Why 4000+ Clients Choose MZBNL Metal Tube Cutting Machines

Are you struggling with inefficient metal tube cutting, leading to costly material waste and time-consuming operations? Many businesses face these exact challenges, hindering their productivity and profitability in a competitive market. At MZBNL, we understand these pain points, and our advanced metal tube cutting machines are engineered to overcome them, empowering your production.

MZBNL metal tube cutting machines are chosen by over 4000 global clients due to their unparalleled innovation, including the No-CAD operating system, efficient front-feeding, and zero-waste tail material cutting. These features significantly enhance precision, reduce operational complexity, and optimize material utilization for diverse industrial applications.

As a high-tech enterprise with 25 years of experience, we've witnessed firsthand the evolving demands of metal fabrication. Our journey has been defined by a relentless pursuit of technological innovation and a deep commitment to our clients' success. This dedication is reflected in every machine we design, manufacture, and deliver worldwide, ensuring that your investment translates into tangible improvements in productivity and profitability.

In today's dynamic manufacturing landscape, simply having a machine is not enough; the true value lies in its ability to adapt, innovate, and solve complex operational challenges. From my perspective at MZBNL, we’ve observed that companies often grapple with bottlenecks related to skilled labor, material waste, and inefficient workflows. For instance, in the Middle East, a client like Ahmed Al-Farsi, who runs a diversified metal fabrication business, frequently encounters issues with conventional machines requiring highly skilled CAD operators, leading to high training costs and slow project turnaround. This critical need for intelligent, user-friendly solutions that also deliver on precision and speed has driven our R&D efforts. We analyze industry research highlighting the rising demand for automation and integrated processes1, aiming to provide solutions that not only cut metal but also redefine operational efficiency and profitability for our global clientele. This proactive approach ensures our technology remains at the forefront, ready to tackle the real-world complexities of modern manufacturing.

What specific challenges do clients face in metal tube cutting?

Are you experiencing bottlenecks due to complex CAD requirements, slow material loading, or excessive material waste in your tube cutting operations? These common issues not only inflate production costs but also severely impact your project deadlines and overall competitiveness. We recognize these critical pain points that hold back many metal fabrication businesses, understanding the urgent need for more efficient solutions.

Clients in metal tube cutting commonly face challenges such as the need for highly skilled CAD operators, inefficient material handling leading to slow production, and significant material waste from traditional cutting processes. These issues often result in increased operational costs, extended lead times, and reduced profitability for manufacturers.

Based on my extensive experience engaging with manufacturers globally, from the bustling workshops in Southeast Asia to the advanced facilities in North America, I consistently hear about shared frustrations in metal tube cutting. Many businesses, including those like Ahmed Al-Farsi's in the UAE, grapple with similar hurdles. They express concerns over the steep learning curve for machine operators, the physical strain and time consumption of manual loading, and the financial drain of unusable material remnants. These challenges aren't just minor inconveniences; they directly impact a company's bottom line and its ability to deliver projects on time and within budget. Understanding these universal pain points is the first step towards developing truly impactful solutions that resonate with the real-world needs of our diverse clientele.

The Burden of Skilled Labor and Manual Processes

One of the most significant challenges our clients articulate is the reliance on highly skilled CAD operators and the prevalence of manual processes. Traditional laser cutting machines often necessitate intricate 3D drawings created by proficient designers, a bottleneck that can severely impede production flow. This requirement not only increases labor costs but also makes businesses vulnerable to high operator turnover, leading to constant retraining burdens and project delays. For instance, my conversations with Ahmed Al-Farsi revealed his frustration with previous machines that mandated skilled CAD operators. He highlighted that "operator turnover was a constant headache, requiring endless retraining and impacting our ability to take on new projects efficiently." This sentiment is echoed across the industry, where finding and retaining specialized talent is a persistent struggle. Without a streamlined system, even minor design modifications can mean a complete halt to production as operators return to the design office, diminishing overall efficiency and increasing non-productive time.

The manual loading and unloading of heavy, long metal tubes also presents a considerable challenge. This labor-intensive task not only reduces feeding efficiency but also poses significant ergonomic risks to workers, leading to fatigue and potential injuries. In many smaller to mid-sized fabrication shops, this step can consume a substantial portion of the overall production cycle, limiting throughput and increasing the per-unit cost. A report by Mordor Intelligence on the Metal Fabrication market noted that automation in material handling can improve efficiency by over 30% and reduce labor costs by 20-25%2. This data directly supports the feedback we receive: manual handling is a major impediment to scaling operations and achieving competitive production speeds. Businesses are actively seeking solutions that mitigate these labor-dependent processes, aiming for greater autonomy and speed.

