How to Laser Cut a Tube Step-by-Step?

Cutting tubes precisely can be a real headache with traditional methods, often leading to wasted time and materials. This frustration mounts when inaccurate cuts derail production schedules and inflate costs, a common pain point for fabricators. Laser tube cutting offers a precise, efficient, and versatile solution, revolutionizing how we approach tube fabrication and achieve superior results.

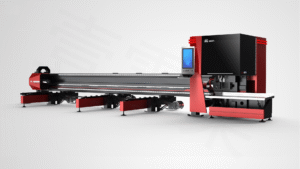

Laser tube cutting is a multi-stage process that begins with digital design creation or import, followed by meticulous machine setup including parameter selection for the specific material and tube profile. The tube is then loaded and securely clamped, after which the automated cutting sequence, guided by a focused laser beam, executes precise cuts. Finally, the finished part is unloaded and inspected.

Understanding the step-by-step process of laser tube cutting is crucial for anyone looking to leverage this advanced technology effectively. It’s far more than just pushing a button; it’s about mastering a system that can significantly enhance your fabrication capabilities and output quality. As someone who has spent 25 years in the metal fabrication industry with MZBNL, I've witnessed firsthand the transformative impact of this technology. We'll delve into each stage, from material selection to final optimization and maintenance, ensuring you gain a comprehensive grasp of the entire workflow. Let's explore how you can achieve perfect cuts, every single time.

Beyond the basic operational steps, true mastery in laser tube cutting lies in understanding the nuances that differentiate a good cut from an exceptional one. This involves a deeper appreciation of material compatibility, the intricate physics of laser-material interaction, and the significant economic impact of process optimization. For instance, at MZBNL, we've guided numerous clients, like Ahmed Al-Farsi from the UAE, who initially faced challenges with the complexities and inefficiencies of older tube processing systems. His journey towards adopting our user-friendly No-CAD system vividly illustrates the industry's broader shift towards more intuitive and efficient solutions. We'll explore how innovations such as front-feeding mechanisms and zero-waste tail material designs—pioneered by forward-thinking companies like ours—directly address common industry pain points and elevate overall production standards. This isn't merely about cutting tubes; it's about strategically enhancing your entire workflow to achieve maximum profitability, efficiency, and a competitive edge. Industry reports consistently demonstrate that businesses adopting advanced laser cutting technologies realize a significant return on investment1 through reduced material waste, lower labor costs, and increased throughput.

What materials and tubes can be processed with laser cutting?

Are you uncertain if your specific tube materials and profiles are suitable for laser cutting, leading to hesitation in adopting this powerful technology? Using an inappropriate cutting process for certain materials can result in poor cut quality, damage to expensive equipment, or even critical safety hazards, ultimately wasting valuable resources and time. Fortunately, laser cutting is an incredibly versatile technology, capable of precisely and easily processing a wide array of materials and diverse tube profiles.

Laser cutting can effectively process a diverse range of materials including carbon steel, stainless steel, aluminum alloys, copper, and brass. It accommodates various tube forms such as round, square, rectangular, and oval, as well as more complex profiles like L-beams and custom extrusions, making it highly adaptable for numerous manufacturing applications.

Knowing precisely which materials and tube shapes are compatible with laser cutting technology is the foundational step before you even contemplate initiating a cut. It’s not just about whether the laser can physically cut the material, but how well it can cut it, and what specific considerations, such as assist gas type or power settings, are necessary for each distinct material and profile. My extensive experience at MZBNL has taught me that a deep understanding of material properties is absolutely key to achieving optimal cutting results and, crucially, avoiding costly mistakes or rework. For instance, a client in the automotive parts sector, much like Ahmed who supplies various components for vehicles, needed to process high-strength steel tubes featuring complex hole patterns. Their previous traditional methods were slow, labor-intensive, and prone to inaccuracies. Switching to laser cutting, specifically with an MZBNL system optimized for their challenging material, dramatically improved their production speed and part consistency. Let's delve deeper into the specifics of these materials and tube types to provide a clearer picture.

Understanding Material Properties and Laser Interaction

Different metals exhibit varied reactions when exposed to laser energy, and understanding these interactions is fundamental to successful laser cutting. Key material properties influencing this process include reflectivity, thermal conductivity, and melting point. For example, highly reflective materials such as aluminum and copper initially reflect a significant portion of the laser beam. This necessitates higher power densities or specific laser wavelengths to achieve efficient absorption and melting. Modern fiber lasers2, which MZBNL specializes in, are generally better suited for these reflective materials compared to older CO2 laser technology due to their shorter wavelength, which is more readily absorbed.

Carbon steel is perhaps the most frequently laser-cut material in tube form, primarily due to its excellent absorption of laser energy across various wavelengths and its relatively low material cost. When cutting mild steel, oxygen is often used as an assist gas. This is not just to blow away molten material, but because oxygen creates an exothermic reaction with the hot steel, generating additional heat that aids the cutting process, allowing for faster speeds on thicker sections. However, this exothermic reaction can lead to a slightly larger heat-affected zone (HAZ) and an oxidized cut edge, which might require post-processing depending on the application. For Ahmed's architectural metalwork projects, achieving a pristine, non-oxidized cut on stainless steel tubes is paramount for aesthetic and corrosion resistance reasons. This typically involves using high-pressure nitrogen as an assist gas to prevent oxidation, resulting in a shiny, burr-free edge that often requires no further finishing.

Stainless steel, while also a ferrous alloy, behaves differently under the laser due to its chromium content, which provides corrosion resistance. As mentioned, nitrogen is the preferred assist gas to prevent oxidation and achieve a clean, bright, and smooth cut edge. The chromium oxide layer that can form with other gases is very hard and difficult to remove. While slightly more challenging to cut than mild steel due to its higher alloy content, fiber lasers have made significant strides in processing stainless steel efficiently and with high quality. Data from industry studies, such as those published by the Fabricators & Manufacturers Association (FMA), consistently show that fiber lasers offer superior cutting speeds and edge quality for stainless steel tubes compared to traditional CO2 lasers, especially in thinner to medium gauges.

Exploring Diverse Tube Profiles and Their Challenges

Beyond simple round, square, and rectangular tubes, laser cutting technology truly excels when handling complex and irregular profiles. This capability includes oval tubes, D-shaped tubes, L-profiles (angle iron), U-channels, and even custom-designed extrusions specific to a client's product. The ability to precisely cut intricate patterns, mitered ends, copes for tube-to-tube connections, and complex hole geometries on these varied profiles opens up vast design possibilities. This versatility is invaluable for industries like high-end furniture manufacturing (a key client type for MZBNL who often use unique tube shapes) and intricate architectural decoration, where aesthetic appeal and precise fit-up are critical.

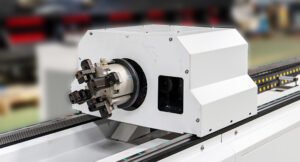

Processing these diverse tube profiles effectively often necessitates advanced chucking systems and sophisticated control software. The machine must maintain accuracy as the tube rotates and translates beneath the laser head, especially when the surface is not uniformly cylindrical. For instance, cutting a consistent bevel on an oval tube requires the laser head to dynamically adjust its angle and maintain a precise focal point relative to the constantly changing surface curvature. Our BNL machines, equipped with intelligent multi-axis clamping systems and intuitive No-CAD programming interfaces, are designed to simplify these complex operations, making them accessible even to operators without extensive CAD/CAM expertise. Ahmed, for his display rack and shelf production, frequently needs to cut various slotted patterns and connection points into rectangular and custom-profiled tubes, a task that our machines handle seamlessly and efficiently.

Wall thickness is another significant factor that influences the laser cutting process for tubes. Thicker-walled tubes naturally require more laser power and consequently slower cutting speeds to ensure complete penetration and a quality cut. Piercing thicker materials can also be a challenge, often demanding specialized piercing routines (e.g., multi-stage piercing, ramp piercing) to create the initial hole without excessive dross, spatter, or damage to the material or optics. The choice of assist gas type, its pressure, and the nozzle diameter must also be carefully calibrated based on both the material type and its wall thickness. According to a 2023 market report by Allied Market Research3 on the global laser cutting machine market, the demand for systems capable of reliably and efficiently handling thicker materials and complex profiles continues to grow, particularly in sectors like construction and heavy equipment manufacturing.

