Understanding Tail Control in Metal Tube Cutting Machines

Have you ever considered the hidden costs of material waste in tube cutting1? The frustrating reality of leftover tail material often goes unnoticed, silently eating into profits and impacting your operational efficiency. We understand this pain, and the good news is, a solution exists.

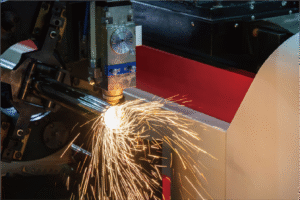

Tail control in metal tube cutting machines refers to the technology and methods employed to minimize or eliminate unusable remnant of material (tail) left at the end of a processed tube. Effective tail control significantly boosts material utilization and reduces operational costs for manufacturers.

For years, the concept of maximizing material usage in tube cutting felt like an elusive goal, with tail material constantly chipping away at profitability. But as I’ve seen through my 25 years in metal fabrication with MZBNL, the industry is now moving beyond mere minimization towards true elimination. Understanding the evolution and latest innovations in this field is no longer just about efficiency; it's about gaining a significant competitive edge and unlocking new levels of profitability for businesses like yours.

When I reflect on the trajectory of metal tube processing, the challenge of tail material has always been a significant hurdle. Early systems, while revolutionary for their time, operated with a inherent design flaw that ensured a certain amount of tube would always become scrap, impacting everything from raw material costs to environmental footprint. This wasn't just an inefficiency; it was a fundamental constraint on profitability, particularly for high-volume operations. Consider a mid-sized fabrication business, similar to Ahmed Al-Farsi’s in the UAE, specializing in railings or automotive parts. Even a small percentage of waste, compounded across thousands of tubes annually, translates into substantial financial losses. My experience with MZBNL, a high-tech enterprise with over 30 patents and a global client base, has shown me that true innovation often stems from addressing these long-standing, seemingly unavoidable problems head-on. The paradigm shift we've championed in tail control isn't merely incremental improvement; it's about fundamentally redesigning the cutting logic to transform what was once considered unavoidable waste into usable material, setting a new industry standard.

Background of tail control in tube cutting technology

Are you struggling with excessive material waste from tube cutting? Traditional methods have long left fabricators grappling with substantial unusable tail material, directly impacting your bottom line and sustainability efforts. This long-standing issue demanded a fundamental shift in approach.

Early tail control in tube cutting technology primarily focused on rudimentary nesting software and manual handling techniques to reduce, but not eliminate, material waste. These methods aimed to optimize material usage by arranging parts efficiently, yet limitations in machine mechanics often resulted in significant leftover remnants.

In the nascent stages of automated tube cutting, the primary focus was on speed and precision, often overlooking the significant, albeit smaller, challenge of leftover material. As I recall from my early days, we were thrilled with the ability to cut tubes automatically, but the reality of consistent tail waste was a quiet, persistent drain. This wasn’t just a minor annoyance; it was a systemic issue. These initial approaches, while a step forward from purely manual processes, relied heavily on fixed chuck positions and basic cutting logic, inherently limiting how close the cut could get to the very end of the tube. This meant that a substantial "tail" of expensive raw material was invariably left unusable, impacting a fabricator's profitability significantly over time. Understanding this historical context helps us appreciate how far we've come and why truly innovative solutions, like those we've developed at MZBNL, were absolutely necessary to overcome these deeply ingrained inefficiencies, paving the way for more economical and sustainable manufacturing.

Evolution of Material Utilization Practices

Historically, metal tube cutting operations were rudimentary, often involving manual hacksaws or abrasive saws, leading to considerable material waste and inconsistent precision. As automation began to emerge, the primary goal was to increase throughput and accuracy, with less emphasis placed on optimizing every last inch of material. Early automated systems, while vastly improving speed and repeatability, still operated on principles that inherently generated tail material. The machine's chuck, designed for secure gripping and stability, required a minimum length of tube to hold onto, meaning the final segment of the tube, often several inches long, could not be processed for valuable parts. This "dead zone" became a recognized, though often tolerated, inefficiency. For a company like Ahmed Al-Farsi’s, producing high volumes of architectural metalwork, even a 5% material waste rate on thousands of tubes annually could translate into tens of thousands of dollars in lost revenue and increased raw material procurement. This early phase was characterized by a mindset of "acceptable waste" rather than "zero waste."