Furthermore, the complexity of operating conventional machines, even beyond CAD, often requires extensive training periods. Operators might need weeks or even months of factory-based training to become fully proficient. This lengthy onboarding process is a significant drain on resources, both in terms of direct training costs and lost productivity during the learning phase. From a client's perspective, this extended training period delays the return on investment for new equipment. The push for "easy-to-operate" and "turnkey" solutions, as emphasized by clients like Ahmed, stems directly from this pain point. They need machines that can be integrated quickly into their existing workflows with minimal disruption, allowing their workforce to adapt rapidly and contribute effectively. The industry trend is clearly moving towards systems that de-skill the operational process, making advanced technology accessible to a wider pool of talent and reducing the overall dependency on highly specialized, difficult-to-find personnel.

The Pervasive Problem of Material Waste

Another critical challenge in metal tube cutting is the ubiquitous issue of material waste, particularly the generation of unusable tail materials. Conventional laser cutting systems typically process tubes starting from the head, which invariably leaves a substantial "tail" at the end of the process. This leftover section, often too short to be utilized for new products, becomes scrap, directly impacting material utilization rates and increasing operational costs. For businesses that process large volumes of expensive raw materials, this waste can accumulate rapidly, eroding profit margins. Consider a typical fabrication shop: if even 5% of material becomes unusable scrap due to tail ends, over a year, this translates into thousands or even tens of thousands of dollars in lost value, depending on material cost and throughput.

Beyond tail material, errors in CAD programming or cutting parameters also contribute significantly to material waste. Miscalculations or imprecise cuts can render entire tube sections unusable, requiring re-processing and further delaying project timelines. This not only consumes more raw material but also wastes valuable machine time and energy. A study on manufacturing efficiency indicated that material waste can account for 10-15% of total production costs3 in metalworking industries if not properly managed. This highlights the financial strain placed on manufacturers striving for lean operations. The challenge is exacerbated when dealing with specialized or custom tube profiles, where material costs are higher, and waste minimization becomes even more critical for project profitability.

Moreover, the inability to efficiently nest or optimize cutting paths for different product lengths within a single tube further contributes to waste. If a machine cannot intelligently adjust its cutting logic to maximize material use, it often defaults to a less efficient sequence, leaving behind irregular, unusable offcuts. This "hidden" waste is less obvious than a large tail end but equally impactful over time. Companies are actively seeking intelligent systems that can dynamically optimize cutting sequences, minimizing remnants and maximizing yield from every single tube. The industry imperative is clear: every millimeter of material saved directly contributes to increased profitability and sustainability, making waste reduction a top priority for competitive manufacturers.

Service & Support Deficiencies and Long Lead Times

A frequently voiced concern among our global clients, especially those venturing into advanced machinery, revolves around the availability and quality of after-sales service and support. Many suppliers, particularly from distant manufacturing hubs, often lack robust local service networks, leaving clients vulnerable when technical issues arise. As Ahmed Al-Farsi articulated, "Equipment from some suppliers lacked local service support, which was a major concern for us." This absence of readily available technical assistance, spare parts, and remote diagnostics can lead to prolonged machine downtime, disrupting production schedules and causing significant financial losses. For a busy fabrication plant, even a few days of inactivity can mean missed deadlines and damaged client relationships.

| Service Aspect | Common Pain Point | Impact on Business |

|---|---|---|

| Local Support | Lack of regional technicians or agencies | Extended downtime, difficulty troubleshooting |

| Spare Parts | Scarcity or long lead times for critical components | Production halts, increased maintenance costs |

| Training | Insufficient or generalized post-sales training | Operator inefficiency, improper machine use |

| Remote Diagnostics | No capability for remote issue identification | Reliance on costly on-site visits, delays |

Furthermore, extended machine lead times present a significant operational challenge. From the moment an order is placed to the final delivery and installation, the waiting period can stretch for months, negatively impacting a company's ability to respond quickly to market demands or secure new projects. This delay can derail expansion plans and reduce competitiveness, especially in fast-paced industries like architectural decoration or automotive parts supply. For clients like Ahmed, who are planning to automate existing manual workflows, long lead times directly affect their strategic implementation schedule and return on investment projections. The market demands agility, and suppliers who can offer quicker delivery and deployment cycles gain a considerable competitive advantage, as businesses prioritize timely upgrades to meet their evolving operational needs.

The cumulative effect of these service and lead time challenges is a reduced total cost of ownership and a more unpredictable operational environment for manufacturers. When a machine is down, or its integration is delayed, the ripple effect on production, labor utilization, and customer satisfaction can be substantial. Therefore, clients are increasingly prioritizing suppliers who not only offer advanced technology but also provide comprehensive, responsive, and locally accessible post-sales support and efficient delivery pipelines. This holistic view of product and service ensures maximum uptime and a smoother operational experience, solidifying the long-term value of the investment.

No-CAD systems reduce labor costsTrue

MZBNL's No-CAD operating system eliminates the need for highly skilled CAD operators, reducing training expenses and turnover issues.

