What Are the Latest Innovations in Laser Tube Cutting Technology?

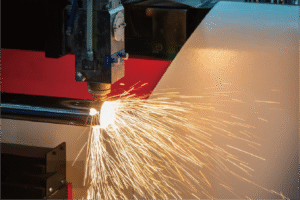

Are you finding that your current metal tube processing methods are becoming a bottleneck, struggling to keep up with demand for complex designs and faster turnarounds? The frustration of material waste, high labor costs for skilled operators, and lengthy setup times can significantly impact your bottom line. At MZBNL, we've seen how these challenges can stifle growth, which is why exploring the latest innovations in laser tube cutting is no longer a luxury, but a necessity for staying competitive.

The latest innovations in laser tube cutting technology center around enhancing automation, operational simplicity, and material efficiency. Key advancements include No-CAD operating systems that eliminate complex drawing requirements, automated front-feeding mechanisms for improved productivity, and zero-waste tail material solutions to maximize material utilization and reduce costs significantly.

As someone who has spent 25 years in the metal fabrication industry, I've witnessed a remarkable transformation in how we approach tube cutting. The journey from manual, labor-intensive processes to sophisticated, automated solutions has been incredible. These advancements aren't just about faster machines; they're about fundamentally changing the way businesses like yours operate, making high-precision, complex tube fabrication accessible and more profitable.

The drive for innovation in laser tube cutting stems from a clear market need: businesses, especially those like Ahmed Al-Farsi's mid-sized fabrication company in the UAE, are constantly seeking ways to upgrade production efficiency and tackle skilled labor shortages. Traditional methods often require highly skilled CAD operators, leading to bottlenecks when such talent is scarce or staff turnover is high. Furthermore, material waste, particularly from unusable tail material, directly erodes profits. As an industry, we've recognized these pain points, and at MZBNL, we've focused our R&D on creating solutions that directly address them, aiming for higher automation, easier operation, and superior material yield. This pursuit has led to breakthroughs that are reshaping expectations for what laser tube cutting machines can achieve.

What is the current landscape of laser tube cutting technology?

Is your business grappling with the complexities of modern metal fabrication, unsure if your current tube cutting technology can meet evolving market demands for precision and speed? You might be experiencing inefficiencies due to outdated machinery or a lack of awareness about the capabilities of newer systems. This situation can lead to lost opportunities and reduced competitiveness. Understanding the current landscape is the first step towards making informed decisions for your operations.

The current landscape of laser tube cutting technology is characterized by the widespread adoption of fiber lasers, advanced CNC controls for high precision, and increasing levels of automation. Machines now handle diverse tube profiles and materials, with software playing a crucial role in design, optimization, and machine operation.

The world of laser tube cutting today is a dynamic and rapidly evolving space. We're seeing a significant shift towards more intelligent, integrated, and user-friendly systems. From small workshops to large-scale industrial operations, businesses are leveraging this technology to produce everything from intricate components for medical devices to robust structural elements for architectural projects. The emphasis is increasingly on solutions that not only deliver superior cutting quality but also streamline the entire production workflow, from design input to finished part. I've seen firsthand how companies that embrace these modern capabilities can significantly enhance their output and market responsiveness.

The current landscape of laser tube cutting technology is a testament to decades of innovation, driven by the increasing demand for complex tube components across various industries. At its core, this technology utilizes a focused laser beam, most commonly a fiber laser source1 today, to melt and cut through metal tubes with exceptional precision and speed. These machines are no longer simple cutting tools; they are sophisticated systems integrated with advanced Computer Numerical Control (CNC) and Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) software. This integration allows for the processing of a wide array of tube shapes – round, square, rectangular, oval, and even custom profiles – and materials, including steel, stainless steel, aluminum, brass, and copper. The ability to perform multiple operations in a single setup, such as cutting, beveling, and marking, further enhances their value. We at MZBNL have focused on pushing these boundaries, particularly in ease of use and material efficiency, which we see as critical differentiators in today's competitive market. The landscape is also marked by a growing trend towards automation, not just in the cutting process itself but also in material handling, with automatic bundle loaders and unloaders becoming increasingly standard features, especially for high-volume production. This automation addresses both labor shortages and the need for continuous, efficient operation, something our client Ahmed in the UAE specifically looks for.

