Revolutionary Innovations in Laser Tube Cutting Technology

For years, I've seen businesses in metal fabrication grapple with complex machinery, skilled labor shortages1, and the constant pressure to improve efficiency while reducing waste. Traditional laser tube cutting, while powerful, often came with these inherent challenges. But what if the very tools you rely on could become dramatically simpler to use, significantly more productive, and remarkably less wasteful?

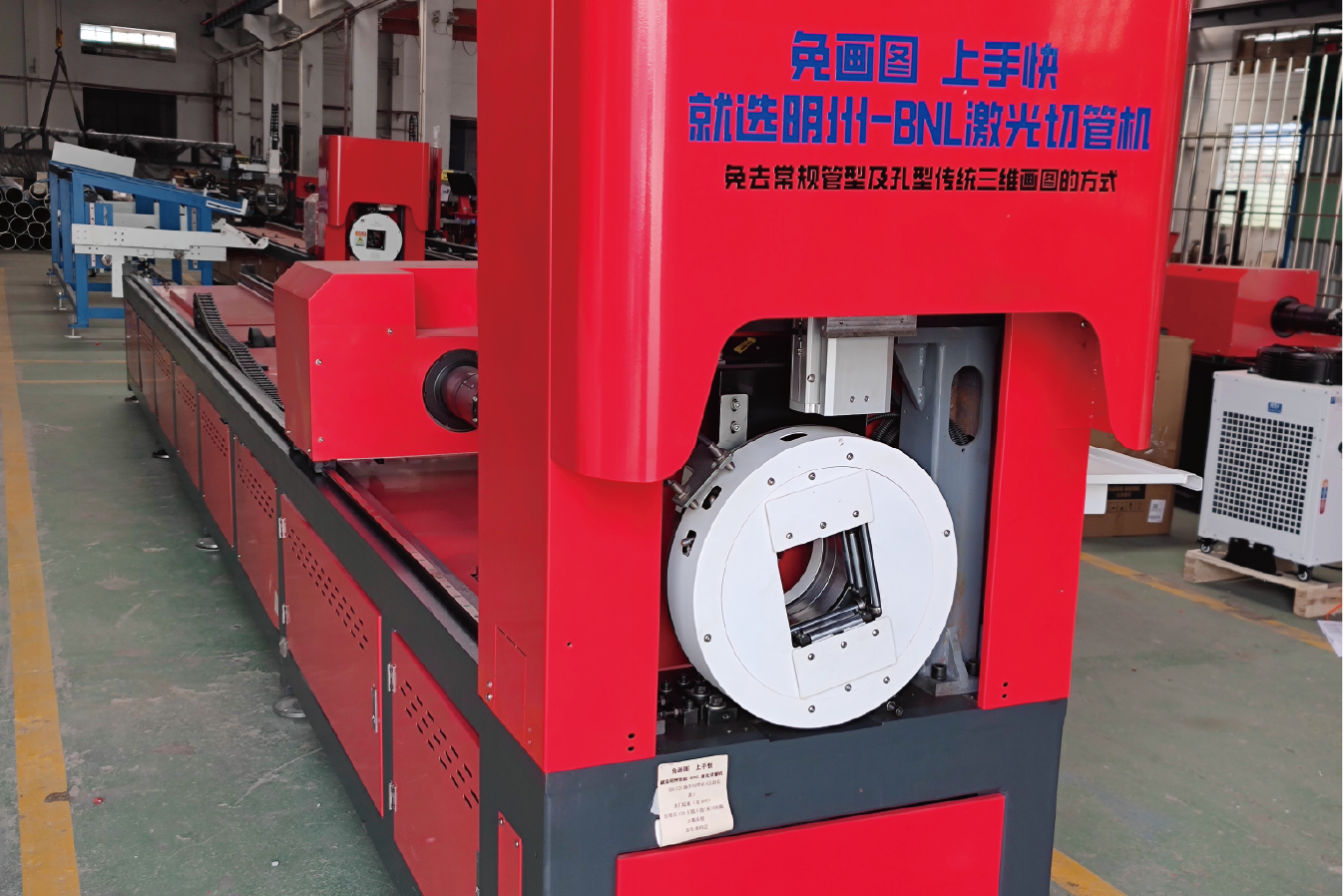

The latest innovations in laser tube cutting technology are revolutionizing the industry, primarily through No-CAD operating systems that allow parameter-based cutting without complex drawings, automated front-feeding mechanisms for enhanced material handling, and intelligent zero-waste tail material designs that maximize material utilization and reduce scrap.

These advancements aren't just incremental improvements; they represent a fundamental shift in how we approach tube fabrication. As someone who has dedicated 25 years to this field with MZBNL, I've witnessed firsthand the transformative power of such innovations. Stick with me, and I'll walk you through what's new and why it matters for your business's competitive edge and bottom line.

The journey of technological evolution in manufacturing is often marked by breakthroughs that redefine efficiency and accessibility. In the realm of laser tube cutting, we're currently experiencing such a pivotal moment. It's not merely about cutting faster or with more precision—though those are important—it's about fundamentally changing the operator's interaction with the machine, optimizing material flow from start to finish, and making a tangible impact on sustainability. Industry studies, like those from market research firms focusing on industrial automation, consistently point towards a growing demand for solutions that reduce complexity and operational overhead. For instance, a recent report highlighted that over 60% of fabrication shops identify skilled labor shortages as a primary growth constraint. Innovations that lower the skill threshold for operating advanced machinery, therefore, directly address this critical industry pain point. At MZBNL, our focus has always been on anticipating these needs and pioneering solutions that empower our clients, like Ahmed Al-Farsi from the UAE, who constantly seeks ways to automate and upgrade his production.

No-CAD System Innovation: The End of Complex Drawings?

Many fabricators, including some of my long-term clients, have expressed frustration over the bottleneck created by CAD drawing dependency. The process of designing, refining, and transferring 3D models to the cutting machine often leads to delays and requires highly specialized personnel. Imagine streamlining this entirely for standard jobs, empowering your operators and freeing up your designers.

No-CAD system innovation in laser tube cutting enables operators to process standard tube types and common hole patterns by directly inputting parameters into the machine's intuitive interface, thereby eliminating the need to create or modify complex 3D CAD drawings for many routine tasks.

