Using Laser Tube Cutters in Medical and Fitness Equipment Production

Are you struggling with the precision and speed demands of medical or fitness equipment manufacturing? Traditional methods often fall short, leading to inefficiencies and higher costs. Laser tube cutting, however, offers the transformative accuracy and efficiency needed to revolutionize your production.

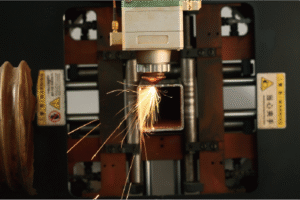

Laser tube cutting technology plays a pivotal role in the production of medical and fitness equipment by enabling high-precision, intricate cuts on various metal tubes. This technology ensures the dimensional accuracy, material integrity, and structural strength essential for critical components in these demanding industries.

The journey from raw metal tubes to life-saving medical devices or robust fitness machines demands unparalleled precision and efficiency. For years, I’ve seen manufacturers grapple with complex geometries, stringent material requirements, and the constant pressure to innovate. This is where advanced fabrication technologies like laser tube cutting become indispensable, offering solutions that traditional methods simply cannot match.

The medical and fitness equipment sectors are characterized by extremely high standards for safety, durability, and performance. Every component, especially those made from tubes, must meet exacting specifications to ensure patient safety or user reliability. My experience at MZBNL, spanning 25 years and working with over 4000 global enterprise clients, has shown me how critical precision and material integrity are. For instance, creating a lightweight yet strong frame for a medical mobility device or a robust structural component for a heavy-duty gym machine requires not just cutting but intelligent fabrication. This technology allows for intricate designs, precise joint preparation for welding, and optimal material utilization, pushing the boundaries of what's possible in product design and manufacturing efficiency, moving beyond basic cutting to advanced, integrated solutions1 that address real-world production bottlenecks.

What is the background of laser tube cutting in medical and fitness equipment manufacturing?

Have traditional cutting methods hindered your ability to produce complex, high-precision tubular components? The limitations of conventional techniques often led to costly rework and design compromises. Laser tube cutting emerged as a game-changer, addressing these inefficiencies and opening new avenues for innovation.

The background of laser tube cutting in medical device production stems from the critical need for superior precision, speed, and design flexibility in manufacturing intricate tubular components. It evolved as a transformative solution, replacing less efficient mechanical processes to meet the stringent demands of medical device and fitness equipment production.

Before the widespread adoption of laser tube cutting, manufacturers often faced significant hurdles in achieving the intricate designs and tight tolerances required for medical instruments and robust fitness equipment. Mechanical cutting methods frequently left burrs, distorted material, and struggled with complex angles or small diameters, necessitating extensive post-processing. This not only increased production time and costs but also limited design freedom, stifling innovation. My company, MZBNL, witnessed this firsthand over two decades ago, prompting our deep dive into developing solutions that could overcome these inherent limitations and propel the industry forward. The shift was driven by a clear demand for cleaner cuts, higher accuracy, and the ability to work with advanced materials, setting the stage for the laser's profound impact on these vital sectors.

Evolution of Manufacturing Precision

The journey from rudimentary metalworking to today's highly advanced medical and fitness equipment production has been marked by a relentless pursuit of precision. Initially, manufacturers relied on methods like sawing, drilling, and stamping for tubular components. While functional, these techniques were notoriously slow, labor-intensive, and struggled to produce the clean, precise cuts essential for applications where even microscopic imperfections could compromise performance or safety. Consider, for example, the internal structures of an endoscope or the intricate joints of a high-end rehabilitation machine; traditional methods often resulted in burrs, material deformation, and the inability to create complex, multi-axis cuts necessary for modern designs.