Key Technological Components in Modern Laser Tube Cutters

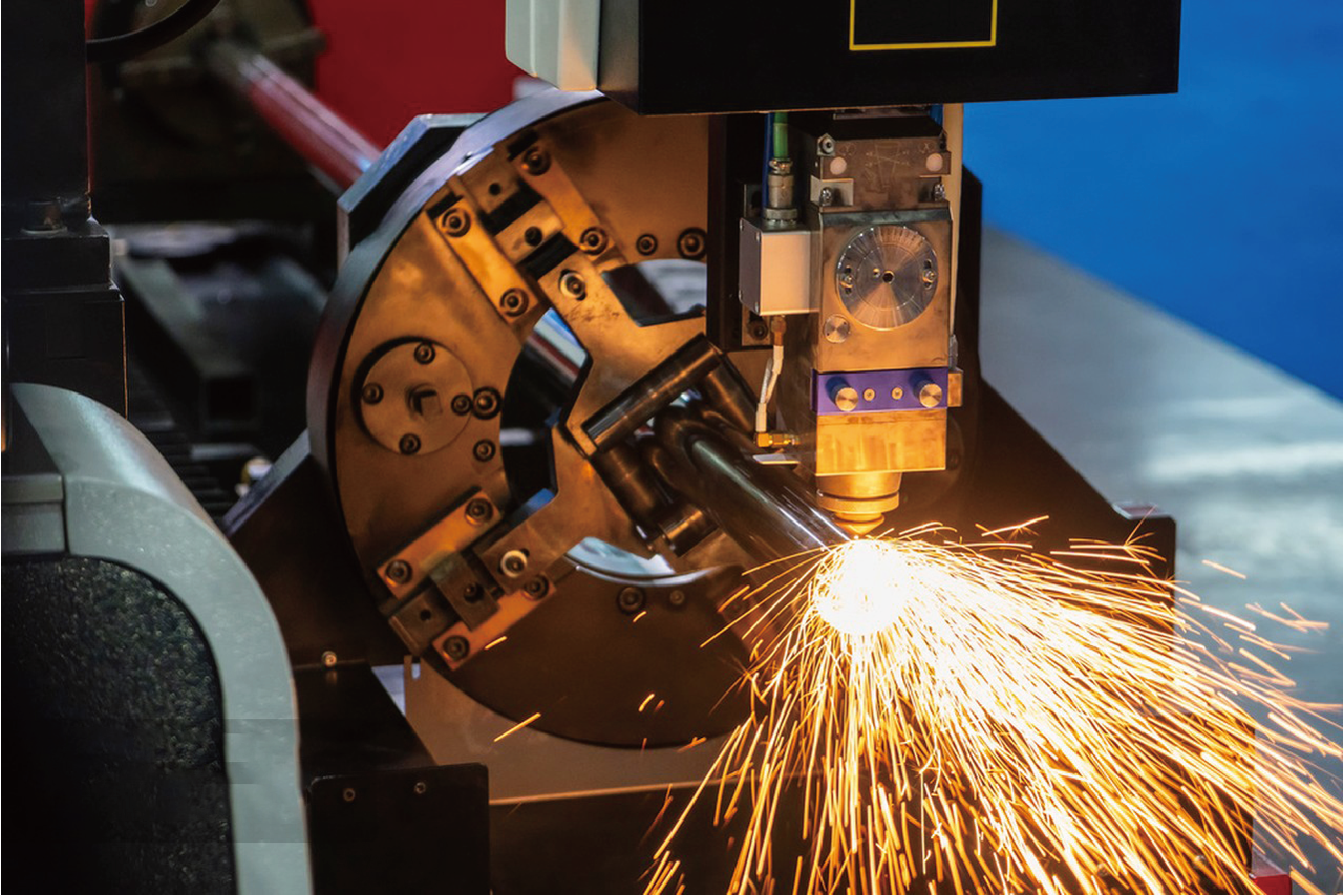

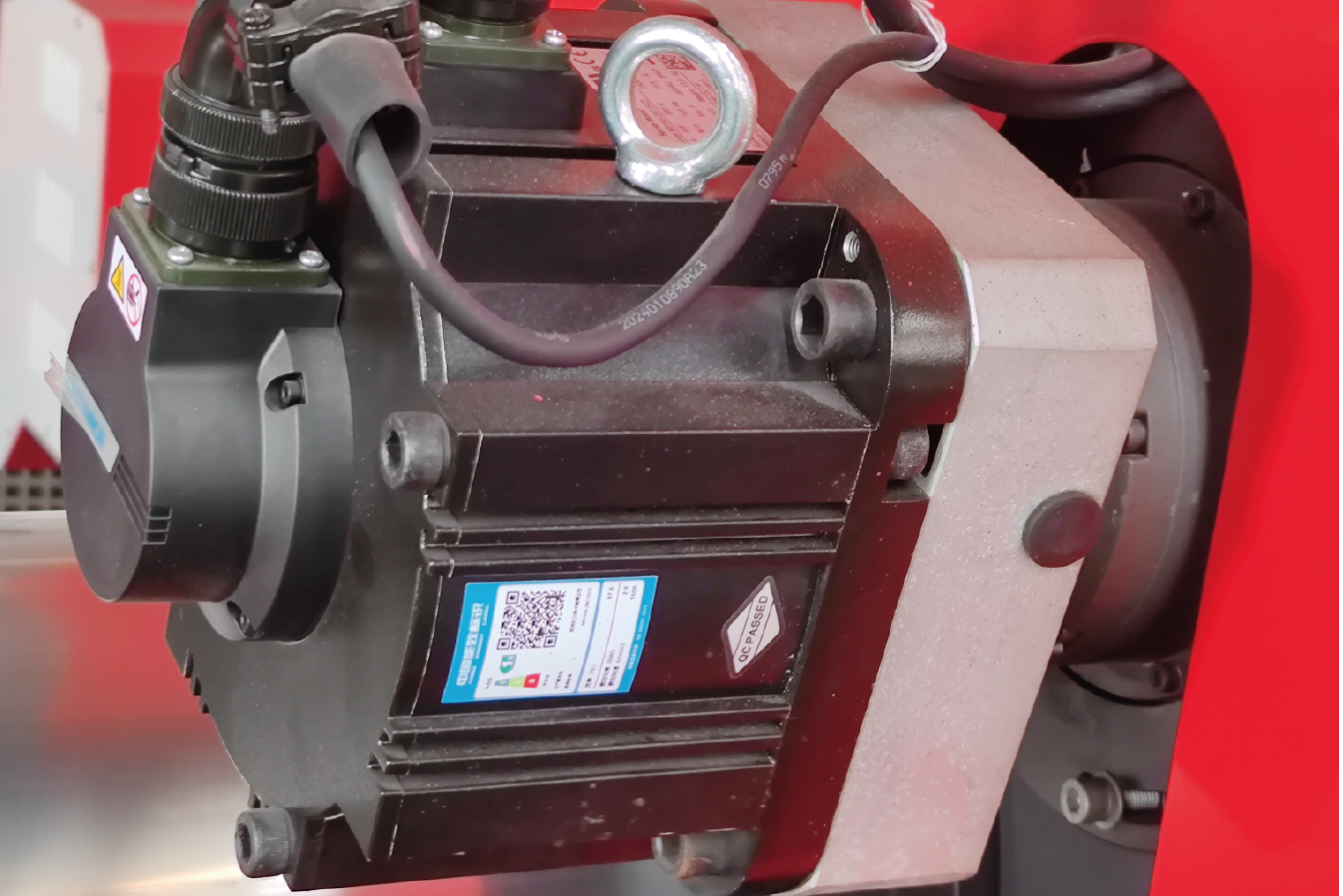

Modern laser tube cutting machines are complex systems, but their core effectiveness hinges on a few key technological components working in harmony. The laser source itself is paramount. While CO2 lasers were once common, fiber lasers now dominate the market for tube cutting due to their higher efficiency, lower maintenance requirements, and superior ability to cut reflective materials like brass and copper. At MZBNL, we've standardized on high-quality fiber laser sources that offer power ranges suitable for a variety of tube thicknesses and materials, typically from 1kW to 6kW or even higher for very demanding applications, ensuring both speed and precision. For instance, a 3kW fiber laser can efficiently cut stainless steel tubes up to 10mm thick, offering a balance of capability and operational cost.

The CNC (Computer Numerical Control) system2 is the brain of the machine, translating digital designs into precise physical movements of the cutting head and the tube. Advanced CNC controllers in today's machines, like those we integrate into our BNL series, support multi-axis operation (often 5-axis or more) enabling complex cuts, including bevels and intricate profiles, with accuracies often within ±0.05mm. This level of precision is critical for industries like automotive parts manufacturing or medical equipment, where tolerances are extremely tight. The sophistication of the CNC also dictates the machine's ability to implement smart features, such as automatic seam detection or collision avoidance, further enhancing reliability and ease of use.

Finally, material handling systems play a crucial role in overall productivity, especially in high-volume settings. These range from semi-automatic loaders to fully automated bundle loading systems that can feed tubes of varying lengths and profiles without manual intervention, and unloading systems that sort finished parts. Our Front-Feeding innovation at MZBNL is a specific enhancement in this area, designed to improve loading efficiency by approximately 40%. Efficient material handling minimizes machine idle time and reduces operator workload, directly impacting the output and cost-effectiveness of the laser cutting operation. This is a key consideration for clients like Ahmed, who prioritize automated solutions to upgrade production efficiency.

Common Applications and Industry Adoption Rates

Laser tube cutting technology has found indispensable applications across a multitude of industries, driven by its ability to produce complex, precise parts quickly and cost-effectively. The automotive sector is a major adopter, utilizing laser-cut tubes for chassis components, exhaust systems, roll cages, and various structural elements. The precision of laser cutting ensures perfect fit-up for subsequent welding and assembly processes, which is critical in automotive manufacturing. Industry reports, such as those from Grand View Research, project continued growth in the laser cutting market, with the automotive segment being a significant contributor, often seeing adoption rates for advanced manufacturing technologies like laser cutting grow by 5-7% annually in developing automotive hubs.

In the furniture and architectural sectors, laser tube cutting allows for creative designs and strong, lightweight frames for chairs, tables, shelving units, and intricate architectural metalwork like railings and facades. For example, a furniture manufacturer client of ours in Europe transitioned to our BNL laser tube cutters and reported a 30% reduction in production time for complex frame designs. Construction also benefits, with laser-cut structural tubes being used in everything from prefabricated buildings to custom support structures. The ability to cut complex joints and connections directly into the tubes simplifies assembly and improves structural integrity.

