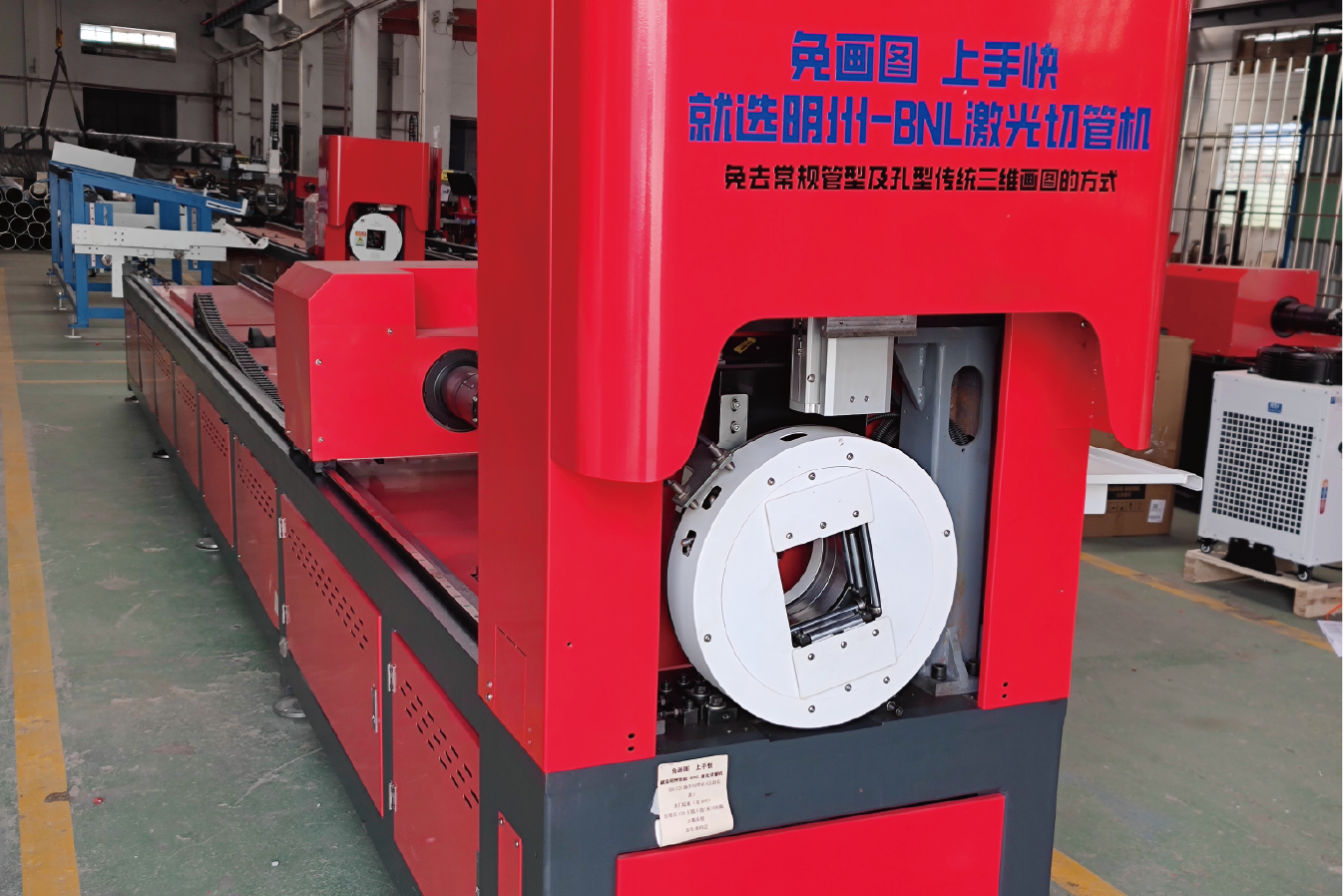

No-CAD Tube Laser Cutting Machines: Faster Setup, Lower Cost

Traditional tube laser cutting often bogs down production with complex CAD programming, demanding skilled operators and creating bottlenecks. This inefficiency leads to higher labor costs, extended project timelines, and missed business opportunities, a situation my client Ahmed in the UAE knew all too well before seeking automation. No-CAD tube laser cutting machines offer a streamlined alternative, simplifying operations for faster, more cost-effective manufacturing.

No-CAD tube laser cutting machines significantly accelerate production setup by eliminating the need for intricate CAD drawings, enabling direct parameter input for standard profiles. This innovation directly translates to lower operational costs through reduced labor requirements, minimized training overhead, and quicker project turnarounds for enhanced productivity.

For years, I've witnessed businesses in the metal fabrication sector grapple with the intricacies of conventional laser cutting. The heavy reliance on skilled CAD designers frequently creates a chokepoint, especially when urgent orders arrive or when design modifications are needed swiftly on the shop floor. Ahmed Al-Farsi, a valued client of mine from the UAE, often shared his frustrations with these very issues before he decided to explore more advanced, user-friendly technologies. Let's explore how this pivotal shift towards No-CAD systems can truly transform your manufacturing operations.

The transition to No-CAD systems signifies more than just a minor technological upgrade; it represents a fundamental evolution in our approach to tube fabrication. In today's fiercely competitive landscape, businesses are perpetually under pressure to deliver superior products faster and more economically. Traditional methodologies, while precise, often entail a convoluted, multi-step journey from design conceptualization to the actual cutting phase, a process that can consume hours, if not days, for particularly complex components. Industry analyses reveal that setup time can constitute as much as 30%1 of the total production duration in some fabrication shops. Ahmed, who manages a dynamic mid-sized fabrication enterprise, astutely recognized that his existing manual workflows and critical dependence on specialized CAD operators were curtailing his capacity to scale operations and compete effectively, particularly with escalating labor costs and the increasing demand for rapid turnarounds from his clients in architectural metalwork and automotive parts. This is precisely where the No-CAD paradigm emerges as a decisive game-changer.

What challenges do traditional CAD setup processes present?

Are you finding that your production is constantly hampered by the need for skilled CAD operators, with designs taking an age to reach the machine? This was a significant operational headache for my client Ahmed. This over-reliance creates frustrating delays, inflates training costs when valuable operators depart, and severely limits your ability to adapt quickly to new or modified customer orders. Understanding these inherent challenges clearly highlights why innovative solutions are absolutely essential for modern manufacturing success.

Traditional CAD setup processes present challenges such as requiring specialized, highly skilled operators, being notably time-consuming for both design creation and subsequent modification, and creating a significant dependency that can slow down the entire production flow, particularly for urgent or customized orders.

I've seen firsthand on numerous occasions how these CAD-related hurdles can profoundly impact a workshop's agility and responsiveness. Ahmed, for instance, operates a bustling and successful metal fabrication business in the United Arab Emirates. He often recounted the deep frustration of having his expensive, high-capacity laser cutter sit idle for extended periods while his team anxiously waited for new drawings or struggled with complex software modifications to accommodate a new client order. This wasn't merely an inconvenience; it was directly and negatively impacting his bottom line and severely restricting his ability to take on a larger volume of projects. The traditional approach, while capable of great precision, unfortunately introduces several layers of operational complexity and potential delays that businesses like his can ill afford in today's intensely fast-paced and demanding market. Let's delve deeper into these specific and often costly pain points.