Industry-Specific Material Applications and Case Studies

In the demanding automotive industry, laser tube cutting is extensively used for manufacturing components from high-strength steel (HSS) and advanced high-strength steel (AHSS) tubes. These materials are used for chassis components, exhaust systems, seat frames, and roll cages, where both strength and weight reduction are critical. The precision of laser cutting allows for complex joints and features that enhance vehicle safety, performance, and fuel efficiency. One of our clients, a Tier 1 supplier producing motorcycle frames similar in scope to Ahmed's vehicle parts supply, reduced their part cycle time for complex coped tubes by over 60% after implementing a BNL laser tube cutter. This improvement was primarily due to its ability to handle varied tube diameters, complex end-cuts, and the elimination of manual reprogramming for different parts, all facilitated by our No-CAD system.

For furniture and sanitary ware manufacturers, aesthetic quality and design flexibility are paramount. Laser cutting enables the creation of intricate designs and clean, sharp edges on materials like stainless steel, aluminum, and brass tubes, which are often used in modern designer furniture and high-end bathroom fixtures. The inherently clean edges and minimal heat-affected zone produced by optimized laser cutting significantly reduce or even eliminate the need for secondary finishing operations such as grinding or deburring, leading to considerable savings in time and labor costs. A client specializing in bespoke retail display racks, who switched from manual cutting and drilling to our laser solutions, reported a 40% reduction in their finishing costs and a 50% increase in production throughput for complex designs.

Architectural decoration companies and fence/railing installation firms heavily rely on the laser cutter's ability to cut custom patterns, intricate designs, and precise angles on a variety of materials, including mild steel, stainless steel, and aluminum. Whether it's creating ornate filigree designs on steel gates, precisely angled joints for complex railing systems, or custom-cut components for building facades, laser cutting provides the necessary flexibility and accuracy. Ahmed Al-Farsi, with his business focus on architectural metalwork in the UAE, frequently leverages this capability for producing unique, high-value decorative elements and structural components. This allows him to offer differentiated products that command a premium in a competitive market, meeting the growing demand for customized architectural solutions.

| Material | Typical Assist Gas | Common Tube Applications | Key Laser Cutting Considerations |

|---|---|---|---|

| Carbon Steel | Oxygen/Nitrogen | Structural frames, machinery parts, general fabrication | HAZ with O2, dross formation, cutting speed vs. quality |

| Stainless Steel | Nitrogen | Food equipment, medical devices, architectural, exhaust | Oxidation prevention, cut edge brightness, cost of N2 |

| Aluminum Alloys | Nitrogen | Automotive components, aerospace, display structures | High reflectivity, dross adherence, thermal conductivity |

| Copper & Brass | Nitrogen/Oxygen | Electrical connectors, plumbing fixtures, decorative | Very high reflectivity, specific laser sources preferred |

| High-Strength Steel | Nitrogen/Oxygen | Automotive safety parts, structural reinforcements | Material hardness, spring-back, maintaining properties |

Laser cutting works on various tube shapesTrue

Laser cutting can process round, square, rectangular, oval tubes and even complex custom profiles.

Oxygen is best for stainless steelFalse

Nitrogen is preferred for stainless steel to prevent oxidation and achieve clean cuts.

How to prepare for laser tube cutting: equipment and safety measures?

Are you concerned that overlooking crucial preparation steps for your laser tube cutting operations could lead to inefficient processes or, worse, serious safety incidents? Improper setup can indeed damage expensive equipment, result in substandard parts, or endanger operators, causing costly downtime, material waste, and potential liabilities. Thorough preparation, which encompasses detailed equipment checks and strict adherence to established safety protocols, is the bedrock for smooth, efficient, and safe laser tube cutting.

Essential preparation involves inspecting the laser cutter's key components (optics, nozzle, gas system), ensuring the correct lens and nozzle are installed for the job, verifying adequate assist gas supply and pressure, loading the appropriate cutting program, and meticulously implementing all safety measures. This includes wearing certified laser protective eyewear, ensuring proper area ventilation and fume extraction, and confirming all machine guarding and interlocks are functional.

Once you've confirmed that your chosen material and tube type are perfectly suitable for laser processing, the next critical phase is thorough preparation. This isn't merely a cursory glance or a quick check; it's a systematic, detailed process that directly underpins the success, quality, and, most importantly, the safety of the entire cutting operation. At MZBNL, we place enormous emphasis on rigorous pre-operation checklists, a habit deeply ingrained from our 25 years of manufacturing and service experience in the metal fabrication sector. I vividly recall a situation where a new client, before they adopted our more streamlined systems, experienced frequent and frustrating cutting errors due to inconsistent and incomplete pre-run checks. Simple, avoidable oversights like a slightly misaligned nozzle or incorrect assist gas pressure were causing significant rework and material wastage. This experience, and many others like it, powerfully highlights why a detailed understanding and diligent execution of equipment setup and safety measures are absolutely non-negotiable for any professional operation. We'll now break down precisely what you need to do to get it right, every single time, ensuring both optimal results and a safe working environment.

Pre-Operation Equipment Checks and Calibration

Before any laser tube cutting operation commences, a meticulous inspection of the laser tube cutting machine is absolutely essential. This initial walk-around and system check should include verifying the condition of the laser source (if accessible or through system diagnostics), the entire beam delivery system components such as mirrors and, most critically, the final focusing lens assembly within the cutting head. Any accumulation of dust, spatter, or fingerprints on optical components can significantly degrade the laser beam's quality and drastically reduce cutting performance, potentially leading to inconsistent cuts or even damage to the optics themselves. Regular cleaning of the protective window and focusing lens, strictly following the manufacturer's recommended procedures and using approved cleaning materials, is paramount. For example, even a small particle or a smudge on a high-power focusing lens can absorb laser energy, leading to localized overheating, thermal lensing effects4, and ultimately, premature failure of this expensive component.

Calibration is a cornerstone of precision in laser cutting. This process fundamentally involves verifying the precise alignment of the laser beam as it passes through the nozzle orifice, ensuring it is perfectly centered. An off-center beam can result in uneven cut edges, increased dross, and inconsistent kerf width. The focal position of the laser beam – its point of smallest diameter – relative to the material surface must also be accurately set and maintained. Most modern laser cutting machines, including those from MZBNL, incorporate auto-focus capabilities that dynamically adjust the focal point, but periodic calibration checks of this system are still necessary to ensure its long-term accuracy. The condition and selection of the cutting nozzle are also critical factors; a worn, damaged, or incorrectly sized nozzle can lead to erratic gas flow, poor cut quality, excessive assist gas consumption, and an increased risk of back-spatter damaging the protective lens. Our BNL machines integrate self-calibration routines and nozzle-centering aids to simplify these critical tasks, but operator vigilance and adherence to procedures remain fundamentally important. Ahmed Al-Farsi, during his initial training on our BNL machine in the UAE, quickly appreciated how these automated checks and simplified calibration procedures significantly reduced his setup time and improved consistency compared to his older, more manual equipment.

The assist gas supply system must be thoroughly verified before starting any cutting job. This includes ensuring that you have the correct type of assist gas selected (e.g., oxygen for most carbon steel applications, high-pressure nitrogen for stainless steel or aluminum) and that there is a sufficient supply at the correct pressure and flow rate for the material and thickness being processed. Fluctuations or inadequate gas pressure can directly and negatively impact cut quality, leading to issues such as heavy dross adhesion, charring on the cut edge, or incomplete cuts that require rework. Performing leak checks in the gas delivery lines, regulators, and fittings is also a good practice to prevent wastage of expensive gases and to ensure consistent, reliable pressure at the cutting head. Industry best practices, frequently highlighted in technical publications like "The Fabricator" or "Welding Journal," consistently stress the importance of dedicated, well-maintained gas delivery systems equipped with high-quality regulators and filters to ensure the purity and consistency of the assist gas, which is vital for repeatable, high-quality laser cutting.

