Key Features of Modern Tube Laser Cutting Machines

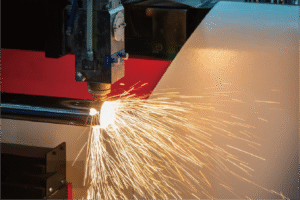

Are you struggling with outdated metal fabrication processes, losing time and material on complex tube cutting? Traditional methods often lack the precision and efficiency needed for today's competitive market, leaving you with bottlenecks and wasted resources. Discover how modern tube laser cutting machines offer revolutionary features designed to transform your operations and boost your bottom line.

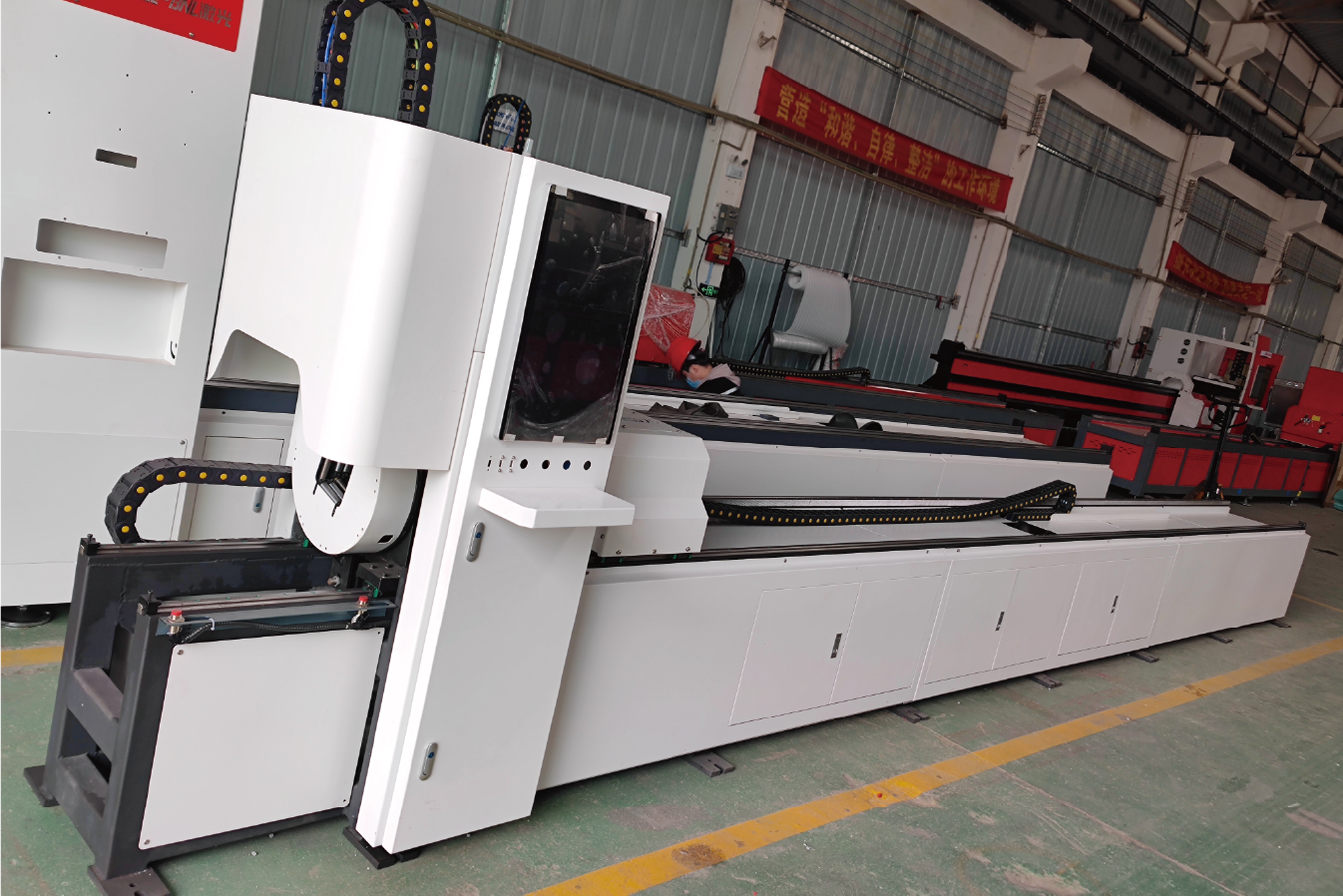

Modern tube laser cutting machines integrate advanced automation, intuitive software, and multi-process capabilities. These defining features significantly enhance precision, speed, and material utilization, addressing common manufacturing bottlenecks and improving overall operational efficiency for businesses like yours.

As someone deeply involved in metal fabrication for over 25 years at MZBNL, I've witnessed firsthand the incredible evolution of laser technology. The shift from manual, labor-intensive processes to highly automated, intelligent systems has redefined what's possible in manufacturing. Now, let's explore the groundbreaking innovations1 making this transformation possible.