The Skill Barrier and Operator Dependency

Traditional CAD-based laser tube cutting operations fundamentally demand operators who possess a significant level of expertise, not just in the mechanical operation of the machine itself, but more critically, in sophisticated 3D CAD software packages such as SolidWorks, AutoCAD, or specialized tube design modules. The global challenge of finding, recruiting, and retaining such skilled personnel is widely acknowledged across the manufacturing sector. In regions like the Middle East, where my client Ahmed operates his facility, this challenge can be even more acute due to local labor market dynamics. Data extracted from a 2022 manufacturing skills gap report2 starkly indicated that nearly 80% of manufacturers reported experiencing significant difficulty in finding qualified workers with the necessary CAD skills. This prevalent skill barrier means that the crucial uptime and productivity of the laser cutting machine become heavily reliant on a few key, highly skilled individuals. If a primary CAD operator is unavailable due to illness, on vacation, or decides to leave the company, production can quickly grind to a halt, leading to costly delays and missed deadlines. Ahmed himself mentioned experiencing this exact scenario, where an urgent order for custom architectural railings was significantly delayed because his main CAD designer was unexpectedly unavailable. The financial investment required for training new CAD operators is also substantial, often involving weeks of intensive, specialized learning, not to mention the initial period of inevitably lower productivity as they acclimatize and get up to speed with the specific software and company procedures. This deep-seated reliance on a small pool of specialized talent creates a fragile and vulnerable operational point for any manufacturing business.

The dependency on specialized CAD skills extends far beyond just the initial creation of new designs. Crucially, any modifications to existing designs, which are often required mid-production or for custom one-off jobs, also necessitate a return to the CAD station and the intervention of a skilled CAD user. This repetitive back-and-forth process between the shop floor and the design office is inherently inefficient and time-consuming. Imagine a scenario where a client requests a seemingly minor change, such as a slight alteration in hole placement or a small adjustment to the overall tube length; the machine operator typically has to stop the machine, physically go to the design office (if it's a separate location), patiently wait for the designer to make the necessary changes in the CAD software, regenerate the G-code or machine program, and then meticulously transfer this updated program back to the laser cutting machine. Each of these steps not only consumes valuable production time but also introduces an opportunity for miscommunication or error. For businesses like Ahmed's, which are striving to implement lean manufacturing principles and optimize workflow, this constant interruption in the production flow represents a significant impediment to achieving peak efficiency.

Furthermore, the inherent complexity of the CAD software itself can act as a significant barrier to wider adoption and operational flexibility. While these software packages are undoubtedly powerful and feature-rich, they typically come with steep learning curves, requiring considerable time and effort to master. This complexity naturally limits the pool of employees within a company who can be effectively cross-trained to operate the laser cutter, thereby reducing overall operational flexibility and resilience. Ahmed's strategic goal was to automate his processes and empower his existing workforce by making technology more accessible, not to create an even greater reliance on a small, highly specialized team whose absence could cripple production. The aspirational dream of "lights-out" manufacturing, or even just achieving highly efficient, flexible production schedules, is significantly hampered by this persistent human-software bottleneck inherent in traditional CAD-centric workflows.

Time-Consuming Design and Programming

The process of creating accurate 3D models and their corresponding cutting programs for various tube profiles, especially those that involve complex joints, intricate copes, or densely packed hole patterns, is an undeniably time-intensive task. Even for highly experienced CAD designers, the journey of translating a conceptual idea or a basic 2D drawing into a fully detailed and machinable 3D tube model can easily consume several hours of focused work. My client Ahmed, whose business frequently supplies custom-designed parts for demanding automotive and architectural projects, often found that the initial design phase for a new component could sometimes take longer than the actual physical cutting process, particularly for smaller production batches. This disproportionate time spent in design clearly indicates an area ripe for optimization. Industry studies consistently show that programming time alone can account for anywhere from 15% to as much as 50% of the total job time for complex, low-volume parts when manufacturers are utilizing traditional CAD/CAM workflows.

This significant expenditure of time is not merely a one-off cost associated with a new product; it's a recurring expense that accumulates with every new design introduced or every significant modification made to an existing one. Consider a common scenario in product development where a prototype needs to undergo several design iterations to perfect its form and function. Each of these iterations typically requires meticulous CAD adjustments, complete re-programming of the cutting paths, and subsequent re-testing on the machine. This iterative loop, while an essential part of the product development lifecycle, becomes excessively long and cumbersome when CAD remains the primary interface for design changes. The table below provides a simplified, illustrative time comparison for a moderately complex tube assembly that involves five unique parts, highlighting the substantial potential for CAD-related delays in a traditional setup:

| Task Stage | Traditional CAD Approach (Hours) | Potential No-CAD (Parameter-based) (Hours) |

|---|---|---|

| Initial Design | 8-16 | 1-2 (if standard profiles/macros exist) |

| Programming | 4-8 | 0.5-1 (automated from parameters) |

| Setup & First Cut | 1-2 | 0.25-0.5 (simplified interface) |

| Total (approx.) | 13-26 | 1.75-3.5 |

This comparative data clearly illustrates how the initial design and subsequent programming stages overwhelmingly dominate the timeline when using a traditional CAD-based approach. For businesses like Ahmed's, which aim to be exceptionally agile and highly responsive to customer needs, such extended lead times for custom work represent a significant competitive disadvantage in the marketplace. He often faced immense pressure from his clients who required very quick turnarounds for prototypes or small-batch production runs, and the traditional CAD process was a constant bottleneck, consistently preventing him from meeting these urgent demands in the most efficient manner. The strong desire to bypass this lengthy and often frustrating design-to-production cycle is, therefore, a key motivating driver for exploring and adopting alternative, more streamlined technologies.

Inflexibility and High Cost of Modifications

The traditional CAD-centric workflow in tube fabrication often suffers from a significant lack of the flexibility required for rapid prototyping or for making swift, on-the-fly adjustments directly on the shop floor. When a design needs to be tweaked – perhaps a hole diameter requires a small change, a slot needs to be repositioned slightly, or a cut angle must be adjusted based on a test fit – the machine operator typically has no choice but to revert the entire process back to the CAD software and the designer. This iterative loop, moving between the physical machine on the factory floor and the digital design environment in the office, as previously mentioned, is inherently inefficient and disruptive. It is not at all uncommon for these seemingly minor adjustments to consume a disproportionate amount of valuable time, especially if the original CAD designer is unavailable at that moment or if the design files themselves are particularly complex and prove difficult to modify quickly. Ahmed recounted several specific instances where a simple customer request for a minor dimensional change led to hours of delay, as his team had to locate the original CAD files, painstakingly make the edits, regenerate the machine code, and then carefully re-upload it to the laser cutter.

This inherent inflexibility in the traditional system directly translates into higher operational costs. The labor hours spent by skilled personnel on making these CAD modifications represent non-value-added time from a pure manufacturing efficiency perspective. Moreover, if design changes are a frequent occurrence, as they often are in custom fabrication environments or during new product development cycles, these associated costs can escalate significantly and eat into profit margins. A comprehensive study conducted by the Aberdeen Group3 found that companies burdened with inefficient engineering change order (ECO) processes experience markedly higher product costs and significantly longer time-to-market compared to their more agile competitors. While ECOs encompass a broader scope than just CAD changes, the underlying principle remains highly relevant: any difficulty in making necessary modifications quickly and efficiently invariably adds to the overall cost of production.

