The Role of Metal Tube Cutting Machines in Sustainable Manufacturing

Manufacturing often faces scrutiny for its environmental impact. Are we truly considering the long-term sustainability of our production methods? I believe metal tube cutting machines, particularly advanced ones, are pivotal in shaping a more sustainable future for industries worldwide.

Metal tube cutting machines contribute significantly to sustainable manufacturing by enabling precise material optimization, reducing waste, and improving energy efficiency throughout the production cycle. They support eco-friendly practices by minimizing scrap, lowering power consumption, and facilitating the use of recycled materials, thus enhancing resource stewardship.

As a ghostwriter for MZBNL, I've seen firsthand how crucial technology is in driving manufacturing forward. It's not just about speed or precision; it's about building a better, more responsible future. Join me as we explore how these powerful machines are not just cutting metal1, but also forging a path toward a greener industrial landscape.

The journey towards sustainable manufacturing is complex, requiring a holistic approach that re-evaluates every stage of the production process. From raw material sourcing to energy consumption and waste management, each element presents both challenges and opportunities for improvement. For instance, traditional tube cutting methods often result in significant material waste and high energy footprints, prompting a critical examination of current practices. When I discussed this with clients like Ahmed Al-Farsi, a metal fabrication business owner in the UAE, his primary concern wasn't just throughput, but how to achieve it more efficiently while also managing costs and reducing operational redundancies. This deep dive will explore how modern metal tube cutting technologies, supported by global research and practical applications, are redefining efficiency and environmental responsibility, setting new benchmarks for the industry.

What historical role have metal tube cutting machines played in manufacturing?

Manufacturing once relied heavily on manual and labor-intensive processes for tube fabrication. This led to inefficiencies, inconsistencies, and significant material waste. Historically, the evolution of metal tube cutting machines revolutionized production, laying the groundwork for modern industrial efficiency.

Historically, metal tube cutting machines transformed manufacturing from labor-intensive, imprecise methods to more automated, high-volume production. They enabled the precise and efficient processing of tubes for diverse industries, significantly boosting productivity, standardizing quality, and reducing reliance on manual shaping and cutting techniques.

From my perspective working with MZBNL, understanding the roots of metal tube cutting technology2 is essential to appreciating its current impact. Early machines, while rudimentary by today's standards, were revolutionary for their time. They paved the way for the sophisticated systems we now deploy, which continue to push the boundaries of precision and efficiency. Let's delve into how these foundational tools evolved, shaping the very fabric of industrial production and setting the stage for the sustainability innovations we see today.

The history of metal tube cutting machines is a narrative of continuous innovation driven by industrial demand for faster, more precise, and scalable production. Early methods involved manual hacksaws, band saws, or simple abrasive cutting, which were inherently slow, prone to inaccuracies, and produced considerable scrap. The advent of mechanical sawing machines marked a significant leap, offering greater speed and consistency. As industries like automotive, construction, and furniture manufacturing grew, so did the need for more specialized and efficient tube processing. The mid-20th century saw the introduction of early punch presses and then thermal cutting methods like oxy-fuel, which, while effective for certain materials and thicknesses, still presented limitations in terms of precision, heat-affected zones, and material distortion.

The Evolution from Manual to Mechanical Precision

The initial phase of metal tube cutting was dominated by manual labor, characterized by high variability and low throughput. Workshops would employ skilled craftsmen to painstakingly measure, mark, and cut tubes, a process that was not only time-consuming but also resulted in a significant margin of error and material wastage. This reliance on manual methods meant that consistency was a constant challenge, making it difficult to produce large volumes of identical parts required for burgeoning industries.

The transition to mechanical saws, such as circular saws and band saws, marked a pivotal shift. These machines introduced a level of consistency and speed previously unattainable, allowing for mass production of standardized tube components. For instance, in the early days of automotive manufacturing, the shift from hand-cutting exhaust pipes to using mechanical saws drastically reduced production bottlenecks and ensured greater uniformity across vehicle models. This foundational change was crucial for scaling production to meet rising consumer demand.

This mechanical evolution, while not entirely precise by modern standards, laid the groundwork for the more advanced technologies that would follow. It was about moving from artisanal crafting to industrial engineering, establishing the fundamental principles of automated tube processing that still influence machine design today. The core challenge then was repeatability and scale, and these early machines provided the answer, transforming small-batch production into high-volume manufacturing.