My journey in the metal fabrication industry, particularly with MZBNL's focus on innovative solutions, has shown me that the true value of modern machinery lies not just in its raw power, but in its strategic integration of smart features. For years, businesses grappled with issues like skilled labor shortages and material waste, problems that traditional equipment only exacerbated. Today, the demand for agility and cost-efficiency is paramount. Consider the shift in market dynamics: from mass production to customized, on-demand fabrication. This necessitates machines that are not only fast but adaptable. The critical question isn't just "What can it cut?" but "How efficiently and intelligently can it integrate into my existing workflow?" Our 30+ patents and relationships with 4000+ global enterprise clients underscore this understanding: a machine is an investment in future productivity, requiring a deep dive into its true potential beyond basic specifications.

What are the most defining features of modern tube laser cutting machines?

Do you find it challenging to keep up with the rapid advancements in metal tube processing? Without understanding the core innovations, you might be missing out on significant competitive advantages and operational improvements. Let's uncover the defining features that set modern tube laser cutting machines apart, transforming precision and productivity.

Modern tube laser cutting machines are characterized by their advanced automation, intelligent software, and integrated multi-functional capabilities. Key features include No-CAD programming, automatic front-feeding systems, and zero-waste tail material cutting, which collectively streamline operations, reduce human error, and maximize material yield.

At MZBNL, our 25 years of experience have taught us that innovation isn't just about adding new functions; it's about fundamentally rethinking how work gets done. When we speak with clients like Ahmed from the UAE, a hands-on decision-maker looking to automate his operations, their main concerns revolve around ease of use, efficiency, and reducing reliance on highly specialized skills. This feedback directly influenced our development of features that address these exact pain points. Now, I want to walk you through the specific innovations that are reshaping the industry, demonstrating how these machines move beyond mere cutting tools to become complete intelligent fabrication solutions, simplifying complex tasks and boosting throughput for businesses just like yours.

Modern tube laser cutting machines are not merely upgraded versions of their predecessors; they represent a paradigm shift in metal fabrication, driven by a confluence of advanced robotics, artificial intelligence, and sophisticated software integration. The defining features transcend basic cutting capabilities, focusing instead on holistic operational efficiency, material optimization, and unparalleled ease of use. This evolution directly addresses critical industry challenges such as the scarcity of skilled labor, the rising cost of raw materials, and the increasing demand for rapid prototyping and mass customization.

The Paradigm Shift: From Manual to Intelligent Automation

For decades, tube cutting relied on manual loading, complex CAD/CAM programming, and significant material waste. This traditional approach, while effective for simpler tasks, became a bottleneck for businesses aiming for high-volume, precision-driven output. Consider a scenario like that faced by Ahmed Al-Farsi, the owner of a mid-sized metal fabrication business in the UAE. His pain points included the constant need for skilled CAD operators and the high operator turnover, which led to continuous retraining burdens. This challenge isn't isolated; it's a global issue affecting manufacturing productivity.

Modern machines alleviate these pressures through features like MZBNL's pioneering No-CAD Operating System. Traditionally, an operator would spend days, sometimes weeks, at the equipment factory for training, or repeatedly return to the design office to create or modify complex 3D drawings for every new job. With our No-CAD system, standard tube types and hole patterns can be processed by simply entering parameters directly on the machine interface. This drastically reduces the skill threshold, cutting training time from 15 days to just 1 day on-site. This innovation doesn't just improve ease of use; it democratizes complex processes, making high-precision tube cutting accessible to a broader workforce and significantly lowering operational overhead related to specialized personnel. This translates directly into faster project delivery and reduced dependence on a shrinking pool of highly specialized designers, a critical factor for businesses like Ahmed's looking to automate existing manual workflows.

Furthermore, the integration of advanced sensors and real-time monitoring capabilities allows for dynamic adjustments during operation, ensuring consistent quality and minimizing human error. According to a recent industry report by Grand View Research, the global laser cutting machine market is projected to reach USD 7.5 billion by 2030, driven largely by the adoption of automated and smart systems that offer higher precision and efficiency, highlighting the industry's strong push towards intelligent automation.

Optimized Workflow: Enhancing Efficiency from Loading to Output

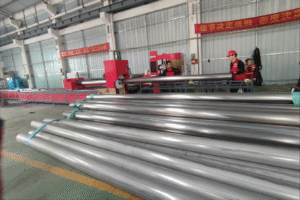

Beyond programming, the physical handling of tubes has historically been a significant source of inefficiency and labor intensity. Traditional machines often require laborious side or rear manual loading, which not only slows down production but also poses ergonomic risks to operators. This inefficiency directly impacts overall productivity, a key concern for any fabrication business aiming for growth.