The Birth of Tail Material Awareness

As the metal fabrication industry matured and competition intensified, businesses began to scrutinize every aspect of their operations for cost savings. This led to a heightened awareness of material waste, specifically the recurring problem of tail material. Manufacturers started exploring rudimentary methods to mitigate this, such as improved nesting software that could arrange multiple parts more efficiently on a single tube. However, these software-based solutions could only optimize within the existing mechanical constraints of the machines. The machine's physical design—specifically the position and functionality of the rear chuck—remained the primary limiting factor. Efforts to reduce the tail involved, for instance, attempting to cut shorter parts at the very end of the tube, but this often led to instability, reduced cut quality, or even machine damage. Industry reports from the early 2000s highlighted that typical tube cutting operations still saw a material waste rate of 3-7% attributed solely to tail ends, underscoring the pressing need for a more fundamental technological breakthrough beyond mere software adjustments.

Technical Limitations of Conventional Systems

The core limitation of conventional laser tube cutting machines stemmed from their mechanical design and cutting logic. Traditionally, the laser head would cut from the front of the tube towards the rear, with the rear chuck gripping the material. Once the laser reached a certain proximity to the chuck, it could no longer cut effectively or safely, leaving an uncut "tail." This constraint arose because the chuck needed sufficient material to maintain a stable grip, prevent vibration, and ensure accurate rotation during the cutting process. Any attempt to cut too close to the chuck risked losing material stability, leading to inaccurate cuts, burrs, or even damaging the laser head. This fundamental design meant that a certain length of tube, typically between 100mm and 200mm, was consistently left as waste. This wasn't a flaw in operation but an inherent design limitation of the process itself, requiring significant innovation to overcome. For instance, if a company processes 10,000 tubes annually, each leaving a 150mm tail, that amounts to 1,500 meters of wasted material, a substantial figure that directly impacts profitability.

| Tail Control Approach | Description | Typical Waste Reduction | Key Limitations |

|---|---|---|---|

| Manual Optimization | Operators manually adjust tube placement and cutting order. | Low (5-10%) | Inconsistent, labor-intensive, operator skill dependent. |

| Basic Nesting Software | Software arranges parts on tube to minimize gaps. | Moderate (10-25%) | Limited by physical chuck limitations; still leaves tail. |

| Fixed Chuck Systems | Traditional machines where the chuck holds a fixed minimum length. | Minimal (0-5% reduction) | Inherent design leads to standard tail waste. |

Tail control boosts material utilizationTrue

Effective tail control technology directly improves material usage by minimizing leftover remnants, as explained in the background section.

Early systems eliminated tail waste completelyFalse

Historical context shows early automated systems still left significant tail material due to mechanical constraints.

Current state of tail control methods and techniques

Are you tired of watching valuable material turn into scrap? Despite advancements, many current tube cutting methods still struggle with persistent tail waste, eroding your profit margins and increasing operational costs. It’s a common issue that demands a more evolved approach.

Currently, tail control methods often involve advanced nesting software, specialized chuck designs, and intelligent part sequencing to reduce leftover material in tube cutting. While these techniques significantly improve material utilization compared to older methods, they frequently still produce some unusable tail, impacting overall efficiency.

While the early days were about simply getting the job done, the current landscape of metal tube cutting has seen significant strides in efficiency, particularly in how we manage material. Today, most advanced fabrication shops employ sophisticated nesting software2 that can optimize part layouts across a tube, minimizing the gaps between components. I've seen firsthand how these systems, combined with more flexible chuck designs that offer a slightly shorter gripping length, have helped businesses like Ahmed Al-Farsi's improve their material yield. However, even with these improvements, the persistent issue of tail material remains a challenge. These contemporary methods, while undoubtedly better, often represent an incremental improvement rather than a fundamental solution. They can reduce the tail, but rarely eliminate it entirely, meaning that a certain percentage of raw material still ends up as scrap. This ongoing waste, though smaller, still adds up, making true "zero-waste" solutions3 highly sought after and underscoring the continuous drive for innovation in our industry.

Common Tail Material Reduction Strategies

Today's metal fabrication industry extensively utilizes several strategies to mitigate tail material waste. One of the most prevalent is advanced nesting software, which intelligently arranges multiple parts onto a single tube to minimize the gaps between cut sections. These algorithms can consider part dimensions, material thickness, and machine kerf to create the most material-efficient layout. For instance, a study by a leading industry analyst indicated that optimal nesting can reduce overall material scrap by 15-20% compared to unoptimized cutting. Another common technique involves using "floating" or "movable" chucks that can re-grip the tube closer to the cutting point, theoretically reducing the minimal material length required. However, even with these sophisticated chuck systems, there's a practical limit to how short the remaining tube can be while still maintaining stability and precision during the cutting process. Many manufacturers also employ "common-line cutting" where adjacent parts share a single cut line, further reducing waste.