This challenge was particularly acute for businesses like Ahmed Al-Farsi's, a prominent metal fabrication owner in the UAE. He frequently mentioned his pain point: the reliance on skilled CAD operators and the high turnover rates, which led to constant retraining burdens for his existing manual workflows. This mirrored a broader industry struggle where manual processes or outdated machinery directly impacted efficiency and product quality. The introduction of early laser cutting systems, primarily CO2 lasers in precision manufacturing2, marked a significant leap forward, offering non-contact processing and the ability to cut complex shapes with greater accuracy. As technology progressed, fiber lasers emerged, providing even greater efficiency, lower operational costs, and the capability to cut a wider array of materials, including highly reflective metals critical for medical devices. This evolution wasn't just about speed; it was about achieving previously unattainable levels of dimensional accuracy, crucial for components that must fit together seamlessly or function flawlessly within the human body. The shift was driven by increasing regulatory demands, such as ISO 13485 for medical devices, which mandate stringent quality and precision standards that only advanced technologies like laser cutting could consistently meet.

Impact on Design and Material Innovation

The advent of laser tube cutting profoundly liberated product designers in the medical and fitness fields. Previously, designs were often constrained by manufacturing limitations; if a complex geometry couldn't be efficiently produced, it was simply abandoned. Laser technology shattered these barriers, allowing for the creation of intricate, lightweight, and ergonomically superior designs. For instance, the ability to cut complex slots, holes, and contours on tubes meant that fitness equipment could be designed not just for strength but also for optimal user comfort and aesthetics. Similarly, in the medical sector, miniaturization became more feasible, with laser cutters crafting incredibly small and precise components for surgical instruments, catheters, and even implants, where internal features and smooth finishes are paramount.

The versatility of laser tube cutting also enabled the widespread adoption of specialized materials. While traditional methods struggled with materials like titanium, medical-grade stainless steel, and various aluminum alloys—chosen for their strength-to-weight ratio, biocompatibility, or corrosion resistance—laser technology handles them with ease. My company, MZBNL, has spent 25 years perfecting our machines to process these challenging materials efficiently, ensuring clean, precise cuts without compromising material integrity. This capability has been instrumental in the development of cutting-edge medical devices that require materials capable of enduring harsh environments, or fitness equipment designed for extreme loads. Furthermore, innovations like our Zero-Waste Tail Material system directly address material efficiency, ensuring that costly specialized alloys are utilized to their maximum potential, a significant benefit for manufacturers conscious of both cost and environmental impact.

Cost-Benefit Analysis and Market Adoption

The transition to laser tube cutting in medical and fitness equipment manufacturing is largely justified by a compelling cost-benefit analysis. While the initial investment in a high-quality laser tube cutting machine can be significant, the long-term returns in terms of reduced labor, lower material waste, and faster production cycles are substantial. For businesses like Ahmed Al-Farsi's, which seeks automated solutions to upgrade production efficiency, the ROI of a laser tube cutting machine quickly becomes evident. By automating previously manual workflows, he could not only reduce operator turnover but also significantly increase output with consistent quality.

Consider a comparison between traditional and laser tube cutting methods:

| Feature | Traditional Cutting (Sawing, Drilling) | Laser Tube Cutting (MZBNL) |

|---|---|---|

| Precision | Moderate, often requires deburring | High, clean edges |

| Speed | Slow, sequential operations | Fast, integrated processes |

| Material Waste | High, especially with complex shapes | Low/Zero (BNL's Zero-Waste) |

| Design Complexity | Limited, difficult for intricate cuts | High, supports complex geometries |

| Skill Req. | High (CAD, manual setup) | Lower (BNL's No-CAD) |

| Post-Processing | Extensive (deburring, cleaning) | Minimal |

| Automation | Low | High (BNL's Front-Feeding) |

This table clearly illustrates the efficiency gains. For example, MZBNL's No-CAD Operating System dramatically lowers the skill threshold, allowing operators to be trained in just 1 day instead of 15 days, directly addressing Ahmed’s pain point regarding operator training. This translates into quicker deployment and reduced labor costs. Globally, the adoption of laser tube cutting continues to accelerate, driven by the persistent demand for higher quality, faster time-to-market, and greater cost-effectiveness in both the medical and fitness sectors. Manufacturers are increasingly recognizing that investing in such technology is not just about upgrading machinery, but about future-proofing their production capabilities and gaining a competitive edge in a demanding market.

Laser cutting enables complex designsTrue

Laser tube cutting technology allows for intricate geometries that were impossible with traditional mechanical cutting methods, liberating product designers in medical and fitness equipment manufacturing.