Furthermore, the risk of errors tends to increase with manual data re-entry or when performing complex modifications within CAD software. A slight misinterpretation of a change request, or a subtle error made during the CAD update process, can easily lead to scrapped parts, wasted valuable material, and further costly production delays. Ahmed emphasized that minimizing material waste was absolutely crucial for maintaining the profitability of his business, especially when working with expensive raw materials common in his projects. The traditional system, with its multiple handoffs between personnel and its inherent potential for miscommunication during the modification process, presented an ongoing and significant risk in this regard. The ideal operational scenario he envisioned was one where his machine operators could confidently and competently make common adjustments directly at the machine interface, without needing to be CAD experts themselves or having to rely on a separate design department for every small, routine change.

No-CAD reduces setup timeTrue

No-CAD systems eliminate CAD programming steps, allowing direct parameter input that cuts setup time by 80-90% compared to traditional methods.

CAD skills aren't essentialFalse

Traditional tube laser cutting absolutely requires skilled CAD operators - the 2022 skills gap report shows 80% of manufacturers struggle to find these specialists.

Why is the No-CAD system innovation crucial for tube laser cutting machines?

Traditional CAD reliance undeniably slows you down, doesn't it? Just imagine the frustration of losing out on lucrative projects simply because of excessively long setup times. My client Ahmed faced this very challenge. This critical bottleneck not only limits your operational agility but also inflates your costs, making it increasingly difficult to compete effectively, especially for businesses that are aiming for substantial growth and market expansion. The No-CAD system emerges as a genuine breakthrough, directly addressing these pressing issues by significantly simplifying operations and dramatically speeding up the entire production cycle.

The No-CAD system innovation is crucial for tube laser cutting machines because it democratizes operation by making advanced technology more accessible, drastically reduces setup times by eliminating complex drawing requirements, and significantly lowers the operator skill threshold.

Having thoroughly explored the numerous frustrations and inefficiencies inherent in traditional CAD setups, it becomes abundantly clear why a fundamental change was desperately needed in the industry. For me, and for forward-thinking clients like Ahmed, the pivotal question became: how can we make powerful, precise laser tube cutting technology more accessible, more user-friendly, and far more responsive to the dynamic demands of modern manufacturing? The answer, I believe, lies in groundbreaking innovations like the No-CAD system, which directly tackle the complexity and time barriers that have long plagued this field. The No-CAD system isn't just another optional feature; it's a fundamental reimagining of the entire workflow, meticulously designed to put greater control back into the hands of the operators and to significantly speed up the entire process from initial concept to the final cut part. This shift is particularly vital in highly competitive markets where operational agility and the ability to offer quick turnaround times are key differentiators and crucial for business success.

Democratizing Access and Reducing Skill Barriers

One of the most significant and transformative impacts of No-CAD system innovation is the genuine democratization of advanced laser tube cutting technology. Traditionally, as we have extensively discussed, operating these sophisticated machines effectively necessitated a deep and specialized understanding of complex CAD software. This prerequisite inadvertently created a specialized class of operators, thereby limiting the number of personnel within an organization who could competently run the equipment and keep production flowing. MZBNL's innovative No-CAD system, by enabling direct parameter-based input for a wide array of standard tube shapes (such as round, square, rectangular, and oval profiles) and common hole patterns (including round, square, oblong, and others), fundamentally changes this restrictive dynamic. Operators no longer need to be CAD wizards or possess extensive design software expertise. Instead, they can efficiently input critical dimensions, required angles, and desired quantities directly into an intuitive, user-friendly machine interface. This represents a massive and beneficial shift in operational accessibility. Ahmed specifically mentioned that the compelling prospect of being able to train his existing machine operators in just a single day, as opposed to the typical 15 days of intensive training often required at an equipment factory for traditional CAD-based systems, was a primary and powerful motivator for him to invest in this new technology.

This substantial reduction in the skill barrier brings forth several profound and far-reaching benefits for manufacturing businesses. Firstly, it significantly widens the pool of potential operators within a company. Existing staff members, perhaps those already familiar with other fabrication processes but lacking formal CAD training, can be quickly and effectively trained to run the laser tube cutter. This greatly increases operational flexibility and critically reduces the business's reliance on a few key, highly specialized individuals. Secondly, it leads to a dramatic reduction in both training costs and the time commitment required for training. Instead of lengthy, often expensive, off-site CAD courses, on-site, machine-specific training becomes highly effective and efficient. For a business like Ahmed's, which had previously experienced significant challenges with operator turnover and the associated retraining burdens, this simplified training protocol drastically reduces the time and expense involved in onboarding new staff. A 2023 survey conducted by the Fabricators & Manufacturers Association (FMA)4 highlighted that finding and training skilled labor remains a top concern for approximately 65% of metal fabricators. No-CAD technology directly and effectively addresses this pressing industry-wide concern.

Moreover, this enhanced ease of use can lead to increased operator satisfaction and a greater sense of empowerment among the workforce. When operators can quickly and confidently set up jobs and see immediate, tangible results without the frustration of wrestling with complex software interfaces, their engagement levels and overall productivity tend to increase significantly. They become more versatile team members, capable of handling a wider range of tasks and contributing more effectively to the production process. This empowerment was something Ahmed was particularly keen to foster within his workforce, aiming to transition them from primarily manual, labor-intensive processes to overseeing and managing automated, high-tech equipment. The No-CAD system acts as a crucial enabler for this important transition, making sophisticated technology less intimidating, more approachable, and ultimately more user-friendly for a broader range of employees.