Limitations of Existing Technologies

Despite these advancements, current tail control methods still fall short of achieving true zero waste. The primary limitation often lies in the mechanical design of the machines themselves. Most laser tube cutting machines still operate on a principle where the tube is fed from one end and gripped by a chuck on the other. This chuck, by its very nature, requires a minimum gripping length to secure the tube effectively for high-speed, high-precision laser cutting. If the tube length inside the chuck becomes too short, it can lead to instability, vibration, or even misalignment, compromising cut quality and potentially damaging the machine. Even with the most sophisticated nesting software, if the machine cannot physically cut within that final gripping zone, a tail will inevitably be left. For example, a common industrial standard for minimum gripping length is often 150-250mm, meaning even if a part could technically be cut from a 100mm piece, the machine's physical limitations prevent it. This results in consistent, albeit reduced, tail material that still translates into significant material loss over time, impacting the profitability of businesses like Ahmed's, who prioritize high cost-performance.

Industry Adoption and Economic Impact

The adoption of these improved tail control methods varies across the industry, with larger, more technologically advanced firms more likely to invest in the latest software and machinery. However, for many mid-sized enterprises, the cost of upgrading to these incrementally better systems can be substantial, making them hesitant to replace existing, albeit less efficient, equipment. The economic impact of even partially reducing tail material is significant. For a company processing 500 tons of tube material annually, where 5% is consistently lost as tail waste, a 20% reduction in that waste (from 5% to 4%) translates to 1 ton of saved material. At an average cost of $1,000 per ton for raw metal, this represents $1,000 in direct savings, not including the environmental benefits. While these savings are positive, they highlight that the problem is not fully solved, and a more revolutionary approach is needed to move from reduction to elimination, a key focus for MZBNL in our offerings for markets like Southeast Asia and North America.

| Method/Technique | Description | Avg. Tail Length Remaining | Material Savings % (Approx.) |

|---|---|---|---|

| Advanced Nesting | Software optimizes part layout on tube. | 100-200mm | 15-20% (of total scrap) |

| Specialized Chucks | Chucks designed for slightly shorter grip. | 50-150mm | 5-10% (additional to nesting) |

| Common-Line Cutting | Sharing cut lines between adjacent parts. | Varies | 5-10% (additional to nesting) |

Nesting software reduces material wasteTrue

Advanced nesting software can reduce material scrap by 15-20% by optimizing part layouts on tubes.

Current methods eliminate all tail wasteFalse

Even with advanced techniques, current methods still leave some unusable tail material due to mechanical limitations.

Challenges faced in achieving efficient tail control

Are you constantly battling the stubborn issue of metal waste? Despite your best efforts, achieving truly efficient tail control in tube cutting machines4 remains a persistent challenge, frustrating manufacturers and limiting profit potential. We understand this ongoing struggle.

Achieving efficient tail control in tube cutting machines is challenging due to mechanical constraints of chuck gripping, complex software algorithms required for dynamic optimization, and material handling dynamics affecting stability at extreme lengths. These factors collectively prevent the complete elimination of unusable material remnants.

Even with the sophisticated methods we just discussed, the journey towards true zero-waste tail control is fraught with technical complexities that often appear insurmountable to those outside the specialized field. When I consult with clients, I often hear frustrations about seemingly small pieces of material still being left behind, despite their investments in advanced machinery. It’s not simply a matter of wanting to cut closer to the end; it involves overcoming fundamental mechanical, software, and material science challenges. Imagine trying to precisely cut a noodle when you can only hold onto a tiny fraction of its end – the instability and lack of rigidity become immediate problems. These hurdles are precisely what prevent many current systems from achieving complete material utilization, keeping the dream of zero-waste just out of reach for most. Our engineers at MZBNL have spent years meticulously dissecting these very pain points, developing solutions that re-engineer the very physics of how tubes are held and cut to circumvent these long-standing obstacles.