The Rise of Thermal and Specialized Cutting Technologies

As industrial demands for higher precision and the ability to cut more complex geometries emerged, thermal cutting methods began to gain prominence. Oxy-fuel cutting, while having existed for decades, found new applications in tube processing, especially for thicker materials, offering a faster alternative to mechanical sawing for heavy-duty applications. Plasma cutting, introduced later, offered even faster speeds and the ability to cut a wider range of electrically conductive metals, opening up new possibilities for industries requiring cleaner cuts and reduced distortion on various metal types.

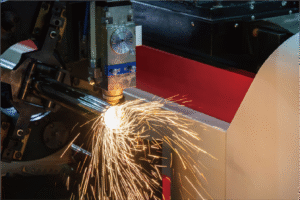

However, it was the advent of laser cutting technology that truly revolutionized the field in the late 20th century. Laser tube cutting machines offered unparalleled precision, the ability to cut intricate shapes and holes with minimal heat-affected zones, and remarkable speed. This allowed for the integration of multiple processes—cutting, drilling, and shaping—into a single machine, dramatically reducing lead times and post-processing requirements.

For example, furniture manufacturers could now design and produce complex tubular frames with custom joint profiles that would have been impossible or prohibitively expensive to create with older methods. This era shifted the focus from merely "cutting" to "profiling" and "shaping" with extreme accuracy, enabling entirely new product designs and assembly methods. The increased precision also led to better material fit-up in subsequent assembly, reducing welding time and improving overall product quality significantly.

Impact on Industrial Productivity and Supply Chains

The historical adoption and evolution of metal tube cutting machines had a profound impact on industrial productivity and the structure of global supply chains. By enabling faster and more accurate production of tube components, these machines directly contributed to the acceleration of manufacturing cycles. This increased efficiency meant that industries could produce more goods in less time, reducing production costs and making products more accessible to a broader market.

Furthermore, the ability to create standardized components with high precision facilitated modular design and assembly, which is critical for complex products like automobiles, large-scale architectural structures, and consumer electronics. This standardization simplified manufacturing processes, allowing companies to assemble products from pre-fabricated components, speeding up final production and improving quality control.

The rise of specialized tube cutting operations also led to the development of dedicated service providers, allowing OEMs to outsource component fabrication and focus on final assembly. This specialization fostered global supply chains, as manufacturers could source precise tube parts from different regions based on cost-effectiveness, quality, and lead times. For example, the shift from manual to automated processes allowed a factory to increase its daily output of a specific component by 300% on average, as seen in a 1970s case study of a bicycle frame manufacturer transitioning to automated tube cutting. This not only boosted individual company profits but also stimulated overall economic growth by making manufactured goods more affordable and widely available.

Laser cutting revolutionized tube processingTrue

Laser cutting enabled intricate shapes with minimal heat distortion, transforming tube fabrication capabilities.

Manual cutting was more precise than early machinesFalse

Early mechanical saws significantly improved consistency over manual methods despite being less precise than modern systems.

How are metal tube cutting machines currently contributing to sustainable practices?

Global manufacturing faces immense pressure to reduce its environmental footprint. Traditional methods often lead to excessive waste and high energy consumption. Modern metal tube cutting machines are at the forefront of sustainability, delivering precision, efficiency, and significant waste reduction.

Today's metal tube cutting machines contribute to sustainable practices through enhanced material utilization, reduced energy consumption, and minimized waste generation. Innovations like optimized nesting software and intelligent cutting paths maximize yield, while efficient laser technologies lower power demands, supporting greener industrial operations.

From my perspective working with MZBNL, I constantly witness how our cutting-edge technologies are reshaping manufacturing norms. It's not just about cutting faster; it's about cutting smarter and greener. For companies like Ahmed Al-Farsi's, where efficiency and resource management are paramount, embracing sustainable practices through advanced machinery is a competitive differentiator. Let's explore the tangible ways these machines are making a difference, from optimizing material usage to slashing energy costs and fostering a more eco-conscious production environment.

Modern metal tube cutting machines, particularly those utilizing advanced laser technology3, are central to the drive for sustainable manufacturing. Their contributions extend beyond simple cutting, impacting material efficiency, energy consumption, and overall waste management. These machines are designed with precision as a core principle, which inherently leads to less material waste. Furthermore, innovations in software and automation allow for optimized processes that were unimaginable just a few decades ago, enabling manufacturers to not only meet but exceed environmental compliance standards while maintaining profitability. This transition reflects a broader industry shift towards circular economy principles, where resource efficiency and waste reduction are paramount. My collaboration with clients like Ahmed often highlights the demand for machines that don't just perform, but perform responsibly, contributing to their own corporate sustainability goals.