Tail material always becomes scrapFalse

MZBNL's zero-waste cutting technology processes tail materials efficiently, unlike conventional systems that leave unusable remnants.

How does MZBNL address these challenges with innovative solutions?

Faced with complex operations, material waste, and labor challenges, how can manufacturers achieve true efficiency? Many feel stuck with outdated technologies that limit their growth and profitability. At MZBNL, we've developed groundbreaking innovations specifically designed to overcome these hurdles, transforming your production capabilities.

MZBNL addresses core metal tube cutting challenges through three major innovations: the No-CAD Operating System, simplifying design and operation; Front-Feeding, enhancing loading efficiency; and Zero-Waste Tail Material cutting, maximizing material utilization. These solutions collectively reduce labor intensity, minimize waste, and improve overall productivity for clients.

From my vantage point, the true measure of innovation lies in its ability to solve real-world problems for our clients, creating tangible value and operational improvements. At MZBNL, our R&D efforts are deeply rooted in understanding the daily struggles faced by businesses like Ahmed Al-Farsi's—from his desire for a "turnkey solution that is easy to install and operate" to his need for "high cost-performance ratio." This client-centric approach has fueled the development of our three hallmark innovations, each meticulously engineered to directly counteract the pain points we discussed earlier. We don't just build machines; we engineer comprehensive solutions that address the core inefficiencies and complexities inherent in traditional metal tube cutting, ensuring that our partners can achieve unprecedented levels of efficiency, precision, and profitability.

Revolutionizing Operation with No-CAD System Innovation

One of MZBNL's most significant breakthroughs is our pioneered and perfected No-CAD Operating System for laser tube cutting machines. This innovation directly tackles the pervasive challenge of skilled labor dependency and complex design processes. Traditionally, operators faced a cumbersome workflow: any design modification or new product required returning to the design office to create or modify intricate 3D drawings, a process that was not only time-consuming but also demanded highly specialized CAD expertise. This bottleneck frequently led to production delays and increased labor costs, as companies struggled to find or retain operators proficient in complex software. Our No-CAD system completely redefines this paradigm.

With BNL's system, standard tube types and common hole patterns can now be processed simply by entering parameters directly into the machine interface—no complex 3D drawing is required. This user-friendly approach dramatically improves ease of use, making advanced laser cutting technology accessible to a wider range of operators. The impact on training is profound: operators now only need a single day of on-site training to become proficient, a stark contrast to the 15 days or more typically spent at an equipment factory for conventional systems. This drastically reduces the skill threshold for machine operation, directly alleviating the pain point of high operator turnover and the associated retraining burdens that clients like Ahmed Al-Farsi have highlighted. My personal observation has been that clients are often amazed by how quickly their teams can integrate and become productive with this intuitive system, accelerating their return on investment significantly.

This innovation not only simplifies operation but also streamlines the entire production workflow. By eliminating the constant back-and-forth between the shop floor and the design office, lead times for custom or small-batch orders are significantly reduced. Businesses can respond to market demands with unprecedented agility, quickly adapting designs or launching new products without the typical delays associated with complex CAD revisions. The No-CAD system transforms the operator from a mere button-pusher to a production manager, empowering them to make real-time adjustments and optimize cutting processes on the fly. This shift enhances operational autonomy and overall plant efficiency, providing a competitive edge in fast-paced industries where quick turnaround is paramount.

Enhancing Efficiency with Front-Feeding Innovation

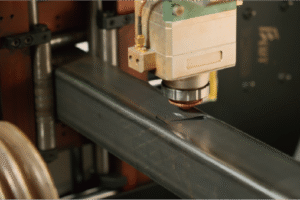

Another cornerstone of MZBNL's commitment to efficiency is our optimized Front-Feeding mechanism. While many traditional machines rely on manual side or rear loading, which is labor-intensive and often inefficient, our innovative design automatically pulls the tube in from the front of the machine. This seemingly simple change yields dramatic improvements in operational efficiency and workplace ergonomics, directly addressing the physical strain and time consumption associated with manual material handling. For operations dealing with large volumes of metal tubes, the cumulative impact of this innovation is substantial, significantly boosting overall productivity.

The benefits of the Front-Feeding design4 are quantifiable and impactful. This mechanism increases feeding efficiency by approximately 40%, directly translating into higher throughput and faster production cycles. Simultaneously, it reduces operator labor intensity by roughly 40%, making the work environment safer and less physically demanding. This reduction in manual effort is particularly appealing to businesses aiming for automated solutions, such as Ahmed Al-Farsi's, who prioritize ease of use and reduced operator burden. By automating the loading process, we minimize the risk of human error, reduce fatigue, and free up operators to focus on other critical tasks, enhancing overall plant productivity. This innovation contributes to a more sustainable and efficient manufacturing operation, directly impacting the bottom line through increased output and reduced operational costs associated with labor.