Accelerating the Design-to-Production Cycle

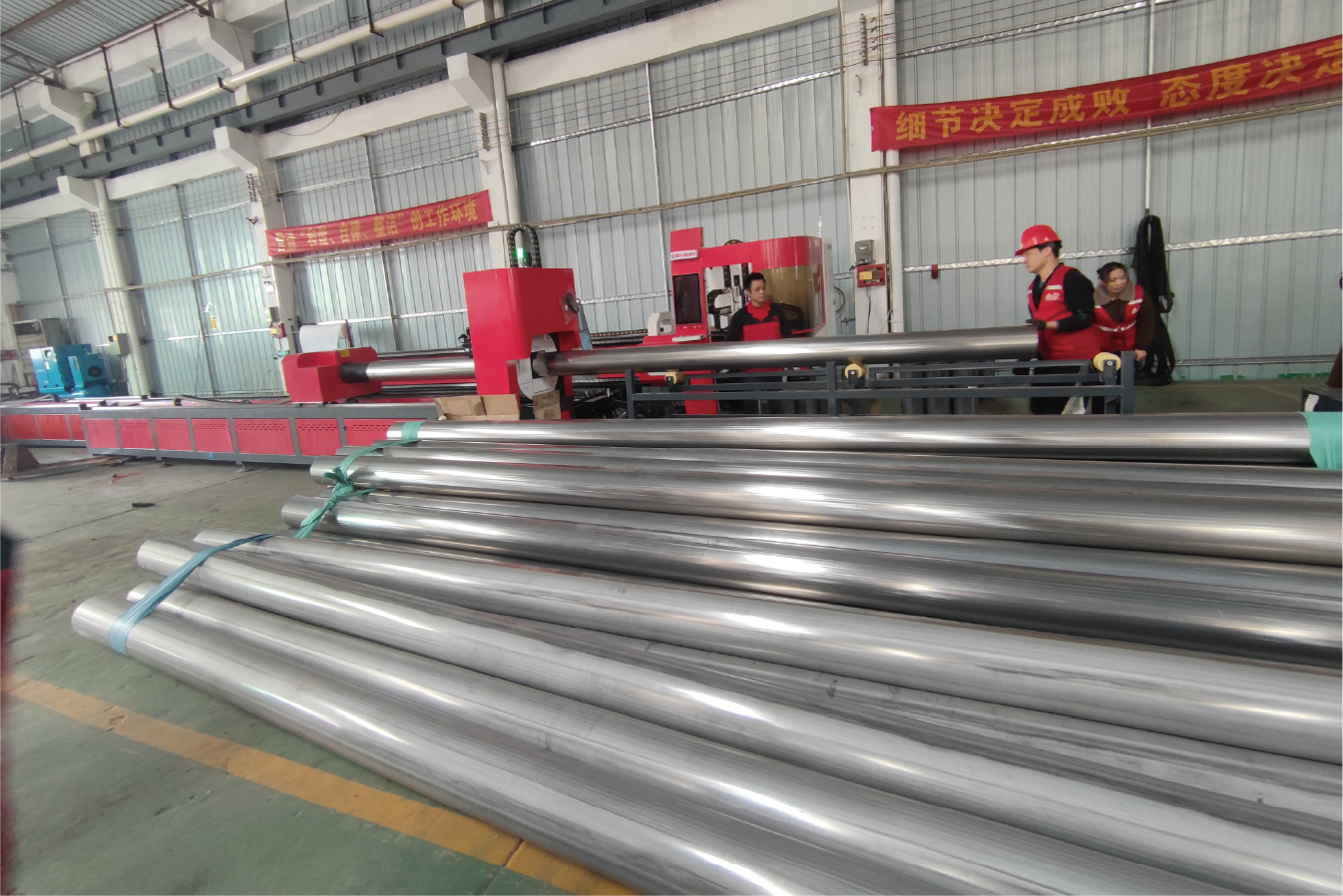

The core, undeniable promise of No-CAD technology is a dramatic increase in speed, particularly in the critical transition phase from receiving a job order to commencing the actual cutting process. By effectively eliminating the mandatory step of creating or modifying complex 3D drawings for many common tube fabrication applications, the system facilitates a much faster and more streamlined setup procedure. Consider a typical job shop scenario: a customer urgently needs a batch of tubes cut to specific lengths, incorporating standard hole patterns. With a traditional, CAD-dependent system, even if the design itself is relatively simple, it must first be meticulously drawn in CAD software, then programmed with appropriate cutting paths, and finally, the resulting program must be transferred to the machine. In stark contrast, with MZBNL's No-CAD system, an operator can simply select the required tube type from a graphical menu, enter the desired length, define the hole type, specify its position, and input the quantity using pre-defined macros or an intuitive parametric interface. The machine controller then intelligently and automatically generates the necessary cutting program. This optimized process can reduce the setup time for such jobs from potentially hours down to mere minutes.

This remarkable acceleration in workflow is particularly beneficial for businesses that routinely handle a high mix of low-volume orders, a common characteristic of operations like Ahmed's, which serves a diverse clientele needing custom railings, unique furniture components, or specialized automotive parts. The ability to quickly and seamlessly switch between different jobs without undergoing a lengthy and complex reprogramming process provides a significant competitive advantage in the marketplace. Industry benchmarks consistently suggest that for standard tube profiles and common cutting operations, No-CAD systems can improve setup efficiency by as much as 70-90%5 when compared directly to traditional drawing-based approaches. For Ahmed, this meant he could confidently take on more rush orders and offer significantly better, more attractive lead times to his customers, thereby directly and positively impacting both his revenue stream and overall client satisfaction levels. He specifically mentioned that the newfound ability to bypass the CAD department entirely for repeat jobs or simple new designs was a complete game-changer for his workshop's throughput and overall productivity.

Furthermore, the No-CAD system makes quick modifications and adjustments feasible directly at the machine, on the shop floor. If a measurement needs a slight adjustment, or if a hole needs to be repositioned based on a shop-floor check or a last-minute client request, the operator can often make these necessary changes swiftly and efficiently via the parametric input on the No-CAD interface, without the need to go back to a separate CAD station or involve a designer. This capability dramatically shortens the iterative cycle for adjustments and fine-tuning, significantly reducing machine downtime and keeping production flowing smoothly. This on-the-fly adaptability is absolutely crucial in today's dynamic manufacturing environments where customer requirements can change quickly and unpredictably, demanding maximum operational flexibility.

Enhancing Overall Equipment Effectiveness (OEE)

No-CAD systems make a direct and substantial contribution to improving Overall Equipment Effectiveness (OEE)6, which is a key performance metric in the manufacturing industry that holistically measures equipment availability, operational performance, and output quality. By significantly reducing setup times (which directly improves the Availability component of OEE) and enabling much faster job changeovers, the laser cutting machine spends a considerably larger proportion of its time actively cutting parts and significantly less time sitting idle waiting for programming or setup. MZBNL’s own internal data suggests a potential 40% increase in feeding efficiency through innovations like their advanced front-feeding mechanism, a feature that often pairs exceptionally well with the rapid setup capabilities inherent in No-CAD systems. While No-CAD primarily impacts the setup phase, its powerful synergy with other efficiency-boosting machine features significantly amplifies the overall OEE benefits.

The performance aspect of OEE, which relates to how close the machine operates to its designed speed, is also notably enhanced by No-CAD technology. When machine operators can confidently and quickly set up new jobs, the machine can be run closer to its optimal cutting speed for longer periods. The reduced reliance on complex CAD files for many standard operations minimizes the chances of programming errors that could lead to slow runs, interruptions, or even machine stops. Ahmed’s previously mentioned concern about high operator turnover and the subsequent retraining burden is directly linked to OEE; a simpler, more intuitive operating system means that new operators can become productive much faster, thereby helping to maintain consistent performance levels across shifts and personnel. The reduced need for highly specialized CAD skills also means that the machine is far less likely to be non-operational due to the temporary unavailability of a qualified CAD operator.

Quality, the third critical component of OEE, also benefits considerably from the implementation of No-CAD systems. Parametric systems, by their very nature, can inherently reduce the chances of human error that might occur during drawing interpretation or manual data entry when creating or modifying CAD models. The use of standardized hole patterns and pre-defined cut types within the No-CAD system's library ensures a high degree of consistency and repeatability from part to part and job to job. While highly complex or entirely custom designs might still necessitate the use of CAD software, a significant portion of everyday tube fabrication work involves standard operations that are exceptionally well-suited to parametric definition. This suitability leads to fewer errors, less rework, and reduced scrap. For Ahmed, who supplies components to the automotive and architectural sectors where precision and quality are absolutely paramount, this inherent accuracy and repeatability offered by a well-implemented No-CAD system was a significant draw, promising fewer rejected parts and ultimately, improved customer satisfaction and loyalty.

No-CAD reduces setup timesTrue

By eliminating complex CAD drawings, No-CAD systems can reduce setup times from hours to minutes for standard tube profiles.

No-CAD requires CAD expertiseFalse

No-CAD systems are designed to lower skill barriers, allowing operators to work without specialized CAD knowledge through intuitive parametric inputs.

How does the No-CAD system result in faster production setup?

Are cumbersome and lengthy production setups slowing your entire manufacturing workflow to a frustrating crawl? This was a constant and significant source of frustration for Ahmed's highly capable team. These persistent delays inevitably mean lost valuable production time, substantially increased labor costs per part produced, and an ongoing difficulty in consistently meeting tight project deadlines. No-CAD systems effectively streamline the entire setup process by allowing for direct parameter input, dramatically slashing the critical time from when an order is received to when the first cut is made on the machine.