Programming and Material Setup

The cutting program, which dictates every movement and action of the laser cutter, is the digital blueprint for the physical part. This program is typically generated from a CAD (Computer-Aided Design) file which is then processed by CAM (Computer-Aided Manufacturing) software to create the machine-specific G-code5. Alternatively, for many standard tube types and common hole patterns (like round, square, or rectangular holes, as well as slots), operators can utilize innovative systems like MZBNL's No-CAD interface. This allows direct input of parameters such as tube dimensions, hole sizes, and precise locations through an intuitive interface on the machine's controller, bypassing the more complex offline CAD/CAM workflow for simpler jobs. Regardless of the input method, it is absolutely crucial to meticulously double-check the loaded program to ensure it perfectly matches the intended part geometry, material type, and thickness. This verification should include reviewing cutting paths, pierce points, lead-in and lead-out strategies, and any special instructions for features like bevels or weld seam avoidance. A misplaced pierce point, for example, could damage a critical feature of the part or result in an aesthetically unacceptable mark.

Securely loading and accurately clamping the tube stock is a vital step for ensuring cutting precision and safety. The tube must be properly supported along its length, especially for longer or heavier tubes, to prevent sagging or vibration during the dynamic cutting process. The machine's chucks and clamps should be appropriate for the tube's specific profile (round, square, rectangular, etc.) and size, applying sufficient force to hold it rigidly without distorting its shape, particularly for thin-walled tubes. Improper clamping can lead to dimensional inaccuracies, poor cut quality, or even cause the tube to shift during cutting, potentially leading to a machine crash or damaged parts. Our BNL machines feature advanced automatic front-feeding mechanisms and intelligent clamping systems that automatically adapt to various tube sizes and profiles, significantly simplifying this critical setup step and enhancing overall operational efficiency—a feature Ahmed found particularly beneficial for his varied production runs involving different tube specifications.

Correctly entering or confirming the material parameters, such as type (e.g., mild steel, stainless steel 304, aluminum 6061) and precise thickness, into the machine's control system is another non-negotiable part of the setup. This information allows the machine to select or suggest the appropriate library of cutting parameters, which typically includes laser power, cutting speed, assist gas type and pressure, and focal position. Using incorrect material parameters can directly result in poor cut quality (e.g., excessive dross, rough edges, charring), increased wear on consumable parts like nozzles and lenses, inefficient processing, or in worst-case scenarios, even damage to the machine itself. While many advanced laser cutting systems store extensive libraries of pre-optimized parameters for common materials and thicknesses, operators should always verify these settings against the specific job requirements and material batch characteristics, making fine adjustments as necessary to achieve the best possible cut.

Essential Safety Protocols and PPE

Laser cutting machines, especially the high-power fiber lasers common in modern tube cutting applications, emit intense, invisible (for fiber lasers) or visible (for some CO2 lasers) radiation that can cause severe and irreparable eye damage, as well as serious skin burns upon direct or scattered exposure. Therefore, the machine's protective enclosure must be fully intact, with all access doors securely closed and safety interlocks fully operational before the laser is activated. It is critically important that safety interlocks are never bypassed or disabled for any reason. All operators and any other personnel in the immediate vicinity of an operating laser cutter must wear appropriate laser safety glasses or goggles. These must be specifically rated for the wavelength and power of the laser being used; standard workshop safety glasses offer no protection against laser radiation and provide a false sense of security.

Proper and effective ventilation is absolutely critical to remove the fumes, smoke, and particulate matter generated during the laser cutting process. These airborne byproducts can be hazardous if inhaled, with their composition varying depending on the material being cut (e.g., metal oxides, volatile organic compounds from coatings). Integrated or stand-alone fume extraction systems, often incorporating multi-stage filtration, must be regularly inspected, cleaned, and maintained to ensure they are functioning at optimal efficiency and providing adequate airflow. Depending on the specific material being processed (for example, plastics, certain coated metals, or alloys containing hazardous elements), additional respiratory protection, such as respirators with appropriate filters, might be necessary to comply with occupational health and safety regulations. Regulatory bodies worldwide, such as OSHA (Occupational Safety and Health Administration) in the United States or HSE (Health and Safety Executive) in the UK, provide strict guidelines on air quality, fume extraction requirements, and permissible exposure limits6 in industrial workshops.

Beyond laser-specific hazards, general workshop safety practices must also be rigorously observed. This includes keeping the area around the laser cutting machine clean, well-lit, and free of clutter or tripping hazards. Ensure that appropriate fire extinguishers (typically ABC rated for general combustibles and electrical fires; Class D for reactive metals, though less common in standard tube cutting) are readily accessible, inspected, and that personnel are trained in their use. All operators must be thoroughly aware of the machine's emergency stop procedures and the location of E-stop buttons. Comprehensive training is paramount; only fully trained, qualified, and authorized personnel should be permitted to operate, maintain, or program laser cutting equipment. At MZBNL, we consider comprehensive operator training, which includes a very heavy emphasis on safe operating procedures and routine safety checks, to be a standard and indispensable part of our machine installation and commissioning process. Ahmed's team in the UAE, for instance, received one full day of intensive on-site training, focusing heavily on the safe operation of their new BNL machine and the critical importance of daily safety and pre-operational checks.

| Preparation Area | Key Checks / Actions | Common Pitfalls to Avoid | Safety Implication |

|---|---|---|---|

| Equipment Optics | Inspect protective lens & nozzle, Confirm beam centering, Check focusing lens condition | Dirty/damaged lens, Misaligned beam, Incorrect nozzle type/size | Poor cut quality, Optic damage, Potential fire risk |

| Assist Gas System | Verify correct gas type, Ensure sufficient pressure & flow, Check for leaks | Wrong gas, Low pressure, Leaks in hoses/fittings | Poor cuts, Gas wastage, Inconsistent performance |

| Software/Program | Load correct cutting program, Verify parameters match material & job specifications | Wrong part program selected, Incorrect material thickness input | Wasted material, Damaged part, Potential machine crash |

| Material Handling | Tube securely clamped & supported, Chucks appropriate for profile, Confirm alignment | Loose tube, Distorted tube from over-clamping, Misalignment | Inaccurate cuts, Vibration, Potential machine jam |

| Operator Safety | Wear certified laser PPE (eyewear), Confirm enclosure integrity & interlocks, Ensure fume extraction | No/improper PPE, Bypassed interlocks, Inadequate ventilation | Severe eye/skin injury, Respiratory illness |

Lens cleaning prevents beam degradationTrue

Regular cleaning of optical components maintains laser beam quality and prevents costly damage to the focusing lens.

Standard safety glasses protect against lasersFalse

Regular workshop safety glasses offer no protection against laser radiation; wavelength-specific laser safety eyewear is required.

What are the main steps in the laser tube cutting process?

Are you new to the world of laser tube cutting and perhaps feeling a bit overwhelmed by the sequence of operations involved in transforming a raw tube into a precisely finished part? Misunderstanding or incorrectly executing the core steps in the laser tube cutting process can unfortunately lead to errors, operational inefficiencies, and considerable frustration, ultimately preventing you from fully harnessing the technology's immense power and potential. The good news is that the laser tube cutting process, when understood, follows a clear, logical, and largely automated sequence from initial design input to the final, accurately cut component, ensuring high levels of precision and repeatability.

The main steps in laser tube cutting include: 1. Design creation or import (using CAD software or a No-CAD parametric system). 2. Machine setup, involving program loading and parameter input. 3. Tube loading, secure clamping, and precise alignment. 4. Automated laser cutting execution, which encompasses piercing and contouring. 5. Finally, part unloading, followed by inspection for quality and accuracy.

With all the essential preparations meticulously completed and safety checks confirmed, we now arrive at the very heart of the matter: the actual laser tube cutting process itself. This is the dynamic stage where your digital design is transformed into a tangible, precisely fabricated component. It’s a fascinating and elegant interplay of sophisticated software, robust mechanics, and high-precision optics all working in perfect concert to achieve the desired outcome. Having personally witnessed literally thousands of cutting cycles on various MZBNL machines over my 25-year career, I can confidently attest to the remarkably seamless and efficient flow of this process when each step is understood and executed correctly. For clients like Ahmed Al-Farsi, who places a high value on operational efficiency and consistent output for his architectural and automotive parts, a clear understanding of this workflow was instrumental in helping them optimize their entire production line, from raw material intake to finished goods dispatch. From the initial design input—whether a complex 3D model or simple parameters—to the final part coming off the machine, each phase plays a critical and interconnected role. Let’s walk through these essential steps in detail to demystify the process and empower you with a comprehensive understanding.