This innovation also addresses space constraints often encountered in workshops. Traditional side-loading machines might require significant lateral clearance, limiting layout flexibility. Our front-feeding mechanism allows for more compact machine placement, optimizing floor space utilization within a factory. Furthermore, the consistent, automated feeding ensures a smoother material flow, reducing instances of material jamming or misalignment that can occur with manual loading. This reliability contributes to higher uptime and more consistent cutting quality, ensuring that production runs are completed on schedule and without costly interruptions. The front-feeding system is a testament to our philosophy of integrating ergonomic design with high-performance automation, creating a holistic solution that benefits both the operation and the workforce.

Maximizing Material Utilization with Zero-Waste Tail Material Innovation

The third major innovation from MZBNL is our Zero-Waste Tail Material design, a direct response to the persistent problem of material waste in conventional laser cutting. Traditional systems typically begin cutting from the tube head, which invariably leaves an unusable remnant or "tail" at the end of the process. This scrap material represents a direct financial loss, especially for businesses processing expensive or high-volume tubes. Our engineering team meticulously redesigned the cutting logic to fundamentally change this wasteful paradigm.

BNL's system calculates the cutting sequence from the rear chuck as the origin. This intelligent approach allows the machine to eliminate leftover tail material entirely, as long as the remaining section is smaller than the product length. This revolutionary "zero-tail" design maximizes material utilization to an unprecedented degree, directly transforming what was once waste into usable product or minimizing it to negligible amounts. For companies like Ahmed Al-Farsi's, where material cost is a significant factor in profitability, this innovation offers substantial savings, directly contributing to a higher profit margin per project. Imagine processing hundreds of tubes per day; the cumulative savings from eliminating tail waste can amount to tens of thousands of dollars annually, providing a significant competitive advantage.

Beyond direct cost savings, the Zero-Waste Tail Material innovation also contributes to more sustainable manufacturing practices by reducing industrial waste. This aligns with global trends towards eco-friendly production and can enhance a company's environmental credentials. Furthermore, by optimizing material usage, businesses can potentially reduce their raw material procurement needs, leading to more efficient inventory management and fewer supply chain complexities. This smart logic demonstrates our commitment not only to operational efficiency but also to resource optimization, ensuring that every centimeter of material is put to its best use. This critical design improvement underscores our dedication to providing cost-effective and environmentally responsible solutions to our global client base.

No-CAD reduces training timeTrue

The No-CAD system reduces operator training from 15+ days to just one day by eliminating complex 3D drawing requirements.

Front-Feeding decreases efficiencyFalse

Front-Feeding actually increases feeding efficiency by 40% while reducing labor intensity by the same percentage.

What are the critical features of MZBNL metal tube cutting machines?

Are you seeking a metal tube cutting machine that truly delivers on precision, speed, and ease of use? Many machines promise performance but fall short on critical features like intelligent operation or multi-process integration. At MZBNL, our machines are packed with critical features designed to elevate your production, ensuring high-speed, high-precision results with unparalleled ease.

MZBNL metal tube cutting machines boast critical features like the No-CAD System for simplified operation, high-speed and high-precision cutting capabilities, smart and digitalized systems for optimal control, and multi-process integration for versatile manufacturing. These features collectively deliver superior performance, ease of use, and cost-effective customized solutions.

Having worked closely with countless businesses, including those focusing on high-volume fabrication like Ahmed Al-Farsi's, I've observed that the true value of a metal tube cutting machine lies not just in its ability to cut, but in the intelligent features that underpin its performance. It's about how seamlessly it integrates into your workflow, how intuitively your operators can use it, and how much it saves you in material and labor. Our MZBNL machines are engineered with this holistic view in mind, packing in functionalities that address every facet of modern metal fabrication. From ensuring cutting accuracy to providing robust after-sales support, we design our machines to be complete solutions that empower our clients to achieve their production goals with confidence and efficiency.

Unmatched Precision and Speed for Diverse Applications

At the core of every MZBNL metal tube cutting machine lies our commitment to high-speed and high-precision cutting. This foundational feature is paramount for a diverse range of industries, from automotive parts and medical equipment to architectural decoration. In sectors where tolerances are tight and production volumes are high, the ability to consistently produce precise cuts at rapid speeds directly translates to product quality and manufacturing throughput. Our machines are equipped with advanced laser technology and robust mechanical structures5 that minimize vibration and ensure consistent beam delivery, allowing for intricate cuts on various tube shapes and materials, including carbon steel, stainless steel, aluminum, and brass.