Other significant applications include the manufacturing of fitness equipment, where complex bent and cut tubes form the backbone of machines, and medical devices, which often require very precise and clean cuts on small-diameter tubes made from specialized alloys. Display rack and shelf suppliers, like those Ahmed caters to, also heavily rely on laser tube cutting for producing customized and standard components efficiently. The adoption in these niche but critical sectors is often driven by the need for customization, high precision, and the ability to work with a variety of materials, reflecting the versatility of modern laser tube cutting technology.

The Role of Software in Optimizing Laser Tube Cutting

Software is the unsung hero of modern laser tube cutting, acting as the crucial link between design intent and physical output, and playing a massive role in optimizing the entire process. Advanced CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software is fundamental. Designers create 3D models of the tube assemblies, and the CAM module then translates these designs into machine-specific G-code, defining cutting paths, laser parameters, and handling instructions. Modern CAM software specialized for tube cutting can automatically identify features like holes, slots, and complex end-cuts, and generate optimized toolpaths, significantly reducing programming time compared to manual methods. For instance, what might take hours to program manually can often be done in minutes with sophisticated CAM.

Nesting software3 is another critical component for optimizing material utilization and reducing waste – a significant concern for any fabrication business. For tube cutting, nesting involves arranging multiple parts on a single stock tube length in the most efficient way possible. Advanced nesting algorithms can account for common-line cutting, part rotation, and even the specific characteristics of the tube (like weld seams) to maximize yield. I've seen clients achieve material savings of 5-15% purely through the implementation of intelligent nesting software, which directly impacts their profitability. This is closely related to our Zero-Waste Tail Material innovation, which takes material optimization a step further at the machine level.

Simulation software, often integrated within the CAM package, allows operators to visualize the entire cutting process before it begins. This helps in verifying the cut paths, checking for potential collisions between the cutting head and the tube or chucks, and ensuring the final part will meet specifications. This pre-production verification minimizes errors, reduces costly scrap, and prevents potential machine damage. The evolution of software has been a game-changer, but traditional CAD/CAM systems still require skilled operators. This is precisely the challenge our No-CAD system at MZBNL addresses, by simplifying the input process for standard shapes and reducing the reliance on extensive CAD expertise for everyday operations.

| Feature Comparison | Traditional CAD-Based System | MZBNL No-CAD System |

|---|---|---|

| Operator Skill Level | High (CAD expertise needed) | Low (Parameter entry) |

| Programming Time | Can be lengthy for new parts | Significantly reduced for std. parts |

| Training Time | Typically 10-15 days | As little as 1 day on-site |

| Flexibility for Custom | High | Optimized for standard profiles |

| Efficiency for Std Jobs | Moderate | Very High |

This table offers a glimpse into how different software approaches can impact operations, with systems like our No-CAD aiming to democratize access to advanced laser cutting capabilities.

Automation reduces labor needsTrue

Advanced material handling systems minimize manual intervention, addressing labor shortages.

All tube shapes cut equallyFalse

Different tube profiles (round, square, custom) require specific machine capabilities and programming.

How has laser tube cutting evolved in recent years?

Are you feeling left behind by the rapid advancements in manufacturing technology, particularly if your current laser tube cutting methods are slow and labor-intensive? This can lead to inefficiencies, higher operational costs, and a struggle to meet modern production demands. Recognizing the evolution of this technology is key to unlocking new levels of productivity and precision in your own operations.

Laser tube cutting has evolved dramatically, shifting from CO2 lasers with manual setups to high-speed fiber lasers with advanced automation, intelligent software, and integrated material handling. This evolution has resulted in faster cutting, higher precision, greater material versatility, and significantly improved ease of use.

I recall when laser tube cutting was a niche technology, often complex and requiring significant expertise. The machines were typically slower, and material handling was largely a manual affair. Over the past decade or two, and especially in recent years, the pace of innovation has been astounding. We've moved into an era where speed, precision, and automation are not just desirable but expected. The transition from CO2 to fiber laser sources marked a pivotal moment, bringing unparalleled efficiency and versatility. This, combined with smarter software and more integrated automation, has truly transformed what's possible, making advanced cutting capabilities more accessible to businesses of all sizes, including clients like Ahmed who are keen on upgrading their production.

The evolution of laser tube cutting technology in recent years has been nothing short of transformative, driven by persistent industry demands for greater efficiency, higher precision, reduced operational costs, and the ability to process increasingly complex designs. Looking back even just a decade, the landscape was quite different. CO2 lasers were prevalent, and while capable, they often came with higher maintenance needs, slower cutting speeds on certain materials, and limitations with reflective metals. Automation was present but often less integrated, and the software, while functional, required a higher degree of specialized knowledge for programming and operation. As I've seen at MZBNL, and through interactions with clients like Ahmed who are always looking for the next efficiency gain, the market continuously pushes for more. This push has led to several key evolutionary trends. The most significant is undoubtedly the widespread adoption and continuous improvement of fiber laser technology. Alongside this, advancements in CNC controls have enabled more complex multi-axis cutting and higher traverse speeds. Software has become more intuitive and powerful, incorporating features like automatic nesting, 3D simulation, and even direct parameter-based programming, which is the core of our No-CAD system. Furthermore, material handling has evolved from basic manual loading to sophisticated automated bundle loaders and intelligent unloading/sorting systems, creating a much more streamlined and less labor-intensive workflow.

From CO2 to Fiber Lasers: A Leap in Efficiency and Capability

The journey from CO2 to fiber lasers represents one of the most significant evolutionary leaps in laser tube cutting technology. Early laser cutting systems, including those for tubes, predominantly relied on CO2 laser sources. While effective for many applications, CO2 lasers had inherent limitations. They required complex mirror systems for beam delivery, which needed regular alignment and maintenance. Their energy efficiency was relatively low, and they struggled with cutting highly reflective materials like copper and brass, as the reflected laser light could damage the optics. Cutting speeds, particularly on thinner materials, were also not as high as what is achievable today. I remember the challenges businesses faced with the upkeep and operational costs associated with these older systems.

The advent and subsequent refinement of fiber laser technology revolutionized the field. Fiber lasers generate the laser beam within an optical fiber, which is then delivered directly to the cutting head via another flexible fiber optic cable. This eliminates the need for complex mirror systems, drastically reducing maintenance and improving beam quality and stability. More importantly, fiber lasers offer significantly higher energy efficiency (wall-plug efficiency can be over 30% for fiber compared to around 10% for CO2), leading to lower power consumption and operational costs. Their shorter wavelength (around 1 micron compared to 10.6 microns for CO2) is better absorbed by metals, resulting in faster cutting speeds, especially on thin to medium-thickness materials. For example, when cutting 1mm stainless steel, a fiber laser can be several times faster than a CO2 laser of comparable power.

This shift has had a profound impact on capability. Fiber lasers excel at cutting reflective materials like aluminum, brass, and copper, opening up new applications and design possibilities. The enhanced speed and efficiency have enabled businesses to increase throughput and reduce per-part costs. At MZBNL, our decision to focus exclusively on fiber laser technology for our tube cutters was driven by these clear advantages, allowing us to provide our clients, including those in demanding sectors like automotive and electronics, with machines that offer superior performance and lower long-term ownership costs. The improved beam quality also contributes to finer cut details and narrower kerf widths, enhancing overall precision.