MZBNL's Front-Feeding Innovation directly addresses this challenge. By introducing an optimized mechanism that automatically pulls the tube in from the front of the machine, we've managed to increase feeding efficiency by approximately 40%. This seemingly simple design change has a profound impact: it reduces operator labor intensity by roughly 40%, significantly enhancing overall productivity and improving workplace ergonomics. For Ahmed, who is actively expanding his business in architectural metalwork and vehicle parts supply, this means his 100+ staff can process more material in less time, freeing up valuable human resources for other critical tasks. This operational optimization isn't just about speed; it's about creating a safer, more efficient work environment, leading to higher employee morale and reduced instances of work-related injuries. This also contributes to faster turnaround times, a critical factor for contract-based fabrication services that earn by delivering finished parts to builders, decorators, and OEMs.

The integration of multi-process capabilities, such as cutting, punching, and marking in a single machine, further streamlines the workflow. This eliminates the need to transfer workpieces between different machines, reducing setup times and potential for error. For example, a furniture manufacturer can now perform all necessary operations on a tube in one go, from intricate decorative cuts to precise punch holes for assembly, drastically shortening the production cycle.

Sustainability and Savings: Maximizing Material Utilization

Material waste has always been a hidden cost in metal fabrication, especially with expensive specialty alloys. Conventional laser cutting systems typically start cutting from the tube head, inevitably generating unusable tail material at the end of the process. This leftover section, often significant, translates directly into lost revenue and increased environmental footprint.

MZBNL's Zero-Waste Tail Material Innovation provides a critical solution to this long-standing problem. We redesigned the cutting logic to calculate from the rear chuck as the origin. This allows the system to effectively eliminate leftover tail material, as long as the remaining section is smaller than the product length. This revolutionary design maximizes material utilization, converting what was once scrap into usable output. For a business processing tons of metal tubing annually, the savings from this innovation can be substantial, directly impacting the bottom line. For instance, if a company typically loses 5% of material to tail waste, and their annual material cost is $1 million, this innovation could save them $50,000 annually. Over several years, these savings compound dramatically, contributing to a significantly higher cost-performance ratio, which Ahmed values.

This innovation also aligns with global trends towards sustainable manufacturing. By reducing waste, businesses not only cut costs but also enhance their environmental credentials, a growing factor in corporate responsibility and customer perception. According to a report by Accenture, companies adopting sustainable practices often see an average of 10-15% reduction in operational costs, making zero-waste strategies a win-win for both profitability and planet. The ability to produce more finished parts from the same amount of raw material directly impacts a business's profit model, especially those operating on contract-based services where material efficiency is directly tied to profit margins.

Here’s a comparison highlighting the impact of these features:

| Feature Category | Traditional Tube Laser Cutting | Modern Tube Laser Cutting (MZBNL Innovations) | Impact on Business (e.g., Ahmed) |

|---|---|---|---|

| Operation/Programming | Complex CAD required (15 days training) | No-CAD System (1 day training) | Significantly lowers skill threshold, reduces retraining burden, faster setup. |

| Material Loading | Manual, side/rear loading (labor-intensive) | Automated Front-Feeding (40% efficiency boost) | Reduces labor intensity, improves throughput, safer workplace. |

| Material Utilization | Unusable tail material | Zero-Waste Tail Material (maximized yield) | Reduces material costs, higher profit margins, eco-friendly. |

| Overall Efficiency | Slower, more manual | High-speed, high-precision, multi-process | Faster project delivery, competitive advantage, higher output volumes. |

No-CAD reduces training timeTrue

Modern tube laser cutting machines with No-CAD systems cut operator training from 15 days to just 1 day by eliminating complex CAD programming requirements.

Front-feeding decreases efficiencyFalse

Front-feeding systems actually increase feeding efficiency by 40% compared to traditional side/rear loading methods, contrary to this false statement.

How do these features improve operational efficiency and precision?

Are you struggling to meet demanding production schedules and maintain tight tolerances with your current equipment? Inefficient processes and imprecise cuts can lead to costly rework, delayed projects, and dissatisfied clients. Explore how the cutting-edge features of modern tube laser machines revolutionize operational efficiency and precision, boosting your bottom line.

Modern tube laser cutting machines enhance operational efficiency through features like automated material handling and intelligent software, while precision is improved by real-time calibration, advanced motion control, and integrated quality checks. These advancements reduce manual intervention, minimize errors, and ensure consistent, high-quality output for demanding applications.

When I talk to potential clients, especially those considering a significant investment like a laser tube cutting machine, their primary drivers are almost always about getting more done, faster, and with impeccable quality. For a business owner like Ahmed Al-Farsi, whose main sourcing key points include cutting speed and accuracy, these aren't just buzzwords; they are non-negotiable requirements for staying competitive in markets ranging from architectural metalwork to vehicle parts. He also seeks turnkey solutions that are easy to install and operate, because complexity directly translates to inefficiency. My insights from developing solutions for 4000+ global clients2 have reinforced that true efficiency comes from seamless integration and intelligent design. Let's delve into how specific innovations deliver measurable improvements in both operational flow and the exactness of every cut.