This high level of precision is critical for maintaining the integrity of complex assemblies, as miscuts can lead to material waste, rework, and costly delays. For example, in the automotive industry, the accuracy of tube cuts for exhaust systems or chassis components directly impacts vehicle safety and performance. Similarly, in the furniture and sanitary ware sectors, precise tube bending and joining rely entirely on the initial cutting accuracy. My experience has shown that clients like Ahmed Al-Farsi, who are expanding into architectural metalwork and vehicle parts, prioritize "cutting speed and accuracy" as key sourcing points. Our machines are designed to meet these exacting standards, ensuring that every cut is clean, burr-free, and dimensionally accurate, thereby reducing post-processing requirements and improving overall product finish.

Furthermore, the emphasis on high-speed operation means that our machines can handle demanding production schedules, maximizing output per shift. This capability is vital for businesses operating in highly competitive markets where rapid delivery times are a decisive factor. By combining speed with unwavering precision, MZBNL machines enable clients to optimize their production lines, take on larger orders, and significantly improve their competitive positioning. We continuously invest in R&D to push the boundaries of laser cutting technology, ensuring our machines remain at the forefront of performance, delivering consistent, high-quality results that our 4000+ global clients have come to expect and rely upon.

Smart Digitalization and Intuitive Operation

One of the distinguishing critical features of MZBNL machines is their integration of smart and digitalized systems, complemented by an inherent ease of operation and maintenance. This focus on user experience directly addresses the industry's need for accessible, high-tech solutions that don't demand a specialized IT or engineering degree to operate. Our digital systems provide comprehensive control over cutting parameters, material databases, and production monitoring, all accessible through intuitive interfaces. This allows operators to quickly set up jobs, monitor progress, and make adjustments on the fly, significantly reducing the learning curve and increasing operational efficiency from day one.

The "No-CAD System," as mentioned previously, is a prime example of this commitment to intuitive operation. By allowing operators to input parameters directly for standard tube types and hole patterns, we eliminate the need for complex CAD drawings, making the machine accessible even to those with limited design software experience. This feature has been a game-changer for many clients, including those facing high operator turnover, as it drastically reduces training time from weeks to just a single day. As Ahmed Al-Farsi values "ease of use (preferably No-CAD system)," our design philosophy perfectly aligns with the needs of modern fabrication shops seeking to streamline their workforce training and deployment. The built-in intelligence also includes error detection and diagnostic tools, which guide operators through troubleshooting, minimizing downtime and maintenance efforts.

Beyond initial operation, our machines are designed for easy maintenance, with modular components and clear access points that simplify routine checks and part replacements. This focus on maintainability minimizes the total cost of ownership over the machine's lifespan and ensures consistent performance. Remote diagnostics capabilities, a feature many clients prioritize, allow our support team to quickly identify and often resolve issues without requiring an on-site visit, further enhancing uptime and reducing service costs. This blend of smart digitalization, intuitive operation, and easy maintenance collectively contributes to a highly efficient, reliable, and user-friendly machine that maximizes productivity and minimizes operational complexities for our diverse global clientele.

Multi-Process Integration and Cost-Effective Customization

MZBNL machines stand out due to their multi-process integration capabilities, offering a versatile solution that goes beyond mere cutting. Our Automatic Punching & Cutting Integrated Machine, for instance, exemplifies this feature by combining two critical operations—cutting and punching—into a single, seamless workflow. This integration eliminates the need for separate machines and multiple handling steps, significantly reducing production time, floor space requirements, and labor costs. For a business like Ahmed Al-Farsi's, which handles contract-based fabrication services for railings, shelving, and auto parts, this multi-process functionality means greater efficiency in producing complex parts that traditionally would require transfers between different workstations, each with its own setup and potential for error.

This integrated approach not only streamlines production but also enhances accuracy. By performing punching and cutting on the same machine, without moving the workpiece, issues related to re-alignment errors are virtually eliminated. This is particularly crucial for components requiring tight tolerances and perfect hole alignment. The ability to execute multiple processes on a single platform also contributes to a more flexible manufacturing environment, allowing clients to diversify their product offerings and take on more complex projects. We understand that every client's needs are unique, which is why we offer cost-effective customized solutions. This means adapting our machines with specific configurations, automation levels, or software adjustments to perfectly fit a client's specific production requirements, materials, and output goals.

Our commitment to customization ensures that our machines are not just off-the-shelf products but tailored investments designed to maximize a client's profitability and operational efficiency. Whether it's integrating with existing factory automation systems or developing specialized cutting capabilities for unique tube profiles, our engineering team works closely with clients to deliver solutions that precisely match their demands. This bespoke approach, coupled with our multi-process integration, empowers clients to achieve higher levels of automation, reduce their overall manufacturing footprint, and gain a decisive competitive advantage in their respective markets. The ability to combine operations and customize solutions makes MZBNL machines a strategic asset for businesses aiming for optimized production and long-term growth.

MZBNL machines offer No-CAD SystemTrue

The No-CAD System allows operators to input parameters directly without complex CAD drawings, simplifying operation.

MZBNL machines require CAD expertiseFalse

The No-CAD System is designed for ease of use, eliminating the need for specialized CAD knowledge.