Traditional methods are more preciseFalse

Laser cutting actually provides superior precision compared to traditional methods like sawing or drilling, which often left burrs and material deformation that compromised component quality.

How is laser tube cutting currently utilized in the production of medical and fitness equipment?

Are you curious about the real-world applications of laser tube cutting in advanced manufacturing? The medical and fitness industries demand components with uncompromising precision and strength. This technology isn't just a trend; it's a fundamental tool that crafts intricate parts with unmatched efficiency.

Currently, laser tube cutting is widely utilized for fabricating precise and complex tubular components for medical instruments, implants, and structural frames for fitness equipment. Its applications range from creating micro-scale features on surgical tools to producing robust, aesthetically pleasing large-diameter parts with integrated punching capabilities.

The versatility of laser tube cutting has made it an indispensable tool across a broad spectrum of manufacturing applications within the medical and fitness sectors. From the minute, delicate tubes found in surgical instruments to the robust, load-bearing structures of professional gym equipment, the technology’s ability to deliver consistent precision across various material types and tube dimensions is unparalleled. It allows for the integration of multiple processes—cutting, punching, and even marking—into a single operation, significantly streamlining production workflows. This multi-faceted capability is precisely what appeals to clients like Ahmed Al-Farsi3, who are constantly seeking turnkey solutions that simplify operations and enhance output for their diverse fabrication needs, whether it’s for architectural metalwork or, hypothetically, medical equipment frames. The precise nature of laser cutting ensures that components fit perfectly, reducing assembly time and enhancing the overall quality and safety of the final product.

Applications in Medical Devices

In the medical device industry, precision is not just a preference; it is a regulatory and functional imperative. Laser tube cutting is essential for creating components where dimensional accuracy, surface finish, and material integrity are critical. Surgical instruments, for example, often require intricate cuts on small-diameter tubes for cannulas, endoscopes, and laparoscopic tools. My company's laser tube cutting machines can perform these delicate operations, ensuring burr-free edges that minimize post-processing and meet stringent hygiene standards. Furthermore, implants, such as orthopedic pins, dental frameworks, or cardiovascular stents, demand biocompatible materials like titanium and medical-grade stainless steel to be cut with extreme precision, often involving complex geometries and internal features. The laser's non-contact cutting method prevents material deformation and contamination, crucial for devices that will be permanently integrated into the human body. This capability also extends to diagnostic equipment frames and laboratory apparatus, where precise tube joining and structural integrity are vital for reliable performance.

For instance, consider the challenges in producing a complex, multi-channel surgical trocar. Traditional methods would struggle with the internal channels and precise tip geometries, leading to extensive manual finishing and potential quality inconsistencies. With a laser tube cutter, the entire component can be precisely cut from a single tube, creating all necessary openings and features in one highly accurate pass. This level of detail and consistency is unattainable with conventional methods, highlighting why laser tube cutting has become the gold standard for high-value, life-critical medical applications. We've seen clients significantly reduce their rejection rates and accelerate their product development cycles by leveraging the unparalleled precision offered by our laser solutions.

Applications in Fitness Equipment

The fitness equipment sector, while perhaps less about microscopic precision, heavily relies on robust, durable, and ergonomically sound designs. Here, laser tube cutting is primarily utilized for fabricating frames and structural components for machines like treadmills, ellipticals, weight benches, and strength training equipment. These applications typically involve larger diameter tubes made from high-strength steel or aluminum alloys. The key benefits here are the ability to create precise interlocking joints, complex bends, and aesthetically pleasing designs that enhance both the functionality and market appeal of the equipment. Accurate cutting ensures that parts fit together seamlessly, reducing assembly time and eliminating the need for extensive welding, which can deform material and add weight.

