Metal Tube Cutting Machines with Front-Feeding: Key Advantages

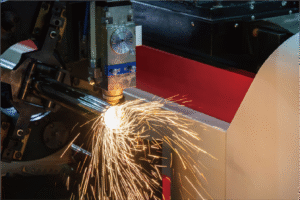

As a veteran in metal fabrication, I’ve seen the industry grapple with inefficiencies in tube cutting. Manual loading is a bottleneck, and traditional automated systems often come with their own set of challenges, leading to higher costs and wasted time. This is where front-feeding technology emerges as a transformative solution.

Front-feeding in metal tube cutting machines offers significant advantages by enhancing operational efficiency, reducing labor intensity, and maximizing material utilization. This innovative approach simplifies the loading process, directly contributing to higher productivity and improved workplace ergonomics, making it a pivotal advancement in modern fabrication.

My journey in the metal fabrication industry has always been driven by a pursuit of innovation, especially in finding solutions that genuinely empower our clients. I’ve witnessed firsthand how traditional methods hinder productivity and elevate operational costs. Understanding these pain points led us at MZBNL to focus on groundbreaking advancements like front-feeding. This commitment to overcoming persistent challenges ensures our technology not only meets but exceeds the evolving demands of a competitive market.

In my 25 years of experience at MZBNL, a high-tech enterprise dedicated to metal fabrication, I’ve seen the critical need for solutions that address the core inefficiencies plaguing tube cutting operations. The demand for speed, precision, and cost-effectiveness has never been higher, pushing the boundaries of what machinery can achieve. This isn't merely about cutting tubes; it’s about optimizing entire production lines, enhancing safety, and ensuring sustainable practices. Many manufacturers, much like Ahmed Al-Farsi, a mid-sized metal fabrication business owner in the UAE, are actively seeking automated solutions to upgrade their production efficiency. They face challenges such as high operator turnover due to strenuous manual tasks and the complexity of traditional CAD-reliant systems. Our focus at MZBNL, backed by over 30 patents and a global clientele of 4000+ enterprises, has always been to critically analyze these industry bottlenecks and engineer solutions that offer not just incremental improvements, but revolutionary leaps forward, shaping the future of metal tube processing.

What is the history and evolution of feeding mechanisms in tube cutting machines?

For years, the efficiency of tube cutting has been hampered by archaic loading methods. This constant struggle with manual handling and cumbersome setups not only slows down production but also introduces unnecessary risks and costs. Fortunately, the industry has seen a progressive evolution in feeding mechanisms, culminating in highly automated and intelligent systems.

The evolution of tube cutting feeding mechanisms progressed from laborious manual loading to semi-automated systems, and then to various automated solutions like side or rear feeding. The latest innovations, such as front-feeding, represent a significant leap, offering enhanced efficiency, reduced labor, and seamless integration with smart machine controls.

Tracing the historical trajectory of feeding mechanisms in metal tube cutting machines provides a crucial perspective on why innovations like front-feeding are so vital today. As I reflect on the journey, from rudimentary manual handling to sophisticated automated systems, I'm reminded of the relentless pursuit of efficiency and safety that has driven our industry forward. This evolution isn't just about technological advancement; it's about solving real-world production bottlenecks and empowering businesses, much like Ahmed Al-Farsi's, to achieve higher output with less effort. The progression from cumbersome, labor-intensive methods to smart, integrated systems highlights a continuous effort to streamline operations, reduce human error, and maximize material utilization, fundamentally transforming how metal tubes are processed.

The Dawn of Tube Processing: Manual and Early Semi-Automated Systems

In the nascent stages of metal tube cutting, the process of loading raw materials into machines was overwhelmingly manual. Operators would physically lift and position tubes onto the cutting bed, a task that was not only arduous and time-consuming but also fraught with safety risks, particularly with larger or heavier tubes. This reliance on brute force often led to inconsistencies in positioning, contributing to material waste and requiring frequent adjustments, thereby slowing down the entire production cycle.