The Rise of Automation: From Manual Loading to Integrated Systems

Another critical evolutionary path in laser tube cutting has been the dramatic rise of automation, transforming what was often a series of disconnected, labor-intensive steps into a streamlined, integrated process. In the early days, loading tubes onto the machine and unloading finished parts were predominantly manual tasks. This not only required significant operator effort but also introduced inconsistencies in cycle times and created bottlenecks in the production flow. An operator might spend a considerable amount of time handling materials rather than overseeing the cutting process or preparing the next job, limiting overall equipment effectiveness.

The first stage of automation involved semi-automatic loading systems, such as hopper feeders or simple cradles, which reduced some of the manual lifting but still required operator intervention. However, the real game-changer has been the development of fully automatic bundle loading systems4. These systems can take a large bundle of raw tubes, automatically select individual tubes, measure their length, orient them correctly (e.g., finding a weld seam), and feed them into the cutting machine without any manual handling. This allows for hours of unattended operation, significantly boosting productivity and enabling "lights-out" manufacturing in some cases. Our MZBNL Front-Feeding innovation, for instance, automates the pulling of the tube from the front, increasing feeding efficiency by about 40% and reducing operator labor intensity. This directly addresses Ahmed's pursuit of automated solutions to upgrade production efficiency.

Beyond loading and unloading, automation is extending to integration with upstream and downstream processes. This includes linking laser tube cutters with punching machines (as in our Automatic Punching & Cutting Integrated Machine), bending cells, welding robots, and automated storage and retrieval systems (ASRS). Such integration creates a fully connected manufacturing ecosystem, minimizing work-in-progress, reducing lead times, and enhancing overall traceability and quality control. This holistic approach to automation is where the industry is heading, moving beyond standalone machines to fully optimized production lines.

Software and Control Systems: The Brains Behind the Evolution

The evolution of laser tube cutting would be incomplete without acknowledging the pivotal role of advancements in software and control systems. These are the "brains" that orchestrate the complex operations of modern machines, translating intricate designs into precisely cut tubes. CNC controllers have become significantly more powerful and sophisticated. Early controllers might have struggled with the complex calculations required for simultaneous multi-axis movements in tube cutting, especially for non-round profiles or bevel cuts. Today's advanced CNCs can process vast amounts of data in real-time, enabling high-speed, high-accuracy contouring and intricate 5-axis (or even 6-axis) cutting5, which is essential for producing complex joints, miters, and weld preparations directly on the tube.

CAD/CAM software has also evolved in parallel, becoming more specialized and intuitive for tube cutting applications. Modern tube CAM packages offer features like automatic feature recognition (identifying holes, slots, end-cuts from a 3D model), parametric design capabilities, and sophisticated algorithms for generating optimal cutting paths that minimize rapid movements and maximize cutting time. They can simulate the entire cutting process in 3D, allowing for offline programming and verification, which drastically reduces machine setup time and potential errors. For example, programming a complex tube assembly that might have taken an entire day can now often be accomplished in a couple of hours, or even less, with the right software.

Furthermore, we're seeing the emergence of more "intelligent" features embedded within the machine software and control systems. These include automatic seam detection (to orient tubes correctly), active collision avoidance, adaptive cutting parameters (where the machine adjusts settings in real-time based on sensor feedback), and remote diagnostics capabilities. Our own No-CAD system at MZBNL is a prime example of software evolution, simplifying the process for standard tube types and hole patterns by allowing parameter entry instead of requiring complex 3D drawings. This innovation significantly lowers the skill threshold for machine operation and shortens setup time, making advanced technology more accessible, a key requirement for customers like Ahmed who prioritize ease of use.

| Evolutionary Aspect | Early Systems (e.g., CO2-based) | Modern Systems (e.g., Fiber-based, Automated) | Impact of Evolution |

|---|---|---|---|

| Laser Source | CO2 | Fiber | Higher speed, better efficiency, lower maintenance, reflective material capability |

| Material Handling | Manual / Semi-Auto | Fully Automatic Bundle Loaders/Unloaders | Increased throughput, reduced labor, unattended operation |

| Software | Basic CAD/CAM, Manual Prog. | Advanced Tube CAM, Simulation, No-CAD options | Faster programming, less skill-dependent, optimized paths, error reduction |

| Control System | Limited Axis, Slower Proc. | Multi-Axis, High-Speed Processing | Complex cuts (bevels, profiles), higher accuracy, faster cycle times |

| Operator Dependence | High | Reduced (especially with No-CAD/Automation) | Lower training burden, more consistent output |

This table highlights the significant strides made, showing a clear trajectory towards more powerful, automated, and user-friendly laser tube cutting solutions.

Fiber lasers cut faster than CO2True

Fiber lasers have shorter wavelengths that are better absorbed by metals, enabling significantly faster cutting speeds especially on thin materials.

CO2 lasers handle reflective metals betterFalse

Fiber lasers actually excel at cutting reflective materials like copper and brass, while CO2 lasers risk damage from reflected light.

What are the challenges faced by businesses using laser tube cutting machines?

Are you investing in laser tube cutting technology but still finding yourself battling unexpected operational hurdles? Perhaps the promise of efficiency is being undermined by issues like skilled labor shortages, higher-than-anticipated material waste, or frequent downtime. These challenges can be frustrating and directly impact your profitability and ability to meet client demands. Identifying them is the crucial first step towards effective solutions.

Businesses using laser tube cutting machines often face challenges such as a shortage of skilled CAD/CAM operators and maintenance technicians, significant material waste from tail remnants and improper nesting, the complexity of programming and setting up jobs, unexpected machine downtime, and managing the initial investment cost effectively.

In my 25 years at MZBNL, I've spoken with countless business owners and production managers, like Ahmed Al-Farsi from the UAE, who have shared their experiences with laser tube cutting. While the technology offers immense benefits, it's not without its operational complexities. The initial investment can be substantial, and maximizing the return requires overcoming several common obstacles. These range from ensuring you have the right personnel to operate and maintain these sophisticated machines, to implementing strategies that minimize waste and keep the machines running optimally. Recognizing these potential pitfalls early on is key to truly leveraging the power of laser tube cutting.

Despite the advanced capabilities of modern laser tube cutting machines, businesses that utilize this technology are not immune to a range of operational and strategic challenges. These hurdles can impact productivity, profitability, and a company's overall competitiveness if not effectively addressed. One of the most frequently cited challenges, and one that Ahmed specifically mentioned as a pain point, is the skilled labor gap. Finding and retaining operators who are proficient not only in running the machine but also in CAD/CAM programming and performing routine maintenance can be difficult and costly. This is compounded by the high operator turnover that some businesses experience, leading to recurring retraining burdens. Another significant challenge revolves around material utilization and waste management. While laser cutting is precise, the process, especially with traditional setups, can generate unusable tail material from each stock tube. Suboptimal nesting of parts on the tube can also lead to excessive scrap. Given the cost of raw materials, particularly specialized alloys, this waste directly impacts the bottom line. At MZBNL, addressing this through innovations like our Zero-Waste Tail Material system has been a key focus. Operational complexities, including machine downtime for maintenance or repairs, and the time taken for job setup and changeovers, also pose challenges. For businesses with diverse, short-run production needs, minimizing setup time is critical. Finally, the initial capital investment for a high-quality laser tube cutting system is considerable, necessitating careful financial planning and a clear strategy to achieve a strong return on investment.