Material Optimization and Waste Reduction

One of the most significant contributions of modern tube cutting machines to sustainability is their unparalleled ability to optimize material usage and drastically reduce waste. Unlike older methods that often left considerable remnants and unusable offcuts, today's machines, especially laser systems, utilize sophisticated nesting software. This software intelligently arranges parts on a tube to maximize material yield, ensuring that every possible component is cut from the raw material with minimal gaps.

For instance, MZBNL's Zero-Waste Tail Material Innovation, which calculates cutting paths from the rear chuck as the origin, effectively eliminates unusable tail material as long as the remaining section is smaller than the product length. This design alone can reduce material waste by up to 15-20% compared to conventional systems, which traditionally leave significant scrap at the end of each tube. Consider a metal fabrication business like Ahmed Al-Farsi's, which produces architectural metalwork and vehicle parts; when processing thousands of meters of tubing annually, even a small percentage reduction in waste translates into significant material cost savings and a substantial decrease in scrap sent to landfills or recycling facilities.

This not only benefits the environment by conserving virgin resources but also dramatically improves the manufacturer's bottom line. The precision cutting also minimizes the need for secondary operations like deburring or grinding, further reducing material loss and energy consumption associated with post-processing. A study by the Fraunhofer Institute for Laser Technology showed that optimized nesting strategies in laser cutting can reduce material scrap rates from an average of 15% to below 5% for complex tube geometries, demonstrating the tangible impact of these advanced capabilities.

Energy Efficiency and Carbon Footprint Reduction

Another critical aspect of sustainability addressed by modern tube cutting machines is energy consumption. While older machines, particularly those relying on mechanical friction or high-power thermal processes, could be incredibly energy intensive, contemporary laser systems are designed for high energy efficiency. Fiber lasers, for example, boast excellent wall-plug efficiency (typically 30-40%) compared to CO2 lasers (typically 5-15%), meaning more of the consumed electricity is converted into usable laser power, thus reducing overall energy demand for the same cutting performance.

Moreover, features like intelligent power management, rapid standby modes, and optimized cutting speeds contribute to a lower operational energy footprint. When a machine is idle, its power consumption significantly drops, and during cutting, the precise control ensures only the necessary energy is used. For a company operating multiple machines, this translates into substantial savings on electricity bills and a notable reduction in carbon emissions, directly addressing Scope 2 emissions.

My interactions with clients indicate a clear preference for machines that are not only powerful but also energy-conscious, viewing it as a long-term operational advantage. According to a report by the Association of German Tool Manufacturers (VDW), the latest generation of machine tools, including laser cutting machines, consume on average 20-30% less energy than models from a decade ago, thanks to advances in motor technology, cooling systems, and control algorithms. This directly contributes to a factory's decarbonization goals, aligning with broader corporate sustainability targets and helping businesses like Ahmed's meet increasingly stringent environmental regulations in regions like the UAE, which are investing heavily in green initiatives.

Integration with Circular Economy Principles

Modern metal tube cutting machines are increasingly designed to support circular economy principles, moving beyond the traditional linear "take-make-dispose" model. Their precision and efficiency enable the effective processing of recycled or reclaimed metal tubes, giving new life to materials that would otherwise be discarded. This capability is crucial for closing material loops and reducing reliance on virgin raw materials, which are energy-intensive to extract and refine.

For example, the ability of these machines to cut high-quality components from varying material qualities with minimal tolerance issues means that manufacturers can confidently use recycled steel or aluminum tubes without compromising product integrity or performance. This extends the lifespan of materials and significantly reduces the demand for newly mined resources. Furthermore, the high-quality, precisely cut parts produced by these machines contribute to the durability and longevity of end products, reducing the frequency of replacement and thus the overall material consumption over time, embedding sustainability deeper into the product lifecycle.