As the industry matured, rudimentary semi-automated solutions began to emerge. These often involved simple roller conveyors or basic mechanical aids designed to reduce the physical strain on operators. While these early innovations offered a slight improvement in workflow, they still required significant human intervention for precise alignment and continuous feeding. The overall efficiency gains were minimal, and the process remained a bottleneck, severely limiting the throughput capacity of cutting machines.

From my perspective at MZBNL, having seen how businesses operate globally, I understand how these early limitations compounded operational challenges. For companies like Ahmed Al-Farsi's, aiming to automate existing manual workflows, the historical context underscores the deep-seated inefficiencies that required radical solutions. The initial steps towards automation were necessary, yet they revealed the vast potential for more integrated and intelligent feeding mechanisms that could truly revolutionize production.

The Rise of Traditional Automated Side/Rear Loading

The next significant leap in feeding mechanisms came with the widespread adoption of traditional automated side or rear loading systems. These systems utilized various mechanisms, such as chain conveyors or robotic arms, to automatically transfer tubes from a storage rack or bundle directly into the machine's chuck. This marked a considerable improvement over manual and semi-automated methods, dramatically increasing throughput and reducing direct human labor for loading.

However, these systems were not without their drawbacks. They often required a substantial physical footprint, as the loading area needed to accommodate long tubes and the complex machinery for side or rear access. Setting up these systems for different tube sizes and geometries could be complex and time-consuming, necessitating highly skilled operators and often requiring CAD drawings for precise material handling and cutting instructions. This complexity presented a significant pain point for businesses like Ahmed's, where a reliance on "skilled CAD operators" and the associated "high operator turnover" created constant "retraining burdens."

Moreover, while automated, these systems often struggled with material utilization, particularly concerning leftover tail material. The fixed starting point for cutting, typically from the tube head, meant that a segment at the end of the tube often remained unused, leading to avoidable material waste. This highlighted the need for further innovation that could combine automation with smarter material management and simpler operation.

The Paradigm Shift: Innovations Driving Efficiency and User-Friendliness

The demand for higher efficiency, reduced operational costs, and simpler interfaces has driven the latest wave of innovation in feeding mechanisms, culminating in the development of sophisticated front-feeding systems. At MZBNL, we pioneered and perfected a "No-CAD Operating System" integrated with our front-feeding technology, fundamentally changing the user experience. Instead of requiring complex 3D drawings, our system allows operators to process standard tube types and hole patterns by simply entering parameters. This innovation drastically reduces setup time and lowers the skill threshold for machine operation, transforming an otherwise intricate process into an intuitive task.

Our "Front-Feeding Innovation" itself is a game-changer. Unlike traditional side or rear manual loading, our optimized front-feeding mechanism automatically pulls the tube directly from the front of the machine. This design not only boosts feeding efficiency by approximately 40% but also significantly cuts operator labor intensity by about 40%, enhancing overall productivity and workplace ergonomics. This directly addresses the need for "automated solutions to upgrade production efficiency" for clients like Ahmed, who seeks to modernize his workflows.

Furthermore, we tackled the pervasive issue of material waste with our "Zero-Waste Tail Material Innovation." Conventional systems often generate unusable tail material. We redesigned the cutting logic to calculate from the rear chuck as the origin, effectively eliminating leftover tail material as long as the remaining section is smaller than the product length. This holistic approach to innovation—simplifying operation, improving efficiency, and eliminating waste—represents a profound paradigm shift, making high-tech metal tube cutting accessible and highly profitable.

| Feeding Mechanism | Efficiency Gain | Footprint Required | Operator Skill Level | Material Waste (Tail) |

|---|---|---|---|---|

| Manual Loading | Low | Small | High | Variable |

| Side/Rear Automatic | Medium | Large | Medium to High | Significant |

| Front-Feeding (MZBNL) | High | Compact | Low (No-CAD) | Minimized (Zero-Waste) |

Front-feeding boosts efficiency by 40%True

The article states front-feeding technology increases feeding efficiency by approximately 40% compared to traditional methods.