The modern tube laser cutting machine transcends its traditional role as a mere cutting tool, evolving into a sophisticated, integrated system designed to optimize every facet of the metal fabrication process. The advancements in operational efficiency and precision are not incidental; they are the direct result of deliberate engineering focused on reducing bottlenecks, minimizing human error, and achieving unprecedented levels of accuracy. This holistic approach ensures that businesses can meet the stringent demands of modern industries, from automotive parts to medical equipment, where even a micron of deviation can be critical.

Streamlined Operations: Automating the Unseen Bottlenecks

Operational efficiency isn't just about faster cutting speeds; it encompasses the entire workflow, from material loading to part unloading. Traditional setups often suffer from significant non-cutting time due to manual adjustments, material handling, and complex programming. This is where modern machines, particularly those integrating MZBNL's innovations3, make a profound difference. The Front-Feeding Innovation, for example, isn't just a convenience; it's a strategic enhancement to throughput. By automatically pulling tubes from the front, it eliminates the need for cumbersome manual placement, which can be time-consuming and physically demanding, especially for long or heavy tubes. For a typical fabrication factory, this automated process reduces loading time by as much as 40%, directly translating into more productive cutting hours per shift.

Furthermore, the integration of smart, digitalized systems ensures seamless data flow. My experience with clients from Southeast Asia to North America shows that "easy to operate and maintain" is not a luxury but a necessity. The intuitive HMI (Human-Machine Interface) and pre-set parameters within systems like our No-CAD innovation reduce the mental load on operators. This means less time spent on complex programming and more time on actual production, drastically shortening setup times for new jobs. Ahmed's pain point regarding "previous machines required skilled CAD operators" is a common industry challenge. By simplifying programming, we address this directly, making the machine accessible even to operators with minimal CAD experience, which in turn reduces training burdens and boosts overall plant productivity. This shift helps convert what was once a highly specialized task into a more accessible operation, empowering a broader workforce and reducing dependence on a shrinking pool of high-end CAD designers. This contributes significantly to a more stable workforce and reduced retraining costs.

Unparalleled Precision: Engineering Excellence Meets Digital Control

Accuracy in tube laser cutting is paramount, especially when dealing with complex geometries, tight tolerances, and high-value materials. Modern machines achieve unparalleled precision through a combination of robust mechanical design and sophisticated digital control. The integration of high-resolution encoders, advanced motion control systems, and active cutting head stabilization ensures that the laser beam remains perfectly aligned and focused, even during high-speed movements or intricate cuts. This level of control minimizes kerf width and reduces the heat-affected zone (HAZ), resulting in cleaner cuts that often require minimal, if any, post-processing.

Consider the precision required for automotive parts or medical equipment – a tiny deviation can lead to product failure. MZBNL's machines are designed for "high-speed and high-precision cutting," reflecting our commitment to this critical aspect. Our 25 years of experience have allowed us to refine these systems, ensuring that even complex cuts, like intricate holes for assembly or aesthetic patterns for architectural elements, are executed with micron-level accuracy. For Ahmed's business, which services industries like vehicle parts and architectural decoration, this precision is a competitive differentiator, enabling him to deliver finished parts that meet strict OEM specifications or aesthetic demands. The ability to achieve consistent quality across thousands of parts directly impacts customer satisfaction and reduces costly scrap or rework. This level of precision is often backed by technologies that include real-time laser power modulation and gas pressure control, adapting to varying material thicknesses and types to ensure optimal cut quality throughout the entire process.

Cost Reduction and Material Savings: The Economic Advantage

The ultimate goal of improving efficiency and precision is to reduce costs and maximize profitability. Modern tube laser cutting machines achieve this through several synergistic features. The Zero-Waste Tail Material Innovation is a prime example. By calculating from the rear chuck as the origin, our machines can virtually eliminate unusable tail material, converting what was once scrap into usable output. For a company processing large volumes of expensive metal, this can translate into significant material savings. For instance, if a manufacturer processes 500,000 meters of tubing annually, and this innovation reduces waste by just 2%, they save 10,000 meters of material. If the material cost is $5 per meter, that’s $50,000 in direct savings each year.

Beyond material, modern machines dramatically reduce labor costs. The aforementioned No-CAD system and automated feeding mechanisms minimize the need for highly skilled operators and manual labor, respectively. This reduces not only direct wages but also indirect costs associated with training, turnover, and workplace injuries. When Ahmed chose MZBNL, he preferred suppliers with "proven technology and global references" and expected "high cost-performance ratio over low price." These features directly contribute to that ratio, offering substantial long-term savings that far outweigh the initial investment. The "multi-process integration" capability also means fewer machines, less floor space, and reduced energy consumption per part, further adding to the cost-effectiveness. The return on investment (ROI) for these advanced systems can be surprisingly rapid, often within 1-2 years, as detailed in various industry case studies focusing on lean manufacturing and operational excellence. This allows companies to scale up their production and diversify their service offerings without a proportionate increase in operational expenditure.