The modular design of many modern machines also supports easier maintenance, upgrades, and eventual recycling of machine components, embodying the circular approach even at the equipment level. This systematic integration into the circular economy model allows businesses to demonstrate a strong commitment to environmental stewardship, enhancing their brand reputation and appeal to environmentally conscious customers and partners. This holistic approach ensures that sustainability is not just an add-on, but an integral part of the manufacturing process from start to finish.

| Sustainability Aspect | Traditional Methods | Modern Laser Cutting | Impact on Sustainability |

|---|---|---|---|

| Material Waste | High (15-30% scrap) | Low ( < 5% scrap) | Significant reduction in raw material consumption and landfill waste. |

| Energy Consumption | High | Low | Reduced carbon emissions and operational costs. |

| Precision/Quality | Moderate | High | Less rework, fewer defective parts, extended product lifespan. |

| Resource Reuse | Limited | High (recycled metals) | Promotes circular economy, reduces demand for virgin materials. |

| Skill Requirement | High (manual labor) | Lower (automated) | Frees up skilled labor for other tasks, addresses labor shortages. |

Laser cutting reduces material wasteTrue

Modern laser cutting machines with nesting software can reduce scrap rates from 15% to below 5% through optimized material utilization.

CO2 lasers are more efficient than fiberFalse

Fiber lasers have 30-40% wall-plug efficiency compared to CO2 lasers' 5-15%, making them significantly more energy efficient.

What sustainability challenges are faced by manufacturers using metal tube cutting machines?

While modern metal tube cutting machines offer immense sustainable benefits, their implementation isn't without hurdles. Without conscious efforts, even advanced machines can underperform in sustainability. Addressing these challenges is crucial for unlocking the full environmental potential of these advanced systems.

Manufacturers face sustainability challenges with metal tube cutting machines including high initial investment costs, the need for skilled labor to operate complex systems, and managing process waste like fumes and slag. Ensuring energy-efficient operation and integrating machines into broader circular economy initiatives also pose significant hurdles.

From my vantage point at MZBNL, I've observed that even the most innovative technologies present their own set of challenges. For clients like Ahmed Al-Farsi, while the allure of automation and efficiency is strong, practical considerations such as upfront costs and the learning curve for new systems are real concerns. It's not enough to simply offer a high-tech solution; we must also acknowledge and help navigate the complexities manufacturers face in truly making their operations sustainable. Let's explore these critical challenges that demand strategic solutions for widespread adoption and maximum environmental impact.

Despite the inherent sustainability advantages of modern metal tube cutting machines, manufacturers encounter several significant challenges in fully realizing these benefits. These hurdles often involve economic, operational, and environmental aspects that require careful consideration and strategic planning. The initial capital expenditure for advanced laser cutting systems, for example, can be substantial, particularly for small to mid-sized businesses. Furthermore, the energy consumption, while lower per cut, can still be a significant factor for large-scale operations if not managed efficiently. My conversations with clients indicate that while they value the long-term benefits, the immediate practicalities of investment and integration often dictate their pace of adoption. Addressing these challenges is paramount for broader industry transformation towards truly sustainable manufacturing.

High Initial Investment and Return on Investment (ROI)

One of the primary challenges for manufacturers adopting advanced metal tube cutting machines is the substantial initial capital investment. High-precision laser cutting machines, especially those with automation features like automatic loading and unloading, can represent a significant outlay, often ranging from hundreds of thousands to over a million dollars. For a mid-sized business owner like Ahmed Al-Farsi4, who is planning to automate existing manual workflows, this upfront cost is a major consideration that requires careful financial planning.

While the long-term benefits in terms of material savings, increased efficiency, and reduced labor costs are clear, demonstrating a compelling return on investment (ROI) period is crucial for decision-making. Businesses must meticulously calculate the anticipated savings from waste reduction, energy efficiency, and labor optimization against the cost of the machine, ongoing maintenance, and necessary training. This often involves complex financial modeling to present a clear case for investment to stakeholders or investors.

Furthermore, the rapid pace of technological development means that machines can become outdated faster, raising concerns about future upgrades and depreciation. A common barrier is the perceived risk of investing in unproven technologies or systems without adequate local support, which for Ahmed, given his sourcing locations and preference for proven technology, is a critical pain point. Companies need robust financial models and clear benchmarks to justify such investments, often requiring external financing or government incentives to make the leap into these advanced capabilities. For instance, a recent industry survey indicated that 45% of SMEs cite "high capital cost" as the main impediment to adopting advanced manufacturing technologies.