Manual loading requires CAD expertiseFalse

Manual loading systems don't require CAD skills; it's the traditional automated side/rear loading systems that often need CAD operators for setup.

How does the current front-feeding system work in metal tube cutting machines?

While the concept of automated feeding might seem straightforward, the intricacies of a modern front-feeding system are quite sophisticated. It's not just about pushing or pulling a tube; it’s about a finely synchronized dance between mechanical precision and intelligent software. Understanding this operational synergy demystifies the technology, revealing its true power to transform production.

A front-feeding system in metal tube cutting machines operates by automatically pulling the raw tube from the front, integrating seamlessly with smart chucks and advanced control software. This mechanism ensures precise material positioning, eliminates manual handling, and works in conjunction with digital parameters, optimizing the entire cutting workflow for enhanced speed and accuracy.

Having explored the historical context and the inherent challenges of traditional feeding mechanisms, it becomes clear why a system like front-feeding represents such a crucial advancement. From my vantage point at MZBNL, we engineered this technology to not only overcome previous limitations but also to integrate flawlessly with our overall machine design, creating a truly intuitive and powerful solution. This isn't merely an attachment; it's a fundamental part of our "smart and digitalized systems1," designed to make complex operations simple for our clients. For a business owner like Ahmed Al-Farsi, who values "turnkey solutions that are easy to install and operate," understanding the seamless functionality of front-feeding is key to appreciating its direct impact on daily operations and overall productivity, freeing up valuable resources for other critical business functions.

Core Mechanism: Automated Tube Manipulation

The fundamental principle of the front-feeding system revolves around automated tube manipulation from the machine's front. Unlike systems that require tubes to be loaded from the side or rear, which often involve complex conveyor belts or robotic arms for initial positioning, front-feeding simplifies the entire process. The raw tube is placed at the front of the machine, typically on a straightforward loading rack or support, and is then automatically gripped by the machine's chuck system.

This initial grip is often performed by a specialized front chuck, which precisely pulls the tube into the machine's cutting zone. As the tube is pulled, it is simultaneously engaged by the main rear chuck, which provides the primary rotational power and stability during the cutting process. The synchronization between the front and rear chucks is paramount, ensuring the tube remains perfectly centered and stable, preventing any wobbling or misalignment that could compromise cutting accuracy. This seamless pulling action eliminates the need for manual heavy lifting, directly contributing to a safer and less strenuous work environment for operators.

In my experience overseeing thousands of installations, this automated pulling mechanism fundamentally streamlines the workflow. It's a precise, repeatable action that removes the variability and fatigue associated with manual loading, ensuring consistent performance. This level of automation is precisely what clients like Ahmed are looking for, as it directly addresses their need for upgrading existing manual workflows to reduce labor intensity and improve overall efficiency.

Seamless Integration with Smart Control Systems

The true power of the front-feeding mechanism is fully unleashed when it's seamlessly integrated with the machine's smart control systems, particularly our proprietary "No-CAD Operating System2." In traditional setups, operators frequently had to create or modify complex 3D CAD drawings for each new tube design or adjustment, often requiring a trip back to the design office. This was a major time sink and a skill barrier for many fabrication shops.

With our "No-CAD Operating System," coupled with front-feeding, this complexity is drastically reduced. Operators can process standard tube types and hole patterns simply by entering parameters directly into the machine's intuitive interface. This means less reliance on highly skilled CAD specialists, directly addressing pain points like "skilled CAD operators" and "high operator turnover." The machine's intelligent software calculates the necessary movements and cutting paths based on these parameters, ensuring high-precision and high-speed cutting without the need for intricate drawing preparations.