The Skilled Labor Gap and Training Overheads

One of the most persistent challenges I've seen businesses face when adopting or scaling up their laser tube cutting operations is the skilled labor gap. Modern laser tube cutters are sophisticated pieces of equipment, and while automation has reduced some manual tasks, there's still a need for personnel who understand how to operate them effectively, program them (especially for complex or custom parts), and perform essential maintenance. Ahmed Al-Farsi highlighted this perfectly when he mentioned that his "previous machines required skilled CAD operators" and that "high operator turnover caused retraining burdens." This isn't an isolated issue; it's a widespread concern across the manufacturing sector globally.

The difficulty lies not just in finding individuals with the requisite CAD/CAM skills, but also in finding those who possess a good understanding of materials, cutting parameters, and machine mechanics. The time and cost associated with training new operators can be substantial. Traditional training might involve sending an operator to the equipment manufacturer's facility for a week or more, incurring travel, accommodation, and lost production time. If that operator then leaves the company, the investment is lost, and the cycle begins anew. This is a significant pain point that we at MZBNL sought to address directly with our No-CAD system, which simplifies operation to the point where on-site training can be completed in just one day, compared to the 15 days often required for conventional systems.

The impact of operator skill (or lack thereof) on production is multifaceted. A less skilled operator might take longer to set up jobs, leading to increased machine idle time. They may be less adept at optimizing cutting parameters, potentially resulting in lower cut quality or slower processing speeds. Furthermore, their ability to troubleshoot minor issues or perform preventative maintenance might be limited, leading to more frequent calls for external technical support and potentially longer downtimes. Therefore, bridging this skills gap through either finding highly skilled individuals, investing heavily in training, or adopting technologies that lower the skill threshold becomes a critical strategic decision for businesses.

Material Utilization and Waste Management

Effective material utilization is paramount in any manufacturing process, and laser tube cutting is no exception. The cost of raw materials, especially for metal tubes which can range from standard carbon steel to more expensive stainless steel or aluminum alloys, forms a significant portion of the final part cost. Therefore, any waste generated directly eats into profit margins. A primary challenge in this area is the issue of "tail material" or "remnant." In many conventional laser tube cutting systems, the chucks that grip and feed the tube require a certain length of material to maintain control, meaning a portion at the end of each stock tube often becomes unusable scrap. For a 6-meter stock tube, this remnant could be anywhere from 100mm to 300mm or more, depending on the machine design. Over hundreds or thousands of tubes, this adds up to a substantial amount of wasted material and money.

Beyond tail material, suboptimal nesting of parts on the tube can also lead to significant waste. Nesting is the process of arranging the parts to be cut along the length of the stock tube in the most efficient way possible. While modern CAM software often includes automatic nesting features, their effectiveness can vary, especially with complex part geometries or a diverse mix of parts. Achieving true 'common-line cutting'6 (where adjacent parts share a cut line) can be challenging with tubes but offers significant material savings when possible. Poor nesting strategies can result in excessive gaps between parts or inefficient use of the tube's surface, increasing the amount of scrap generated.

The financial impact of this waste is obvious, but there's also an environmental aspect to consider. Reducing material waste aligns with sustainability goals and can even be a selling point for environmentally conscious customers. This is why innovations focused on maximizing material yield are so critical. Our MZBNL Zero-Waste Tail Material innovation, for instance, redesigns the cutting logic to calculate from the rear chuck as the origin. This allows the system to utilize almost the entire tube, eliminating leftover tail material as long as the remaining section is smaller than the product length. We've seen this feature alone provide material savings of 5-10% for some clients, which can translate into tens of thousands of dollars annually depending on their production volume.

Machine Downtime, Maintenance, and Operational Complexity

Even the most advanced laser tube cutting machines are subject to wear and tear, requiring regular maintenance and occasionally suffering unexpected breakdowns. Machine downtime is a major challenge for businesses as it directly translates to lost production capacity, missed deadlines, and increased operational costs. Ahmed identified a crucial point here: "Equipment from some suppliers lacked local service support," and "Long machine lead times affected project delivery." This highlights the importance of not just the machine's reliability but also the supplier's service infrastructure. Preventative maintenance schedules are essential to minimize unplanned downtime, but these themselves require time and skilled personnel.

The complexity of modern laser systems can also make diagnosing and troubleshooting issues a challenge. These machines integrate laser optics, precision mechanics, sophisticated electronics, and complex software. Identifying the root cause of a problem often requires specialized knowledge and diagnostic tools. While some routine maintenance tasks can be handled by well-trained operators, more significant repairs or persistent issues typically necessitate support from the equipment manufacturer or their local service agents. The availability and responsiveness of this support can make a huge difference in how quickly a machine is back online. This is why Ahmed prioritizes "spare parts availability and remote diagnostics" and the presence of a "local agent or distributor."

Operational complexity extends beyond just maintenance. Setting up new jobs, especially those involving different tube profiles, materials, or complex cutting geometries, can be time-consuming if the machine interface and software are not user-friendly. Optimizing cutting parameters for new materials or thicknesses can also involve a degree of trial and error if the machine doesn't have a robust, pre-programmed materials library or adaptive control features. These operational aspects add to the overall challenge of maximizing machine uptime and efficiency. At MZBNL, we strive to mitigate these issues through robust machine design, intuitive software like our No-CAD system, comprehensive training, and a responsive global service network, understanding that reliable operation is just as important as cutting-edge features.

| Challenge Category | Specific Issues | Potential Business Impact | MZBNL Approach / Solution Example |

|---|---|---|---|

| Skilled Labor | Shortage of CAD/CAM operators, high training costs, operator turnover | Increased labor costs, production bottlenecks, quality issues | No-CAD System (1-day training), intuitive interfaces |

| Material Waste | Tail material remnants, inefficient nesting | Increased material costs, reduced profitability, environmental impact | Zero-Waste Tail Material Innovation, advanced nesting software support |

| Downtime/Maintenance | Unexpected breakdowns, lack of local support, complex troubleshooting | Lost production, missed deadlines, high service costs | Robust design, remote diagnostics, global service network, spare parts |

| Operational Complexity | Lengthy job setups, difficult parameter optimization for new materials/jobs | Reduced machine utilization, lower overall efficiency | No-CAD System for fast setup, pre-set parameter libraries |

| Initial Investment | High upfront cost of advanced machinery | Financial strain, ROI pressure | Cost-effective customized solutions, focus on long-term value |

This table summarizes some key challenges and how a proactive approach, often involving technological innovation from suppliers like MZBNL, can help businesses overcome them.

Skilled labor shortage is a key challengeTrue

The article highlights the difficulty in finding operators skilled in CAD/CAM programming and machine maintenance as a major operational hurdle.

Material waste doesn't impact profitabilityFalse

The text clearly states that tail material remnants and inefficient nesting directly reduce profit margins by increasing material costs.

How can businesses overcome challenges in laser tube cutting processes?

Are you actively seeking ways to conquer the common hurdles in your laser tube cutting operations, aiming for smoother workflows and better returns? Perhaps you're tired of battling skill gaps, excessive waste, or frustrating downtimes that chip away at your efficiency. The good news is that with the right strategies and technological choices, these challenges are not insurmountable.

Businesses can overcome challenges in laser tube cutting by investing in user-friendly technologies like No-CAD systems, implementing robust automation for material handling, prioritizing comprehensive operator training, optimizing processes for material efficiency, and selecting equipment suppliers who offer strong after-sales support and reliable service.