No-CAD systems result in faster production setup by enabling direct parameter input for standard tube profiles and common cutting operations, thereby eliminating the time-consuming step of creating or modifying 3D CAD drawings, and by leveraging extensive pre-programmed libraries.

We've clearly established that No-CAD technology is crucial for modern tube fabrication, but now let's get into the specific nuts and bolts of how it actually achieves such remarkable and impactful speed improvements during the critical production setup phase. It's not magic, of course; it's the result of smart, innovative engineering that fundamentally rethinks and redesigns the traditional, often convoluted, workflow. For my client Ahmed, witnessing this streamlined process in action was a genuine eye-opener. He was thoroughly accustomed to the old "hurry up and wait" rhythm, where expensive machines frequently stood idle, patiently waiting for programs to be created or modified. The profound shift to a system where his operators could simply walk up to the machine, input the necessary parameters, and start cutting parts almost immediately was truly transformative for his shop's overall agility and daily output. Let's break down the underlying mechanics behind this significantly accelerated setup process.

Direct Parameter Input and Pre-defined Libraries

The absolute cornerstone of achieving faster setup times in No-CAD systems, such as the pioneering one developed by MZBNL, is the remarkable ability for machine operators to directly input all the critical parameters for a job without ever needing to interact with separate, often complex, CAD software. Imagine an operator who needs to cut a batch of 50mm square tubes, each 1000mm long, with two precisely positioned 10mm diameter holes located 50mm from each end of the tube. Instead of the lengthy traditional process – opening a CAD program, meticulously drawing the tube to scale, accurately positioning the holes, and then generating the complex toolpaths – the operator simply approaches the machine's Human-Machine Interface (HMI)7. Here, they can easily select "square tube" from a clear, graphical menu, then input "50mm" for the side dimension and "1000mm" for the length. Subsequently, they access a pre-programmed hole-cutting macro, select "round hole," input "10mm" for the diameter, and then specify the precise positions (for example, X=50, Y=25 and X=950, Y=25 on an unrolled surface representation). The system's embedded intelligence then automatically and instantly generates the necessary machine code to perform the cuts. This entire process can take just a few minutes, compared to potentially much longer durations for traditional CAD-based programming, especially if the dedicated CAD operator is busy with other tasks or if it’s an entirely new part requiring a design from scratch.

These advanced No-CAD systems come equipped with extensive and comprehensive libraries of pre-defined standard tube shapes (such as round, square, rectangular, L-profiles, U-profiles, and many others) and a wide array of common cutting operations (including various types of holes, slots, miters, copes, and notches). This built-in intelligence means that much of the intricate geometric calculation and cutting path planning, which would normally require significant designer input, is now largely automated. For instance, MZBNL’s system allows for the efficient processing of standard tube types and common hole patterns simply by entering the relevant parameters directly at the machine. This drastically reduces the cognitive load on the operator and, just as importantly, minimizes the chance of errors that can easily occur when manually drawing complex geometries or inputting coordinates. Ahmed astutely noted that for approximately 60-70% of his typical job requirements, which predominantly involved standard profiles and common cuts for items like railings and shelving units, this parametric approach would cover his needs perfectly. This would, in turn, free up his sole CAD designer to focus their valuable time and expertise exclusively on the truly complex, bespoke projects that genuinely require advanced design skills.

The positive impact on setup time is both immediate and highly significant. A detailed study conducted by a leading machine tool manufacturer found that for simple to moderately complex parts, parametric programming8 (which forms a core component of No-CAD systems for standard shapes) can effectively reduce the combined programming and setup time by up to an astounding 75% when compared directly to traditional manual CAD/CAM methods. This is not merely a theoretical gain posited by academics; it's a tangible, real-world benefit that directly translates into substantially increased machine uptime and overall production throughput. For Ahmed and his business, this meant he could confidently process a greater number of jobs per shift using the same machine and existing staff levels, leading to increased revenue and improved profitability.

Elimination of the CAD Bottleneck

A primary and compelling reason why No-CAD systems so effectively speed up the production setup process is the direct and almost complete elimination of the CAD department, or the specialized CAD operator, as a mandatory and often time-consuming step for a large majority of jobs. In traditional manufacturing workflows, every new part or even minor modification, however trivial it may seem, frequently requires the creation or alteration of a CAD file. If the company's CAD designer is overloaded with work, temporarily on leave, or if there's a lengthy queue of design requests already submitted, the expensive laser cutting machine often sits idle, unproductive, simply waiting for the necessary program. This scenario was a frequent and significant pain point for Ahmed, whose business growth was sometimes visibly hampered by the limited capacity of his design resources. The No-CAD system effectively decouples a significant portion of the daily production workload from this potential bottleneck, thereby ensuring a smoother and more continuous flow of work through the shop.

By empowering the machine operators themselves to confidently and competently handle a large percentage of job setups, companies can achieve a much greater degree of operational agility and responsiveness. Urgent rush orders or simple repeat jobs that require only minor modifications (for example, changing only the length of a previously run part while all other parameters remain the same) can be quickly programmed directly at the machine interface in a matter of minutes. This was a key selling point of MZBNL’s system for Ahmed – the compelling promise that his machine operators, after undergoing just one day of focused training, could independently manage most standard cutting tasks without needing constant recourse to a designer. This newfound autonomy significantly reduces the overall lead time from the moment an order is received to the moment production actually commences. Think of the cumulative time saved: no need to create a formal work order for the design department, no waiting time for the designer to become available, no waiting for the program to be generated, no time spent transferring the program to the machine, and then finally, the setup itself. Instead, it becomes a direct, streamlined path from order parameters to active machine operation.

This strategic removal of dependency on a separate design function also improves the workflow and job satisfaction for the CAD designers themselves. They are effectively freed from the often mundane and repetitive task of drawing simple, standard parts or making trivial modifications that don't fully utilize their advanced skills. Instead, their valuable expertise can be focused on genuinely complex designs, critical new product development initiatives, or optimizing intricate cutting patterns for challenging materials or applications that do indeed require advanced CAD/CAM skills. This makes much better use of highly skilled and often expensive human resources and can significantly improve job satisfaction for designers, who can then tackle more challenging, engaging, and ultimately more rewarding work. Ahmed anticipated that this shift would allow his designer to contribute more substantially to research and development efforts and to the preparation of bids for complex, high-value projects, rather than being constantly bogged down in routine daily programming tasks.

Streamlined Job Changeover and Data Management

Faster production setup isn't just about the initial programming of an entirely new part; it's also critically about the efficiency and speed of changing over the machine from one completed job to the next. No-CAD systems often feature highly intuitive job management interfaces that allow operators to quickly and easily recall previously run jobs from memory, modify parameters if needed for the new batch, and then start the next production run with minimal delay and effort. If a customer reorders a part that was previously made using parametric input, the operator can simply find the saved job in the system's memory, confirm or update the quantity required, and hit the "start" button. This process is significantly faster and more reliable than the traditional method of searching for old CAD files (which might be stored in various locations or formats), reopening them in the CAD software, potentially regenerating the G-code, and then re-uploading the program to the machine.

Data management for standard parts also becomes considerably simpler and more organized with a No-CAD system. Instead of managing a vast and potentially confusing library of individual CAD files for every minor variation of a part, the system effectively stores parametric recipes. A single "program" or template for a square tube with specific end holes, for example, can serve for countless variations in tube size, overall length, and hole diameter or position, simply by changing the relevant input parameters at the machine interface. This approach significantly reduces data storage requirements and makes it much easier to maintain consistency and accuracy across different production runs of similar parts. Ahmed, who was strategically planning to expand his product range to cater to new market segments, saw this streamlined data management as a highly effective way to manage a growing portfolio of parts without a corresponding and unmanageable explosion in CAD file management complexity.

