + white sheet metal (Other colors can be custom-made)

Important Notice

Changes in equipment appearance and parameters are subject to availability without prior notice. Only our technical solutions and confirmed order terms are binding. Contract and actual product prevail.

Optional Accessories

Enhance your laser cutting system with our comprehensive range of optional accessories

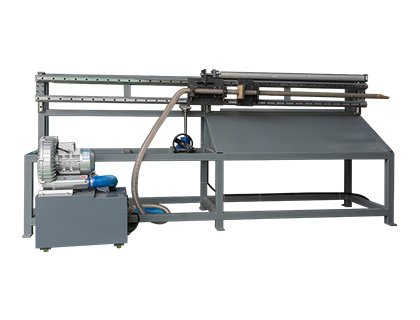

Front Entry and Exit Manual Loading & Unloading Rack

Efficient manual loading system for front entry and exit operations, providing flexible material handling capabilities.

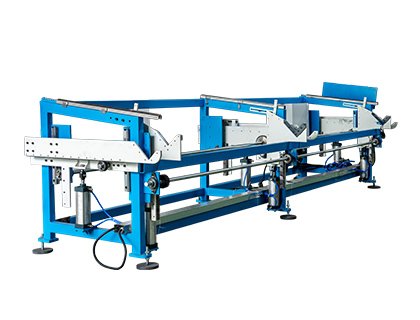

Rear Side Arranged Semi-Automatic Feeding Rack

Advanced rear-mounted semi-automatic feeding system for continuous material supply and improved productivity.

Rear Side Key Strip Semi-Automatic Feeding Rack

Specialized key strip feeding system for precise material positioning and automated workflow optimization.

Slag Extraction System

Efficient slag and debris extraction system ensuring clean operation and maintaining optimal cutting quality.

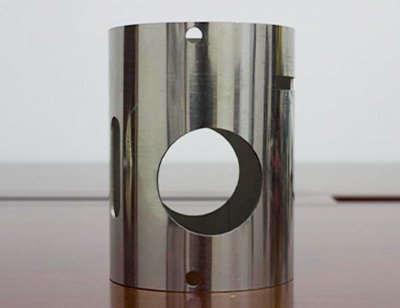

Cutting Samples

Showcase of precision cutting results achieved with our high-speed 3D laser pipe cutting machines across various materials and applications

Cutting Specifications

Our machines deliver exceptional cutting quality across a wide range of materials and thicknesses

Cutting Accuracy

±0.02mm positioning accuracy

Pipe Diameter

6mm - 325mm range

Wall Thickness

0.5mm - 20mm capacity

Cutting Speed

Up to 40m/min feed rate