Step 1: Design Input and Program Generation

The journey of every laser-cut tube begins with a digital design. Traditionally, this involves an engineer or designer creating a detailed 3D model of the tube, complete with all necessary cuts, holes, bevels, copes, and other features, using specialized CAD (Computer-Aided Design) software7 such as SolidWorks, AutoCAD, or Inventor. This CAD model is then typically imported into CAM (Computer-Aided Manufacturing) software. The CAM software processes the geometry, allows the programmer to define cutting strategies (like lead-ins, lead-outs, and cutting order), and ultimately generates the G-code or machine-specific numerical control (NC) program. This program contains all the instructions that will guide the laser cutter's movements and operations. While this CAD/CAM workflow is incredibly powerful and versatile for complex parts, it often requires skilled and experienced CAD operators and can be a time-consuming bottleneck, especially for standard geometric features or repetitive production tasks.

This is precisely where innovative solutions like MZBNL's proprietary No-CAD operating system offer a significant advantage for many common applications. For a wide range of standard tube types (round, square, rectangular) and frequently used hole patterns or end cuts (e.g., circular holes, rectangular slots, simple miters), operators can completely bypass the traditional, often complex, CAD/CAM workflow. Instead, they can directly input key parameters – such as tube dimensions (diameter, wall thickness), hole sizes, specific locations, and desired angles – into an intuitive, user-friendly graphical interface directly on the machine's controller. The BNL system then automatically generates the necessary cutting path and machine instructions in real-time. This groundbreaking approach not only dramatically lowers the skill threshold required for machine operation but also significantly speeds up the setup time for many jobs, making the machine more accessible and productive. Ahmed Al-Farsi, our client in the UAE, specifically sought out a No-CAD system to overcome the persistent challenge of finding and retaining skilled CAD operators and to reduce the significant retraining burdens associated with high staff turnover, a common pain point that our technology directly addresses for businesses worldwide.

Regardless of whether the cutting program is generated via a full CAD/CAM suite or through a parametric No-CAD system, the resulting program will meticulously define every movement of the laser head and the tube itself. This includes precise instructions for piercing strategies (how the laser first penetrates the material), cutting speeds for different sections or features, laser power levels, focus adjustments, and the type and pressure of assist gas8 to be used. Absolute accuracy in this initial programming stage is paramount, as any errors, miscalculations, or overlooked details here will be directly and faithfully translated into the physical part, potentially leading to scrap or rework. Many modern CAM software packages, and even some advanced machine controllers, include sophisticated simulation features. These allow the operator to visually verify the entire cutting path, check for potential collisions between the cutting head and the tube or fixtures, and estimate cycle times before a single piece of material is actually processed, providing a valuable opportunity for error correction and optimization.

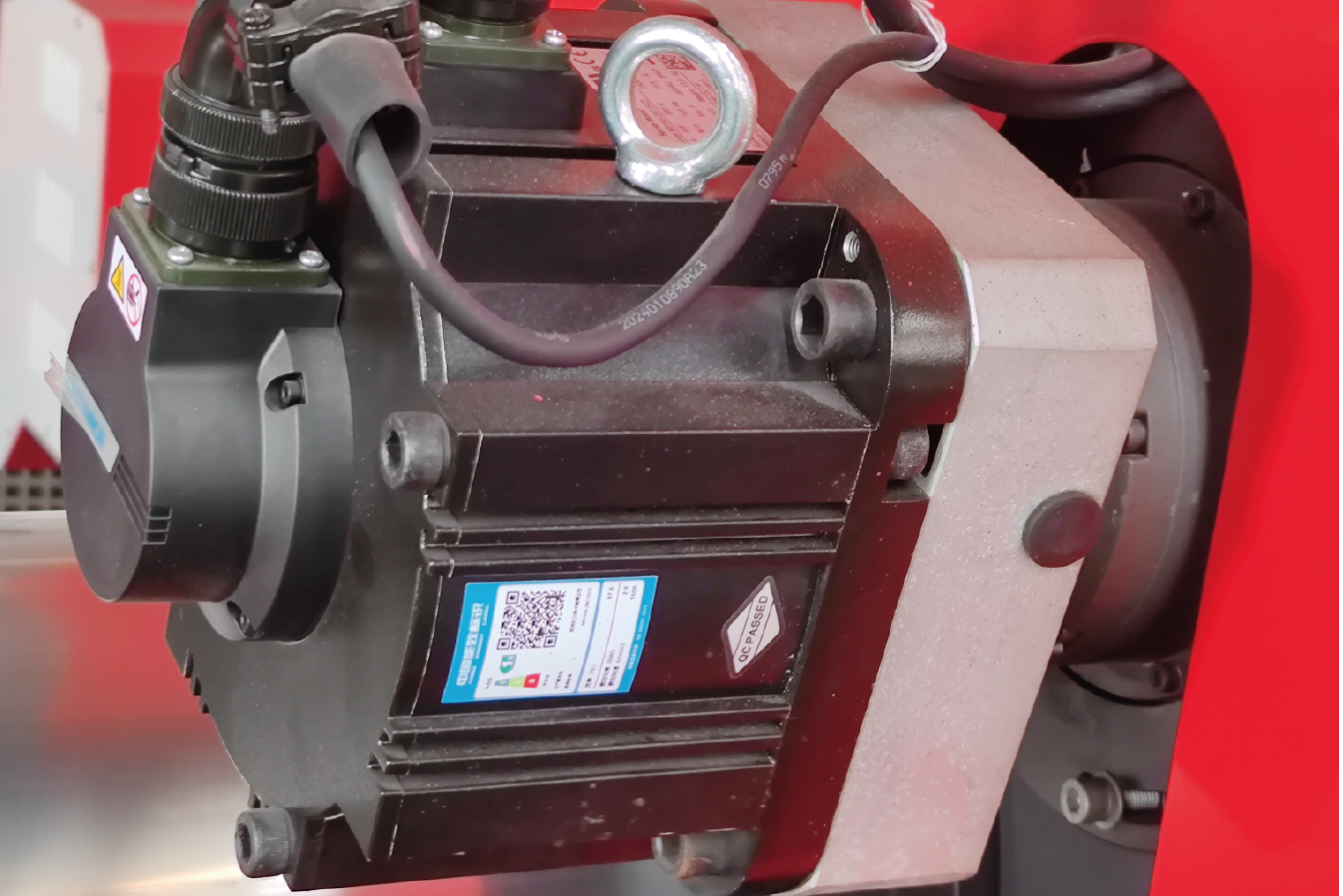

Step 2: Machine Setup and Tube Loading

This step transitions from the digital realm of programming to the physical setup of the laser cutting machine. It involves loading the previously generated and verified cutting program into the machine's CNC (Computer Numerical Control) controller9. The operator will then confirm or, if necessary, adjust the cutting parameters based on the specific material batch being used (as slight variations can exist between batches), the condition of the machine's consumables, or particular job requirements. This might involve fine-tuning the focal height of the laser, selecting the optimal nozzle diameter and type for the material and thickness, and precisely setting the assist gas pressure. As thoroughly discussed in the preparation phase, ensuring that the correct optical consumables (such as the protective lens window and the focusing lens itself) are installed, clean, and in excellent condition is absolutely vital for achieving consistent, high-quality cuts and for protecting the more expensive components of the laser system.