Furthermore, the potential for integration with higher-level business systems such as ERP (Enterprise Resource Planning) or MES (Manufacturing Execution Systems)9 can be more straightforward and effective for parametrically defined jobs. Work orders originating from these systems can digitally transmit key parameters and production quantities directly to the No-CAD machine, further automating the setup process and significantly reducing the risk of manual data entry errors. While not all No-CAD systems currently offer this level of deep integration out-of-the-box, the inherently structured, data-driven nature of parametric input makes such connections much easier to implement and maintain compared to the complexities of interpreting varied CAD file formats from different sources. This strategic move towards greater digitalization and automation was a key component of Ahmed's long-term vision for his company's future, and the No-CAD approach aligned perfectly with this forward-thinking strategy, promising a more integrated and efficient manufacturing ecosystem.

No-CAD eliminates CAD bottlenecksTrue

No-CAD systems allow operators to directly input parameters at the machine, bypassing the need for CAD designers for most standard jobs.

No-CAD requires complex CAD skillsFalse

No-CAD systems are designed for machine operators to use with minimal training, not CAD experts.

In what ways do No-CAD tube laser cutting machines reduce operational costs?

Are consistently high operational costs significantly eating into your hard-earned profits? The expenses associated with specialized labor and lengthy, inefficient setups are indeed very costly. My client Ahmed knew this all too well. These relentless costs not only limit your overall competitiveness in the market but also make it increasingly harder to invest in crucial business growth and innovation, a constant worry for ambitious businesses aiming to thrive. No-CAD machines strategically attack these costs directly by substantially reducing labor needs, minimizing extensive training requirements, and critically boosting material utilization through greater accuracy and efficiency.

No-CAD tube laser cutting machines reduce operational costs by minimizing the need for highly paid CAD specialists, drastically cutting down on training time and associated expenses, increasing valuable machine uptime through significantly faster setups, and improving material yield.

Beyond the undeniably impressive speed gains achieved in the setup phase, the thoughtful adoption of No-CAD tube laser cutting machines translates directly and demonstrably into tangible, significant cost savings across various operational areas. For any business owner, much like my astute client Ahmed, the bottom line is always paramount. He wasn't just looking for increased speed for its own sake; he was strategically seeking enhanced efficiency that would positively and directly impact his company's profitability. The inherent beauty of No-CAD technology is that its manifold benefits ripple effectively through various aspects of the manufacturing operation, ultimately leading to a leaner, more agile, and demonstrably more cost-effective production process. Let's now examine in more detail the specific avenues through which these substantial and welcome savings are consistently realized.

Reduced Labor Costs and Training Expenses

One of the most significant and immediate cost reductions stemming from the adoption of No-CAD technology comes from the decreased reliance on highly skilled, and therefore often highly paid, CAD operators for many routine and standard tube cutting tasks. As we have previously established, No-CAD systems empower less specialized personnel to confidently and accurately set up and run a large percentage of the jobs that pass through the workshop. This directly implies that businesses might not need to hire as many dedicated CAD designers, or alternatively, their existing highly skilled designers can be reallocated to focus on higher-value activities such as complex new product development or process optimization. The salary differential between a general machine operator and a specialist CAD/CAM programmer10 can be quite substantial in most labor markets. For instance, in many industrialized regions, a skilled and experienced CAD/CAM programmer can command a salary that is typically 30-50% higher than that of a general machine operator. Ahmed meticulously calculated that by enabling his existing shop floor staff to handle the majority of machine setups independently, he could confidently defer the need to hire an additional CAD specialist, thereby saving tens of thousands of dollars annually in salary, benefits, and associated overheads.

Training expenses, which can be a considerable burden for many manufacturing companies, are also dramatically curtailed with the implementation of No-CAD systems. MZBNL's compelling claim of reducing the necessary on-site training duration from a typical 15 days (often required for traditional CAD-based systems and usually conducted at the equipment factory) to just a single day for their user-friendly No-CAD system represents a powerful and attractive cost-saver. Consider the array of costs normally associated with a 15-day training program: employee travel expenses, accommodation costs, the lost productivity of the trainee during this extended period, and often, the trainer's professional fees. These combined expenses can easily run into thousands of dollars per operator. When you multiply this figure by the number of operators who need to be trained, or factor in the recurring costs of retraining due to operator turnover (a specific pain point that Ahmed had personally experienced), the cumulative savings achievable from a streamlined 1-day training program become immense and undeniable. This significantly lower training threshold also means that new hires can become productive members of the team much faster, thereby reducing the non-productive period during their initial onboarding and integration into the workforce.

Furthermore, the reduced operational complexity inherent in No-CAD systems directly lowers the likelihood of costly errors that might otherwise occur when less experienced operators attempt to navigate and utilize complex CAD software. While any new system will inevitably have some learning curve, a well-designed No-CAD interface is inherently more intuitive and user-friendly for performing parametric tasks. This improved usability leads to fewer mistakes being made during programming, resulting in less scrapped material, reduced rework, and less machine downtime caused by incorrect setups. These indirect savings, though sometimes harder to quantify precisely, nonetheless contribute significantly to the overall reduction in labor-associated costs and improve the general efficiency of the shop floor.

Increased Machine Uptime and Throughput

Faster setup times, which are a widely recognized hallmark and key benefit of No-CAD systems, directly and positively translate into increased valuable machine uptime. If a sophisticated laser cutting machine spends significantly less time being programmed and meticulously set up for each new job, it logically follows that it can spend considerably more time actively cutting parts and generating revenue. This marked improvement in Overall Equipment Effectiveness (OEE)11 means that a company can produce a greater volume of parts with the very same machine within the same amount of operational time. For Ahmed, whose existing machines sometimes sat frustratingly idle while waiting for programs to be prepared or modified, the prospect of significantly boosting the active cutting time of his equipment was a major motivating factor in his decision to invest in No-CAD technology. This increase in throughput effectively means that the substantial capital investment made in the laser cutting machine yields a faster and more favorable return for the business.

Consider a typical fabrication shop that operates on two shifts per day, totaling approximately 16 hours of potential production time. If traditional CAD-based setup procedures for the various jobs processed throughout the day consume, for example, an average of 3-4 hours of that available time, then the machine is only actively productive for roughly 12-13 hours. However, if No-CAD technology can reduce that cumulative setup time by an estimated 70%, thereby saving approximately 2-3 hours per day, that saving represents a direct 15-20% increase in available cutting time for the machine. This newly available additional capacity can then be strategically utilized to take on more customer orders, offer reduced lead times for existing valued customers (enhancing customer satisfaction), or even potentially avoid the significant capital expenditure required to purchase an additional machine to meet growing production demand.

This valuable increase in throughput, achieved without a proportional increase in fixed operational costs (such as machine depreciation, rent for the facility, or other standard overheads), directly results in a lower manufacturing cost per part. Innovations such as MZBNL's front-feeding mechanism, which itself can increase feeding efficiency by about 40%, perfectly complement the No-CAD system's rapid setup capabilities. When these advanced features are combined, they can lead to substantial and impressive gains in overall productivity and operational efficiency. Ahmed's strategic goal of automating his existing manual workflows was precisely aimed at achieving such significant efficiencies, allowing him to handle a larger volume of work for his important architectural metalwork and vehicle parts clients without experiencing a linear and unsustainable increase in his operational expenditure.