This is more than just a convenience; it's a fundamental shift in workflow that can unlock significant productivity gains and reduce reliance on a limited pool of CAD experts. For businesses like Ahmed's in the UAE, which handles diverse projects from architectural metalwork to vehicle parts, the ability to quickly set up jobs for standard profiles without waiting for a CAD designer can be a game-changer. It accelerates quoting, production, and ultimately, project delivery. We've seen at MZBNL how this innovation not only speeds up operations but also broadens the accessibility of advanced laser cutting technology to a wider range of users within an organization, fostering a more agile and responsive manufacturing environment.

The advent of No-CAD systems marks a significant departure from traditional workflows that have long characterized the metal fabrication industry. For decades, the mantra was \"design first, then cut,\" which invariably meant a dependency on skilled CAD engineers to translate concepts into machine-readable instructions. While essential for bespoke and highly intricate parts, this approach becomes a cumbersome hurdle for the vast majority of tube cutting applications involving standard shapes, hole patterns, and common end-cuts. The No-CAD paradigm, pioneered and perfected by companies like us at MZBNL, directly challenges this inefficiency by embedding design intelligence for common tasks directly into the machine's operating system. This empowers shop floor personnel to become more autonomous, dramatically reducing the lead time from job conception to finished part. The implications are far-reaching, touching upon everything from operational speed and cost-efficiency to labor utilization and market responsiveness. It’s about making sophisticated technology feel intuitive and accessible, a core philosophy that drives our development at MZBNL.

Breaking Free from the Design Bottleneck

The traditional workflow in laser tube cutting can be a multi-stage, time-consuming process. It typically begins with a concept, which is then translated into a detailed 2D or 3D CAD drawing by a skilled designer. This drawing then needs to be converted into a CAM program, which instructs the laser cutting machine on the precise paths, power settings, and gas usage. Any modification, however minor, often requires a return to the design office, creating a loop that can significantly stall production, especially in high-mix, low-volume environments. This reliance on specialized CAD personnel not only creates a bottleneck but also adds to the overhead costs. I recall a conversation with Ahmed, who mentioned that his lead CAD designer was often overwhelmed, leading to frustrating delays for his urgent architectural metalwork projects.

The No-CAD system fundamentally alters this dynamic. At MZBNL, our system allows operators to select from a library of standard tube profiles (round, square, rectangular, oval, etc.) and common operations like through-holes, blind holes, slots, and various end-cuts directly on the machine's control panel. By simply inputting key parameters such as tube dimensions, hole diameter, hole spacing, and cut angles, the machine generates the cutting program automatically. This bypasses the need for separate CAD/CAM software for a large percentage of jobs. The impact is immediate: setup times are drastically reduced, and the machine can be put into production much faster. For instance, we've found that operator training for our No-CAD system takes just one day on-site, compared to the traditional 15 days often required at an equipment factory to master complex CAD/CAM interfaces for tube cutting.

This simplification doesn't mean a compromise on capability for standard tasks. Instead, it streamlines the process for the most frequent operations, freeing up CAD designers to focus on genuinely complex, non-standard parts that require their specialized expertise. For a business like Ahmed's, this means his team could directly handle many standard railing or shelving components, allowing his designer to concentrate on intricate custom designs for high-value vehicle parts. The result is a more efficient allocation of resources, faster turnaround times across the board, and an increased capacity to take on more work without a proportional increase in design staff. This shift significantly enhances a workshop's agility and responsiveness to customer demands.

Democratizing Laser Tube Cutting: Lowering the Skill Threshold

One of the most significant advantages of No-CAD systems is the democratization of advanced laser tube cutting technology. Historically, operating these sophisticated machines required a considerable level of technical expertise, particularly in interpreting and sometimes even troubleshooting CAD/CAM programs. This created a high barrier to entry and made businesses heavily reliant on a small pool of highly skilled, and often highly paid, operators and programmers. The global shortage of such skilled labor, a point often raised in industry forums and manufacturing surveys, further exacerbates this challenge. Many factory owners I've spoken to, including Ahmed, have highlighted high operator turnover and the subsequent retraining burdens as major pain points.

No-CAD systems directly address this by simplifying the human-machine interface. Instead of navigating complex software menus and understanding G-code, operators interact with a user-friendly, often graphical, interface where they input straightforward dimensional parameters. This dramatically lowers the skill threshold required to operate the machine effectively for a significant portion of everyday tasks. Consequently, businesses can train a wider range of employees to use the laser tube cutter, reducing dependence on a few key individuals and making recruitment and training processes quicker and less costly. For example, an operator familiar with general machine operation but without specific CAD expertise can become proficient on a No-CAD system in a fraction of the time.

This accessibility opens up new possibilities for small and medium-sized enterprises (SMEs) that may have previously found advanced laser tube cutting technology to be too complex or too resource-intensive to adopt. It also improves labor flexibility within larger organizations, allowing for easier cross-training and staff rotation. The reduction in training time, from a potential 15 days down to just 1 day as we've achieved with the MZBNL system, translates directly into cost savings – not just in terms of trainer fees or lost production during off-site training, but also in the speed at which a new operator can become a productive member of the team. This ultimately contributes to a more resilient and adaptable workforce.

Real-World Impact: Speed, Simplicity, and Savings

The tangible benefits of No-CAD systems extend far beyond just operational convenience; they translate into measurable improvements in speed, simplicity, and cost savings, which are critical for maintaining competitiveness in today's fast-paced manufacturing landscape. The speed enhancement is multi-faceted. Firstly, the elimination of the CAD/CAM programming step for standard jobs drastically cuts down job preparation time. What might have taken hours can now be achieved in minutes. This is particularly beneficial for businesses that handle a high mix of jobs or require rapid prototyping. Secondly, the simplicity of the interface reduces the likelihood of human error during data entry or program setup, leading to less rework and material wastage.

Consider the financial implications. The direct cost savings come from reduced reliance on specialized CAD personnel for routine tasks, lower training expenses, and minimized errors. Indirectly, the increased machine uptime and throughput contribute to a higher return on investment (ROI) for the equipment. At MZBNL, we've seen clients report significant improvements in their overall equipment effectiveness (OEE) after adopting our No-CAD enabled machines. For instance, a furniture manufacturer client was able to reduce their time-to-market for new designs involving standard tube components by nearly 30%, simply by empowering their shop floor team to handle adjustments and new standard part programs directly.