Mechanical and Structural Constraints

One of the primary challenges in achieving efficient tail control is inherent in the mechanical design of traditional laser tube cutting machines. The chuck system, which holds and rotates the tube, requires a minimum gripping length to ensure stability and precision during the high-speed cutting process. This essential requirement creates a "dead zone" at the very end of the tube that the laser simply cannot reach without compromising the integrity of the cut or damaging the machine. If the tube becomes too short within the chuck, it can vibrate excessively, leading to inaccurate cuts, burrs, or even catastrophic failure of the laser head. This structural limitation is a fundamental design constraint, meaning that no matter how sophisticated the software, if the chuck cannot grip a super-short piece, it cannot be cut. For a precise and repeatable process, a firm grip is non-negotiable, and traditionally, this grip demands a certain length of material to clamp onto, often ranging from 150mm to 200mm depending on the machine model and tube diameter.

Software and Algorithmic Complexity

Beyond mechanical limitations, the software and algorithmic complexity involved in truly optimizing tail control present another significant hurdle. While advanced nesting software can plan layouts, it typically operates within the known mechanical constraints of the machine. Developing algorithms that can dynamically adjust cutting paths, re-sequence operations, and account for real-time material variations—all while minimizing the tail to near zero—is incredibly challenging. Such software needs to integrate seamlessly with the machine's mechanics, sensors, and laser control system to make instantaneous decisions. Moreover, for a truly zero-waste system, the software must be able to calculate and cut from a dynamic origin, rather than a fixed one, and intelligently manage the precise lengths of remaining material to ensure they are fully utilized. This requires a level of intelligence that goes far beyond standard CAD/CAM programming, demanding sophisticated predictive models and real-time feedback loops to ensure stability and accuracy during the final cuts, even on very short sections.

Material Handling and Processing Dynamics

The physical handling of very short tube remnants also poses substantial challenges. As the tube gets shorter towards the end of a cut cycle, its stability within the machine can decrease, increasing the risk of vibration, misalignment, or even dropping the material. Ensuring consistent cutting quality on the very last section of a tube requires highly precise material feeding and support mechanisms that prevent any movement or deformation. For example, if a tube is 6 meters long and only 100mm remains in the chuck, the forces acting on that short piece during high-speed cutting can cause it to flex or vibrate, leading to inaccuracies. Maintaining the necessary rigidity and control for precision laser cutting on such short lengths requires specialized design in both the feeding system and the chuck itself. This is why many manufacturers opt to leave a longer tail, prioritizing stable processing over complete material utilization, highlighting the need for a truly innovative approach to overcome these processing dynamics.

| Challenge Category | Description | Typical Impact on Waste |

|---|---|---|

| Mechanical Grip | Chucks need minimum length for stable hold. | 150-200mm tail |

| Software & Logic | Complex algorithms needed for dynamic optimization. | Difficult to achieve near-zero. |

| Material Dynamics | Stability issues when cutting very short remnants. | Risk of inaccuracy, vibration. |

Chucks require minimum grip lengthTrue

Mechanical stability demands 150-200mm of material for proper chuck gripping, creating unavoidable waste.

Standard CAD/CAM enables zero-wasteFalse

Achieving near-zero waste requires advanced predictive algorithms beyond basic CAD/CAM programming.

Innovative solutions for improving tail control in cutting machines

Are you fed up with material waste eating into your profits? The persistent challenge of tail material has long plagued the metal fabrication industry, but revolutionary solutions are now emerging, promising to transform your operational efficiency and profitability. This is where innovation truly shines.

Innovative solutions for tail control, such as MZBNL's Zero-Waste Tail Material Innovation, redefine cutting logic by operating from the rear chuck as the origin. This breakthrough allows the machine to utilize nearly the entire tube, dramatically reducing leftover material and maximizing productivity while ensuring precision.

For years, the metal fabrication industry considered a certain amount of tail waste as an unavoidable part of the process, a frustrating but accepted inefficiency. But at MZBNL, we refuse to accept limitations. We understood that incremental improvements wouldn't be enough; what was needed was a fundamental re-imagining of how a tube is processed from start to finish. This commitment to challenging the status quo led us to develop groundbreaking innovations, particularly our Zero-Waste Tail Material Innovation. This isn't just a tweak; it's a paradigm shift that fundamentally changes the cutting logic, effectively turning what was once unusable scrap into valuable product. It’s solutions like these that truly empower businesses, giving them a significant edge in material cost savings and operational efficiency, proving that with dedicated R&D and a deep understanding of customer pain points, seemingly impossible challenges can indeed be overcome.