Potential for Material Savings and Reduced Waste

While the primary strength of No-CAD technology lies in streamlining operational flow and reducing setup times, its intelligent integration with smart machine design features can also significantly contribute to valuable material savings. For instance, MZBNL’s innovative \"Zero-Waste Tail Material Innovation,\" a system where the cutting logic intelligently calculates from the rear chuck as the origin point, works synergistically with efficient job setup procedures facilitated by No-CAD. Faster setups mean that more efficient nesting algorithms12 and optimized cutting plans can be implemented quickly and easily by the operator. Although the zero-tail innovation is technically a distinct feature, the inherent ease of programming associated with No-CAD can make it considerably simpler for operators to optimize their cutting lists to take full advantage of such material-saving capabilities, often without needing to perform complex CAD simulations for every single production run. This practical application directly reduces the amount of unusable remnant material.

Reduced errors during the programming phase, largely due to the simpler and more intuitive parametric input method offered by No-CAD for standard tasks, also lead directly to less material waste resulting from incorrectly cut parts. Every single tube that is scrapped due to a programming error represents a direct material cost, compounded by the loss of valuable machine time and the labor already invested in that part. Ahmed was particularly conscious of material costs, especially when working with high-value alloys, and therefore, minimizing scrap was a key operational goal for his business. A system that is inherently easier to program accurately, especially for common and repetitive tasks, naturally reduces the incidence of such costly errors when compared to workflows that require manually manipulating complex CAD models for every job.

Furthermore, the ability to quickly program and test a single part or a very small batch without undergoing a lengthy and involved CAD process encourages more efficient prototyping and faster first-article inspection procedures. This agility means that any potential issues with dimensions, fit, or functionality can be identified and rectified with minimal material consumption before committing to a large and potentially wasteful production run. This iterative agility, greatly facilitated by quick No-CAD setups, helps to refine designs efficiently and cost-effectively, ultimately reducing the waste that might occur if a large batch was run based on a flawed initial CAD drawing. The table below presents a sample framework illustrating potential cost impact areas where No-CAD systems can deliver savings:

| Cost Category | Traditional CAD System Impact | No-CAD System Advantage | Estimated Annual Savings (Medium Shop Example) |

|---|---|---|---|

| Specialized Labor | High demand, high salary, scarcity | Reduced need, upskill existing general operators | $15,000 - $50,000+ |

| Training | Lengthy, costly, often off-site | Short, efficient, typically on-site | $5,000 - $15,000 per operator |

| Machine Downtime | High due to setup complexity/CAD wait | Minimized setup time, less waiting for programs | Increased capacity / Potentially deferred capex |

| Material Waste (errors) | Higher risk with complex manual input | Lower risk with guided parametric input, fewer errors | $2,000 - $10,000+ |

| CAD Software Licenses | Multiple specialized seats often needed | Fewer specialized software seats required | $1,000 - $5,000+ |

Disclaimer: This table is intended to be illustrative, and actual savings will vary based on specific shop size, prevailing local labor rates, the complexity of jobs undertaken, and material costs. Ahmed's detailed internal analysis for his own business projected significant and compelling savings across all these categories, ultimately making the strategic investment in a No-CAD laser cutting machine a financially sound and forward-looking decision for his company's growth and sustainability.

No-CAD reduces labor costsTrue

No-CAD systems enable less specialized personnel to handle setups, reducing the need for expensive CAD specialists.

No-CAD increases material wasteFalse

No-CAD's parametric input and faster setups actually reduce errors and material waste compared to traditional CAD systems.

Simply acquiring No-CAD technology isn't the final step; are you perhaps unsure how to truly maximize its extensive benefits for your operation? My client Ahmed wanted clear, actionable strategies. Without proper and thoughtful implementation, you might not achieve the full potential in speed enhancements and cost savings that the technology promises, potentially leading to disappointment with the investment. Adopting specific, proven best practices ensures that you can effectively harness the full transformative power of No-CAD for remarkable and sustainable results in your workshop.

Optimizing No-CAD technology involves thorough operator training focused on parametric input mastery, developing a comprehensive library of frequently used parts and profiles, intelligently integrating No-CAD workflows with overall job scheduling, and regularly reviewing processes for further efficiencies.

Acquiring a state-of-the-art No-CAD tube laser cutting machine is undoubtedly a fantastic and significant step towards achieving greater manufacturing efficiency, but like any powerful and sophisticated tool, its true effectiveness is considerably magnified when it is used strategically and intelligently. I've had the privilege of working closely with clients like Ahmed to not just install such advanced machines, but to thoughtfully integrate them deeply into their existing manufacturing ethos and operational culture. It's fundamentally about building robust processes and cultivating positive habits around the technology that systematically unlock its full, untapped potential for delivering consistently faster setups and substantially lower operational costs. Simply having the feature available isn't the ultimate end goal; optimizing its daily use is where the real, sustainable competitive advantage truly lies. Let's now explore some key best practices to ensure you get the absolute most out of your valuable No-CAD investment.

Comprehensive Operator Training and Skill Development

While modern No-CAD systems, such as the user-friendly version MZBNL has expertly pioneered, are meticulously designed for exceptional ease of use and can dramatically reduce intensive training requirements from weeks down to, in some cases, a single day, that initial training period is still absolutely crucial and should be thoroughly comprehensive. The primary focus of this training should strategically shift away from teaching intricate CAD modeling techniques and instead concentrate on ensuring operators master the machine's specific parametric interface. This includes understanding its extensive library functions, and learning how to efficiently and accurately input data for a wide variety of standard tube profiles and common hole types. Operators need to become completely comfortable and proficient in navigating the Human-Machine Interface (HMI)13, selecting the correct parameters for each job, and clearly understanding how those chosen parameters directly translate to the final specifications of the finished part. Ahmed astutely made sure that his team leaders were an integral part of this initial training program so they could effectively cascade their knowledge to other team members and confidently troubleshoot minor operational issues as they arose.

Beyond the critical initial training phase, a commitment to continuous skill development for operators is equally important for long-term success. Encourage your operators to actively experiment with the system's diverse capabilities, perhaps on non-critical jobs or during planned development time, to allow them to build a deeper, more nuanced understanding of its particular strengths and potential limitations. This hands-on exploration might involve teaching them how to create and save custom parametric templates for frequently recurring non-standard (but still parametrically definable) parts that are unique to your business. For example, if Ahmed's company frequently manufactures a specific type of bracket with unique hole spacing that isn't included in the standard system library, his operators could learn to build a custom parametric template for it within the No-CAD system, provided it supports such customization. Alternatively, they could meticulously document the precise parameter sequence required for rapid reentry. This internally developed knowledge base, cultivated over time, becomes an incredibly valuable and proprietary asset for the company.

Cross-training multiple operators on the No-CAD system is also a highly recommended best practice. While the very nature of No-CAD significantly reduces the dependency on a single, highly specialized CAD expert, inadvertently relying on only one No-CAD proficient operator can reintroduce a similar operational bottleneck, albeit at a different point in the process. By systematically training several staff members, you ensure crucial operational continuity during employee absences due to illness or vacation and can distribute the daily workload much more effectively across the team. Ahmed strategically planned a rotation system for his facility to ensure that all his relevant production staff gained essential hands-on experience with the new No-CAD machine, thereby fostering a more versatile, skilled, and resilient production team. This proactive approach also helps in identifying those operators who show a particular aptitude for the system and could potentially become 'super-users' or even effective internal trainers for new staff in the future.