Automation reduces loading timeTrue

Front-feeding systems can cut loading time by 40% by eliminating manual tube placement.

Precision affects material wasteFalse

While precision improves quality, it's the zero-waste innovation that directly reduces material waste by utilizing tail ends.

What is the impact of smart technology integration in these machines?

Are your current manufacturing processes lagging in data insights and automated decision-making? Without smart technology, you're missing opportunities for predictive maintenance, real-time optimization, and truly intelligent production. Discover how smart technology integration in modern tube laser machines is revolutionizing efficiency, reliability, and profitability.

Smart technology integration in modern tube laser cutting machines enables real-time monitoring, predictive maintenance, and adaptive process control. This significantly reduces downtime, optimizes material usage, and enhances overall productivity through data-driven decision-making, transforming traditional workshops into intelligent, interconnected fabrication hubs.

From my perspective at MZBNL, having led the development of advanced machinery for over two decades, the integration of "smart and digitalized systems" isn't just an add-on; it's the very core of what defines a truly modern machine. It’s what transforms a powerful tool into an intelligent partner in production. Think about Ahmed Al-Farsi's desire for automated solutions to upgrade production efficiency – smart technology is precisely what delivers that. His concerns about equipment from some suppliers lacking local service support and the need for remote diagnostics4 highlight the importance of connectivity and intelligent self-monitoring capabilities. Let's delve into how these digital advancements are creating unprecedented levels of efficiency, reliability, and insight, fundamentally reshaping the manufacturing landscape.

The infusion of smart technology into modern tube laser cutting machines represents a transformative leap, transitioning them from standalone mechanical workhorses to intelligent, interconnected components of a larger digital ecosystem. This integration, often referred to as Industry 4.0 or the Industrial Internet of Things (IIoT), empowers machines with the ability to collect, analyze, and act upon vast amounts of data in real-time. The impact extends far beyond simple automation, fundamentally altering maintenance strategies, optimizing production flows, and fostering a level of adaptability previously unattainable. This paradigm shift addresses critical industry challenges such as unforeseen downtime, inconsistent product quality, and inefficient resource allocation, which are common pain points for manufacturers globally.

Predictive Maintenance and Remote Diagnostics: Minimizing Downtime

One of the most significant impacts of smart technology is the shift from reactive to predictive maintenance. In traditional setups, maintenance is often performed on a fixed schedule or only after a component fails, leading to unexpected downtime and production halts. However, modern laser machines equipped with an array of sensors can continuously monitor critical components—such as the laser source, cutting head, chucks, and motors—for signs of wear, temperature fluctuations, or performance degradation. This real-time data is then analyzed by algorithms that can predict potential failures before they occur. For example, slight variations in laser power output or unusual vibrations in the feeding mechanism can trigger an alert, prompting proactive maintenance.

This capability is particularly vital for a business owner like Ahmed Al-Farsi, who values "after-sales service and training support" and "spare parts availability and remote diagnostics." With MZBNL's smart systems, our service team can often diagnose issues remotely, guiding Ahmed's local technicians through troubleshooting steps or even dispatching the correct spare parts proactively. This drastically reduces the "long machine lead times" that affected his project delivery in the past. Instead of waiting days for a technician to arrive and diagnose a problem, issues can often be resolved in hours, minimizing production loss and maximizing machine uptime. A study by McKinsey & Company suggests that predictive maintenance can reduce machine downtime by 30-50% and increase machine lifespan by 20-40%, offering substantial long-term cost savings and improved operational reliability. This foresight allows for scheduled, targeted maintenance, avoiding costly, emergency repairs and keeping production lines running smoothly.

Real-time Optimization and Adaptive Process Control: Enhancing Quality and Efficiency

Smart technology integration also enables real-time optimization of the cutting process itself, ensuring consistent quality and maximizing efficiency. Modern laser machines use sophisticated algorithms that can adapt cutting parameters (laser power, gas pressure, cutting speed, focal position) based on real-time feedback from sensors monitoring material thickness, composition, and even surface conditions. For instance, if a slight variation in material thickness is detected, the system can instantly adjust the laser power to maintain optimal cut quality and prevent burrs or incomplete cuts.

This level of adaptive control is crucial for maintaining "high-precision cutting" and producing "finished parts to builders, decorators, and OEMs," which are key to Ahmed's profit model. My 25 years of experience have shown that even minor inconsistencies in material can lead to significant scrap if not compensated for. By leveraging data analytics, these machines can learn from previous cuts, refining their performance over time through machine learning algorithms. This self-optimization leads to higher first-pass yield, reducing rework and material waste, and ultimately lowering the cost per part. Furthermore, integrated vision systems can perform immediate quality checks, identifying defects as they occur rather than at the end of the production line, ensuring that only high-quality products proceed to the next stage. This proactive quality assurance is a significant differentiator in competitive markets, where product consistency is highly valued.