For example, a modern elliptical machine might feature a curvilinear frame designed for optimal biomechanics and a sleek appearance. Achieving these complex tube shapes with traditional sawing and drilling would be extremely challenging, labor-intensive, and prone to error. Laser tube cutting, however, allows for intricate profiling and piercing along the tube's length, enabling designers to create innovative and visually striking products that stand out in a competitive market. Furthermore, MZBNL's Automatic Punching & Cutting Integrated Machine4 offers a significant advantage by combining two processes into one, allowing manufacturers to cut the tube to length and punch all necessary holes for bolt attachments or cable routing in a single, automated cycle. This multi-process integration is a game-changer for high-volume production, ensuring both speed and accuracy for every frame.

Process Integration and Efficiency Gains

One of the most significant advantages of laser tube cutting in both medical and fitness equipment production is its capacity for seamless process integration and the resulting efficiency gains. Modern laser tube cutters are not just cutting machines; they are often integrated systems capable of automated material feeding, sorting, and even secondary operations. My company’s Front-Feeding Innovation5, for example, increases feeding efficiency by about 40% and reduces operator labor intensity by approximately 40%, showcasing how intelligent automation directly impacts productivity. This automated handling, coupled with the laser's speed, significantly reduces the overall lead time from raw material to finished component.

For a mid-sized metal fabrication business like Ahmed Al-Farsi's, the appeal of such a "turnkey solution" is immense. He explicitly seeks machines that are easy to install and operate, value a high cost-performance ratio, and expect customization with post-sales training. Our integrated systems provide precisely this. By reducing manual intervention and combining multiple steps, manufacturers can achieve significantly higher throughput and consistent quality, which is crucial for meeting tight production deadlines and maintaining product consistency. Furthermore, the precise nature of laser cutting minimizes rework and material waste, especially when combined with features like our Zero-Waste Tail Material Innovation, which maximizes material utilization. This holistic approach to manufacturing means that a single machine can perform multiple tasks with unparalleled accuracy, contributing to a leaner, more efficient production line and ultimately, a more profitable operation for our clients.

Laser cutting ensures burr-free edgesTrue

The non-contact nature of laser tube cutting produces clean cuts without burrs, which is critical for medical devices requiring high hygiene standards.

Traditional methods are more preciseFalse

Laser tube cutting achieves superior precision for complex geometries compared to conventional sawing/drilling methods, especially for internal features.

What challenges do manufacturers face when using laser tube cutters in this sector?

Embracing cutting-edge technology like laser tube cutting can be transformative, but it's not without its hurdles. Manufacturers often encounter specific challenges that can impede efficiency and ROI. Understanding these obstacles is the first step toward optimizing your operations and maximizing the benefits.

Manufacturers utilizing laser tube cutters in the medical and fitness sectors often face challenges related to high initial investment, operator training for complex software, precise material handling for diverse alloys, and stringent regulatory compliance. Overcoming these requires strategic planning and robust supplier support.

While the benefits of laser tube cutting in medical and fitness equipment manufacturing are undeniable, implementing this advanced technology often comes with its own set of unique challenges. Manufacturers, especially those transitioning from more traditional methods, must navigate complexities ranging from the initial capital outlay to the intricacies of operator training and the stringent demands of quality control. For a client like Ahmed Al-Farsi, whose business is stable but planning to automate existing manual workflows, these pain points—such as the need for skilled CAD operators6 and equipment lacking local service support—are very real. My company, MZBNL, understands these concerns deeply, which is why we’ve focused our innovations on directly addressing these common industry hurdles, ensuring that our solutions don't just cut metal, but also cut down on operational headaches. It's about empowering businesses to fully leverage the power of laser technology without being bogged down by its inherent complexities.

Technical and Operational Complexities

One of the primary challenges manufacturers face when adopting laser tube cutters is managing the technical and operational complexities. While modern machines are increasingly user-friendly, they still represent sophisticated pieces of technology that require proper setup, programming, and maintenance. Historically, this meant a steep learning curve for operators, particularly those transitioning from manual or less automated equipment. Many systems required extensive knowledge of CAD software for creating or modifying complex 3D drawings7, a significant bottleneck that Ahmed Al-Farsi himself pointed out as a major pain point—the need for skilled CAD operators and the burden of retraining due to high turnover. This challenge isn't just about initial training; it also extends to troubleshooting, optimizing cutting parameters for different materials and thicknesses, and performing routine maintenance to ensure peak performance and longevity.