The Concept of Rear-Chuck Origin Cutting

One of the most revolutionary innovations in modern tube cutting technology, pioneered by MZBNL, is the concept of cutting from the rear chuck as the origin5. Traditional machines cut from the tube head, leaving an unusable tail where the chuck grips the tube at the end of the process. Our Zero-Waste Tail Material Innovation re-engineers this fundamental logic. Instead of focusing on the front, the system calculates and processes cuts with the rear chuck as the constant reference point. This means that as long as the remaining section of the tube is shorter than the product length being cut, it can be fully utilized. This ingenious design allows the system to process the entire tube length, virtually eliminating leftover tail material. For instance, if Ahmed Al-Farsi, our typical client in the UAE, previously wasted 150mm on every 6-meter tube, this innovation could save him approximately 2.5% of material per tube. Over a year of high-volume production, processing thousands of tubes, this translates into substantial savings on raw material costs, directly enhancing his profit margins.

Integrated Software Algorithms for Dynamic Optimization

The success of such a radical mechanical innovation hinges on equally intelligent software. MZBNL's advanced systems integrate sophisticated algorithms for dynamic optimization6 to achieve zero tail waste. This isn't static programming; it's real-time, adaptive intelligence. The software continuously monitors the remaining tube length, compares it against the required part lengths, and intelligently re-sequences or adapts the cutting path to ensure that even the smallest remnant is used if it can form a complete part. This capability eliminates the need for manual intervention or complex operator calculations to salvage short pieces. For example, if a 5.5-meter tube is being cut into 1-meter sections, and a final 0.7-meter piece remains after four cuts, our system can recognize that if the next required part is, say, a 0.6-meter section, it can utilize that last 0.7-meter piece, rather than discard it. This level of integrated software intelligence maximizes material utilization and dramatically boosts cutting efficiency, reducing the need for highly skilled CAD operators, a direct answer to one of Ahmed's pain points regarding operator turnover.

Impact on Production Efficiency and Cost Savings

The tangible benefits of innovative solutions like MZBNL's Zero-Waste Tail Material Innovation are profound. Firstly, and most obviously, there are significant material cost savings. By virtually eliminating tail waste, manufacturers can make the most of every foot of raw material purchased, directly impacting their bottom line. Consider a typical fabrication shop using $500,000 worth of tube material annually; if 5% was previously lost as tail waste, that's $25,000. With zero-waste technology, this entire amount could be saved and converted into usable products. Secondly, it streamlines the production process by eliminating the need to manage and dispose of scrap material, saving labor time and waste management costs. Thirdly, it contributes to a more sustainable manufacturing footprint, aligning with growing global environmental consciousness. For clients like Ahmed, who seeks automated solutions to upgrade production efficiency and values a high cost-performance ratio, this innovation is a game-changer. It not only saves money but also enhances operational flow and competitiveness in markets like architectural metalwork and vehicle parts, offering a clear competitive advantage over businesses using older, less efficient machines.

| Feature | Traditional Systems (Approximate) | MZBNL's Zero-Waste Innovation | Impact |

|---|---|---|---|

| Tail Waste | 150-200mm per tube | < 10mm (virtually zero) | Significant material cost savings |

| Material Utilization | 95-98% | > 99.5% | Maximized raw material value |

| Scrap Management | Regular scrap collection needed | Minimal | Reduced labor & disposal costs |

| Cutting Logic | Front-feed, fixed origin | Rear-chuck origin | Enables full tube utilization |

Rear-chuck origin reduces wasteTrue

MZBNL's innovation uses the rear chuck as the cutting origin, allowing nearly full tube utilization.

Traditional cutting wastes 50% materialFalse

Traditional systems waste 150-200mm per tube (2.5-3.3%), not half the material.

Technical recommendations for optimizing tail control performance

Are you seeking to maximize your tube cutting efficiency? Achieving optimal tail control is crucial for any metal fabrication business aiming to cut costs and boost productivity. Discover the technical recommendations that can transform your operations.

To optimize tail control performance in metal tube cutting, prioritize machines with zero-waste design capabilities, implement comprehensive software-driven nesting, and ensure regular maintenance combined with thorough operator training. These technical steps collectively enhance material utilization and operational efficiency for your fabrication business.

While breakthrough innovations like MZBNL's Zero-Waste Tail Material Innovation set new industry benchmarks, simply acquiring advanced machinery isn't the sole answer to achieving peak tail control performance. I often tell my clients, including those considering distributing our products in regions like the Gulf, that the machine is only one part of the equation. To truly unlock the full potential of your investment and ensure minimal waste, it’s crucial to adopt a holistic approach that integrates technology with best practices. This means not just focusing on what the machine can do, but how it's operated, maintained, and supported by your overall workflow. These technical recommendations go beyond just the hardware, encompassing the critical interplay between advanced software, diligent maintenance, and well-trained personnel, ensuring that your cutting operations are not just efficient, but exceptionally optimized for maximum material yield and sustained profitability.

