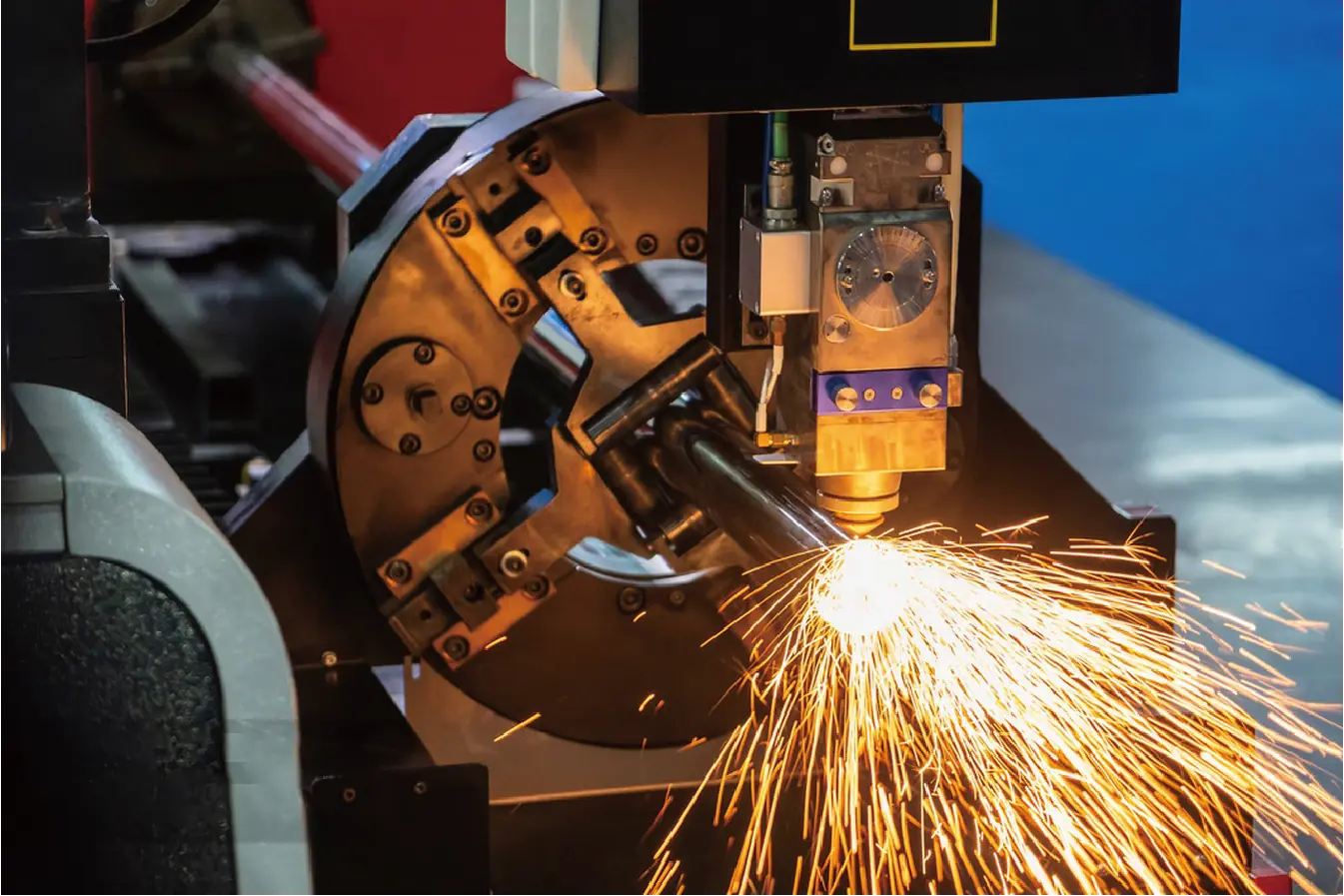

Laser Machinery: The Future of Industrial Manufacturing? (How it Enables Zero-Waste)

Struggling with rising material costs and production waste? This inefficiency eats into your profits and holds your factory back. Laser machinery is the solution, enabling a shift to zero-waste manufacturing.

Laser machinery represents the future of industrial manufacturing by offering unmatched precision, speed, and automation. Its core strength lies in its ability to execute complex processes with minimal material loss, making it the essential technology for achieving zero-waste production, enhancing profitability, and ensuring sustainable operations.