However, MZBNL has directly addressed this with our pioneering No-CAD Operating System. This innovation dramatically simplifies the process, allowing operators to process standard tube types and hole patterns simply by entering parameters—no complex drawing required. This reduces on-site training from a typical 15 days at the equipment factory down to just 1 day. This ease of use significantly lowers the skill threshold and retraining burdens, making it much more accessible for businesses like Ahmed's to integrate advanced automation. Furthermore, ensuring consistent output and avoiding costly errors demands a comprehensive understanding of the machine's capabilities and limitations, which necessitates ongoing technical support and responsive after-sales service, a key preference for Ahmed and many other global clients.

Material and Design Specifics

The medical and fitness equipment sectors demand versatility in material processing, which presents another set of challenges for laser tube cutting. Manufacturers often work with a diverse range of materials, from various grades of stainless steel and aluminum alloys to more exotic and reflective materials like titanium, often with varying wall thicknesses. Each material reacts differently to the laser beam, requiring specific power settings, cutting speeds, and gas pressures to achieve clean, burr-free cuts without compromising material integrity. For medical devices, achieving a perfect, sterile-grade finish is paramount, while for fitness equipment, maintaining structural strength in high-stress areas is critical. Cutting very thin-walled tubes for surgical instruments or exceptionally thick tubes for heavy-duty gym frames each presents unique technical hurdles in terms of laser stability and beam focus.

Moreover, the intricate and often custom designs in both industries add another layer of complexity. Creating precise interlocking joints for a fitness machine frame or micro-features on a medical implant requires advanced programming and precise machine movement. Any slight deviation can lead to material waste and product failure. The challenge lies in optimizing cutting paths to minimize material consumption—especially for expensive, medical-grade alloys—while ensuring dimensional accuracy and edge quality. This requires sophisticated software capabilities and precise machine calibration. Our Zero-Waste Tail Material Innovation, which calculates from the rear chuck as the origin to eliminate leftover tail material, directly addresses the challenge of material optimization, helping clients achieve maximum utilization and significant cost savings, particularly8 when working with high-value materials.

Cost and Regulatory Compliance Hurdles

The initial investment in a high-precision laser tube cutting machine can be substantial, posing a significant financial hurdle for many manufacturers, particularly mid-sized businesses like Ahmed Al-Farsi’s. Justifying this capital expenditure requires a clear understanding of the return on investment (ROI) through increased efficiency, reduced labor costs, and enhanced product quality. Beyond the purchase price, there are also operational costs, including consumables (like gases and nozzles), electricity, and ongoing maintenance. For companies based in regions like the UAE, which may consider local agent or distributor presence a key sourcing point, ensuring reliable local service and spare parts availability is crucial for long-term cost-effectiveness.

Furthermore, both the medical and fitness equipment industries are subject to rigorous regulatory compliance. Medical devices must adhere to strict standards such as FDA regulations (in the US), CE marking (in Europe), and ISO 13485, which govern quality management systems. Fitness equipment also has safety and performance standards (e.g., ASTM, EN standards). Laser cutting processes must be validated to ensure consistent quality, traceability, and adherence to these standards. This involves meticulous documentation, process control, and validation protocols to prove that the manufacturing process consistently yields compliant products. Any machine downtime or inconsistency can directly impact compliance and market access. MZBNL's commitment to delivering high-performance, precise, and reliable machines, backed by our global distributor networks and responsive after-sales support, directly alleviates many of these financial and regulatory concerns, providing a more secure and predictable operational environment for our clients.

Laser cutters require CAD expertiseTrue

Traditional laser tube cutters often require skilled CAD operators for programming complex cuts, creating a significant training burden.

All materials cut the same wayFalse

Different materials like stainless steel, aluminum and titanium require unique laser settings for optimal cutting results.

What strategies can optimize the use of laser tube cutters in this industry?

Do you want to unlock the full potential of your laser tube cutter? Simply owning the technology isn't enough; maximizing its impact requires smart, strategic approaches. Implementing advanced techniques is key to boosting efficiency, reducing waste, and maintaining a competitive edge.