Moreover, the simplicity fosters a more agile production environment. If a customer requires a slight modification to a standard part, or if a last-minute order for a common profile comes in, a No-CAD system allows for quick adaptation without disrupting the entire design-to-production workflow. This flexibility is invaluable. Ahmed’s business, which supplies both architectural elements requiring aesthetic precision and automotive parts demanding functional accuracy, would benefit immensely. He could swiftly process orders for standard fence posts or support frames using the No-CAD system, while his design team focuses on the more complex geometries for custom vehicle chassis components. This dual capability, enabled by the No-CAD system’s targeted simplification, ultimately allows businesses to serve a broader range of customer needs more efficiently and profitably.

| Feature | Traditional CAD Workflow | MZBNL No-CAD System Workflow |

|---|---|---|

| Design Input | Complex 2D/3D Drawings Required | Direct Parameter Input for Standards |

| Operator Skill | High (CAD/CAM proficiency essential) | Low (Basic machine operation skills) |

| Job Setup Time | Long (Drawing creation, import, programming) | Short (Direct parameter entry on HMI) |

| Training Duration | Typically 10-15 days (off-site/intensive) | Approx. 1 day (on-site, intuitive) |

| Flexibility for Mods | Lower; requires return to design office | Higher for standard parameter changes |

| Error Potential | Higher due to multiple data transfer steps | Lower due to simplified direct input |

| Design Staff Load | High for all jobs | Reduced; focused on complex tasks |

No-CAD systems eliminate CAD drawingsTrue

No-CAD systems allow operators to input parameters directly into the machine's interface for standard tasks, bypassing the need for complex CAD drawings.

No-CAD requires CAD expertiseFalse

No-CAD systems actually lower the skill threshold, allowing operators with basic machine operation skills to perform standard cutting tasks without CAD knowledge.

Front-Feeding Innovation: Automating for Efficiency and Ergonomics

Imagine your production line where heavy metal tubes are loaded manually, one by one. This is not only slow and physically demanding for your team but also a point where efficiency can easily be lost. Now, picture a system that automatically and precisely feeds tubes from the front, keeping the pace with your cutting needs.

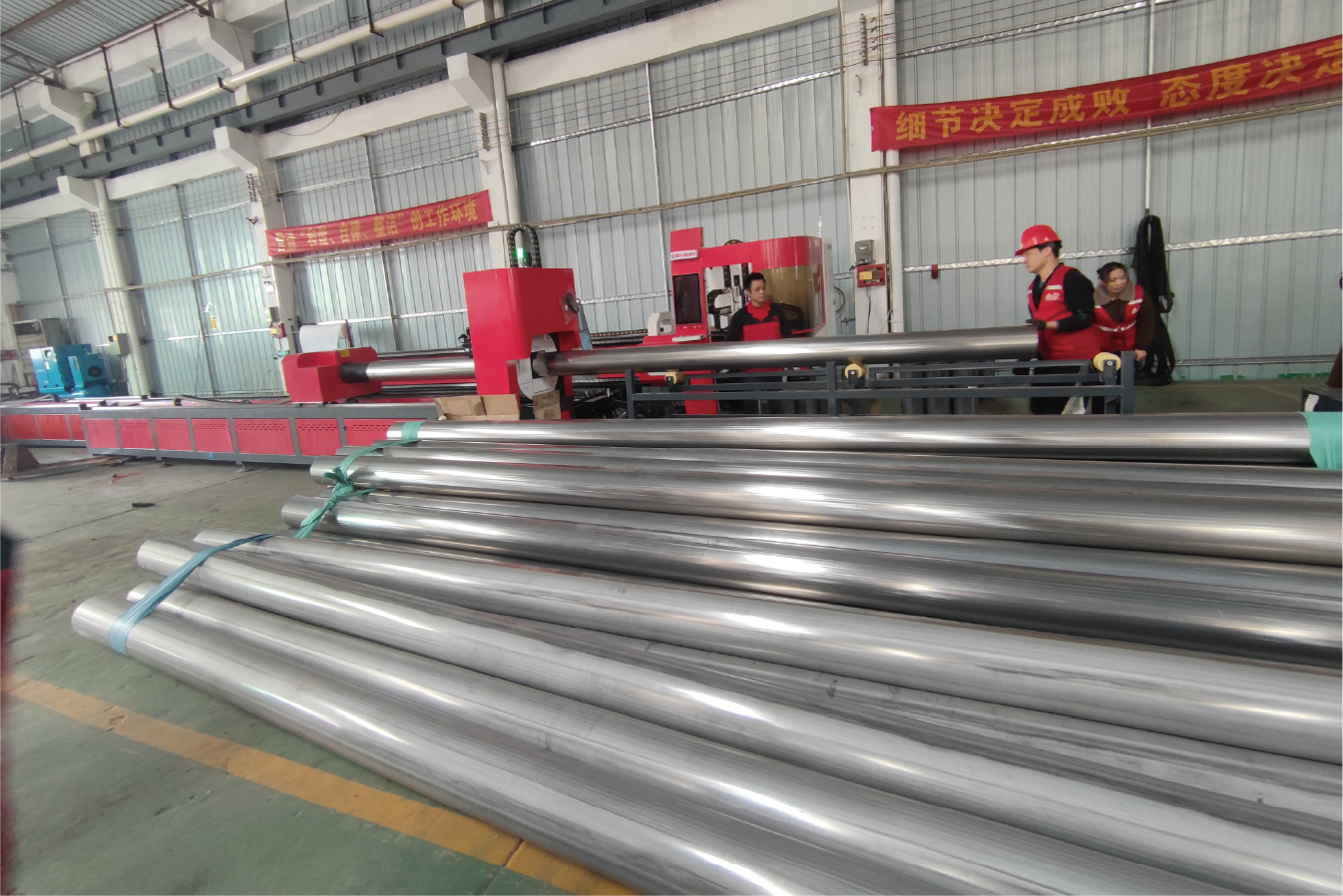

Front-feeding innovation in laser tube cutting incorporates an optimized, automated mechanism that smoothly pulls tubes into the machine from the front, significantly boosting material handling efficiency by approximately 40% and reducing operator labor intensity by a similar margin.

This advancement transforms a traditionally labor-intensive part of the process into a streamlined, automated function. For businesses like Ahmed's, which might be handling long production runs for automotive components or large batches of identical parts for shelving systems, such automation can lead to substantial improvements in throughput and a more comfortable, safer working environment for operators. It's about working smarter, not just harder, and ensuring that the material flow to the cutting head is as seamless and efficient as the cutting process itself. This is a cornerstone of MZBNL's approach to holistic machine design.