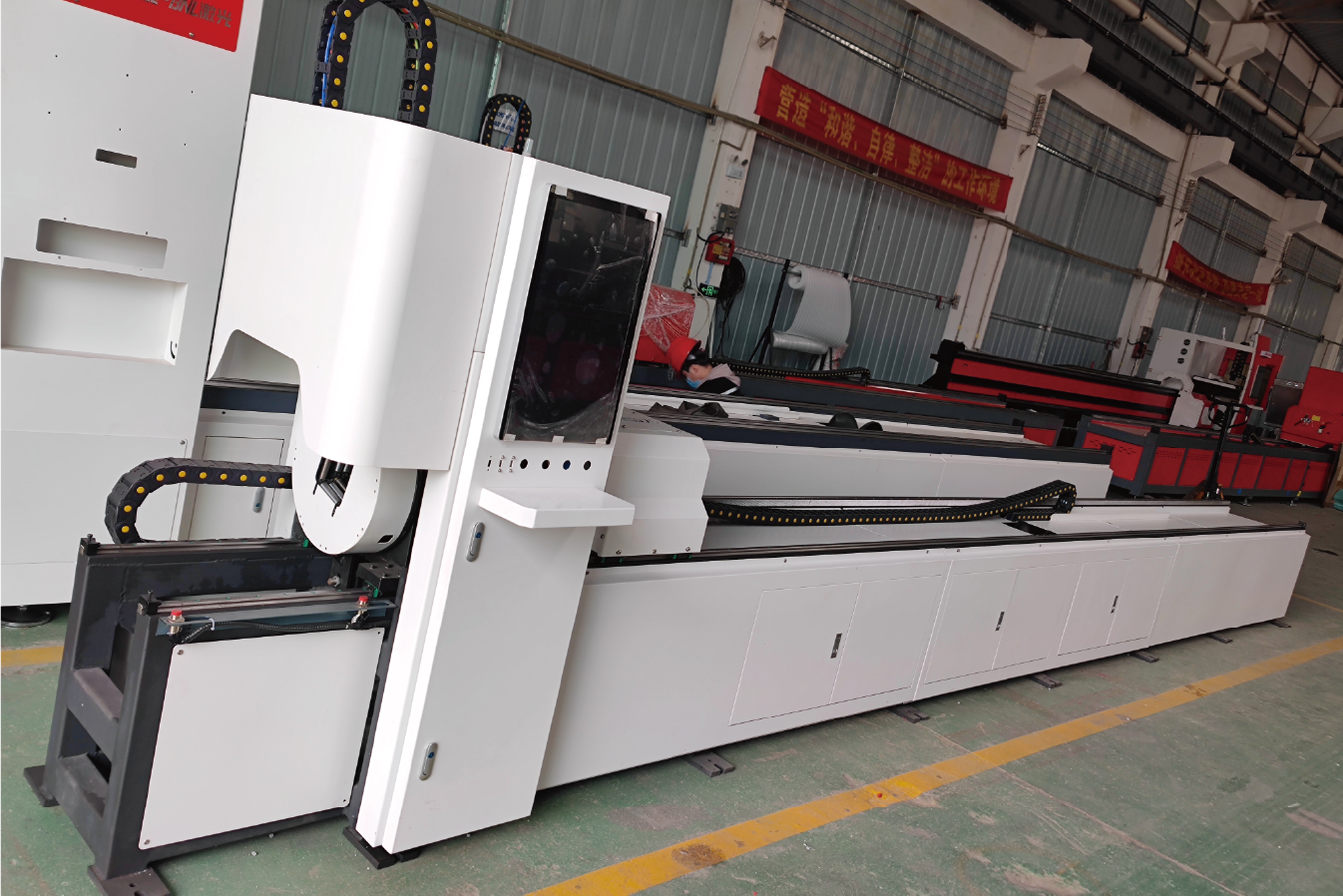

The raw tube stock, which could be full lengths of tube or pre-cut sections, is then loaded onto the machine's feeding and support system. Traditional laser tube cutting machines often rely on manual side-loading or rear-loading methods, which can be physically demanding for operators, potentially time-consuming, and less efficient, especially when dealing with long, heavy, or large-diameter tubes. This is another area where MZBNL has innovated with its automatic front-feeding mechanism. This system allows the machine to automatically draw individual tubes from a bundle or magazine positioned at the front of the machine, feeding them into the cutting area. This design not only significantly increases feeding efficiency by approximately 40% but also substantially reduces operator physical strain and the risk of handling-related injuries. Once fed into the working zone, the tube is securely gripped by the machine's chucks – typically a front chuck that rotates and feeds the tube, and often a rear chuck for additional support and precision, especially for longer tubes or when minimizing tail waste. Proper alignment of the tube within the chucks and secure, distortion-free clamping are crucial to prevent any movement, slippage, or vibration during the high-speed, high-accuracy cutting process.

Many advanced laser tube cutting machines, including BNL models, are equipped with sophisticated features such as automatic tube centering, which uses sensors to precisely locate the tube's centerline relative to the laser head, ensuring symmetrical cuts. Some systems also incorporate weld seam detection capabilities. The presence and location of a longitudinal weld seam (common in ERW tubes) can be important because cutting directly through or very near this seam can sometimes affect cut quality due to material inconsistencies or hardness variations. Moreover, a significantly raised internal or external weld bead could potentially interfere with the cutting head or internal support mechanisms. Weld seam detection systems can identify the seam's angular position, allowing the machine to automatically orient the tube so that critical cuts, features, or aesthetically important surfaces avoid the seam, or so the cutting parameters can be adjusted when crossing it. This level of automation further enhances precision and reduces the need for manual intervention, contributing to overall efficiency.

Step 3: Laser Cutting Execution and Unloading

Once the tube is securely loaded, precisely aligned, and the correct cutting program is initiated by the operator, the automated laser cutting process begins. The very first action for almost any enclosed cut or internal feature is typically piercing, where the stationary or slowly moving laser beam creates an initial penetration hole through the tube wall. Different piercing strategies are employed depending on the material type, thickness, and the desired quality of the pierce point. For instance, "pulse piercing" uses a series of short, high-power laser pulses for thick materials to minimize heat input and spatter, while "ramp piercing" involves moving the laser head slightly as it pierces to help clear molten material. The assist gas plays a crucial role during piercing, forcefully expelling the molten material and debris from the pierce point to ensure a clean start for the subsequent contouring cut.

Following successful piercing, the laser head and/or the tube itself (depending on the machine's kinematics – some machines move the head in X, Y, Z, while the tube rotates and moves axially; others have multi-axis heads that can tilt and rotate) move in a precisely coordinated manner to cut the programmed contours. The highly focused laser beam melts and vaporizes the material along the programmed path, and the coaxial jet of assist gas continuously expels the molten material (elet) and vaporized debris from the kerf (the narrow slot or groove created by the laser). The machine's CNC controller meticulously manages the cutting speed, laser power output, assist gas flow, and focal position throughout the entire cutting process to achieve the desired geometric accuracy, edge quality, and surface finish. For complex 3D cuts, such as beveled edges, mitered joints, or intricate copes for tube-to-tube intersections, advanced multi-axis laser cutting heads can articulate (tilt and rotate) to maintain the correct angle and focal point relative to the tube's curved or changing surface, enabling the creation of highly complex geometries in a single setup.

After a part is completely cut from the parent tube, it needs to be unloaded from the machine. This unloading process can be manual, where the operator removes the finished part, or it can be partially or fully automated. Some advanced laser tube cutting machines have integrated unloading systems that can automatically transfer the finished part to a designated collection bin, a conveyor belt for subsequent processing, or even a robotic handling system. An important innovation in this area, pioneered by MZBNL, is our zero-waste tail material design. Traditional laser tube cutting systems often start processing from the tube head and typically generate an unusable remnant or tail material at the very end of the tube due to chuck gripping limitations. By redesigning the cutting logic to calculate from the rear chuck as the origin point, our BNL system can effectively minimize or, in many cases, completely eliminate this leftover tail material, as long as the remaining section of the tube is smaller than the length of the product being cut. This significantly maximizes material utilization and can lead to substantial cost savings for our clients, especially when processing expensive materials. The final operational step, though often considered post-processing, is a thorough inspection of the cut part for dimensional accuracy, conformity to specifications, and overall cut quality, ensuring it meets all required standards before it moves to subsequent manufacturing stages, assembly, or shipping.

| Process Step | Key Actions | Technology Involved | Typical Output/Outcome |

|---|---|---|---|

| 1. Design & Program | Create/Import CAD model, Generate G-code via CAM, or Use No-CAD parametric input | CAD/CAM Software, Machine CNC Controller, No-CAD System | Machine-readable cutting instructions, Digital part definition |

| 2. Setup & Loading | Load program, Set/Verify parameters, Load tube stock, Secure clamping, Align tube | CNC Controller, Auto/Manual Feeding System, Chucks, Sensors | Machine ready for operation, Tube correctly positioned |

| 3. Piercing | Laser creates initial penetration hole, Assist gas clears molten material | Laser Source, Cutting Head Optics, Assist Gas System | Clean entry point established for the cutting path |

| 4. Contouring & Cutting | Laser head/tube move to cut programmed shapes, Assist gas ejects elet | Motion System (Axes), Laser Source, CNC, Gas System | Desired geometry accurately cut into the tube |

| 5. Unloading & Insp. | Remove finished part (manual/auto), Quality check against design specifications | Unloading System (if equipped), Inspection Tools | Finished part produced, Quality and accuracy verified |

No-CAD systems reduce setup timeTrue

No-CAD systems allow direct parameter input, bypassing complex CAD/CAM workflows, which significantly speeds up job setup.