I've spent my career on factory floors, watching technology evolve. I've seen firsthand how the right equipment can transform a business from struggling to leading the market. The shift toward laser technology isn't just a trend; it's a fundamental change in how we think about production. Below, I'll break down the advancements, applications, and specific strategies that make laser machinery the key to a zero-waste future.

What advancements have positioned laser machinery as the future of industrial manufacturing?

Are your current machines struggling to keep up with today's demands? Your production line feels slow and overly complex. Key laser advancements streamline operations, delivering speed and precision far beyond traditional methods.

The most impactful advancements are high-power fiber lasers, intelligent software systems, and integrated automation. These innovations have dramatically increased cutting speeds, improved accuracy, and made it possible to automate the entire production workflow, cementing laser machinery's role as a cornerstone of modern manufacturing.

When I first started in this industry, laser cutters were impressive but often complex and slow. Today, the technology is almost unrecognizable. Let's dive deeper into the key developments that have made this transformation possible.

The Power and Efficiency of Fiber Lasers

The single biggest leap has been the widespread adoption of fiber lasers. Compared to older CO2 lasers, fiber technology is more energy-efficient, requires significantly less maintenance, and can cut reflective materials like brass and copper with ease. This has not only lowered operating costs but has also expanded the range of applications, making laser cutting a viable solution for nearly any metal processing factory. The speed increase alone is staggering; I've seen clients double their output overnight simply by upgrading their machines.

Intelligent Software and Simplified Operation

In the past, operating a laser cutter required a highly skilled technician who could create complex CAD drawings. This created a bottleneck. At MZBNL, we tackled this head-on with our No-CAD System. I'm particularly proud of this innovation because it allows an operator to process standard tubes just by inputting parameters like length and hole position directly into the machine. We've reduced on-site training from a typical 15 days down to just one. This isn't just an improvement; it's a democratization of technology, making powerful manufacturing accessible to more businesses.

How is laser machinery currently being utilized in manufacturing processes?

You see your competitors moving faster and producing higher quality parts. You're wondering what technology gives them the edge. They are likely using laser machinery for everything from cutting to welding.

Currently, laser machinery is integral for high-precision cutting, welding, marking, and engraving across countless industries. From automotive components and medical devices to furniture frames and display racks, lasers enable the rapid, flexible production of complex parts with superior quality and consistency.

The versatility of laser technology is its greatest strength. It’s not a niche tool; it’s a foundational manufacturing process. I've worked with over 4,000 clients globally, and the applications are incredibly diverse.

A Multi-Industry Workhorse

I remember visiting a client in the furniture industry who was struggling with a multi-step process for producing chair frames: sawing tubes to length, moving them to a punching machine, and then manually deburring them. Each step introduced potential for error and waste. By implementing one of our integrated laser tube cutting machines, they consolidated all those processes into a single, automated step. The machine cuts, punches, and finishes the part in one go. The result was a 50% reduction in production time and a near-elimination of scrapped parts. This story repeats itself across many sectors.

Here’s a quick look at where we see our machines making the biggest impact:

| Industry | Primary Application | Key Benefit |

|---|---|---|

| Furniture & Sanitary Ware | Cutting complex joints and holes | Design freedom, process integration |

| Automotive & Motorcycle | High-volume parts production | Speed, precision, and repeatability |

| Display Racks & Shelves | Custom cutting for varied designs | Flexibility and rapid changeover |

| Medical & Fitness Equipment | Clean, burr-free cutting | High quality and structural integrity |

| Architectural Decoration | Intricate pattern cutting | Aesthetic precision and customization |

This technology empowers manufacturers to be more agile and responsive to market demands, which is a critical advantage in today's economy.

What are the challenges in achieving zero-waste with traditional manufacturing methods?

Your material costs are climbing, and every piece of scrap feels like lost profit. Traditional methods like sawing and punching inherently create significant, unavoidable waste that directly hurts your bottom line.

Traditional methods face challenges like wide kerf widths from saw blades, material deformation from stamping, and the inability to process the end of a workpiece (tail material). This results in substantial scrap, making a true zero-waste goal practically impossible and costly to pursue.

For years, waste was just accepted as a "cost of doing business." When you use a saw, the blade itself turns a portion of your material into dust. When you punch a hole, the slug is often discarded. But the biggest and most frustrating source of waste, especially in tube processing, has always been tail material.