The material loading phase in tube processing has historically been a significant area for potential improvement. Traditional methods often involve manual or semi-automated side or rear loading, processes that can be cumbersome, time-consuming, and physically taxing for operators, especially when dealing with long or heavy tubes. These methods can introduce inconsistencies in feeding speed and alignment, potentially impacting the overall cycle time and even the quality of the first few cuts. Recognizing this, innovators in the laser tube cutting sphere, including our team at MZBNL, have focused on re-engineering the feeding mechanism to enhance both efficiency and ergonomics. The development of automated front-feeding systems represents a major leap forward, directly addressing these longstanding challenges by creating a more fluid, reliable, and operator-friendly material input process.

The Mechanics of Enhanced Productivity

Automated front-feeding systems fundamentally change how tubes are introduced into the laser cutting machine. Instead of operators manually lifting and aligning each tube, or relying on gravity-assisted side loaders that may require careful staging, a front-feeding mechanism typically uses a set of powered rollers or a gripper system integrated at the front of the machine. This system automatically grasps the end of a tube from a bundle or a pre-loaded magazine and pulls it into the machine's chucking system. The process is precise, controlled, and significantly faster than manual alternatives. At MZBNL, our front-feeding innovation is designed to seamlessly integrate with the machine's overall control system, ensuring that a new tube is ready for processing almost immediately after the previous one is finished.

This automation translates directly into quantifiable productivity gains. We've measured an increase in feeding efficiency of approximately 40% with our front-feeding systems compared to traditional manual methods. This isn't just about the speed of loading a single tube; it's about the consistency and reduction of idle time between tubes. For a business like Ahmed's, which produces automotive parts often requiring high-volume, continuous production runs, this consistent feeding speed means more parts per shift and a more predictable output. The reduction in operator labor intensity, also around 40%, means that operators are less fatigued and can focus on overseeing the cutting process, quality control, and managing the overall workflow rather than being bogged down by strenuous physical tasks.

Furthermore, automated front-feeding can handle a variety of tube lengths and profiles with minimal adjustment, offering greater flexibility. The precision of the automated feed also contributes to better material alignment in the chucks, which can lead to more accurate cuts, especially at the beginning of the tube. This mechanical efficiency ensures that the high-speed capabilities of modern laser cutters are not bottlenecked by a slow or inconsistent material input process, thereby maximizing the utilization of the machine's cutting potential and improving overall throughput.

Ergonomics and Operator Well-being

The impact of front-feeding innovation extends beyond mere productivity metrics; it plays a crucial role in enhancing workplace ergonomics and operator well-being. Manual loading of metal tubes, especially those of considerable length (e.g., 6 meters or more) and weight, exposes operators to significant physical strain. Repetitive lifting, awkward postures, and the risk of impact injuries are all inherent hazards in traditional manual loading processes. Industry safety data from organizations like OSHA (Occupational Safety and Health Administration)2 frequently highlights manual material handling as a leading cause of musculoskeletal disorders (MSDs)3 in manufacturing environments. These injuries not only cause suffering for the employees but also result in lost workdays, increased insurance premiums, and reduced morale for businesses.

Automated front-feeding systems dramatically mitigate these risks. By taking over the heavy lifting and precise positioning of tubes, these systems reduce the physical demands on operators to near zero in terms of material handling. This leads to a safer working environment and significantly lowers the likelihood of strain-related injuries. Ahmed, for example, employs over 100 staff, and ensuring their safety and well-being is paramount for maintaining a stable and productive workforce. Introducing machines with advanced ergonomic features like front-feeding can be a strong selling point for attracting and retaining skilled labor, as it demonstrates a company's commitment to modern, safe working practices.

Improved ergonomics also contributes to higher operator satisfaction and focus. When operators are not constantly fatigued by physical exertion, they can better concentrate on the critical aspects of the laser cutting process, such as monitoring cut quality, managing job queues, and performing routine maintenance. This heightened alertness can lead to fewer operational errors and a greater sense of ownership and engagement with their work. In my experience visiting numerous fabrication shops, the difference in the working atmosphere in plants with well-designed automated handling systems is palpable; operators are generally less stressed and more engaged.

Seamless Integration and Continuous Operation

The true power of front-feeding innovation is realized when it's viewed as part of an integrated, continuous production system. Modern front-feeding mechanisms are often designed to be compatible with upstream automation, such as automatic tube bundle loaders or storage and retrieval systems (AS/RS). This allows for a fully automated flow of material from raw stock storage directly into the laser cutting machine, enabling extended periods of unattended or minimally supervised operation. For businesses aiming for 'lights-out' manufacturing capabilities4 or simply seeking to maximize machine utilization across multiple shifts, this level of integration is invaluable.

Consider the reduction in downtime between jobs or tube changes. With manual loading, the machine often sits idle while the operator fetches, positions, and secures the next tube. An automated front-feeder, especially when coupled with a buffer or magazine, can have the next tube ready to load almost instantaneously after the previous one is ejected. This minimizes non-productive time and keeps the laser head working for a greater percentage of the available hours. This continuous operation is particularly beneficial for high-volume production environments like those supplying parts for the automotive or furniture industries, where every second of uptime counts towards profitability.

MZBNL's front-feeding system, for example, is engineered for robust, reliable performance, ensuring that it can keep pace with our high-speed cutting heads without becoming a bottleneck. The system's intelligence also allows for smooth handling of different tube sizes and profiles with minimal changeover time, further enhancing its contribution to continuous operation. For a client like Ahmed, who is actively looking to expand his business and upgrade production efficiency, the prospect of a seamlessly integrated system that runs consistently with minimal manual intervention is highly attractive. It allows for better production planning, more reliable delivery schedules, and ultimately, a stronger competitive position in the market.

| Aspect | Traditional Manual Loading (Side/Rear) | MZBNL Automated Front-Feeding |

|---|---|---|

| Labor Intensity | High, physically demanding | Low, significantly reduced (~40%) |

| Feeding Efficiency | Lower, operator-dependent | Higher, consistent, automated (~40%+) |

| Operator Fatigue | Significant, potential for MSDs | Minimal, improved ergonomics |

| Cycle Time Consistency | Variable, prone to delays | Highly consistent, reduced idle time |

| Safety Risks | Higher (lifting, strains, impacts) | Lower, automated handling |

| Integration Potential | Limited | High (e.g., with bundle loaders) |

| Machine Utilization | Lower due to manual intervention | Higher due to continuous operation |

Front-feeding boosts efficiency by 40%True

The article states front-feeding systems increase material handling efficiency by approximately 40% compared to manual methods.