How have these features influenced the buying decisions of global enterprises?

In a crowded market, how do global enterprises distinguish truly valuable metal tube cutting solutions from the rest? Many face analysis paralysis, struggling to identify machines that genuinely meet their complex operational needs and long-term strategic goals. Our innovative features, proven by over 4000 global clients, have profoundly influenced purchasing decisions by offering clear solutions to critical pain points and delivering measurable ROI.

MZBNL's No-CAD system, front-feeding efficiency, and zero-waste innovations significantly influence global enterprises' buying decisions by simplifying operations, reducing labor, cutting material waste, and offering turnkey solutions. These features provide a clear competitive advantage, demonstrating high cost-performance and reliable after-sales support crucial for long-term investment.

As someone deeply involved in the machinery sector, I've observed that global enterprises, especially those with established operations and substantial investments, make purchasing decisions based on a blend of immediate operational needs and long-term strategic vision. It's not merely about the initial price tag; it's about the total cost of ownership, the reliability of the supplier, and the measurable impact on productivity and profitability. Our 4000+ global enterprise clients, including those across Southeast Asia, the Middle East, Europe, and North America, consistently tell us that our innovative features directly address their most pressing pain points, leading to significant improvements that drive their buying preference towards MZBNL.

Addressing Core Pain Points and Delivering Tangible ROI

The primary influence on global enterprises' buying decisions is MZBNL's direct addressal of their core operational pain points, translating into clear, measurable returns on investment (ROI). For many manufacturers, the cost associated with skilled labor, material waste, and operational bottlenecks is substantial. Our No-CAD System directly reduces the reliance on highly trained CAD operators, a significant pain point for businesses like Ahmed Al-Farsi's, who grappled with "high operator turnover caused retraining burdens." By simplifying the operational interface, we enable quicker onboarding and greater flexibility in staffing, which directly reduces labor costs and training expenditures. This translates into faster production ramp-ups and consistent output, even with a less specialized workforce.

Moreover, the financial impact of our Zero-Waste Tail Material innovation is a powerful incentive. In industries where raw material costs constitute a significant portion of overall production expenses, eliminating unusable scrap material directly boosts profit margins. Consider a large-scale metal pipe processing factory: even a 2-3% reduction in material waste due to our zero-tail design can amount to hundreds of thousands of dollars in annual savings, making the investment in an MZBNL machine economically compelling. A recent industry report indicated that optimizing material utilization can improve overall manufacturing profitability by 5-10% in the long term. Our Front-Feeding innovation further enhances this ROI by increasing feeding efficiency by 40% and reducing operator labor intensity by 40%. This translates to higher throughput and reduced manual handling costs, directly impacting the operational efficiency and profitability metrics that global enterprises meticulously track.

The cumulative effect of these feature-driven savings in labor, material, and increased efficiency is a highly attractive return on investment that strongly influences purchasing committees. Enterprises are no longer just buying a machine; they are investing in a comprehensive solution that mitigates their biggest operational risks and delivers a clear competitive advantage. Our integrated R&D and manufacturing model ensures that these innovations are not just theoretical concepts but robust, battle-tested features that provide tangible, quantifiable benefits to our diverse global clientele, making MZBNL a preferred choice for businesses seeking long-term value and operational excellence.

Assurance of Reliability, Support, and Customization

Beyond immediate operational benefits, MZBNL's influence on buying decisions stems from our commitment to reliability, comprehensive after-sales support, and cost-effective customization. Global enterprises, especially those with complex supply chains and geographically dispersed operations, prioritize suppliers who can offer proven technology and reliable post-sales assistance. Our status as a high-tech enterprise with 30+ patents and 25 years of experience in metal fabrication provides a strong foundation of credibility. Clients like Ahmed Al-Farsi explicitly seek "suppliers with proven technology and global references," a criterion we consistently meet with our extensive client base across Southeast Asia, the Middle East, Europe, and North America. This established track record minimizes perceived risk and builds trust, which is crucial for high-value machinery investments.

Our robust after-sales service and training support are critical differentiators. While some suppliers may lack local presence, we actively develop global distributor networks and offer remote diagnostics and spare parts availability. Ahmed's "pain point" regarding "equipment from some suppliers lacked local service support" directly highlights the value of our commitment to accessible and responsive post-sales assistance. We understand that machine downtime is costly, and our proactive support ensures maximum uptime for our clients. This includes comprehensive training programs, often just one day on-site thanks to our No-CAD system, empowering local teams to operate and maintain the machines effectively, thereby reducing ongoing operational costs and increasing self-sufficiency.