This digitalized approach not only shortens setup time significantly but also lowers the skill threshold required to operate the machine. Operators typically only need 1 day of on-site training instead of spending 15 days at the equipment factory, as was common with more complex systems. This ease of use and reduced training burden translate directly into cost savings and faster deployment, making the system incredibly appealing to businesses looking for "cost-effective customized solutions" and "easy to operate and maintain" machinery.

Workflow Optimization and Material Flow

Beyond the immediate loading process, front-feeding significantly optimizes the entire workflow and material flow within the cutting operation. By pulling the tube from the front, the system facilitates a continuous, linear material path, which is inherently more efficient than systems requiring tubes to be moved laterally or repositioned multiple times. This streamlined flow contributes to a higher overall processing speed and reduced cycle times per part.

Furthermore, the integration of front-feeding with advanced cutting logic, such as our "Zero-Waste Tail Material Innovation3," revolutionizes material utilization. Conventional systems typically cut from the tube head, leaving an unusable segment at the tail end. Our redesigned logic calculates from the rear chuck as the origin, allowing the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. This intelligent calculation maximizes material usage, converting what was once scrap into usable output, and thereby significantly boosting cutting efficiency and reducing raw material costs.

For clients like Ahmed, who often supply finished parts to builders, decorators, and OEMs, this "multi-process integration" with optimized material flow is invaluable. It means not only faster production but also a more sustainable and profitable operation due to minimized waste. The combination of easy setup, high efficiency, and superior material utilization offered by front-feeding ensures that MZBNL machines provide a "high cost-performance ratio," aligning perfectly with his buying preferences and enabling him to expand his business in architectural metalwork and vehicle parts supply more effectively.

Front-feeding uses front and rear chucksTrue

The system synchronizes front and rear chucks to maintain tube stability during cutting.

No-CAD system eliminates CAD drawingsFalse

The No-CAD system reduces but doesn't eliminate CAD drawings; it simplifies parameter input for standard operations.

What challenges did traditional feeding mechanisms present in metal tube cutting?

For too long, the metal fabrication industry has grappled with the inherent inefficiencies and hidden costs embedded in traditional tube feeding mechanisms. These methods, while once standard, acted as silent saboteurs of productivity, constantly eroding profit margins and limiting operational growth. Addressing these pain points became a driving force for our innovations.

Traditional feeding mechanisms in metal tube cutting posed significant challenges including high labor intensity, leading to increased operational costs and safety risks. They also contributed to substantial material waste due to inefficient cutting logic and necessitated complex, time-consuming setups, often requiring specialized skills and occupying large operational footprints.

My experience spanning over two decades in metal fabrication has given me a deep understanding of the practical challenges faced by manufacturers worldwide. I've personally observed how the limitations of traditional feeding mechanisms, rather than simply being minor inconveniences, actively constrained growth and profitability for countless businesses. These weren't isolated issues; they were systemic problems that often led to higher operator turnover, extended project lead times, and an unavoidable amount of material waste. This stark reality was a primary motivator for our research and development at MZBNL, pushing us to innovate beyond the conventional. We recognized that to truly empower our clients, like Ahmed Al-Farsi, who grapples with "long machine lead times" and the need for "local service support," we had to fundamentally rethink the entire tube cutting process, starting with the most basic yet critical step: feeding the material.

Labor Intensity and Ergonomic Strain

One of the most persistent and costly challenges presented by traditional feeding mechanisms was the high degree of labor intensity required. Manual loading of metal tubes, especially long or heavy ones, is a physically demanding task. Operators frequently had to lift, carry, and precisely position tubes, leading to significant ergonomic strain and a heightened risk of workplace injuries. This constant physical exertion directly contributed to operator fatigue, which in turn could lead to errors, reduced productivity towards the end of a shift, and increased safety incidents.

From an operational standpoint, this labor intensity translated into higher labor costs. Businesses needed more personnel to manage the loading process, or they incurred overtime expenses to meet production deadlines. More critically, as Ahmed Al-Farsi experienced, "high operator turnover" became a significant burden. When skilled operators leave due to the physically demanding nature of the job, companies face "retraining burdens," which are costly in terms of time and resources, directly impacting profitability and project delivery schedules.