Manual loading is safer than automatedFalse

The text explains automated front-feeding significantly reduces safety risks compared to manual loading which causes strain injuries.

Front-feeding improves cut accuracyTrue

Automated feeding provides better material alignment leading to more accurate initial cuts.

Operators must lift heavy tubes manuallyFalse

With front-feeding systems, automated mechanisms handle all heavy lifting, eliminating manual exertion.

Automation enables lights-out manufacturingTrue

Front-feeding systems can integrate with upstream automation for extended unattended operation.

Manual loading provides better consistencyFalse

Automated systems provide far more consistent feeding speeds and reduce idle time between tubes.

Zero-Waste Tail Material Innovation: Sustainability Meets Profitability

Every fabricator knows the frustration of seeing valuable material end up as unusable scrap. The tail end of a tube, often discarded in conventional cutting processes, represents a direct loss of material and profit. What if you could reclaim that material, ensuring almost every inch of the tube is put to productive use?

Zero-waste tail material innovation in laser tube cutting employs redesigned cutting logic, frequently calculating from the rear chuck as the origin, to ensure that no unusable tail material is generated as long as the remaining tube section is shorter than the product length being cut.

This intelligent approach to material utilization is not just an environmental win; it's a significant economic advantage. For Ahmed's business, which fabricates components for display racks and other high-volume items where material costs are a critical factor, minimizing tail waste directly translates to improved profit margins on every project. At MZBNL, we've engineered our systems to make this level of material efficiency a practical reality, maximizing your resource utilization and boosting cutting efficiency.

The issue of tail material waste has long been an accepted, albeit undesirable, byproduct of traditional laser tube cutting processes. Conventional systems typically begin their cutting operations from the tube head (the end first fed into the machine), and as the tube is processed, a certain length at the tail end becomes too short to be securely held by both front and rear chucks for further cutting, or it's simply the leftover portion after all programmed parts are cut. This remnant, often referred to as the "tail" or "rest piece," becomes scrap. While seemingly small on a per-tube basis, this waste accumulates significantly over time, impacting material costs and environmental sustainability. The innovation in zero-waste (or minimal-waste) tail material cutting addresses this problem head-on through smarter processing logic and sometimes through modified chuck designs, aiming to convert what was previously scrap into usable product.

The Smart Logic Behind Waste Reduction

The core of zero-waste tail material innovation lies in a fundamental shift in how the cutting process is planned and executed. Traditional systems often work with a fixed reference point at the front chuck or the tube's leading edge. In contrast, MZBNL’s zero-tail design redefines the cutting logic by calculating from the rear chuck as the origin or by employing advanced nesting algorithms5 that consider the entire usable length of the tube more effectively. This allows the system to intelligently plan cuts in such a way that the final piece(s) can be processed even when the remaining material is relatively short, as long as it can be securely gripped and is equal to or longer than the required part length.

Specifically, our system can eliminate leftover tail material if the remaining section of the tube, after the last full part is cut, is smaller than the length of the products being cut from that tube. For example, if you are cutting 150mm long parts from a 6000mm tube, and after cutting multiple parts, 100mm of material remains, this 100mm piece would typically be scrap. However, with optimized logic, the machine ensures that if parts can be nested to use up virtually the entire tube, or if the final part can be safely cut from what would have been the tail, no unusable tail is left. This often involves the rear chuck being able to advance very close to the cutting head and maintain a secure grip on a minimal length of material.

Ahmed, who fabricates a variety of components, often deals with expensive materials for some of his architectural and automotive projects. For him, saving even a few centimeters of material per tube, when multiplied by hundreds or thousands of tubes processed annually, can result in substantial cost reductions. Imagine a scenario where a standard 6-meter tube typically yields a 150mm (0.15m) tail. This is 2.5% waste per tube. If his material cost is, say, $50 per tube, that's $1.25 wasted per tube. Over 1000 tubes, this amounts to $1250 in direct material loss, not to mention disposal costs. The smart logic of a zero-tail system aims to recover this value.

Economic and Environmental Advantages

The economic benefits of minimizing or eliminating tail material waste are direct and easily quantifiable. The most obvious saving comes from increased material yield; more parts can be produced from the same quantity of raw material. This directly reduces the cost per part. If a company processes, for example, 10,000 six-meter tubes annually and can save an average of 100mm of material per tube by eliminating the unusable tail, that equates to 1,000 meters of material saved per year. Depending on the cost of the material – which can range from relatively inexpensive carbon steel to costly stainless steel or aluminum alloys – these savings can run into thousands or even tens of thousands of dollars annually.

Beyond direct material cost savings, there are also reductions in scrap handling and disposal costs. Less scrap means less labor required to collect, sort, and transport it, and potentially lower fees paid to recycling or waste management services. This contributes to a leaner and more efficient operation. From an environmental perspective, maximizing material utilization is a cornerstone of sustainable manufacturing6. Reducing scrap means less demand for virgin raw materials, which in turn lessens the environmental impact associated with material extraction, processing, and transportation. This improved resource efficiency can also enhance a company's green credentials, which is increasingly important for attracting environmentally conscious customers and meeting corporate social responsibility (CSR) goals7.

For Ahmed, whose business is expanding and likely facing increased scrutiny on environmental practices in the UAE market, adopting technology that promotes sustainability can be a competitive differentiator. The ability to demonstrate efficient material use not only improves his bottom line but also aligns with growing global trends towards circular economy principles8. Furthermore, the reduced need to inventory and manage scrap simplifies workshop logistics and frees up valuable floor space.

Boosting Overall Cutting Efficiency and Process Streamlining

While the primary focus of zero-waste tail material innovation is on material savings, it also contributes to overall cutting efficiency and a more streamlined production process. When the machine's logic is optimized to use as much of the tube as possible, it often involves more sophisticated nesting of parts or more continuous cutting sequences. This can reduce the number of loading cycles for a given production volume if more parts are extracted per tube. Although the cutting of the very last piece might require specific handling by the chucks, the overall time spent per usable part can decrease due to higher material yield.