Having navigated these challenges with numerous clients over my 25 years at MZBNL, I've learned that a multi-pronged approach is usually most effective. It's not just about buying the latest machine; it's about creating an ecosystem around that machine that supports optimal performance. This involves empowering your team with the right skills and tools, streamlining your processes from design to dispatch, and forging strong partnerships with suppliers who understand your needs and are committed to your success. Ahmed's proactive approach in seeking turnkey solutions and prioritizing support is a testament to this forward-thinking mindset.

Overcoming the inherent challenges in laser tube cutting processes requires a strategic blend of technological adoption, process optimization, workforce development, and smart partnerships. It's rarely a single solution but rather a concerted effort across different facets of the operation. For instance, tackling the skilled labor gap7 involves not only trying to hire experienced personnel but also investing in machines that are easier to operate and program, thereby broadening the pool of potential operators. Our MZBNL No-CAD system is a direct response to this, aiming to reduce the dependency on highly specialized CAD skills for many common cutting tasks. Similarly, combating material waste goes beyond just encouraging careful material handling; it involves leveraging software for optimal nesting and investing in machine technologies, like our Zero-Waste Tail Material innovation, that intrinsically minimize scrap. Addressing machine downtime necessitates a proactive maintenance culture, coupled with choosing suppliers who offer responsive service and readily available spare parts, a key concern for our client Ahmed. Ultimately, the goal is to create a more resilient, efficient, and profitable laser tube cutting operation that can adapt to changing market demands and maintain a competitive edge.

Investing in User-Friendly Technology and Automation

One of the most direct ways businesses can overcome prevalent challenges in laser tube cutting is by strategically investing in technology that prioritizes ease of use and automation. The issue of skilled operator shortages, as highlighted by Ahmed's experience with machines requiring skilled CAD operators and the subsequent retraining burdens, can be significantly mitigated by choosing systems with intuitive interfaces and simplified programming. This is where innovations like MZBNL's No-CAD system truly shine. By allowing operators to process standard tube types and hole patterns simply by entering parameters without needing to create or modify complex 3D drawings, we drastically lower the skill threshold. This not only makes it easier to train new staff – reducing our training time from 15 days at the factory to just 1 day on-site – but also empowers existing operators to be more productive and versatile.

Automation in material handling is another critical area. Manual loading and unloading of tubes are time-consuming, labor-intensive, and can be a source of production bottlenecks. Investing in automatic bundle loaders8, like those often integrated with modern laser tube cutters, or specialized solutions like MZBNL's Front-Feeding innovation, can yield substantial improvements. Our front-feeding mechanism, for example, increases feeding efficiency by about 40% and reduces operator labor intensity by a similar margin. This means the machine spends more time cutting and less time waiting for material, directly boosting output and allowing operators to focus on higher-value tasks. Ahmed's preference for \"turnkey solutions that are easy to install and operate\" underscores the market demand for such integrated and user-friendly automation.

Furthermore, intelligent machine features play a crucial role in simplifying operations and minimizing errors. Modern laser tube cutters are increasingly equipped with capabilities like automatic seam detection (to ensure consistent cut quality relative to the tube's weld seam), automatic nozzle cleaning and calibration, and adaptive cutting control that adjusts parameters in real-time based on material variations or sensor feedback. These features reduce the need for constant operator intervention, minimize the chance of human error, and contribute to more consistent and reliable production. By selecting machines that incorporate these smart technologies, businesses can make their laser cutting processes more robust and less dependent on operator expertise for routine adjustments.

Implementing Effective Training and Skill Development Programs

While user-friendly technology can lower the skill barrier, effective training and continuous skill development remain crucial for maximizing the potential of any advanced manufacturing equipment. Even with a system as intuitive as our No-CAD technology, which significantly reduces initial training time, ensuring operators understand the machine's full capabilities, routine maintenance procedures, and basic troubleshooting is essential for long-term success. Businesses should look beyond just the initial operator training provided by the supplier and consider developing ongoing internal skill development programs. This could involve structured on-the-job training, peer-to-peer mentoring, and regular refresher courses.

Leveraging supplier training resources to their fullest extent is also key. At MZBNL, our 1-day on-site training for the No-CAD system is designed to get operators productive quickly, but we also provide comprehensive documentation and access to support for more advanced queries. Businesses should ensure that their key personnel, including maintenance staff where appropriate, receive thorough training. Creating a culture of continuous learning, where operators are encouraged to explore new features, share tips and tricks, and proactively identify potential process improvements, can lead to significant gains in efficiency and problem-solving capabilities within the team.

Investing in skill development isn't just about machine operation; it can also extend to areas like advanced programming (for non-standard parts if applicable), preventative maintenance best practices, and quality control procedures. For instance, training operators to perform daily and weekly preventative maintenance checks can significantly reduce the likelihood of unexpected breakdowns and prolong the life of the machine. Well-trained operators are also more likely to identify and rectify minor issues before they escalate into major problems, contributing to higher uptime and more consistent output. This proactive approach to skill development transforms operators from mere machine minders into valuable contributors to the overall efficiency and quality of the production process.

Strategic Supplier Selection and Partnership

The choice of an equipment supplier is a long-term strategic decision that goes far beyond the initial purchase price of the laser tube cutting machine. To effectively overcome ongoing operational challenges, businesses need to view their supplier as a partner. Ahmed's sourcing key points clearly reflect this: he prioritizes \"After-sales service and training support,\" \"Spare parts availability and remote diagnostics,\" and the presence of a \"Local agent or distributor.\" These factors are critical for ensuring machine uptime and resolving issues quickly when they arise. A supplier with a robust and responsive after-sales service network, capable of providing both on-site support and remote diagnostics, can make a significant difference in minimizing downtime and keeping production on track.

Considering suppliers who offer customization and tailored solutions is also important. Not all businesses have the same production needs, and a one-size-fits-all machine may not be the most efficient solution. At MZBNL, we emphasize our ability to provide \"cost-effective customized solutions\" because we understand that adapting the machine configuration, software features, or automation level to a client's specific application can lead to better performance and a faster return on investment. This collaborative approach, where the supplier works to understand the client's unique challenges and goals, is a hallmark of a strong partnership.

Finally, the value of a long-term partnership extends to ongoing support, access to software updates, and information about future technological advancements. A proactive supplier will keep their clients informed about new features or upgrades that could benefit their operations. Ahmed's consideration of becoming a regional distributor if the machine performs well and support is reliable further illustrates the potential for a deeper, mutually beneficial relationship. Choosing a supplier with a proven track record, strong global references (MZBNL has 4000+ global enterprise clients), and a commitment to innovation and customer success is an investment in the long-term health and competitiveness of your laser tube cutting operations.

| Strategy for Overcoming Challenges | Key Actions | Expected Benefits | Example from MZBNL/Ahmed's Needs |

|---|---|---|---|

| User-Friendly Technology | Invest in No-CAD systems, intuitive interfaces | Reduced skill dependency, faster setup, lower training costs, increased productivity | MZBNL No-CAD System (1-day training), Ahmed's preference for ease of use |

| Automation | Implement automatic loaders/unloaders, integrated handling | Increased throughput, reduced labor, consistent workflow, better ergonomics | MZBNL Front-Feeding (40% efficiency gain), Ahmed's focus on automation |

| Training & Skill Development | Comprehensive initial & ongoing training, leverage supplier resources | Improved operator proficiency, better maintenance, higher uptime, quality | MZBNL's training programs, Ahmed's concern over retraining burdens |

| Process Optimization | Implement advanced nesting, adopt waste-reduction tech | Maximized material utilization, reduced costs, improved sustainability | MZBNL Zero-Waste Tail Material, optimized CAM software |

| Strategic Supplier Selection | Prioritize after-sales support, spare parts, local presence, customization | Reliable machine operation, quick issue resolution, tailored solutions, long-term ROI | Ahmed's sourcing criteria, MZBNL's global network & customized solutions |

This table provides a framework for how businesses can systematically address the common challenges associated with laser tube cutting technology, ultimately leading to more efficient and profitable operations.