Prioritizing Advanced Machine Features (e.g., Zero-Waste Design)

The most impactful recommendation for optimizing tail control is to invest in machinery that incorporates advanced, fundamentally re-engineered features like MZBNL's Zero-Waste Tail Material Innovation. This isn't about incremental gains; it's about eliminating the problem at its source. When considering a new laser tube cutting machine, look beyond basic specifications and inquire specifically about the minimum tail length capabilities and how the machine achieves this. Systems that cut from the rear chuck as the origin, as ours do, inherently maximize material utilization by ensuring that as long as a remaining piece can form a product, it will be used. This feature alone can reduce material waste by an average of 2-5% compared to conventional machines, which translates into significant cost savings over time. For a business owner like Ahmed, who values a high cost-performance ratio and seeks turnkey solutions, prioritizing these proven technological innovations in machine selection offers an unparalleled return on investment, not just in raw material savings but also in streamlined operations and reduced waste disposal costs.

Implementing Comprehensive Software-Driven Nesting and Planning

Even with the most advanced zero-waste machines, comprehensive software-driven nesting and production planning remain critical for overall material optimization. While the machine handles the final tail, smart nesting ensures that multiple parts are arranged on the tube in the most efficient layout possible before cutting even begins. This includes considering different part lengths, diameters, and geometries to minimize internal scrap (material between parts) and maximize the number of parts from each tube. Modern nesting software, often integrated with No-CAD systems like BNL's, can simulate various cutting scenarios, identify potential material conflicts, and suggest optimal cutting sequences. Regularly updating and utilizing this software to its full potential is paramount. For example, if your production schedule requires 100 pieces of one length and 50 of another, the software can intelligently combine these orders onto the fewest possible tubes, leveraging the machine's zero-waste capability to then fully utilize those tubes. This proactive planning significantly contributes to reduced material consumption and higher throughput.

Regular Maintenance and Operator Training for Peak Performance

Finally, even the most technologically advanced machines require consistent maintenance and highly trained operators to perform at their peak, particularly concerning intricate features like tail control. Regular calibration of the chucks, laser head, and feeding mechanisms ensures that the machine maintains its precision, even when cutting at extreme ends of the tube. Wear and tear on components can lead to slight misalignments that, over time, can impact the machine's ability to achieve minimal tail lengths. Furthermore, comprehensive operator training is essential. While BNL's No-CAD system significantly lowers the skill threshold, providing advanced training on machine settings, material handling best practices, and troubleshooting common issues empowers operators to maximize efficiency and proactively identify potential problems. An operator who understands the machine’s capabilities and limitations can ensure the optimal functioning of tail control features, prevent costly errors, and contribute to the longevity and high-performance of the equipment. This focus on human expertise combined with robust technology is what truly separates efficient operations from average ones.

| Optimization Area | Key Recommendation | Expected Benefit |

|---|---|---|

| Machine Selection | Choose zero-waste design (e.g., MZBNL). | Near-zero tail waste, significant material savings. |

| Software | Utilize comprehensive nesting & planning. | Optimized material layout, reduced internal scrap. |

| Operations | Regular maintenance & thorough training. | Sustained precision, extended machine lifespan. |

Zero-waste machines cut from rear chuckTrue

Cutting from the rear chuck as origin maximizes material utilization by ensuring any remaining piece that can form a product will be used.

Advanced machines alone ensure peak performanceFalse

Peak performance requires a holistic approach combining advanced machines with proper software, maintenance and operator training.

Conclusion

Revolutionary tail control, exemplified by MZBNL's innovations, transforms metal tube cutting from a process of unavoidable waste to one of maximum material utilization. By embracing cutting-edge technology and best practices, businesses can significantly reduce costs, enhance efficiency, and achieve a truly sustainable, profitable future in metal fabrication.

-

Discover how leftover materials affect profitability and operational efficiency. ↩

-

Discover how nesting reduces material waste by optimizing part arrangement ↩

-

Explore innovative methods aiming to completely eliminate waste tails ↩

-

Understand typical challenges in minimizing waste in tube cutting operations. ↩

-

Discover how cutting from the rear chuck eliminates unnecessary material waste. ↩

-

Understand the software's role in optimizing cutting sequences and minimizing waste. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.