The Problem of Tail Material

In a traditional tube cutting setup, the material is held by chucks. To ensure a stable grip and prevent the cutting head from colliding with the chuck, a certain length of the tube at the very end—the tail material—cannot be processed. For a standard 6-meter tube, this can be 80mm or more of pure waste. If your factory processes hundreds or thousands of tubes a day, this adds up to a staggering financial loss and environmental impact. I’ve seen warehouses with entire bins filled with these identical, unusable end pieces. It's a clear symbol of inefficiency.

Process Inflexibility and Errors

Furthermore, traditional manufacturing often requires multiple machines for different operations. A tube might go from a saw to a drill press to a deburring station. Each transfer and setup introduces opportunities for human error, leading to misaligned holes or incorrect lengths, which results in more scrapped parts. This multi-step workflow is not only slow but also inherently wasteful.

How does laser machinery provide solutions to these zero-waste challenges?

You're searching for a definitive solution to reduce waste. You need a practical, powerful technology that gets the job done. Laser machinery directly targets the primary sources of manufacturing waste with intelligence and precision.

Laser machinery solves waste challenges with its micro-fine cutting beam that minimizes material loss. More importantly, advanced software enables optimal part nesting, and innovative machine designs, like rear-chuck cutting logic, completely eliminate tail material waste, maximizing material utilization.

This is where I get really excited, because we are no longer just reducing waste; we are engineering it out of the process entirely. This is the core of our mission at MZBNL and the focus of our most important innovations.

The Breakthrough: Our Zero-Waste Tail Material Innovation

The problem of tail material has frustrated me for years. So, we redesigned the entire cutting process. Our Zero-Waste Tail Material technology is a game-changer. Instead of feeding the tube past the cutting head, our system allows the rear chuck to pass through the front chuck and feed the final section of the tube directly to the laser. This means the machine can process the entire tube, right down to the last millimeter. There is no leftover tail material. Zero. This single innovation can save a company tens of thousands of dollars a year in material costs alone, directly boosting their profitability while achieving a sustainability goal that was previously impossible.

Intelligent Nesting and CAD-Free Operation

Beyond hardware, intelligent software plays a huge role. Modern laser systems can automatically "nest" parts—arranging them on the tube in the most efficient way to minimize scrap between cuts. Furthermore, our No-CAD System contributes to waste reduction by minimizing human error. By allowing operators to input simple parameters instead of loading complex drawings, we reduce the chance of incorrect setups and ruined first articles. It's about making the process foolproof.

What technological recommendations can optimize laser machinery for zero-waste manufacturing?

You're ready to invest but want to make the smartest choice. How do you ensure your new machine truly delivers on the promise of zero-waste? You must focus on integrated, intelligent systems.

To optimize for zero-waste, I recommend selecting machines with end-to-end automation, including automatic loading and unloading. Prioritize intelligent software that enables CAD-free operation and, most critically, insist on proven technology specifically engineered to eliminate tail material waste.

Buying a laser cutter is a major decision. To ensure you get the best return on your investment and truly future-proof your factory, you need to look beyond the basic specifications. Here is the advice I give to all my potential clients.

1. Demand a Holistic, Automated System

A fast cutting head is great, but manufacturing efficiency is about the entire workflow. Look for a fully integrated solution. Our Front-Feeding Mechanism, for example, automates the loading process, increasing efficiency by about 40% and reducing operator labor. When combined with automatic unloading, you create a seamless production line that minimizes downtime and manual handling, which are hidden sources of inefficiency and potential errors.

2. Prioritize Simplicity and Intelligence

The best machine is one that your team can use effectively from day one. Don't be swayed by overly complex systems that require specialized skills. A system like our No-CAD technology empowers your existing workforce, reduces the learning curve, and gets you into production faster. Smart, simple software is no longer a luxury; it's essential for agile and waste-free manufacturing.

3. Insist on True Zero-Waste Capability

When you talk to vendors, ask them one simple question: "How do you handle tail material?" Don't settle for "low waste" or "minimal waste." Ask for proof of a zero-waste solution. Our Zero-Waste Tail Material technology is the benchmark. It’s a clear, measurable feature that provides a direct and significant financial return. This should be a non-negotiable requirement for any new tube cutting machine you consider.

Conclusion

In summary, laser machinery is undeniably the future of manufacturing because it directly solves the critical issue of waste. Innovations like zero-waste cutting logic, simplified CAD-free operation, and full automation are making sustainable, highly profitable production a reality for factories worldwide. This is the path forward.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.