I’ve personally consulted with numerous factories where the bottleneck wasn't the cutting speed of the laser, but the speed and consistency of manual loading. This human element, while indispensable in many areas, became a critical limiting factor, directly impeding a company's ability to automate existing manual workflows4 and upgrade production efficiency, a goal keenly pursued by forward-thinking owners like Ahmed.

Material Waste and Inefficient Utilization

Traditional laser cutting systems predominantly operate by starting the cutting process from the tube head, pushing the tube through the machine. While seemingly straightforward, this method inherently led to the generation of "unusable tail material" at the end of each tube. Once the cutting reaches the very end of the tube, a short segment—the "tail"—is often too small to be gripped effectively by the chucks or to complete a final cut according to product specifications. This leftover tail material, typically a few inches to a foot long, could not be utilized for new products and was simply discarded as scrap.

The economic implications of this waste were substantial. Over a year of high-volume production, these small, discarded segments accumulated into tons of scrap metal. This represented a direct loss of raw material investment and an environmental burden. For a business focused on cost-performance ratio and efficiency, this ongoing waste diminished profit margins and increased overall production costs. It forced businesses to purchase more raw material than was effectively used, impacting their competitiveness.

This issue of material waste was a primary target for our "Zero-Waste Tail Material Innovation"5 at MZBNL. We recognized that eliminating this waste wasn't just about saving material; it was about maximizing the value extracted from every inch of raw stock, offering a tangible financial advantage to our clients and contributing to more sustainable manufacturing practices. It's a critical factor for businesses like Ahmed's that are always looking to optimize every aspect of their profit model.

Setup Complexity and Operational Footprint

Another pervasive challenge with traditional feeding mechanisms, especially older automated systems, was their inherent setup complexity and the significant operational footprint they often required. Many older systems demanded precise alignment and extensive calibration for different tube sizes, shapes, or cutting patterns. This often meant that "operators had to return to the design office to create or modify complex 3D drawings" for even minor adjustments or new projects. This reliance on specialized CAD skills added layers of bureaucracy and delays to the production process, directly contributing to "long machine lead times" and frustrating for businesses that need agility.

Furthermore, traditional side or rear loading systems typically required a large physical space to accommodate the loading mechanism, the tube storage racks, and the clearance needed for material movement. This sprawling footprint could be a significant constraint for factories with limited floor space, impacting overall plant layout efficiency and limiting the number of machines that could be installed. Such spatial requirements often added to the cost of factory setup or expansion, making it less attractive for businesses looking for compact, efficient solutions.

The combination of complex setup, reliance on specialized skills, and large physical space made traditional systems less accessible and less adaptable. This contrasts sharply with the modern demand for "easy to operate and maintain6" machinery and "cost-effective customized solutions." It’s precisely these pain points—the need for skilled CAD operators, the burden of retraining, and the lack of local service support for complex systems—that MZBNL aimed to alleviate with innovations like our "No-CAD Operating System" and optimized front-feeding designs, transforming the user experience and operational efficiency for clients like Ahmed.

Traditional feeding mechanisms cause material wasteTrue

The article explains how traditional systems generate unusable tail material at the end of each tube, leading to significant scrap accumulation over time.

Manual loading improves cutting precisionFalse

The text states that manual loading leads to operator fatigue and errors, actually reducing precision and productivity.

What are the significant advantages of using front-feeding in metal tube cutting machines?

In the competitive landscape of metal fabrication, gaining a tangible edge requires embracing technologies that offer more than incremental improvements. Front-feeding in tube cutting machines is not merely a feature; it’s a strategic advantage that redefines operational efficiency, significantly reduces costs, and fundamentally transforms the production environment.

The significant advantages of front-feeding include remarkable increases in feeding efficiency and overall productivity, substantial reductions in operator labor intensity, and maximized material utilization through zero-waste cutting. Additionally, it simplifies operations with intuitive interfaces, making advanced metal tube cutting more accessible and cost-effective for businesses.