Optimizing laser tube cutter utilization in medical and fitness manufacturing involves implementing automated material handling, adopting user-friendly software like No-CAD Operating System, leveraging predictive maintenance, and emphasizing continuous operator training. These strategies enhance throughput, minimize waste, and improve overall operational agility and cost-effectiveness.

Having invested in a state-of-the-art laser tube cutting machine, the next crucial step is ensuring its optimal utilization to truly realize its full potential. My company, MZBNL, frequently guides our clients on implementing strategies that go beyond basic operation, transforming their production lines into highly efficient, intelligent systems. For example, a client like Ahmed Al-Farsi, who values high cost-performance and seeks customization, would greatly benefit from these strategies. It’s not just about cutting tubes; it’s about creating a seamless workflow that minimizes downtime, maximizes material yield, and empowers operators. From integrating smart systems to fostering strong supplier partnerships, these approaches collectively contribute to superior product quality, reduced operational costs, and a significant boost in production capacity, allowing manufacturers to respond rapidly to market demands and maintain their competitive edge.

Embracing Automation and Smart Systems

Optimizing the use of laser tube cutters heavily relies on integrating advanced automation and smart systems into the manufacturing process. Manual material loading and unloading can be time-consuming and labor-intensive, particularly for long or heavy tubes commonly used in fitness equipment, or delicate, small-diameter tubes for medical devices. This is a challenge that my company, MZBNL, directly addresses with our innovative Front-Feeding mechanism. This optimized design automatically pulls the tube in from the front, increasing feeding efficiency by approximately 40% and reducing operator labor intensity by about 40%. This not only speeds up the production cycle but also significantly enhances workplace ergonomics, alleviating a common pain point for manufacturers struggling with labor intensity and seeking automated solutions9 like Ahmed Al-Farsi.

Beyond material handling, integrating laser tube cutters with Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) systems allows for streamlined production planning, real-time monitoring, and data-driven decision-making. Smart sensors on the machines can track key performance indicators (KPIs) like cutting speed, material consumption, and machine uptime, providing valuable insights for continuous improvement. This level of connectivity enables manufacturers to optimize production schedules, predict maintenance needs, and manage inventory more effectively. For example, a manufacturer can use real-time data to identify bottlenecks, reallocate resources, or even adjust designs on the fly to improve efficiency, ensuring that every minute of machine operation contributes maximally to output. Such automation transforms a high-tech machine into a truly intelligent production asset.

Skill Development and User-Friendly Interfaces

A significant barrier to the optimal use of laser tube cutters has traditionally been the high skill requirement for operators, particularly in programming complex cuts. As Ahmed Al-Farsi noted, the need for skilled CAD operators and the associated retraining burdens due to high turnover can severely impact a business's operational efficiency. To counter this, a key optimization strategy is to invest in user-friendly interfaces and robust operator training programs that reduce reliance on highly specialized CAD knowledge. My company, MZBNL, pioneered and perfected a No-CAD Operating System10 for laser tube cutting machines specifically to address this.

With our No-CAD system, standard tube types and hole patterns can be processed simply by entering parameters—no complex 3D drawing required. This innovation dramatically improves ease of use, shortens setup time, and lowers the skill threshold for machine operation, allowing operators to achieve proficiency in just 1 day of on-site training instead of spending 15 days at the equipment factory. This not only accelerates machine deployment but also empowers existing staff to operate advanced equipment, significantly reducing labor costs and training overheads. Furthermore, fostering a culture of continuous learning through regular workshops and offering remote diagnostics and support, as MZBNL does, ensures that operators can troubleshoot minor issues and leverage advanced features, maximizing machine uptime and maintaining consistent product quality. This focus on simplifying complex operations allows manufacturers to fully utilize their laser tube cutters without being limited by their workforce's prior technical expertise.

Material Optimization and Waste Reduction

Material costs, particularly for high-grade stainless steel, titanium, and aluminum alloys used in medical and fitness equipment, constitute a significant portion of production expenses. Therefore, a crucial optimization strategy for laser tube cutting involves maximizing material utilization and minimizing waste. This can be achieved through advanced nesting software that intelligently arranges multiple parts on a single tube to reduce scrap. However, even with the best nesting, conventional laser cutting systems typically generate unusable tail material at the end of the process, which can accumulate into substantial waste over time.