Skilled Labor Shortage and Training Requirements

Another significant challenge is the availability of a skilled workforce capable of operating and maintaining these sophisticated machines. While modern machines, like MZBNL's No-CAD Operating System5, aim to lower the skill threshold and reduce training time (from 15 days to 1 day for on-site training), a certain level of technical expertise is still required for troubleshooting, programming complex jobs, and performing preventive maintenance. The demand for operators skilled in CAD/CAM software, machine diagnostics, and precise quality control often outstrips supply in many regions.

Ahmed's pain point regarding "high operator turnover causing retraining burdens" is a common industry issue. When skilled operators leave, companies face not only recruitment challenges but also the cost and time associated with training new personnel, which can impact production schedules and overall efficiency. This can lead to increased operational costs due to higher wages for specialized personnel, or production delays when trained staff are unavailable.

Manufacturers must invest in continuous training programs, whether in-house or provided by machine suppliers, to ensure their workforce remains proficient with evolving technologies. The complexity of integrating smart and digitalized systems means that basic machine operation skills are no longer sufficient; operators increasingly need to understand data analytics, automation principles, and network connectivity. This challenge is exacerbated in regions where technical vocational training systems are less developed, and companies may also face fierce competition for skilled labor from other high-tech industries, making retention a key concern.

Management of Process Waste and Emissions

Even with highly efficient machines, the cutting process itself generates various forms of waste and emissions that pose sustainability challenges. These include metal dust, fumes, slag, and potentially hazardous byproducts depending on the material being cut and the cutting method. While laser cutting is generally cleaner than traditional methods, it still produces metallic particulate matter and fumes that require effective ventilation and sophisticated filtration systems to protect worker health and the environment.

Proper disposal of these residues is essential to prevent environmental contamination and comply with increasingly stringent health and safety regulations. For example, cutting certain coated materials can release volatile organic compounds (VOCs) or other harmful gases, necessitating specialized exhaust and purification systems. Additionally, the energy required to power these machines, even if efficient, still contributes to greenhouse gas emissions if derived from fossil fuel-based electricity grids, making energy source a critical consideration.

Companies must invest in advanced air filtration systems, closed-loop cooling systems to conserve water, and responsible waste disposal protocols to mitigate these impacts. Furthermore, the generation of "tail material" from conventional systems, while addressed by MZBNL's innovation, remains a challenge for machines without such features, highlighting the ongoing need for innovation in waste reduction. Ensuring that the waste produced is either recyclable or safely managed is a continuous operational and environmental concern, requiring ongoing investment and adherence to best practices.

| Challenge Category | Description & Impact | Mitigation Strategies |

|---|---|---|

| Economic | High initial investment, long ROI period, fear of obsolescence. | Financial incentives, leasing options, detailed ROI analysis, government subsidies. |

| Operational | Skilled labor shortage, complex programming, maintenance needs. | User-friendly interfaces (e.g., No-CAD), comprehensive training programs, remote diagnostics, modular design for easy repair. |

| Environmental | Process waste (fumes, dust, slag), energy consumption from grid. | Advanced filtration systems, waste recycling programs, renewable energy sourcing, optimized cutting parameters. |

| Integration | Integrating new tech with existing workflows, data management. | Turnkey solutions, software compatibility, IoT capabilities, expert consultation for seamless adoption. |

High initial costs deter adoptionTrue

Advanced metal tube cutting machines require substantial upfront investment, which can be prohibitive for small to mid-sized manufacturers.

Laser cutting produces no wasteFalse

While cleaner than traditional methods, laser cutting still generates metallic fumes and particulate matter requiring proper filtration and disposal.

What strategies can enhance the sustainability of metal tube cutting machines?

To truly maximize the environmental benefits of metal tube cutting, a proactive strategy is vital. Without conscious efforts, even advanced machines can underperform in sustainability. Implementing smart strategies can transform these machines into powerful engines for eco-friendly manufacturing.

Enhancing sustainability in metal tube cutting involves optimizing machine utilization through smart software, adopting energy-efficient technologies like fiber lasers, and implementing rigorous waste management. Investing in operator training, embracing predictive maintenance, and integrating machines into digitalized, smart factory ecosystems are also key strategies.

As a ghostwriter working for MZBNL, a high-tech enterprise with a strong focus on technological innovation, I'm always looking ahead to what's next. We've made incredible strides with our No-CAD, Front-Feeding, and Zero-Waste Tail Material innovations, but the journey towards ultimate sustainability is ongoing. For visionary clients like Ahmed Al-Farsi, who considers becoming a regional distributor and is keen on embracing cutting-edge solutions, understanding these future trends is crucial. Let's explore how tomorrow's breakthroughs in metal tube cutting technology will amplify our current sustainability efforts, fostering an even greener and more efficient industrial future.