Seamless Integration and Data-Driven Decision Making: The Connected Factory

The ultimate vision of smart technology integration is the creation of a truly connected factory. Modern tube laser cutting machines can communicate seamlessly with other systems within the manufacturing ecosystem, including Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), and CAD/CAM software. This interoperability enables automated job scheduling, material tracking, and production reporting, providing a holistic view of the factory's operations.

For a forward-thinking business owner like Ahmed, who is considering becoming a regional distributor, access to this level of data is invaluable. He can monitor production metrics, analyze machine performance trends, and identify areas for further optimization from anywhere. This "smart and digitalized" capability provides actionable insights, moving from reactive problem-solving to proactive strategic planning. For example, historical data on machine utilization and part production can inform decisions about future investments, capacity planning, and even pricing strategies for contract-based fabrication services. Furthermore, cloud-based connectivity allows for software updates and new feature deployments remotely, ensuring the machine remains cutting-edge throughout its lifespan without physical intervention. This seamless integration facilitates a more agile, responsive, and ultimately more profitable manufacturing operation, empowering businesses to adapt quickly to market changes and leverage their production data for continuous improvement.

Predictive maintenance reduces downtimeTrue

Smart technology enables predictive maintenance by monitoring machine components in real-time, allowing issues to be addressed before they cause failures.

Smart machines cannot adapt cutting parametersFalse

Modern laser machines use sensors and algorithms to automatically adjust cutting parameters like power and speed based on material conditions.

How do modern features contribute to cost reduction and material savings?

Are you constantly battling rising material costs and struggling to reduce operational overhead? Inefficient processes and excessive material waste can significantly erode your profit margins and competitive edge. Discover how cutting-edge features in modern tube laser machines are designed to dramatically reduce costs and maximize material savings, boosting your profitability.

Modern tube laser machines contribute to significant cost reduction through features like Zero-Waste Tail Material cutting and No-CAD operation, which minimize material scrap and reduce reliance on skilled labor. Automated feeding and high-precision cutting also lower energy consumption, minimize rework, and improve overall throughput, leading to substantial long-term savings.

At MZBNL, our design philosophy has always been centered on maximizing value for our clients. We understand that for businesses like Ahmed Al-Farsi's, where the profit model is contract-based fabrication services, every penny saved on materials and every minute gained in efficiency directly impacts the bottom line. Ahmed's preference for "high cost-performance ratio over low price" resonates deeply with our commitment to delivering "cost-effective customized solutions." It’s not just about the upfront investment; it's about the total cost of ownership and the return on investment over the machine's lifespan. I want to share how our specific innovations are engineered to chip away at common manufacturing expenses, turning waste into profit and complexity into simplicity.

The economic advantages of modern tube laser cutting machines are profound, extending far beyond the initial purchase price. These machines are engineered with an acute understanding of the financial pressures facing manufacturers, integrating features that systematically attack the twin challenges of high operational costs and material waste. The goal is not just to cut metal, but to revolutionize the economics of metal fabrication, ensuring that every piece of material is utilized to its fullest potential and every labor hour is maximized for productivity. This strategic approach makes them indispensable assets for businesses aiming for sustainable growth and enhanced competitiveness in a demanding global market.

Direct Material Cost Savings: The Zero-Waste Revolution

One of the most impactful contributions to cost reduction is the dramatic reduction in material waste. Traditional laser cutting systems, by their design, often leave an unusable "tail" at the end of each tube. This leftover material, seemingly small on a per-tube basis, aggregates into significant financial losses over time, especially for high-volume operations or when processing expensive alloys. For businesses like Ahmed's, which process large quantities of metal pipes for various architectural and automotive applications, even a small percentage of material waste can translate into tens of thousands of dollars annually.

MZBNL’s Zero-Waste Tail Material Innovation directly addresses this critical issue. By redefining the cutting logic to calculate from the rear chuck as the origin, our machines can virtually eliminate this tail material, provided the remaining section is smaller than the product length. This means nearly 100% of the purchased material can be converted into sellable parts. For instance, if a company processes 1,000 tons of steel tubing per year, and traditional methods result in a 3% tail waste, that's 30 tons of scrap. At an average cost of $800 per ton, that's $24,000 lost annually just on tail waste. Our innovation can recover a significant portion of this, directly contributing to the profit margin. This not only offers substantial financial savings but also aligns with corporate sustainability goals, reducing environmental impact and improving resource efficiency. The competitive advantage derived from lower material costs allows businesses to offer more competitive pricing or achieve higher profit margins on their contract-based fabrication services.