Furthermore, our ability to provide cost-effective customized solutions is a significant factor for enterprises with unique production requirements. Instead of a one-size-fits-all approach, we tailor our machines with specific configurations, multi-process integrations, or software adjustments to perfectly align with a client's specific industry, materials, and output goals. For large enterprises operating in specialized niches, this level of customization ensures that their investment is optimally aligned with their strategic objectives, delivering precisely the capabilities they need to maintain a competitive edge. This personalized approach, combined with our proven reliability and strong global support, solidifies MZBNL's position as a preferred partner for long-term, high-value investments in metal tube cutting technology.

No-CAD reduces labor costsTrue

The No-CAD system minimizes the need for specialized CAD operators, lowering training and staffing expenses.

Zero-waste increases profitsTrue

Eliminating material waste directly improves profit margins by reducing raw material costs.

What are the best practices for utilizing MZBNL machines in different industries?

How can businesses maximize the transformative potential of advanced metal tube cutting machines across diverse industries? Many underestimate the strategic integration required to unlock full efficiency and competitive advantage. Discover the best practices for leveraging MZBNL machines, ensuring optimal performance and profitability whether you're in automotive, furniture, or architectural fabrication.

Utilizing MZBNL machines effectively across industries involves leveraging the No-CAD system for rapid prototyping in furniture, optimizing front-feeding for high-volume automotive production, and implementing zero-waste cutting for cost-sensitive architectural projects. Best practices also include continuous operator training, integrating smart features for process optimization, and proactive maintenance to ensure sustained peak performance.

After witnessing the profound impact our machines have had on over 4000 global clients, I've gathered invaluable insights into how various industries can truly maximize the power of MZBNL technology. It's one thing to acquire a state-of-the-art machine, but it's another to master its application for specific industry nuances and production challenges6. From the precision demands of medical equipment manufacturing to the high-volume needs of automotive parts production, understanding the best practices for machine utilization is paramount. Our goal is to empower our clients to not just cut tubes, but to revolutionize their entire production workflow, ensuring they extract the maximum value and competitive advantage from their MZBNL investment.

Optimizing for High-Volume and Rapid Prototyping

For industries characterized by high-volume production, such as automotive and motorcycle parts, or for those requiring rapid prototyping like furniture and display rack manufacturing, optimizing the utilization of MZBNL machines centers around leveraging their speed and efficiency features. In high-volume environments, the Front-Feeding Innovation is paramount. By significantly increasing feeding efficiency and reducing operator labor intensity, this feature enables continuous, uninterrupted production runs, crucial for meeting demanding quotas. For instance, an automotive parts producer can utilize the automated front-feeding to process thousands of identical tube components daily, minimizing manual intervention and maximizing throughput. Implementing a lean manufacturing approach, where tubes are pre-staged and integrated seamlessly with the front-feeding system, can further enhance the production flow, reducing non-value-added time. Regular calibration checks, integrated within the machine's smart digitalized system, ensure that the high precision is maintained even during prolonged, high-speed operations, preventing costly errors and ensuring consistent part quality necessary for assembly lines.

Conversely, for industries requiring rapid prototyping or frequent design changes, like custom furniture or architectural decoration, the No-CAD System becomes the cornerstone of efficient utilization. This innovative feature allows for quick modifications and new product trials by simply entering parameters, eliminating the lengthy CAD design cycles. A furniture manufacturer can rapidly iterate on new chair designs or custom shelving units, moving from concept to physical prototype within hours rather than days. This agility significantly shortens development cycles and allows businesses to respond to market trends or client-specific demands with unprecedented speed. Best practice here involves empowering operators with a comprehensive understanding of the No-CAD system's capabilities, encouraging them to experiment and optimize parameters directly on the machine interface. Integrating this capability with a flexible production schedule allows for seamless transition between small-batch custom orders and larger production runs, making the MZBNL machine an incredibly versatile asset for adaptive manufacturing.

Moreover, for both high-volume and rapid prototyping scenarios, effective material management is key. By combining our Zero-Waste Tail Material innovation with intelligent nesting software (which often works in conjunction with our smart systems), manufacturers can significantly reduce material consumption. For high-volume producers, this translates into massive cost savings over time, while for prototypers, it means less wasted expensive material during experimentation. Implementing strict inventory management practices and utilizing the machine's data logging features to track material usage and waste levels provides valuable insights for continuous process improvement, ensuring maximum yield from every tube processed. This dual focus on speed/efficiency and material optimization is essential for maximizing ROI across diverse production environments.

Strategic Integration for Complex Workflows and Quality Control

For industries like medical and fitness equipment manufacturing, or elevator equipment integration, where complex workflows, stringent quality control, and multi-process capabilities are paramount, strategic utilization of MZBNL machines focuses on leveraging their multi-process integration and smart systems. Our Automatic Punching & Cutting Integrated Machine is a prime example of how these features simplify intricate production sequences. Instead of transferring tubes between separate cutting and punching stations, which introduces potential for misalignment and extends processing time, the integrated machine performs both operations seamlessly. This level of integration ensures superior accuracy, as the workpiece remains fixed throughout the combined process, crucial for components requiring precise hole alignment for subsequent assembly in sensitive applications like medical devices.