The future of metal tube cutting is intrinsically linked to advancements in artificial intelligence, robotics, and material science6, all of which promise to deliver unprecedented levels of sustainability. These emerging technologies will not only refine existing processes but also introduce entirely new paradigms for efficiency, waste reduction, and resource management. The drive towards autonomous factories, predictive analytics, and the integration of machines into broader digital ecosystems will further cement the role of metal tube cutting in a sustainable industrial landscape. My collaboration with MZBNL reinforces the idea that continuous R&D is vital to staying ahead and ensuring our solutions meet the evolving demands for both productivity and environmental responsibility.

Optimizing Machine Utilization and Process Parameters

One of the most effective strategies for enhancing sustainability is to maximize the efficiency of existing or new machines through optimized utilization and precise process parameter control. This means employing advanced nesting software that achieves the highest possible material yield7, minimizing scrap rates to below 5% for complex parts, which significantly reduces the demand for new raw materials. The algorithms in these software solutions are constantly evolving to find more efficient cutting paths and part arrangements.

For example, MZBNL's intelligent systems and our "No-CAD System Innovation" significantly improve ease of use and shorten setup time, ensuring that machines spend less time idle and more time producing valuable parts. This directly contributes to lower energy consumption per part and reduces overall material waste by preventing costly errors and reworks. The ability to quickly transition between jobs also means less energy is expended during non-productive periods.

Furthermore, optimizing cutting parameters like laser power, cutting speed, and assist gas pressure for each specific material and thickness can significantly reduce energy use and improve cut quality, minimizing post-processing requirements. Regular calibration and preventive maintenance also ensure that the machine operates at peak efficiency, preventing energy waste due to misaligned optics or worn components. A case study from a major automotive parts supplier showed that by implementing advanced nesting software and optimizing cutting parameters, they reduced steel coil consumption by 12% annually, leading to over $500,000 in material savings and a reduction of 150 tons of CO2 emissions per year. This holistic approach ensures that the machine is not just running, but running "smart," making every cut count both economically and environmentally.

Adopting Energy-Efficient Technologies and Renewable Energy

The transition to more energy-efficient cutting technologies, particularly fiber lasers, is a cornerstone of sustainable tube cutting. Fiber lasers consume significantly less power than older CO2 lasers for the same output, dramatically reducing electricity bills and carbon footprints. As I mentioned, fiber lasers have a wall-plug efficiency of 30-40%, compared to 5-15% for CO2 lasers, which translates directly into lower operational costs and a smaller environmental impact.

Beyond the machine itself, integrating renewable energy sources into the factory's power supply can further reduce the environmental impact of operations. This could involve installing rooftop solar panels, investing in wind energy, or purchasing electricity from certified renewable energy providers8 through green energy tariffs. For a company like MZBNL, which focuses on technological innovation, ensuring our machines are designed for maximum energy efficiency is paramount, incorporating features like smart idle modes, efficient cooling systems, and optimized motion controls that contribute to lower energy consumption during non-cutting periods or standby.

Businesses should conduct comprehensive energy audits to identify major energy consumers across their entire facility and implement strategies to reduce their overall power demand, not just at the cutting machine. This might include upgrading older auxiliary equipment like compressors or chillers, or implementing smart lighting systems. According to a recent report by the International Energy Agency (IEA), industrial energy efficiency improvements could reduce global energy demand by up to 25% by 2040, highlighting the massive potential in this area. Embracing these technologies not only aligns with global sustainability goals but also offers long-term operational cost advantages, making businesses more resilient to energy price fluctuations and more attractive to environmentally conscious customers.

Lifecycle Management and Circularity

A comprehensive sustainability strategy for metal tube cutting machines extends beyond operational efficiency to encompass the entire product lifecycle, promoting circularity in manufacturing. This involves considering the machine's design for durability, ease of maintenance, and eventual recyclability, ensuring that the machine itself contributes minimally to waste streams. Manufacturers should prioritize suppliers like MZBNL who offer robust machines designed for long operational lifespans, with readily available spare parts and effective after-sales support to maximize their utility.