Reduced Labor and Operational Overheads: Beyond Direct Wages

Beyond material, labor costs and associated operational overheads are significant components of a manufacturer's budget. Modern tube laser cutting machines significantly reduce these costs through automation and simplification. The No-CAD Operating System, for example, dramatically lowers the skill threshold required for machine operation. As I mentioned, training time can be reduced from 15 days to just 1 day. This directly addresses Ahmed's pain point of "previous machines required skilled CAD operators" and the associated "high operator turnover caused retraining burdens." By simplifying the programming process, businesses can utilize existing staff more effectively or train new hires rapidly, reducing reliance on highly paid, specialized CAD engineers.

Similarly, the Front-Feeding Innovation reduces operator labor intensity by approximately 40%. This doesn't just speed up the loading process; it reduces physical strain on employees, contributing to fewer workplace injuries and higher morale, which indirectly lowers costs related to absenteeism and workers' compensation. Furthermore, the multi-process integration capabilities of these machines mean that a single machine can perform cutting, punching, and marking operations. This eliminates the need for multiple machines, reduces floor space requirements, minimizes inter-machine material handling, and lowers energy consumption per finished part. According to a study by Deloitte, advanced automation can reduce manufacturing labor costs by up to 30%, showcasing the immense economic leverage provided by these technologies. These combined efficiencies result in a lower cost per piece produced, strengthening the overall economic viability of the fabrication process.

Enhanced Throughput and Quality: Boosting Revenue and Customer Satisfaction

The contributions to cost reduction also come from increased throughput and superior quality, which indirectly boost revenue and enhance customer satisfaction. High-speed and high-precision cutting, coupled with minimal downtime due to smart technology and predictive maintenance, means more parts can be produced in less time. This allows businesses to take on more projects, meet tighter deadlines, and increase overall production capacity without expanding their physical footprint or workforce proportionately. For Ahmed, whose business relies on delivering finished parts to builders, decorators, and OEMs, faster delivery times are a crucial competitive edge.

Moreover, the precision and consistency achieved by modern machines significantly reduce the likelihood of errors, rework, and scrap due to poor quality. This means fewer materials are wasted on defective parts, and less labor is expended on correcting mistakes. The ability to consistently produce high-quality parts also builds a strong reputation, attracting more clients and potentially allowing for premium pricing. My conversations with clients like Ahmed often highlight that "proven technology and global references" are key buying preferences because they signify reliability and consistent quality. This consistent quality also minimizes returns and warranty claims, leading to higher customer satisfaction and repeat business. Ultimately, by reducing costs at every stage of production and enhancing the quality of output, modern tube laser cutting machines provide a powerful economic advantage, transforming manufacturing challenges into opportunities for growth and profitability.

Zero-Waste Tail Material reduces scrapTrue

MZBNL's innovation calculates cuts from the rear chuck, eliminating unusable tail material and maximizing material utilization.

No-CAD systems require skilled operatorsFalse

No-CAD operating systems actually reduce the need for specialized CAD skills, cutting training time from 15 days to just 1 day.

What recommendations are there for selecting a machine with these key features?

Faced with a myriad of options, are you overwhelmed trying to select the right tube laser cutting machine? Choosing the wrong machine can lead to operational bottlenecks, underperformance, and a significant drain on your investment. Equip yourself with essential recommendations to identify a machine featuring the innovations that will truly elevate your production capabilities.

When selecting a modern tube laser cutting machine, prioritize suppliers offering No-CAD systems, automatic front-feeding, and zero-waste tail cutting to maximize efficiency and savings. Additionally, evaluate after-sales support, customization options, and global references, ensuring the machine aligns with your specific production needs and offers a strong long-term cost-performance ratio.

From my vantage point at MZBNL, having helped countless businesses globally, including those expanding into new markets like Ahmed Al-Farsi's in the UAE, I can tell you that selecting the right laser tube cutting machine is not just a procurement decision; it's a strategic investment in your future. Ahmed, for instance, specifically looks for "turnkey solutions that are easy to install and operate5" and values "customization and post-sales training/support," along with "proven technology and global references6." These insights are critical because they highlight what truly matters beyond the spec sheet. Based on our 25 years of experience and 30+ patents in the field, I've distilled the most crucial considerations to help you make an informed decision that ensures high cost-performance and long-term success.

Selecting a modern tube laser cutting machine is a complex decision that requires a comprehensive understanding of both your operational needs and the market's technological landscape. With the rapid evolution of these machines, focusing solely on basic specifications can be misleading. A truly strategic acquisition involves a deep dive into features that promise long-term efficiency, material savings, and robust support, aligning with the specific challenges and growth aspirations of your business. As a high-tech enterprise with 30+ patents and 4000+ global clients, MZBNL has learned that the best machine is one that not only performs optimally but also seamlessly integrates into and enhances your entire production ecosystem.