Laser cutting requires manual tube alignmentFalse

Modern machines feature automatic tube centering and weld seam detection, minimizing manual alignment needs.

How can you optimize precision and speed during laser cutting?

Are you constantly struggling to achieve that perfect, delicate balance between cutting speed and the high levels of precision that your projects and customers demand? Sacrificing precision for the sake of increased speed often leads to a higher rate of rejected parts and costly material waste, while being overly cautious and too slow directly impacts overall productivity and, consequently, your profit margins. The key lies in a holistic approach: optimizing your laser tube cutting operations involves a careful fine-tuning of critical parameters, leveraging advanced machine features effectively, and adopting smart operational strategies to consistently achieve superior results in both speed and accuracy.

To optimize precision and speed in laser tube cutting, meticulously select and adjust laser power, cutting speed, assist gas type and pressure, and focal point position. Additionally, utilize advanced machine features like dynamic corner control and fly cutting, and critically, ensure consistent machine calibration and preventative maintenance schedules are strictly followed.

Achieving both exceptionally high precision and optimal cutting speed simultaneously in laser tube cutting operations is often considered the holy grail for fabricators worldwide. It’s not just about making cuts in a tube; it’s about making perfect, flawless cuts, quickly, efficiently, and consistently, day in and day out. At MZBNL, we have dedicated significant research and development efforts into designing and integrating features that specifically enhance this crucial balance, primarily because we know it’s a core concern and a key performance indicator for our clients, like Ahmed Al-Farsi. Ahmed needs to meet tight production deadlines for his architectural metalwork and automotive parts supply business without ever compromising on the stringent quality standards his customers expect. Simply cranking up the speed dial on the machine is rarely the answer and often counterproductive; true optimization requires a nuanced understanding of various interacting parameters, the specific capabilities of your laser cutting machine, and the characteristics of the material being processed. Let's explore the key strategies and techniques you can employ to elevate your cutting performance to the next level.

Fine-Tuning Core Cutting Parameters

The \"golden triangle\" of laser cutting parameters, which every experienced operator becomes intimately familiar with, consists of laser power (typically measured in watts or kilowatts), cutting speed (usually in mm/second or inches/minute), and the assist gas settings (type, pressure, and flow rate). These three elements are intrinsically linked and must be balanced for optimal results. Generally, increasing laser power allows for higher cutting speeds, but this relationship is not linear and holds true only up to a certain point for any given material and thickness. Exceeding the optimal power for a specific application can lead to detrimental effects such as a wider kerf (the width of the cut), excessive heat input into the material resulting in a larger heat-affected zone (HAZ)10, and poor edge quality, which can manifest as burning, increased dross adhesion, or even charring on certain materials.

Cutting speed must be carefully matched to the material type (e.g., mild steel, stainless steel, aluminum), its thickness, and the geometric complexity of the part being cut. Attempting to cut too fast for the available power or material characteristics can result in incomplete cuts (where the laser doesn't fully penetrate the material), rough or ragged edges, or excessive striations on the cut surface. Conversely, cutting too slowly can cause overheating of the material, leading to a wider HAZ, thermal distortion (especially in thin materials or complex parts), and excessive, hard-to-remove dross on the underside of the cut. For intricate patterns, sharp corners, or very small features, the cutting speed often needs to be significantly reduced in those specific areas to allow the motion system to accurately trace the path and maintain precision. Modern CNC controllers on advanced laser cutters often have sophisticated features like \"corner slowdown,\" \"power ramping,\" or \"dynamic corner control\" that automatically adjust speed and sometimes power when approaching and navigating corners or detailed sections, ensuring accuracy without unduly slowing down the entire process.

The choice of assist gas, its delivery pressure, and the design of the cutting nozzle are absolutely critical for both speed and quality. For instance, when cutting mild steel with oxygen as the assist gas, the pressure needs to be precisely optimized. Too low a pressure might not effectively clear the molten material or support the exothermic reaction, while too high a pressure can cool the cut zone excessively, disrupt the stable burning process, or blow molten material back onto the nozzle and protective lens. For stainless steel or aluminum, typically cut with high-pressure nitrogen to prevent oxidation and achieve a clean, bright edge, the pressure and flow rate must be sufficient to rapidly and efficiently eject the molten material from the kerf. An incorrect nozzle standoff distance (the gap between the nozzle tip and the material surface) or a worn, damaged, or incorrectly sized nozzle can severely disrupt the coaxial gas flow, leading to poor cut quality, reduced cutting speed, and increased gas consumption. Regular inspection and timely replacement of nozzles are essential maintenance tasks for optimal performance. Industry data and numerous studies suggest that meticulous optimization of assist gas parameters alone can improve cutting speed by up to 15-20%11 in certain applications while simultaneously enhancing edge quality.

Leveraging Advanced Machine Features and Software

Modern laser tube cutting machines, such as those engineered by MZBNL, are often equipped with a suite of advanced features specifically designed to enhance both processing speed and cutting precision. \"Fly cutting\" or \"on-the-fly piercing\" is a highly efficient technique used for cutting grids of holes, perforations, or multiple small, closely spaced features without the laser head needing to stop and perform a full piercing cycle for each individual feature. In fly cutting, the laser beam pierces and cuts in a continuous, fluid motion as the head (or tube) moves, significantly reducing overall cycle time, especially for parts with many small internal features. This technique is particularly beneficial for products like perforated tubes for filtration, acoustic panels, or display racks featuring numerous mounting holes, which are common in Ahmed's diverse production requirements.

Autofocus systems play a crucial role in maintaining the optimal focal position of the laser beam relative to the tube surface, consistently and automatically. These systems can compensate for minor variations in material straightness, surface irregularities, or slight deviations in tube positioning, which is vital for achieving consistent kerf width, cut quality, and reliable cutting speeds. Some highly advanced systems offer dynamic focus adjustment, which means the focal point can be actively changed during the cutting process itself – for example, using a different focal position for piercing than for contour cutting, or adjusting focus based on material thickness changes or cutting speed. Our BNL machines incorporate highly responsive and accurate autofocus systems, which our clients consistently report contribute to more stable cutting processes and more consistent, high-quality results across different tube batches and varying job complexities.

Software capabilities are equally important in the optimization equation. Advanced nesting software, for instance, optimizes the arrangement and placement of multiple parts (or multiple instances of the same part) along a length of tube to maximize material utilization and significantly reduce scrap – a direct cost saving. This software can also optimize the cutting path (the sequence in

which features are cut) to minimize rapid traverse times (non-cutting movements) and reduce the overall cycle time per part. Path optimization algorithms can intelligently reorder cutting sequences to minimize heat buildup in one specific area of the part (reducing thermal distortion) or to ensure that smaller, delicate features are cut before larger sections that might cause the part to shift. Furthermore, the innovative No-CAD systems, like the one integrated into MZBNL machines, further accelerate the entire process from design to finished part by eliminating the need for complex offline CAD/CAM programming for many standard cuts and profiles. This allows for much quicker job changeovers and makes the machine more responsive to urgent or small-batch orders.