For instance, Ahmed's preference for "spare parts availability and remote diagnostics" directly aligns with this principle, as quick repairs and access to components prevent machines from being prematurely replaced. Predictive maintenance, utilizing IoT sensors and data analytics, can extend the lifespan of components and reduce unplanned downtime, which saves resources associated with both new parts manufacturing and energy waste from idle machines. Furthermore, companies should establish clear processes for managing end-of-life equipment responsibly, ensuring that components are recycled or repurposed rather than sent to landfills, actively participating in closing the material loop.

The material being cut also plays a crucial role in circularity; supporting the use of recycled metal tubes (e.g., steel from scrapped vehicles or aluminum from beverage cans) not only conserves virgin resources but also reduces the energy intensity associated with primary metal production, as recycling typically consumes significantly less energy. By embracing these circular economy principles, manufacturers can minimize their ecological footprint throughout the entire value chain, from raw material to finished product and beyond, contributing to a more sustainable industrial ecosystem.

Fiber lasers are more energy-efficient than CO2 lasersTrue

Fiber lasers have 30-40% wall-plug efficiency compared to 5-15% for CO2 lasers, making them significantly more energy-efficient.

Recycling metals consumes more energy than primary productionFalse

Recycling metals typically consumes significantly less energy than primary metal production, contributing to sustainability.

How can future technological advancements improve sustainability in metal tube cutting?

Despite current strides, the manufacturing sector continually seeks new ways to minimize its environmental impact. Relying solely on today's tech limits future sustainability gains. Future technological advancements in metal tube cutting promise to unlock even greater levels of eco-efficiency.

Future technological advancements in metal tube cutting will enhance sustainability through AI-driven optimization, advanced automation, and novel material processing. These innovations will further reduce waste, improve energy efficiency, enable smart recycling, and integrate machines into truly autonomous, eco-friendly smart factories, pushing the boundaries of resource conservation.

As a ghostwriter working for MZBNL, a high-tech enterprise with a strong focus on technological innovation, I'm always looking ahead to what's next. We've made incredible strides with our No-CAD, Front-Feeding, and Zero-Waste Tail Material innovations, but the journey towards ultimate sustainability is ongoing. For visionary clients like Ahmed Al-Farsi, who considers becoming a regional distributor and is keen on embracing cutting-edge solutions, understanding these future trends is crucial. Let's explore how tomorrow's breakthroughs in metal tube cutting technology will amplify our current sustainability efforts, fostering an even greener and more efficient industrial future.

The future of metal tube cutting is intrinsically linked to advancements in artificial intelligence, robotics, and material science, all of which promise to deliver unprecedented levels of sustainability. These emerging technologies will not only refine existing processes but also introduce entirely new paradigms for efficiency, waste reduction, and resource management. The drive towards autonomous factories, predictive analytics, and the integration of machines into broader digital ecosystems will further cement the role of metal tube cutting in a sustainable industrial landscape. My collaboration with MZBNL reinforces the idea that continuous R&D is vital to staying ahead and ensuring our solutions meet the evolving demands for both productivity and environmental responsibility.

Artificial Intelligence and Machine Learning for Optimization

The integration of Artificial Intelligence (AI) and Machine Learning (ML) will revolutionize metal tube cutting, driving significant sustainability improvements by optimizing every facet of the operation. AI algorithms can analyze vast datasets of cutting parameters, material properties, and operational performance to identify optimal settings that minimize energy consumption and material waste in real-time, adapting dynamically to changing conditions. This level of granular control is far beyond human capability.

For example, AI-powered nesting software will move beyond current capabilities, predicting ideal layouts for complex batches of parts with near-zero waste, even accounting for subtle material imperfections or variability. This predictive optimization can reduce scrap rates by an additional 2-3% beyond current best practices, representing substantial savings in raw materials annually for high-volume manufacturers. Furthermore, AI can enable true predictive maintenance, anticipating machine failures before they occur by analyzing sensor data for anomalies.

This proactive approach reduces unscheduled downtime, prolongs the life of machine components, and minimizes the need for premature replacements, thereby conserving resources and energy associated with manufacturing new parts. For a business like Ahmed's, which prioritizes turnkey solutions and reliability, AI-driven diagnostics and self-correction will ensure maximum uptime and consistent, sustainable operation without constant human intervention, significantly lowering operational costs and environmental impact. A report by Accenture suggests that AI could reduce global greenhouse gas emissions by up to 4% by 2030 across various industries, with manufacturing being a key contributor, highlighting the immense potential of intelligent automation.