This specific problem is where MZBNL's Zero-Waste Tail Material Innovation11 provides a groundbreaking solution. We redesigned the cutting logic to calculate from the rear chuck as the origin, allowing the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This "zero-tail" design directly maximizes material utilization and significantly boosts cutting efficiency, leading to substantial cost savings, especially when dealing with expensive medical-grade tubing. For a manufacturer like Ahmed, who prioritizes cost-performance ratio, such an innovation directly impacts the bottom line. By reducing material waste, businesses not only cut costs but also contribute to more sustainable manufacturing practices. Furthermore, precise cutting reduces the need for extensive post-processing like deburring or grinding, which further saves labor, time, and reduces the likelihood of damaging valuable parts, ensuring that every cut tube is a high-quality, usable component ready for the next stage of assembly.

Automation boosts efficiencyTrue

Front-Feeding mechanisms and MES integration improve productivity by 40% while reducing labor intensity.

CAD skills remain essentialFalse

No-CAD systems enable operators to achieve proficiency in 1 day without 3D drawing knowledge.

What technological advancements are enhancing laser tube cutting for medical and fitness equipment?

Are you curious about the cutting edge of metal fabrication? The medical and fitness equipment industries continually demand more from their manufacturing processes. Emerging technological advancements in laser tube cutting are not just incremental improvements; they are fundamentally redefining what's possible, driving unparalleled precision and efficiency.

Technological advancements in laser tube cutting are enhancing capabilities through more powerful fiber lasers, integrated multi-process functions, AI-driven intelligent controls, and advanced automation. These innovations deliver superior precision, increased speed, and greater material versatility, crucial for evolving medical device and fitness equipment production needs.

The landscape of laser tube cutting is continually evolving, driven by relentless innovation and the specific, exacting demands of sectors like medical and fitness equipment. What was considered state-of-the-art five years ago might now be a standard feature, and what’s new today promises to redefine tomorrow's manufacturing capabilities. My company, MZBNL, prides itself on being at the forefront of this evolution, investing heavily in R&D to deliver the "three major innovations" that lead the industry: No-CAD System, Front-Feeding, and Zero-Waste Tail Material. These aren't just buzzwords; they are tangible advancements that directly translate into greater efficiency, precision, and cost-effectiveness for our clients worldwide, including those in the medical and fitness fields. These advancements are crucial for manufacturers aiming to push the boundaries of design and production efficiency.

Next-Generation Laser Sources and Optics

The core of any laser cutting machine is its laser source, and significant advancements in this area are continuously enhancing the capabilities of tube cutters for medical and fitness applications. The transition from traditional CO2 lasers to more powerful, efficient, and versatile fiber lasers has been a game-changer. Fiber lasers offer superior beam quality, which translates to finer cuts, smaller kerf widths, and smoother edges—all critical for applications requiring high precision like surgical instruments or delicate medical implants. Their higher energy efficiency also reduces operational costs, a direct benefit for manufacturers seeking high cost-performance ratios like Ahmed Al-Farsi.

Furthermore, advancements in laser power output mean that even thicker or more challenging materials, such as heavy-gauge steel for robust fitness equipment or highly reflective copper and brass alloys for certain medical components, can be cut with increased speed and accuracy. The development of specialized optics, including intelligent beam shaping and focusing technologies, allows for greater control over the cutting process. This enables manufacturers to optimize the cut quality for different materials and thicknesses, preventing heat-affected zones (HAZ) and material distortion, which are crucial concerns for maintaining the structural integrity of fitness frames and the biocompatibility of medical parts. These combined innovations in laser sources and optics ensure that today's laser tube cutters are more capable, faster, and more precise than ever before, pushing the boundaries of what can be fabricated from tubular materials.