The reduction in scrap material also simplifies downstream processes. There's less non-value-added material to handle, sort, and account for. This can lead to a cleaner, more organized workshop environment, which itself contributes to efficiency and safety. Operators can spend less time managing waste and more time focusing on value-added activities like quality control, machine monitoring, and preparing for the next job. This streamlining effect, though perhaps less direct than the material cost savings, contributes to a smoother, faster overall workflow.

MZBNL's zero-tail design is engineered not just to save material but to do so without compromising the speed or quality of the cutting process for the main body of the tube. The intelligence built into the control system ensures that the final cuts are made with the same precision as all preceding cuts. For a business like Ahmed's, aiming for high efficiency in producing railings, shelving, and auto parts, this means that the benefits of material saving do not come at the expense of production speed or part quality. It's an integrated solution where the advanced chucking capabilities9 and smart cutting algorithms work in concert to maximize both material yield and operational throughput, leading to a more competitive and profitable fabrication process.

| Feature | Traditional Laser Tube Cutting | MZBNL Zero-Waste Tail Cutting |

|---|---|---|

| Cutting Origin Logic | Typically from tube head / front chuck | Calculated from rear chuck / optimized |

| Typical Tail Material | Common, often 50mm-200mm+ unusable | Eliminated or significantly minimized |

| Material Utilization | Lower due to tail scrap | Maximized, near 100% for usable length |

| Cost per Part (Material) | Higher | Lower due to less waste |

| Scrap Handling | More significant, higher costs | Minimal, reduced labor and disposal |

| Environmental Impact | Higher raw material consumption | Lower, supports sustainability goals |

| Overall Efficiency | Potentially reduced by waste handling | Enhanced by streamlined material flow |

Zero-waste cuts from tube tailTrue

Advanced systems can utilize tube sections shorter than product length by calculating cuts from the rear chuck.

Tail waste is unavoidableFalse

With optimized cutting logic and chuck designs, tail material waste can be completely eliminated.

Rear chuck enables zero-wasteTrue

Using the rear chuck as origin point allows cutting final parts from what would be tail material.

Traditional cutting is more efficientFalse

Zero-waste systems improve overall efficiency by reducing material handling and increasing yield.

Material savings boost profitsTrue

Eliminating 2.5% waste per tube can save thousands annually in material costs alone.

Scrap handling costs are negligibleFalse

Scrap collection, sorting and disposal represent significant hidden operational costs.

The Synergistic Power: How These Innovations Converge

While each innovation – No-CAD systems, front-feeding, and zero-waste tail material – offers substantial benefits on its own, their true transformative power is unleashed when they converge. It's like assembling a high-performance engine; each component is crucial, but their synchronized operation is what delivers exceptional results. Many businesses might focus on one aspect, but overlook the amplified advantages of a holistic solution.

The synergistic power of these laser tube cutting innovations lies in their collective ability to create a highly streamlined, efficient, cost-effective, and user-friendly manufacturing process, addressing multiple operational pain points simultaneously from design input through to material output.

This convergence means that the speed gained from No-CAD isn't lost to slow manual loading, and the material saved by zero-waste design isn't offset by inefficient machine uptime. For Ahmed, considering an upgrade to his facility, understanding this synergy is key to achieving the comprehensive automation and efficiency he seeks. It’s about creating a virtuous cycle where each innovation reinforces the benefits of the others, leading to a far greater impact than the sum of their individual parts. This holistic view is central to how we at MZBNL approach the development and integration of our technologies.

In the competitive landscape of modern metal fabrication, incremental improvements are no longer sufficient to guarantee a leading edge. True advancement comes from systemic enhancements where multiple innovations work in concert. The latest breakthroughs in laser tube cutting—No-CAD operation, automated front-feeding, and zero-waste tail material solutions—are prime examples of such synergistic technologies. While deploying any one of these can yield noticeable benefits, it is their combined implementation that offers a paradigm shift in operational capability. This convergence creates a production ecosystem that is not only faster and more cost-effective but also more agile, sustainable, and less dependent on highly specialized, scarce labor. As we guide clients like Ahmed through their technological upgrade journey, we emphasize this holistic perspective, demonstrating how these innovations build upon each other to create a truly optimized manufacturing environment.

Synergies in Action: A More Agile and Profitable Workshop

Imagine a typical job arriving in Ahmed's workshop. With a No-CAD system, if it's a standard profile for an architectural railing, his operator can quickly input parameters and start the job in minutes, bypassing the CAD design queue. This immediate responsiveness is then complemented by the automated front-feeding system, which ensures that tubes are loaded efficiently and continuously, maintaining a high throughput without operator fatigue, especially crucial for a batch of automotive components. As these parts are cut, the zero-waste tail material logic ensures that every possible centimeter of expensive raw material is utilized, directly impacting the profitability of both the railing and automotive part orders. The speed from No-CAD is maintained by efficient feeding, and the profit margin is protected by minimal waste.

This interplay creates a highly agile workshop environment. Quick changeovers enabled by No-CAD, coupled with consistent material flow from front-feeding, allow businesses to profitably handle smaller batch sizes and a greater variety of jobs without significant downtime. The overall equipment effectiveness (OEE).)10 sees a substantial boost because non-productive time (setup, loading, material waste) is drastically reduced. This means the laser cutter, a significant capital investment, spends more of its operational hours actually cutting parts and generating revenue.

Furthermore, the reliability and predictability offered by this integrated system enhance production planning and scheduling. Ahmed could provide his clients with more accurate lead times and confidently accept urgent orders, knowing his modernized laser tube cutting cell can deliver. The reduction in errors – from simplified programming with No-CAD to consistent loading with front-feeding – also contributes to a smoother workflow with less rework and fewer quality-related delays, further solidifying the workshop's reputation for reliability and quality. This holistic efficiency doesn't just make the workshop faster; it makes it smarter and more profitable.

Meeting Modern Manufacturing Demands: Customization and Speed

Today's manufacturing environment is characterized by increasing customer demand for customization, shorter product lifecycles, and the expectation of rapid delivery – trends often encapsulated by terms like mass customization11 or just-in-time production12. The convergence of No-CAD, front-feeding, and zero-waste innovations directly empowers fabricators to meet these demanding requirements effectively. The No-CAD system provides the flexibility to quickly program or adjust designs for custom orders or small variations of standard parts without extensive reprogramming, making low-volume, high-mix production economically viable. This capability is essential for businesses like Ahmed’s that cater to diverse sectors such as architectural decoration (often highly customized) and automotive parts (requiring precision and sometimes frequent design updates).