Impact of Machine Maintenance and Operator Skill

A well-maintained laser tube cutting machine is absolutely fundamental to achieving and sustaining optimal speed and precision over the long term. This encompasses a program of regular preventative maintenance, including diligent cleaning and precise alignment of all optical components (mirrors, lenses, protective windows), thorough checking and lubrication of mechanical components like linear guide rails, ball screws, and drive systems, and ensuring the laser source itself is performing according to its specifications. A poorly maintained machine, with issues like dirty optics, misaligned beam, or excessive mechanical play in its motion system, will inevitably struggle to hold tight tolerances, may require significantly slower cutting speeds to compensate for these deficiencies, and will be prone to producing inconsistent results. Preventative maintenance schedules, as recommended by the equipment manufacturer, should be viewed as essential operational procedures and strictly followed.

Operator skill, knowledge, and ongoing training are indispensable assets, even with the increasing automation in modern laser cutting machines. While these machines can perform many tasks automatically, a knowledgeable and experienced operator can identify subtle issues that a sensor might miss, can expertly fine-tune cutting parameters for specific or unusual material batches, and can troubleshoot problems effectively and efficiently when they arise. A deep understanding of how different parameters interact, and the ability to recognize the visual signs of a suboptimal cut (e.g., the characteristics of dross formation, variations in kerf width, unusual edge striations or burning) allows for quick, informed adjustments that can save material and time. This is precisely why MZBNL invests heavily in comprehensive operator training programs for our clients; even with our exceptionally user-friendly No-CAD system, a well-trained operator, like those on Ahmed Al-Farsi's team, can extract the maximum performance and efficiency from the equipment.

Finally, never underestimate the impact of raw material quality on cutting performance. Inconsistent material thickness across a batch of tubes, variations in chemical composition, or poor surface conditions (e.g., excessive rust, scale, oil, or paint) can significantly affect the stability of the laser cutting process, necessitating frequent parameter adjustments and potentially leading to variable cut quality, reduced cutting speeds, and increased dross. While it might seem counterintuitive, investing slightly more in high-quality, consistent raw materials from reputable suppliers can often pay significant dividends in the form of reduced processing issues, higher achievable cutting speeds, better cut quality, and increased overall throughput. A study published by the Laser Institute of America (LIA)12 has demonstrated a direct and measurable correlation between raw material consistency and the ability to maintain high cutting speeds while consistently holding tight manufacturing tolerances.

| Optimization Factor | Strategy | Impact on Precision | Impact on Speed |

|---|---|---|---|

| Core Cutting Parameters | Balance Laser Power, Cutting Speed, Assist Gas (Type, Pressure, Nozzle) | Critical for edge quality, kerf width, HAZ control | Directly determines material removal rate |

| Focal Position | Maintain optimal focus using auto-focus; Calibrate regularly | Ensures consistent kerf, clean cuts, prevents defocusing | Consistent piercing, stable cutting at higher rates |

| Advanced Features | Utilize Fly Cutting, Dynamic Corner Control, Intelligent Piercing Routines | Maintains accuracy during complex geometries & high-speed moves | Significantly reduces non-cutting time, boosts throughput |

| Software Optimization | Employ Nesting for material yield, Path optimization for reduced travel | Indirectly by ensuring stable, predictable cuts | Minimizes air-cut time, optimizes cutting sequence |

| Machine Maintenance | Regular optics cleaning, Mechanical system checks, Laser source calibration | Prevents degradation of accuracy, ensures beam quality | Allows machine to operate at its peak capability |

| Operator Skill/Training | Parameter fine-tuning, Early problem diagnosis, Process understanding | Ability to achieve and consistently maintain tight tolerances | Efficient setup, quick troubleshooting, less downtime |

| Material Quality | Use consistent, high-quality tube stock; Clean surfaces | Reduces variability, leads to more predictable results | Allows for more stable, higher-speed processing |

Assist gas affects cutting speedTrue

Optimizing assist gas type and pressure can improve cutting speed by 15-20% while enhancing edge quality.

Higher power always means faster cuttingFalse

While increasing power can allow higher speeds, this relationship isn't linear and excessive power can cause poor edge quality and wider kerf.

What are the maintenance tips for laser tube cutting equipment?

Are you worried that neglecting the consistent maintenance of your valuable laser tube cutter will inevitably lead to unexpected breakdowns, disruptive downtime, and costly, emergency repairs? Poor or inconsistent maintenance practices are a common cause of decreased cutting performance, premature failure of critical components, and frustrating production halts, all of which directly and negatively impact your bottom line and your ability to meet delivery schedules. Implementing and diligently adhering to a consistent, preventative maintenance routine for your laser tube cutting equipment is the most effective strategy to ensure its longevity, maintain optimal performance, and minimize the risk of expensive, unscheduled downtime.

Key laser tube cutter maintenance includes daily checks and cleaning of optics (nozzle, protective lens), weekly lubrication of guide rails and motion components, monthly inspection and replacement of filters (fume extractor, water chiller), regular checks of the assist gas system integrity, and periodic professional servicing for critical tasks like laser source health checks and comprehensive optical alignment.

Investing in a sophisticated piece of technology like a laser tube cutting machine is a significant financial and operational commitment for any business. However, protecting that substantial investment through diligent, proactive, and consistent maintenance is equally, if not more, crucial for long-term success. It truly is the difference between a machine that performs reliably and efficiently for many years, contributing positively to your profitability, and one that becomes a constant source of operational frustration, unexpected expenses, and production bottlenecks. At MZBNL, we consistently stress to all our clients, including growth-oriented businesses like Ahmed Al-Farsi's operation in the UAE which is actively scaling its production capabilities, that proactive maintenance is absolutely non-negotiable for achieving sustained productivity and maximizing the return on their investment. Experience across the industry clearly shows that preventative maintenance is far more cost-effective in the long run than dealing with reactive repairs after a failure has occurred. Let’s explore the essential maintenance tips and schedules that will help keep your valuable laser tube cutting equipment in peak operational condition.

Daily and Weekly Maintenance Routines

Daily checks form the crucial first line of defense in any effective preventative maintenance program for laser tube cutting equipment. Before commencing any cutting operations for the day, operators should perform a visual inspection of the cutting head assembly, paying particular attention to the condition of the nozzle tip and the protective lens window (also sometimes called a cover slide). The nozzle should be free of any accumulated spatter, perfectly centered relative to the laser beam, and not excessively worn. The protective lens window, which shields the more expensive internal focusing lens from cutting debris and spatter, should be impeccably clean and free from any haze, cracks, or burns. If this window is dirty, fogged, or damaged, it can absorb laser energy, leading to poor cutting performance, beam distortion, and can even cause catastrophic damage to the focusing lens itself. A quick, careful wipe with an appropriate optical cleaning solution and lint-free lens tissue, following manufacturer guidelines, can make a substantial difference to daily performance and lens longevity. This simple yet critical check was a key component of the practical, 1-day on-site training curriculum we provide at MZBNL for all new machine installations.

Also on a daily basis, operators should verify the assist gas supply, ensuring there is sufficient gas volume and that the regulated pressure at the machine inlet is correct for the job scheduled. It's also good practice to quickly inspect the general area around the machine for any loose debris, offcuts, or potential obstructions that could interfere with machine movement or safety. After the day's operations are complete, or at least at the end of each shift, it's highly recommended to clean cutting dust, slag, and small metal particles from the machine bed, support slats, and around the cutting head area. This prevents the buildup of debris that can contaminate optical components, interfere with the smooth movement of mechanical parts, or even create a fire hazard if allowed to accumulate excessively.

On a weekly basis, a more thorough cleaning of the machine's exterior surfaces and easily accessible interior parts should be performed. This is also the typical interval for lubrication of linear guide rails, ball screws, and other critical moving parts, as specified in the machine manufacturer's maintenance manual, using the recommended type and amount of lubricant. Proper lubrication is absolutely crucial to ensure smooth, accurate, and low-friction motion of the machine axes, preventing premature wear. Operators or maintenance personnel should also check the water level and temperature of the chiller unit; the laser source (especially fiber lasers) requires very precise temperature control for stable operation and longevity13, and any chiller malfunctions or insufficient cooling can lead to alarms, shutdowns, or even costly damage to the laser resonator. Additionally, it's important to inspect the fume extraction system's ducting, hoses, and connections for any signs of leaks, blockages, or damage that could impair its efficiency in removing harmful fumes and particulates from the work area. Ahmed’s team in the UAE, operating in an environment that can sometimes be dusty, found that strict adherence to these weekly cleaning and lubrication schedules significantly reduced the occurrence of minor operational hiccups and contributed to more consistent machine performance.