No-CAD systems reduce training timeTrue

MZBNL's No-CAD system reduced training time from 15 days to just 1 day by eliminating complex CAD requirements.

Automation decreases productivityFalse

Automation like front-feeding systems actually increases productivity by 40% by reducing manual handling time.

What innovative solutions are leading the laser tube cutting industry today?

Are you wondering what the next leap forward is for your metal tube fabrication processes, seeking solutions that offer more than just incremental improvements? If you're aiming to significantly boost efficiency, simplify operations, and reduce costs, then understanding the leading-edge innovations is crucial. These aren't just futuristic concepts; they are practical solutions transforming workshops and factories right now.

Leading innovative solutions in the laser tube cutting industry today are spearheaded by No-CAD operating systems, advanced automated front-feeding mechanisms, and groundbreaking zero-waste tail material designs. These innovations collectively enhance ease of use, dramatically improve material utilization, and significantly boost overall production efficiency.

As someone deeply involved in the development of these technologies at MZBNL, I've seen firsthand the transformative impact these innovations have on businesses. We moved beyond just making machines cut faster; we focused on solving core industry challenges related to operator skill, material costs, and workflow efficiency. Our clients, like Ahmed, who are actively seeking ways to automate and upgrade, are the driving force behind this push for smarter, more intuitive, and resource-conscious laser tube cutting solutions. It's exciting to be at the forefront of this change.

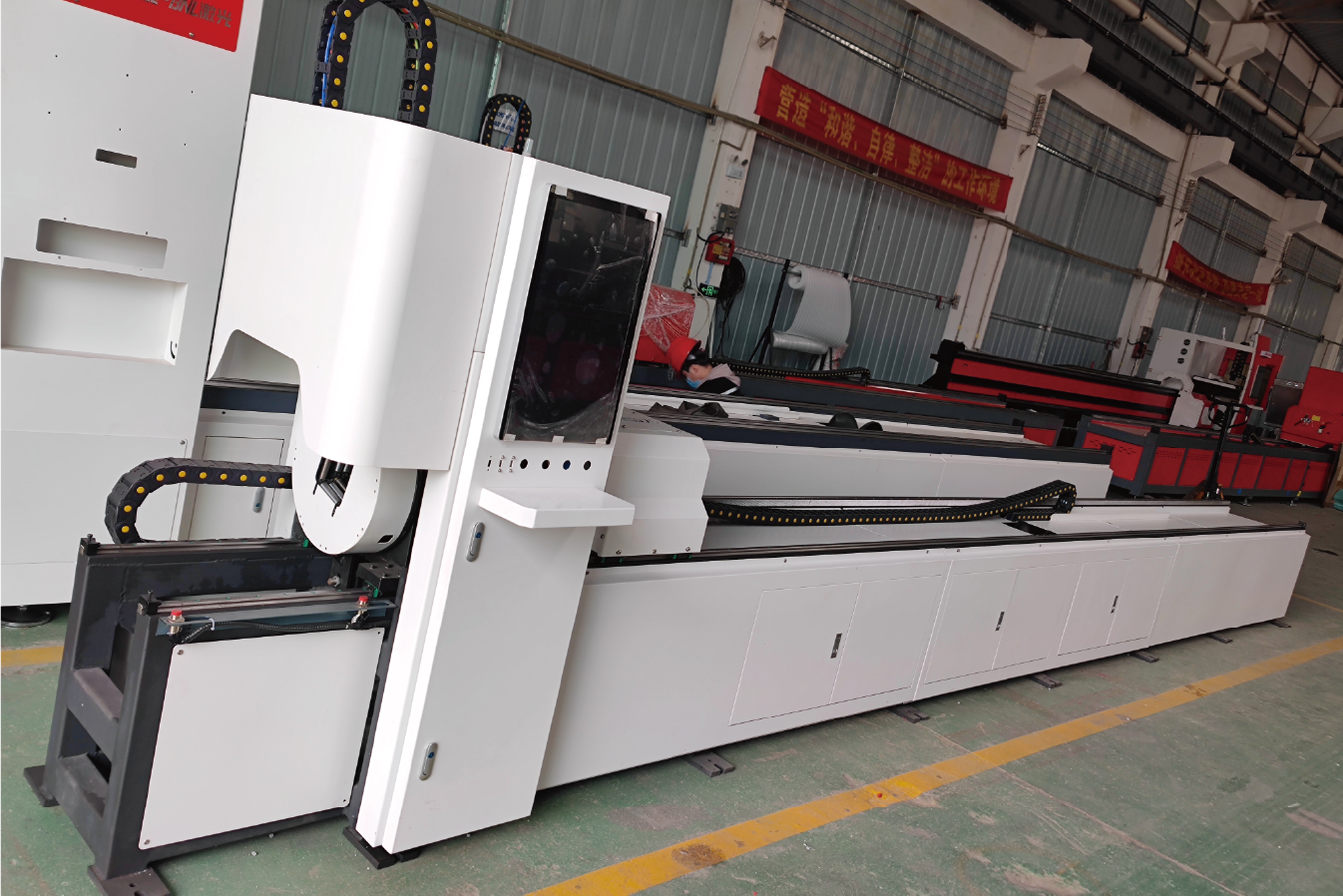

The laser tube cutting industry is currently experiencing a wave of innovation aimed squarely at addressing long-standing challenges and unlocking new levels of performance and accessibility. While improvements in laser power, cutting speed, and basic automation continue, the most impactful recent advancements are those that fundamentally rethink traditional workflows and resource management. These leading solutions are not just about refining existing processes but about introducing entirely new paradigms of operation. At MZBNL, our R&D has been laser-focused on three such innovations that we believe are setting new industry benchmarks: the No-CAD Operating System, our optimized Front-Feeding mechanism, and the Zero-Waste Tail Material design. These aren't isolated features but interconnected solutions designed to deliver a superior user experience, maximize material yield, and significantly enhance overall productivity. They respond directly to the needs expressed by forward-thinking businesses like Ahmed's, who require ease of use, high efficiency, and tangible cost savings to stay competitive in demanding markets like architectural metalwork and vehicle parts supply.

The Game-Changer: No-CAD Operating Systems

The traditional workflow for laser tube cutting has long been dependent on skilled CAD operators. Typically, a design engineer would create a 2D or 3D CAD drawing9 of the required tube part, which would then be imported into CAM software10 for toolpath generation before finally being sent to the machine. This process, while effective, has several inherent inefficiencies: it's time-consuming, especially for minor modifications or standard repetitive tasks, and it creates a bottleneck if CAD-skilled personnel are unavailable or overloaded. As Ahmed noted, "Previous machines required skilled CAD operators," and "High operator turnover caused retraining burdens," highlighting a significant industry pain point.