Automated front-feeding supports this agility by ensuring that material handling can keep pace with rapid job changes and continuous production needs. Whether it's quickly loading a different tube profile for a custom job or maintaining high-speed feeding for a long run of standardized components, the automation removes a significant bottleneck and source of operator variability. This consistent material flow is critical for just-in-time environments where delays can have cascading effects on downstream processes or delivery commitments.

The zero-waste aspect further enhances competitiveness by optimizing material costs, which is crucial when dealing with potentially expensive materials for customized products or when bidding on price-sensitive high-volume contracts. By minimizing scrap, businesses can offer more competitive pricing or achieve better margins. At MZBNL, our approach is to provide these core innovations as part of tailored solutions that address the specific needs of our clients, whether they are small workshops or large industrial enterprises. This allows them to respond with unprecedented speed and efficiency to shifting market demands, turning customization from a challenge into a competitive advantage.

The Competitive Edge: Staying Ahead with Advanced Technology

Early adoption of these integrated technological advancements provides a significant and sustainable competitive edge. In a market where efficiency, speed, quality, and cost are paramount, businesses equipped with holistically optimized laser tube cutting systems are better positioned to outperform competitors still relying on older, more fragmented technologies. This edge manifests in several ways: lower production costs allow for more aggressive pricing or higher profit margins; faster turnaround times attract clients with urgent needs; and higher quality output builds a stronger brand reputation.

Furthermore, investing in modern, ergonomic, and easy-to-use technology like No-CAD systems and automated front-feeders can be a powerful tool for attracting and retaining skilled labor. In an industry facing a shortage of experienced operators13, offering a clean, safe, and technologically advanced working environment makes a company a more desirable employer. Operators are generally more satisfied and productive when working with tools that reduce physical strain and empower them to achieve better results with less frustration. This was a key consideration for Ahmed, who recognized that high operator turnover was a hidden cost and a barrier to consistent quality and efficiency.

Ultimately, this technological superiority positions businesses for future growth and diversification. A highly efficient and agile production capability allows companies to confidently explore new markets, take on more complex projects, or even consider new business models, such as Ahmed's interest in becoming a regional distributor if the technology proves reliable and well-supported. The ability to consistently deliver high-quality products, on time and at a competitive cost, builds the foundation for long-term success and market leadership. This is why at MZBNL, we don't just sell machines; we partner with our clients to implement solutions that drive their competitive advantage forward.

| Innovation Synergy Point | Benefit of No-CAD | Benefit of Front-Feeding | Benefit of Zero-Waste | Combined Synergistic Outcome |

|---|---|---|---|---|

| Job Setup & Start | Rapid programming for standards | - | - | Drastically reduced time from order to first cut |

| Continuous Production | Reduces design iteration delays | Ensures consistent material supply | Optimizes parts per tube | Higher overall throughput and machine utilization |

| Cost Efficiency | Lowers training & design labor costs | Reduces manual handling labor costs | Minimizes direct material costs | Significantly lower total cost of ownership & operation |

| Operator Experience | Simplifies operation, less stress | Improves ergonomics, reduces fatigue | Less scrap handling | Higher operator satisfaction, safety, and productivity |

| Agility & Customization | Easy adaptation for varied designs | Quick material changeover support | Cost-effective for varied materials | Enhanced ability to serve diverse, custom orders profitably |

Synergy amplifies innovation benefitsTrue

When No-CAD, front-feeding and zero-waste systems work together, they create greater efficiency than their individual benefits combined.

Zero-waste eliminates all material costsFalse

While zero-waste systems minimize material costs, they don't completely eliminate them as some minimal waste is often unavoidable.

Beyond the Machine: The Human Element in Technological Advancement

While we've explored incredible machine innovations, it's crucial to remember the people behind them and those who operate them. Investing in new technology is only part of the equation; empowering your team to leverage it effectively is where the real magic happens. Ignoring the human element can lead to underutilized potential and frustration.

The human element in technological advancement for laser tube cutting involves ensuring that operators are adequately trained, comfortable with new systems, and that the technology itself is designed with user-centric principles to enhance, not replace, human skill and oversight.

This means focusing on intuitive interfaces, comprehensive training programs like MZBNL's one-day on-site training for No-CAD systems, and reliable post-sales support. For Ahmed, knowing that his team can quickly master new equipment and receive ongoing assistance is as important as the machine's technical specifications. It’s about building a partnership where technology serves people, enabling them to perform their jobs more effectively, safely, and with greater satisfaction, ultimately driving the business forward.

In our enthusiasm for technological breakthroughs like No-CAD systems, automated feeding, and zero-waste solutions, it's easy to focus solely on the hardware and software. However, my 25 years of experience at MZBNL have consistently shown me that the success of any advanced manufacturing technology is deeply intertwined with the human element. The most sophisticated machine can underperform if operators are not confident, properly trained, or if the technology is not designed with their needs and capabilities in mind. Therefore, a holistic approach to innovation must extend beyond the machine itself to encompass user experience, training, support, and the evolving role of the operator in an increasingly automated environment. For clients like Ahmed, who are not just buying a machine but an operational upgrade, this human-centric aspect is paramount for realizing the full return on their investment.

Empowering Operators: Training and User-Centric Design

The transition to new technology, however beneficial, can be met with apprehension if not managed correctly. Effective training is the bridge that connects human potential with technological capability. At MZBNL, we recognized early on that the complexity of traditional CAD/CAM systems14 was a major barrier. Our No-CAD system was therefore co-developed with a focus on an intuitive, user-friendly interface, specifically designed to shorten the learning curve. The goal was to empower operators, not overwhelm them. This philosophy led to our signature one-day on-site training program, a stark contrast to the weeks of off-site training often required for older systems. This rapid upskilling minimizes disruption to production and instills confidence in the operators from day one.

User-centric design goes beyond just the interface; it considers the entire operator interaction with the machine. For instance, our front-feeding innovation wasn't just about speed; it was also about reducing the physical strain on operators, making their workday safer and more comfortable. When operators feel that the technology is working for them, improving their work environment and enabling them to be more productive with less effort, their engagement and job satisfaction increase significantly. This positive human-machine interaction is critical for consistent quality and optimal machine performance. I've seen Ahmed's focus on his team's capabilities; providing them with tools that are powerful yet easy to master is key to his vision of an automated, efficient workshop.