Monthly and Periodic Maintenance Tasks

On a monthly schedule, several other important maintenance tasks typically come due. Filters within the fume extraction system (such as pre-filters, HEPA filters, or activated carbon filters) and those in the water chiller unit usually require inspection and, depending on their condition and the machine's usage intensity, may need cleaning or replacement. Clogged filters significantly reduce the efficiency of these auxiliary systems, can put undue strain on their motors or pumps, and in the case of the fume extractor, can lead to inadequate removal of hazardous airborne contaminants from the workshop. It's also advisable to inspect any beam path bellows (more common on CO2 laser systems, but some fiber systems have protective bellows on moving axes) for any tears, punctures, or signs of wear. Damaged bellows can allow dust, moisture, or other contaminants to enter the protected beam path or sensitive mechanical areas, potentially damaging mirrors or precision guides.

During monthly or quarterly checks, depending on the laser type and manufacturer recommendations, it may be necessary to inspect and clean external optics, such as beam delivery mirrors in a CO2 laser system. For fiber laser systems, while the beam is delivered via a sealed fiber optic cable directly to the cutting head, the optics within the cutting head itself (collimating lens, focusing lens, and the protective window) still require regular attention as part_of the daily/weekly checks and more thorough inspection periodically. Any cleaning of optical components must be done with extreme care, strictly following the manufacturer's prescribed procedures and using only approved cleaning materials and techniques, as improper cleaning can easily scratch or damage delicate optical coatings, degrading performance and necessitating premature replacement.

On a quarterly or semi-annual basis, again depending on machine usage and the manufacturer's guidelines, more in-depth checks and calibrations are generally advisable. This might include verifying the overall laser beam alignment through the entire optical path (for CO2 lasers) or within the cutting head, calibrating the auto-focus system to ensure its continued accuracy, and inspecting electrical connections, cables, and safety interlocks for any signs of wear, looseness, or damage. Some machine manufacturers, including MZBNL, offer advanced remote diagnostics capabilities. These allow our service technicians to connect to the machine over the internet (with client permission) to help identify potential issues, analyze error logs, or guide local maintenance personnel through troubleshooting procedures before an issue becomes critical and causes a shutdown. We often guide clients like Ahmed through these more detailed periodic checks remotely, helping them to ensure their machines maintain peak operational performance with minimal disruption to their production schedules. Data accumulated from our global service department consistently shows that clients who diligently follow a robust periodic maintenance schedule experience up to 30% less unscheduled downtime14 compared to those with more reactive maintenance practices.

Importance of Professional Servicing and Record Keeping

While many routine daily, weekly, and even monthly maintenance tasks can and should be handled by well-trained machine operators or in-house maintenance staff, certain highly specialized tasks are best left to qualified service technicians from the machine manufacturer or their authorized service providers. These typically include major servicing of the laser source itself (e.g., checking resonator condition, power output calibration), comprehensive optical alignment procedures that require specialized tools, or complex mechanical adjustments and calibrations. Most laser cutting machine manufacturers recommend a professional servicing visit annually or bi-annually, depending on the machine's age, type, and intensity of usage. These professional check-ups ensure that critical, often non-visible, components are inspected, tested, and maintained by experts who have in-depth knowledge of the specific machine model and access to the latest service bulletins and software updates.

It is incredibly important to keep meticulous, accurate, and up-to-date records of all maintenance activities performed on the laser cutting machine. This should include dates of service, a clear description of the tasks performed, details of any parts replaced (including part numbers), any measurements taken (e.g., power output readings), and any pertinent observations made by the operator or technician. This comprehensive maintenance log becomes an invaluable historical record for tracking the machine's performance over time, identifying any recurring issues or patterns of wear, effectively scheduling future preventative maintenance, and can be extremely useful if complex troubleshooting is ever required. Furthermore, for businesses that are aiming for or have achieved quality management certifications like ISO 9001, well-documented maintenance records are often a mandatory requirement to demonstrate process control and equipment upkeep.

Finally, establishing a system for managing and having readily available spare parts for common consumables and frequently replaced wear items can significantly reduce potential machine downtime. This typically includes items like cutting nozzles of various sizes, protective lens windows, ceramic insulator parts for the cutting head, and perhaps certain filters. While Ahmed Al-Farsi was initially concerned about the availability and lead times for spare parts for a machine sourced from China, our well-established global distributor networks and MZBNL's strong commitment to comprehensive post-sales support, which includes maintaining readily available stocks of critical spares in regional hubs, quickly reassured him. Establishing a good, communicative relationship with your machine supplier for ongoing technical support, training updates, and efficient spare parts logistics is a key, often overlooked, part of ensuring long-term operational success and maximizing the productive life of your laser cutting equipment. Our experience at MZBNL clearly shows that proactive customers who maintain a sensible stock of critical consumables on-site experience significantly shorter downtimes if a minor, easily replaceable part fails, getting back into production much faster.

| Maintenance Frequency | Task Examples | Purpose | Responsibility |

|---|---|---|---|

| Daily | Inspect/Clean Nozzle & Protective Lens, Check Assist Gas Pressure, Clean Machine Debris | Prevent immediate cut quality issues, Ensure operational readiness, Basic safety checks | Operator |

| Weekly | Lubricate Guide Rails & Motion Components, Check Chiller Water Level & Temp, Inspect Fume Hoses | Ensure smooth motion, Protect laser source, Maintain air quality system integrity | Operator/Maintenance |

| Monthly | Clean/Replace Filters (Fume Extractor, Chiller), Inspect Beam Path Bellows (if any) | Maintain auxiliary system efficiency, Prevent optical path contamination | Trained Maintenance Staff |

| Periodic (Qtr/Semi-Ann) | Verify Beam Alignment (as applicable), Calibrate Autofocus, Inspect Electricals & Interlocks | Ensure long-term precision & safety, Pre-emptive issue detection, Confirm calibrations | Qualified Tech/Maint. |

| Annual/As Recommended | Laser Source Health Check/Service, Major Optical Alignment, Complex Mechanical Adjustments | Maintain peak performance of critical systems, Address complex wear/issues, Software updates | Prof. Service Technician |

Daily lens cleaning prevents beam distortionTrue

The protective lens window must be kept clean to avoid absorbing laser energy which can distort the beam and damage internal components.

Lubrication is only needed annuallyFalse

Critical moving parts like guide rails and ball screws require weekly lubrication to prevent premature wear and ensure smooth operation.

Conclusion

Mastering the intricacies of laser tube cutting, from careful material selection and precise step-by-step execution to diligent, ongoing maintenance, empowers your operation to achieve consistently precise and efficient fabrication. By embracing these detailed steps and best practices, particularly with advanced solutions like MZBNL's innovative No-CAD and efficient feeding systems, you can truly transform your production capabilities and achieve superior results in today's competitive metalworking landscape.

-

Explore data on how laser cutting boosts profitability through reduced waste and increased efficiency. ↩

-

Learn about fiber laser advantages, especially for reflective metals and cutting efficiency. ↩

-

Access insights from the 2023 laser cutting market report on industry trends and growth. ↩

-

Learn how heat absorption can distort laser beams and impact cutting precision. ↩

-

Understand the programming language that dictates laser cutter movements and operations. ↩

-

Learn about safety standards for airborne contaminants generated during laser cutting. ↩

-

Learn about CAD software's role in creating precise digital models for manufacturing. ↩

-

Discover how different assist gases improve cut quality and efficiency in laser cutting. ↩

-

Understand the function of CNC controllers in automating and guiding laser cutting machines. ↩

-

Learn about HAZ, its formation, and impact on material properties in laser cutting. ↩

-

Explore studies showing how assist gas optimization improves laser cutting speed and edge quality. ↩

-

Access LIA research on how material quality affects laser cutting speed and precision. ↩

-

Understand how stable temperatures protect fiber lasers and ensure consistent cutting performance. ↩

-

Explore industry data on how proactive maintenance significantly cuts costly production interruptions. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.