MZBNL pioneered and perfected a No-CAD Operating System specifically to address this challenge. With our system, for a wide range of standard tube types (round, square, rectangular, etc.) and common hole patterns or end cuts, operators can now process tubes simply by entering key parameters directly at the machine's control interface – no drawing is required. For instance, if you need to cut a 50mm square tube to a specific length with a series of predefined holes at certain intervals, you input these dimensions and parameters, and the machine generates the cutting program automatically. This innovation dramatically improves ease of use and significantly shortens setup time for a large percentage of common jobs.

The benefits are substantial. Firstly, it lowers the skill threshold for machine operation considerably. As I mentioned earlier, operators can become proficient with our No-CAD system with just 1 day of on-site training, a stark contrast to the 15 days often required at the equipment factory for traditional CAD/CAM-based systems. This makes it easier to onboard new staff and reduces the dependency on a small pool of highly specialized programmers. Secondly, it speeds up the process for standard jobs, allowing for quicker turnaround times and increased machine utilization. For businesses like Ahmed's, who prioritize "Ease of use (preferably No-CAD system)," this kind of innovation is not just a convenience but a critical factor in operational efficiency and cost management. It empowers shop floor personnel to handle a wider range of tasks directly, streamlining the workflow from job order to finished part.

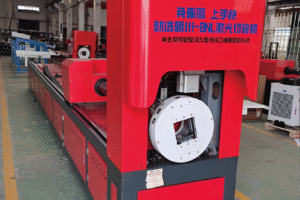

Revolutionizing Material Handling: Front-Feeding Innovation

Material handling, specifically the loading of raw tubes into the laser cutting machine, has traditionally been a focus area for automation, but not all automation is created equal in terms of efficiency and ergonomics. Many conventional machines rely on side-loading or rear-loading mechanisms, which can sometimes be cumbersome, require significant floor space, or involve manual assistance, especially for aligning or initially positioning the tubes. These methods can limit the overall speed of the material feeding cycle and contribute to operator fatigue over a long shift.

Recognizing these limitations, MZBNL introduced an optimized Front-Feeding mechanism. Instead of pushing tubes from the side or rear, our system is designed to automatically pull the tube in from the front of the machine. The operator or an automated system simply places the tube (or bundle of tubes in a magazine) at the designated front-loading area. The machine's feeding system then intelligently grips and draws the tube into the cutting zone. This approach offers several advantages. It often results in a more compact machine footprint for the loading area and provides a more direct and efficient path for the tube into the chucks.

The impact on productivity and workplace ergonomics is significant. We've measured that our Front-Feeding innovation increases feeding efficiency by approximately 40% compared to some traditional manual or semi-automatic side/rear loading methods. This reduction in loading time means the machine spends more time cutting and less time idle, directly contributing to higher throughput. Concurrently, it reduces operator labor intensity by a similar margin (around 40%), as the physical effort and repetitive motions associated with manual loading are greatly diminished. This not only improves operator comfort and safety but also frees up their time to supervise multiple machines or perform other value-added tasks, aligning perfectly with the industry trend towards greater automation and improved overall equipment effectiveness (OEE)11.

Maximizing Material Utilization: Zero-Waste Tail Material Innovation

One of the most persistent and costly issues in conventional laser tube cutting has been the generation of unusable tail material. In most systems, the tube is fed through a rear chuck and supported by a front chuck. The cutting typically starts from the tube head (the end closest to the front chuck). As the tube is processed and moves forward, the rear chuck eventually reaches a point where it can no longer securely grip the remaining section of the tube while still allowing the cutting head access. This often results in a significant piece of "tail material" – the portion of the tube between the rear chuck's minimum grip point and the last cut part – becoming unusable scrap. This waste can easily account for several percentage points of total material consumption, a direct hit to the bottom line.

MZBNL tackled this problem by fundamentally redesigning the cutting logic and chucking system to enable our Zero-Waste Tail Material innovation. Instead of always calculating from the tube head, our system can intelligently calculate cuts from the rear chuck as the origin, especially for the final pieces on a tube. This, combined with optimized chuck design and cutting head accessibility, allows the system to continue processing the tube until the remaining section is smaller than the length of the product being cut. Essentially, as long as there's enough material left to make one more complete part (and sometimes even utilize smaller remnants for very short parts if programmed), our system is designed to use it.

The impact of this zero-tail design is twofold: it maximizes material utilization and, often as a byproduct, can boost cutting efficiency for the final parts on a tube. By virtually eliminating the unusable tail remnant for many common scenarios, businesses can achieve significant material savings. For a company processing thousands of tubes a year, even a 5% reduction in material waste can translate into substantial cost savings and improved profitability. This innovation directly addresses a key financial and sustainability concern for metal fabricators and is a powerful example of how intelligent design can lead to tangible economic and environmental benefits.

| Innovation by MZBNL | Traditional Challenge Addressed | Key Feature/Mechanism | Tangible Benefit for Businesses (e.g., Ahmed's) |

|---|---|---|---|

| No-CAD Operating System | High skill requirement for CAD, long programming/setup times | Parameter-based input for standard tubes/holes, no 3D drawing needed for many jobs | Reduced training time (1 day vs 15), lower skill threshold, faster setup, increased ease of use (Ahmed's preference) |

| Front-Feeding Innovation | Inefficient manual/side/rear loading, high operator labor intensity | Automatic tube pulling from the front of the machine | ~40% increase in feeding efficiency, ~40% reduction in operator labor intensity, improved productivity, better ergonomics |

| Zero-Waste Tail Material Innovation | Significant unusable tail material waste from conventional processing | Cutting logic calculates from rear chuck as origin, utilizes maximum tube length | Maximized material utilization (potential 5-10% savings), reduced scrap costs, improved cutting efficiency for last parts, better sustainability |

These three innovations from MZBNL represent a concerted effort to push the boundaries of what's possible in laser tube cutting, focusing on practical solutions that deliver real-world benefits in ease of use, efficiency, and cost reduction.

No-CAD systems reduce training timeTrue

The No-CAD system requires only 1 day of training compared to 15 days for traditional CAD/CAM systems.

Front-feeding increases floor spaceFalse

Front-feeding actually results in a more compact machine footprint for the loading area.

Conclusion

In my experience, the latest laser tube cutting innovations, especially No-CAD systems, automated front-feeding, and zero-waste designs, are fundamentally reshaping our industry. These advancements significantly boost efficiency, drastically cut operational costs, and make sophisticated metal fabrication far more accessible for businesses worldwide.

-

Learn about fiber laser technology and its benefits for metal tube cutting applications. ↩

-

Understand CNC's role in achieving precision and automation in laser cutting. ↩

-

Discover how nesting software minimizes material waste and improves efficiency in tube fabrication. ↩

-

Discover how automated bundle loaders improve efficiency and enable unattended laser tube cutting operations. ↩

-

Understand the complex cutting capabilities offered by multi-axis laser tube cutting systems. ↩

-

Discover how common-line cutting techniques can significantly reduce material waste. ↩

-

Understand the manufacturing sector's skilled labor shortage, its impact, and current trends. ↩

-

Explore how automatic bundle loaders enhance efficiency and reduce manual labor in tube laser cutting. ↩

-

Learn the basics of CAD drawings and their role in modern manufacturing processes. ↩

-

Discover how CAM software translates designs into machine instructions for laser cutters. ↩

-

Understand OEE, a key metric for measuring manufacturing productivity and identifying improvement areas. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.