Standardizing Workflows and Building Parametric Libraries

To fully and effectively leverage the powerful capabilities of your No-CAD system, it is highly beneficial to standardize your internal workflows around its inherent strengths. This important process involves carefully identifying and categorizing the types of jobs that are best suited for direct parametric input using the No-CAD interface versus those that still genuinely require the more detailed approach of full CAD modeling. For instance, Ahmed's team could implement a simple job routing system where incoming orders are quickly classified: "Standard Profile - Suitable for No-CAD Processing" versus "Custom/Complex Geometry - CAD Design Required." This clear and consistent delineation ensures that the No-CAD system is predominantly used where it offers the most significant time savings and efficiency gains. This might even involve creating a simple, visual decision tree or checklist to assist staff in routing jobs appropriately and consistently.

Building and diligently maintaining a well-organized, easily accessible library of frequently used parametric programs or "recipes" within the No-CAD system itself is absolutely key to maximizing its efficiency. If your company regularly produces certain standard tube lengths with specific, recurring hole patterns for a particular client (much like Ahmed's ongoing contracts for standardized railings or shelving components), saving these as named, easily identifiable jobs in the machine's memory allows for near-instant setup for any repeat orders of those parts. This "digital toolkit" of pre-defined, validated parts minimizes the need for repetitive data re-entry, significantly reduces the chance of human errors during setup, and dramatically speeds up job changeovers between different production runs. Many modern No-CAD systems allow users to save their own customized sets of frequently used parameters, making this practice even more powerful.

It is also good practice to regularly review and refine this internal parametric library. Are there new common parts being produced that could beneficially be added? Are there old, outdated parameters or job files that are no longer used and are merely cluttering the system, potentially causing confusion? This ongoing process of continuous improvement and library maintenance ensures that your digital asset remains relevant, efficient, and a genuine aid to productivity. In Ahmed's case, as he strategically planned to expand his business into new product lines, he proactively intended to add the standard components for these new items to his machine's parametric library from the outset. This foresight would ensure that his team could quickly and efficiently adapt to producing these new items as soon as orders came in. A disciplined, systematic approach to managing these valuable digital assets is truly vital for achieving long-term operational efficiency with No-CAD technology.

Integrating No-CAD with Production Planning and Data Analysis

For maximum operational impact and efficiency, the No-CAD laser cutting machine should not operate in isolation as a standalone piece of equipment. Intelligently integrating its operations with broader production planning and scheduling systems, where feasible, can unlock significant further efficiencies throughout the entire manufacturing process. Even without direct, sophisticated software integration between the machine and an ERP/MES system14, simply ensuring that job schedulers and production planners fully understand and appreciate the rapid setup capabilities of the No-CAD machine allows them to schedule shorter production runs more effectively. They can also strategically group similar parametric jobs together to minimize even the small changeover times that still exist, thereby optimizing machine utilization. Ahmed was actively exploring how his production supervisor could better optimize the daily job list to take full advantage of the No-CAD machine's inherent speed for certain types of customer orders, particularly those with tight deadlines.

Collecting, tracking, and systematically analyzing pertinent data on setup times, actual cutting times, and error rates for jobs processed via the No-CAD system versus those processed using traditional CAD methods can provide invaluable insights for continuous improvement. This data-driven approach can help to accurately quantify the benefits being achieved, identify any remaining areas for further process improvement, and enable more informed decisions regarding future technology investments or necessary workflow adjustments. For example, if the collected data reveals that certain parts initially deemed "complex" (and thus routed to CAD) are frequently being slightly modified and re-run, it might prompt a deeper investigation into whether a robust parametric template could, in fact, be developed for them within the No-CAD system. Alternatively, it might indicate that operators require more specific training on advanced modification techniques available directly within the No-CAD interface. The table below presents a sample framework of key data points that could be beneficial to track:

| Metric | Data to Collect (No-CAD Jobs) | Data to Collect (CAD Jobs) | Purpose of Analysis |

|---|---|---|---|

| Average Setup Time per Job | Time from job assignment to first cut | Time from program receipt by operator to first cut | Quantify time savings, identify any remaining setup bottlenecks |

| Operator Programming Time | Time spent at HMI entering parameters | Time spent by CAD designer creating program | Direct labor cost comparison, assess skill allocation efficiency |

| First Part Correct Rate | Percentage of jobs correct on the first try | Percentage of jobs correct on the first try | Measure accuracy improvements, identify specific training needs |

| Machine Utilization for Jobs | Percentage of scheduled time actively cutting | Percentage of scheduled time actively cutting | Assess overall impact on OEE, identify reasons for any idle time |

| Material Scrap Rate (setup) | Amount/cost of material wasted during setup | Amount/cost of material wasted during setup | Identify if No-CAD directly reduces setup-related material waste |

Finally, and perhaps most importantly, strive to foster a pervasive culture of continuous improvement throughout your organization. Actively encourage operators to provide regular feedback on the No-CAD system's usability, its features, and any challenges they encounter. Empower them to suggest practical ways to streamline workflows further based on their daily hands-on experience. Regular, structured meetings between operators, supervisors, and even designers (where their input is still applicable for complex jobs) can help to collaboratively identify fresh opportunities to expand the effective use of No-CAD technology or to improve the interface and handoff between No-CAD processed jobs and those that still genuinely require dedicated CAD input. Ahmed planned to implement regular kaizen (continuous improvement) events15 specifically focused on his new automated cutting cell, ensuring that his entire team was always actively looking for innovative ways to make the process smoother, faster, more reliable, and more cost-effective, leveraging the No-CAD technology as a central pillar of this ongoing improvement strategy.

No-CAD reduces training timeTrue

No-CAD systems can reduce intensive training requirements from weeks to potentially a single day by focusing on parametric input rather than CAD modeling.

One operator is sufficientFalse

Cross-training multiple operators is recommended to avoid operational bottlenecks and ensure continuity during absences.

Conclusion

No-CAD tube laser cutting machines, like those from my company MZBNL, truly revolutionize fabrication. They drastically speed up setup times and significantly lower operational costs. This empowers businesses like Ahmed's to enhance overall efficiency, reduce critical reliance on highly specialized skills, and ultimately boost their competitiveness.

-

Understand how setup time impacts overall production duration in fabrication, supported by industry data. ↩

-

Access the report detailing the widespread shortage of skilled CAD professionals in manufacturing. ↩

-

Explore findings on how inefficient ECO processes increase costs and time-to-market for manufacturers. ↩

-

View FMA survey data on skilled labor challenges faced by metal fabricators. ↩

-

Discover industry benchmarks on No-CAD's impact on tube fabrication setup efficiency. ↩

-

Understand OEE, a key metric for measuring manufacturing productivity and its components. ↩

-

Understand the role of HMIs in operator interaction with modern manufacturing equipment. ↩

-

Learn how parametric programming speeds up machine setup by using variable inputs for designs. ↩

-

Discover how ERP/MES integration enhances automation and data flow in modern production environments. ↩

-

Compare salaries: CAD/CAM programmers vs. machine operators to understand labor cost savings. ↩

-

Learn what OEE means and how it measures manufacturing productivity and efficiency improvements. ↩

-

Discover how nesting algorithms optimize material use and cut down waste in manufacturing. ↩

-

Learn about HMI systems and their role in modern industrial machine operation and control. ↩

-

Discover how ERP/MES integration enhances production planning, visibility, and overall operational efficiency. ↩

-

Understand Kaizen principles for fostering continuous improvement and efficiency on the factory floor. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.