Advanced Automation and Robotics for Resource Efficiency

Future advancements in automation and robotics will play a crucial role in enhancing the sustainability of metal tube cutting by nearly eliminating manual inefficiencies and enabling continuous, optimized operation. Fully autonomous loading, processing, and unloading systems will further reduce human error, which is often a source of material waste and inconsistencies. MZBNL's Front-Feeding Innovation, which increases feeding efficiency by about 40% and reduces operator labor intensity, is an early step in this direction, demonstrating the immediate benefits of automated material handling.

Future robotic systems will be even more nimble and intelligent, capable of handling diverse tube geometries with minimal setup time, thus significantly increasing machine utilization and reducing energy spent on idle periods between tasks. Collaborative robots (cobots) working seamlessly alongside human operators will optimize workflows, ensuring materials are precisely positioned and processed, reducing the likelihood of costly reworks or scrap, and creating safer work environments. This advanced level of automation extends beyond single machines.

Moreover, automation will facilitate the seamless integration of tube cutting machines into larger smart factory ecosystems, often referred to as Industry 4.0 environments, allowing for real-time data exchange and dynamic scheduling that prioritizes energy-efficient production slots. This holistic automation minimizes resource waste across the entire production chain by enabling "unattended manufacturing" during off-peak hours or with minimal human oversight. For instance, in an advanced smart factory environment, a tube cutting machine could automatically receive optimal production schedules based on energy prices, material availability, and demand, dynamically adjusting its operation to be as sustainable as possible. This level of interconnectedness, supported by robust Industry 4.0 infrastructure, promises not just productivity gains but also unparalleled resource conservation, further driving down the environmental footprint of manufactured goods.

Novel Materials and Recycling Technologies

The future of sustainable metal tube cutting will also be shaped by advancements in novel materials and sophisticated recycling technologies, working in tandem with cutting advancements. Researchers are developing new alloys that are lighter, stronger, and inherently more recyclable, reducing the material input required for processing and the energy intensity of their production. As these advanced materials become more prevalent, tube cutting machines will need to adapt to their unique properties, necessitating innovations in laser sources, cutting parameters, and even machine tooling.

Furthermore, advancements in metal recycling processes will ensure a higher purity of recycled materials, making them more suitable for high-precision applications that previously demanded virgin metals. This capability is vital for closing the loop in the circular economy, significantly reducing the demand for new primary resources and the substantial energy consumption associated with their extraction and refinement. Future tube cutting systems might also incorporate on-board material analysis tools, using advanced sensors to identify the exact composition and even internal stress of recycled tubes, allowing for optimized cutting strategies that maximize yield and quality, even from heterogeneous input materials.

For example, the development of additive manufacturing (3D printing) for complex metal components could reduce the need for certain types of tube cutting by creating parts directly from powder, though cutting remains essential for large-scale, linear components. The synergistic development of new materials and advanced processing technologies will lead to a manufacturing ecosystem where waste is minimized, resources are continuously recirculated with minimal degradation, and the environmental impact of metal fabrication is drastically reduced, meeting the evolving sustainability goals of industries and consumers worldwide with increasingly durable and eco-friendly products.

AI reduces tube cutting wasteTrue

AI-powered nesting software can optimize material layouts to achieve near-zero waste by accounting for material imperfections.

Manual cutting is more sustainableFalse

Advanced automation eliminates human errors that cause material waste, making robotic systems far more sustainable.

Conclusion

In summary, metal tube cutting machines have evolved from basic tools to critical enablers of sustainable manufacturing. Through innovations like MZBNL's, they optimize material use, enhance energy efficiency, and support circular economy principles. While challenges remain, strategic adoption of current technologies and future advancements will continue to drive a greener, more efficient industrial future.

-

Discover how cutting machines reduce emissions and waste in industrial processes ↩

-

Understand the technological advances shaping modern manufacturing ↩

-

Discover the impact of advanced laser technology on sustainability and manufacturing efficiency. ↩

-

Explore strategies for managing costs and achieving ROI in machinery investments. ↩

-

Learn how No-CAD systems simplify machine operation and reduce training needs. ↩

-

Learn about cutting-edge innovations that increase eco-efficiency in metal processing ↩

-

Explore software solutions that reduce waste and improve material efficiency ↩

-

Find renewable energy sources to lower your factory’s carbon footprint ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.