Best practices for complex workflows involve pre-planning the entire part geometry to fully utilize the integrated punching capabilities, minimizing the need for secondary operations. This could involve, for an elevator equipment integrator, designing support structures where all necessary holes for fasteners are punched concurrently with the cutting of the tube length. This reduces handling, setup times, and the risk of errors that can occur when moving parts between machines. Regular calibration and rigorous quality checks, possibly leveraging the machine's digital reporting features, are essential to maintain the high precision required for critical components. Furthermore, integrating the MZBNL machine's data output with a factory's broader enterprise resource planning (ERP) system can provide real-time insights into production status, material consumption, and machine performance, enabling proactive adjustments and optimized resource allocation.

For industries with stringent quality control requirements, such as those supplying parts for the aerospace or high-end architectural sectors, the machine's inherent precision and the consistency offered by features like the Zero-Waste Tail Material system contribute significantly. By minimizing inconsistencies and reducing human error through automation, our machines help maintain uniform product quality across large batches. Implementing a robust quality management system that includes regular checks of cutting parameters, tool wear monitoring (often aided by smart diagnostics), and post-production measurements of finished parts ensures that every component meets the exact specifications. The ability to produce high-quality, perfectly matched parts consistently reduces rework, minimizes warranty claims, and enhances the manufacturer's reputation for reliability and excellence, which is invaluable in competitive markets.

Enhancing Sustainability and Future-Proofing Operations

Beyond immediate production benefits, best practices for utilizing MZBNL machines also involve considering their contribution to sustainability and future-proofing operations, particularly relevant for environmentally conscious enterprises and those planning long-term growth. The Zero-Waste Tail Material Innovation is a cornerstone here. By maximizing material utilization and significantly reducing scrap, our machines not only offer substantial cost savings but also contribute directly to a greener manufacturing footprint. For companies aiming for ISO 14001 certification or simply wishing to reduce their environmental impact, this feature is invaluable. Best practice involves meticulous planning of cutting jobs to fully exploit the zero-tail capability, possibly through advanced nesting algorithms that our smart systems can facilitate, ensuring every inch of raw material is effectively used. This also reduces waste disposal costs and contributes to a more circular economy approach within the factory.

Furthermore, the "Smart and Digitalized Systems" embedded in MZBNL machines contribute to future-proofing operations by enabling data-driven decision-making and facilitating integration with Industry 4.0 initiatives. These systems can collect data on machine performance, material consumption, and production efficiency, providing valuable insights for continuous improvement. Companies that actively analyze this data can identify bottlenecks, optimize processes, and predict maintenance needs, moving from reactive to proactive operational management. This data-centric approach enhances overall efficiency and resilience, making the manufacturing process more adaptable to future technological advancements and market shifts. For clients like Ahmed Al-Farsi, who is considering becoming a regional distributor, understanding the long-term, scalable benefits of such integrated systems is key to his strategic planning.

Finally, the ease of operation and maintainability of MZBNL machines, coupled with our global after-sales support, ensures operational longevity and minimizes obsolescence risks. The one-day training for the No-CAD system means that new operators can quickly become productive, reducing labor dependency. Our focus on remote diagnostics and spare parts availability, along with the option for local agent presence, provides a safety net for sustained operation. Enterprises should establish proactive maintenance schedules, leveraging the machine's diagnostic capabilities, and ensure their teams are regularly updated on software enhancements. By adopting these best practices, businesses don't just acquire a machine; they invest in a resilient, efficient, and environmentally responsible manufacturing solution that is capable of evolving with future industry demands.

Front-feeding boosts automotive productionTrue

The front-feeding innovation in MZBNL machines enables continuous high-volume production crucial for automotive parts manufacturing.

No-CAD requires lengthy design cyclesFalse

The No-CAD system actually eliminates lengthy design cycles by allowing direct parameter entry for rapid prototyping.

Conclusion

MZBNL machines are chosen by 4000+ global clients due to their innovative solutions to industry pain points. Our No-CAD, Front-Feeding, and Zero-Waste innovations simplify operations, cut costs, and boost efficiency, delivering a high cost-performance ratio. We offer tailored solutions, robust support, and proven reliability, making MZBNL the smart choice for transforming metal tube cutting operations worldwide.

-

Explore how automation trends are redefining operational efficiency in metal fabrication ↩

-

Understand the benefits of automation in reducing labor costs and improving efficiency ↩

-

Gain insights into the cost impact of material waste in metalworking ↩

-

Find out how front-feeding design improves loading efficiency ↩

-

Discover the role of laser technology in achieving high-precision cuts. ↩

-

Discover tailored solutions provided by MZBNL technology for varied industry applications. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.