Prioritizing Transformative Innovations for Operational Gains

The first and foremost recommendation is to prioritize machines that incorporate transformative innovations designed to address common industry pain points and dramatically enhance operational efficiency. This means looking beyond basic cutting speed and focusing on features that simplify complex processes and automate labor-intensive tasks. Our MZBNL experience has shown that innovations like the No-CAD Operating System are game-changers. For a potential client like Ahmed Al-Farsi, whose "previous machines required skilled CAD operators" and who suffered from "high operator turnover caused retraining burdens," a No-CAD system is invaluable. It reduces the dependency on highly specialized personnel, democratizing machine operation and significantly cutting down on training time (from 15 days to just 1 day). This ensures faster deployment and reduced ongoing labor costs.

Similarly, an automated material handling system, such as MZBNL's Front-Feeding Innovation, is crucial. While traditional methods require manual loading, which is slow and labor-intensive, front-feeding can increase efficiency by 40% and reduce operator intensity by a similar margin. This isn't just about speed; it's about optimizing the entire material flow, minimizing bottlenecks, and freeing up human resources for more strategic tasks. Furthermore, seek out machines with integrated multi-process capabilities (cutting, punching, marking in one go). This "multi-process integration" capability significantly reduces setup times and eliminates the need to move workpieces between different machines, streamlining the production line and reducing potential for errors. When evaluating, ask for clear demonstrations of these features and quantified data on their impact on setup times and labor reduction.

Evaluating Long-Term Cost-Effectiveness and Material Optimization

The true cost of a machine extends far beyond its initial purchase price, encompassing material utilization, energy consumption, maintenance, and scrap rates. Therefore, a critical recommendation is to meticulously evaluate how a machine's features contribute to long-term cost reduction and material savings. The Zero-Waste Tail Material Innovation is a prime example of a feature that directly impacts your bottom line. By calculating from the rear chuck as the origin, it significantly reduces or eliminates unusable tail material, converting what was once scrap into usable parts. For a business processing large volumes of material, this translates into substantial savings over the machine's lifespan. During a typical year, this can save thousands to tens of thousands of dollars in material costs alone, significantly improving profit margins for contract-based fabrication services.

Furthermore, consider the machine's energy efficiency. Modern fiber lasers are significantly more energy-efficient than older CO2 lasers. Look for "smart and digitalized systems" that offer energy management features, such as automatic standby modes and optimized power consumption based on material and thickness. This directly impacts your utility bills. My discussions with clients about their "cost-effective customized solutions" always emphasize that the overall "cost-performance ratio" is paramount. A machine that appears cheaper upfront but leads to higher material waste, increased labor needs, and higher energy consumption will inevitably be more expensive in the long run. Request detailed ROI analyses from suppliers, including projections on material savings and operational cost reductions based on your specific production volumes and material types.

Assessing Supplier Support, Customization, and Global Presence

Finally, the success of your investment heavily relies on the support and partnership offered by the supplier. A machine, no matter how advanced, is only as good as the service and expertise behind it. My experience with MZBNL, a company with 25 years in metal fabrication and main export countries across Southeast Asia, Middle East, Europe, and North America, highlights the importance of a robust global support network. For a client like Ahmed, who is in the UAE and seeks "after-sales service and training support," "spare parts availability and remote diagnostics," and a potential "local agent or distributor presence," these factors are non-negotiable.

Look for suppliers who offer comprehensive post-sales training, not just initial setup, but ongoing skill development for your team. Enquire about the availability of spare parts and the speed of their delivery. Companies that provide "remote diagnostics" can often troubleshoot issues quickly, minimizing downtime. Furthermore, assess the supplier's willingness and capability to provide "customization" options. Your specific production needs might evolve, and a flexible supplier can offer tailored solutions. Lastly, verify the supplier's "proven technology and global references." A company with a strong track record, a large global client base (like MZBNL's 4000+ global enterprise clients), and positive testimonials indicates reliability and a commitment to long-term client relationships. This diligence ensures that your investment is not just in a machine, but in a long-term partnership that supports your business growth and minimizes future pain points.

No-CAD systems reduce training timeTrue

No-CAD systems simplify operation, cutting training time from 15 days to just 1 day by eliminating the need for specialized CAD skills.

Front-feeding decreases efficiencyFalse

Front-feeding actually increases efficiency by 40% by automating material handling and reducing manual labor requirements.

Conclusion

Modern tube laser cutting machines redefine fabrication through automation, precision, and efficiency. BNL’s innovations, including No-CAD, front-feeding, and zero-waste tail material, dramatically cut costs, save material, and boost output. Selecting wisely, focusing on these features and robust support, ensures a transformative investment for your business's future.

-

Learn about the latest technologies revolutionizing manufacturing processes ↩

-

Gain insights into MZBNL's global client success stories and efficiency improvements ↩

-

Discover how MZBNL innovations streamline operations in metal fabrication ↩

-

Understand how remote diagnostics enhance maintenance and reduce machine downtime ↩

-

Get insights into simplified installation and operational ease for laser cutting machines. ↩

-

Learn the advantages of using machines with vetted technology and wide industry acceptance. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.