Integrated Multi-Process and Automation Solutions

The trend in advanced manufacturing is towards integrated solutions that combine multiple processes into a single, seamless operation, and laser tube cutting is no exception. My company, MZBNL, champions this approach with products like our Automatic Punching & Cutting Integrated Machine. This machine allows manufacturers to perform both precise laser cutting and efficient punching operations on tubes within one system, eliminating the need for separate machines and multiple handling steps. This multi-process integration significantly reduces setup times, minimizes material handling, and enhances overall throughput, moving closer to the ideal of "lights-out" manufacturing.

For example, a fitness equipment manufacturer can now cut a tube to length, punch all necessary holes for assembly, and even engrave part numbers—all in one automated cycle. This level of integration is highly appealing to clients like Ahmed Al-Farsi, who prefers turnkey solutions that are easy to install and operate, as it simplifies their production line, reduces labor requirements, and lowers the potential for human error. In the medical sector, this means creating complex tubular parts with integrated features for attachment or fluid flow in a single, high-precision operation. Beyond punching, future integrations may include automated deburring, bending, or even in-line quality inspection, further streamlining the manufacturing process and ensuring that finished parts meet the most stringent specifications with minimal manual intervention. This holistic approach to automation is key to unlocking new levels of efficiency and quality.

Smart Systems, AI, and IoT Integration

The future of laser tube cutting, particularly for the demanding medical and fitness equipment industries, is increasingly intertwined with smart systems, Artificial Intelligence (AI), and the Internet of Things (IoT). These technologies are transforming machines from mere tools into intelligent, self-optimizing manufacturing assets. AI algorithms can analyze real-time data from the cutting process, automatically adjusting parameters like laser power, cutting speed, and gas pressure to optimize cut quality and efficiency, even for challenging materials or complex geometries. This intelligent control minimizes human intervention and ensures consistent, high-precision results, which is vital for the exacting standards of medical devices.

Furthermore, IoT integration allows for remote monitoring, predictive maintenance, and real-time diagnostics. Machines can communicate their status, alert operators to potential issues before they cause downtime, and even allow for remote troubleshooting by manufacturers like MZBNL. This capability is highly valued by global clients like Ahmed Al-Farsi, who explicitly mentions "remote diagnostics" and "after-sales service and training support" as key sourcing points. Imagine a medical equipment manufacturer in a remote location: instead of waiting for a technician to travel, MZBNL could potentially diagnose and assist with a machine issue remotely, significantly reducing costly downtime and ensuring continuous production. Data collected from these smart systems can also be used for long-term trend analysis, enabling manufacturers to refine their processes, predict material needs, and continuously improve their overall operational efficiency, leading to higher quality products and more sustainable manufacturing practices within the framework of Industry 4.0.

Laser cutting ensures material integrityTrue

Laser tube cutting preserves the structural properties of materials during fabrication, which is critical for medical/fitness equipment safety.

Traditional methods match laser precisionFalse

Conventional cutting techniques cannot achieve the micron-level accuracy or complex geometries possible with laser tube cutting technology.

Conclusion

Laser tube cutting is indispensable for precision and efficiency in medical and fitness equipment manufacturing. MZBNL's innovations, including the No-CAD system, Front-Feeding, and Zero-Waste Tail Material, directly address industry pain points. This ensures manufacturers achieve superior quality, cost-effectiveness, and operational excellence in these critical and evolving sectors.

-

Learn about manufacturing solutions that transcend basic cutting techniques to solve production challenges ↩

-

Learn how CO2 laser technology enhances cutting accuracy ↩

-

Learn about real-world applications of laser tube cutting in diverse industries. ↩

-

Understand the advantages of process integration in manufacturing high-quality fitness equipment. ↩

-

Learn about the technological innovations that boost productivity in tube cutting operations. ↩

-

Discover the importance and benefits of skilled CAD operators in laser cutting industries ↩

-

Explore commonly used CAD software solutions in laser tube cutting applications ↩

-

Understand how zero-waste technology enhances efficiency and reduces material costs in laser cutting ↩

-

Learn about the system that simplifies laser tube cutting by eliminating CAD requirement ↩

-

Discover automated systems that enhance feeding efficiency in laser tube cutting ↩

-

Explore how zero-tail design maximizes material use and efficiency in cutting operations ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.