Moreover, empowering operators means providing them with clear information and diagnostic tools. Modern systems should offer real-time feedback on the cutting process, material status, and machine health. This transparency allows operators to make informed decisions, troubleshoot minor issues proactively, and contribute to the continuous improvement of the production process. When operators understand the 'why' behind the technology and feel a sense of control, they transform from mere button-pushers into valuable contributors to the manufacturing ecosystem.

The Evolving Role of the Manufacturing Workforce

As automation and intelligent systems become more prevalent in laser tube cutting, the role of the manufacturing workforce is undeniably evolving. Innovations like No-CAD systems reduce the need for constant, specialized CAD input for routine tasks, and automated feeding lessens the manual labor involved in material handling. However, this does not diminish the importance of human workers; rather, it shifts their responsibilities towards higher-value activities. Operators of advanced laser cutting systems are increasingly becoming supervisors of sophisticated automated cells, responsible for overseeing production, managing job flows, ensuring quality control, performing preventive maintenance15, and optimizing system performance.

This evolution requires a new set of skills, including a greater understanding of system-level operations, basic troubleshooting, and data interpretation. Forward-thinking companies, and indeed technology providers like MZBNL, must support this transition by offering not just initial training but also ongoing learning opportunities. For Ahmed, who is considering becoming a regional distributor, understanding this evolving skill set will be crucial for advising his future customers and ensuring they can successfully integrate advanced technology into their operations. The workforce of the future in fabrication will be less about manual dexterity and more about technical acumen and problem-solving abilities.

Furthermore, the 'human touch' remains indispensable in areas like custom design verification, complex problem-solving that goes beyond the machine's programmed capabilities, and adaptive responses to unforeseen production challenges. Technology can automate repetitive tasks and execute precise instructions, but human ingenuity, critical thinking, and experience are still vital for navigating the complexities of real-world manufacturing. The goal of innovation, therefore, should be to create a symbiotic relationship where technology augments human capabilities16, allowing people to focus on tasks that require uniquely human skills.

Building a Culture of Continuous Improvement and Support

The successful integration and sustained performance of advanced laser tube cutting technology depend heavily on establishing a culture of continuous improvement17 and having access to robust post-sales support. Technology is not a one-time fix; it's an ongoing journey. Operators and maintenance staff should be encouraged to provide feedback on system performance, suggest improvements to workflows, and share best practices. This collaborative approach, where insights from the shop floor are valued and acted upon, can lead to significant incremental gains in efficiency and productivity over time.

At MZBNL, we view our relationship with clients like Ahmed as a long-term partnership. This means providing comprehensive after-sales service, readily available spare parts, and remote diagnostic capabilities to minimize downtime and resolve issues quickly. The availability of local agents or distributor presence, a key point for Ahmed, is crucial in providing timely, hands-on support when needed. This assurance allows businesses to invest in new technology with confidence, knowing that they will not be left unsupported should challenges arise.

Ultimately, the human element extends to the relationship between the technology provider and the user. Trust, reliability, and a shared commitment to success are fundamental. When a company like MZBNL invests in innovations that are not only technologically advanced but also user-centric and well-supported, it demonstrates an understanding that the true value of technology is realized through the people who use it every day. This focus on human factors ensures that businesses can fully leverage the power of innovations in laser tube cutting to achieve their strategic objectives, from enhancing efficiency and reducing costs to fostering a skilled, engaged, and future-ready workforce.

| Human Element Focus Area | MZBNL's Approach / Innovation Link | Benefit for Client (e.g., Ahmed) | Long-Term Impact |

|---|---|---|---|

| Operator Training | 1-day on-site training for No-CAD, intuitive interfaces | Rapid skill acquisition, reduced downtime for training | Faster ROI, increased operator confidence & productivity |

| User-Centric Design | Ergonomic front-feeding, simplified No-CAD controls | Reduced physical strain, lower error rates, operator satisfaction | Improved safety, higher morale, better staff retention |

| Evolving Skill Sets | Focus on system oversight, QC, proactive maintenance | Operators become process managers, adding more value | More adaptable and skilled workforce, ready for future tech |

| Post-Sales Support | Global distributor networks, remote diagnostics, spare parts | Minimized downtime, quick issue resolution, peace of mind | Sustained operational efficiency, strong supplier partnership |

| Continuous Improvement | Encouraging feedback, collaborative problem-solving | Optimized workflows, enhanced system performance over time | Culture of innovation, sustained competitive advantage |

Training is key to tech adoptionTrue

The article emphasizes that comprehensive training programs like MZBNL's one-day on-site training are crucial for successful technology implementation.

Automation eliminates human jobsFalse

The text explains that automation shifts human roles to higher-value activities rather than eliminating jobs, requiring new skills like system oversight and quality control.

Conclusion

These latest innovations—No-CAD systems, front-feeding, and zero-waste tail material solutions—are fundamentally reshaping laser tube cutting. They offer businesses like yours unprecedented efficiency, ease of use, substantial cost savings, and a clear path towards more sustainable and profitable manufacturing operations. Embrace them to lead.

-

Learn about manufacturing's skilled labor shortage challenge and its industry impact. ↩

-

Learn OSHA's role and safety guidelines for manual material handling in manufacturing environments. ↩

-

Understand common workplace MSDs, their causes, and prevention, especially in manufacturing. ↩

-

Explore the concept of fully automated 'lights-out' manufacturing and its operational advantages. ↩

-

Learn how software optimizes material use by arranging parts efficiently on raw material. ↩

-

Explore practices that minimize environmental impact and enhance resource efficiency in production. ↩

-

Understand how businesses integrate social and environmental concerns into their operations and strategy. ↩

-

Discover how to keep resources in use longer, extract maximum value, and recover products. ↩

-

See how precise material gripping enables cutting closer to tube ends, reducing waste. ↩

-

Learn how OEE measures manufacturing productivity and helps identify improvement areas. ↩

-

Explore how businesses offer personalized products at scale to meet diverse customer needs. ↩

-

Understand JIT principles for reducing waste and improving efficiency in production flows. ↩

-

Discover challenges of operator shortages and how technology can help address them. ↩

-

Understand the typical complexities of older CAD/CAM software that new systems aim to solve. ↩

-

Discover how preventive maintenance for machinery reduces downtime and extends equipment life. ↩

-

Explore how automation and human skills can combine for enhanced productivity and innovation. ↩

-

Learn methods to establish and benefit from a continuous improvement culture on the factory floor. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.