Having thoroughly examined the historical landscape and the inherent challenges that traditional feeding mechanisms presented, the transformative benefits of front-feeding become exceptionally clear. For me, witnessing these innovations come to life at MZBNL, from conceptual design to empowering thousands of global enterprise clients, has been incredibly rewarding. We’ve meticulously engineered our front-feeding systems to directly address the most pressing pain points in the industry, offering solutions that genuinely elevate production capabilities. This isn't just about raw speed; it's about creating a smarter, safer, and more profitable operation. For a discerning client like Ahmed Al-Farsi, who prioritizes ease of use, high cost-performance, and proven technology with global references, these advantages translate directly into a competitive edge, enabling his business to expand confidently in architectural metalwork and vehicle parts supply.

Drastically Improved Efficiency and Throughput

One of the most compelling advantages of integrating front-feeding systems into metal tube cutting machines is the substantial boost in operational efficiency and overall throughput. Our "Front-Feeding Innovation" at MZBNL, for instance, demonstrably "increases feeding efficiency by about 40%." This isn't just a marginal gain; it means a significantly faster continuous flow of material into the cutting zone, dramatically reducing the idle time between cutting operations. Less time spent loading translates directly into more time spent cutting, which is the core revenue-generating activity.

This higher feeding efficiency directly contributes to the overall "high-speed and high-precision cutting" capabilities of MZBNL machines. The rapid and consistent feeding allows the laser to operate at its optimal performance levels without being bottlenecked by the material supply. For businesses operating on tight deadlines and high production volumes, this enhanced throughput is critical. It allows factories to complete orders faster, take on a greater volume of work, and ultimately improve their responsiveness to market demands.

For Ahmed Al-Farsi, who is seeking "automated solutions to upgrade production efficiency" and has experienced "long machine lead times" from previous suppliers, this advantage is a game-changer. The ability to process more tubes in less time, without sacrificing precision, directly impacts his profit model, which relies on delivering finished parts efficiently to builders, decorators, and OEMs. This ensures that his contract-based fabrication services remain competitive and highly profitable.

Enhanced Ergonomics and Reduced Labor Costs

The transition to front-feeding mechanisms also brings profound improvements in workplace ergonomics and a direct reduction in labor costs. By automatically pulling the tube into the machine, the system virtually eliminates the need for operators to manually lift and position heavy or long tubes. Our MZBNL system "reduces operator labor intensity by approximately 40%," which has a direct and positive impact on the health and well-being of the workforce. This translates into fewer physical injuries, reduced fatigue, and a more comfortable working environment for operators.

From a business perspective, these ergonomic enhancements lead to tangible financial benefits. With a less physically demanding job, operator "turnover" tends to decrease, mitigating the "retraining burdens" that can be so costly and disruptive. Furthermore, it allows for more efficient allocation of labor, as operators can focus on supervision, quality control, and other value-added tasks rather than strenuous physical labor. This optimizes the human capital within a factory.

Ahmed Al-Farsi's concern about "high operator turnover caused retraining burdens" is directly addressed by this advantage. By providing a safer and less physically demanding work environment, front-feeding systems contribute to higher job satisfaction and retention among staff. This, combined with the "easy to operate and maintain" nature of the machines (thanks to innovations like No-CAD), contributes to a powerful "high cost-performance ratio," aligning perfectly with Ahmed's preference for solutions that not only perform well but also make economic sense in the long run.

Maximized Material Utilization and Simplified Operations

One of the most innovative and economically impactful advantages of front-feeding, particularly as implemented by MZBNL, is the "Zero-Waste Tail Material Innovation"7. Unlike conventional systems that start cutting from the tube head and often leave an unusable tail segment, our redesigned cutting logic calculates from the rear chuck as the origin. This allows the system to efficiently process the entire tube length, eliminating leftover tail material as long as the remaining section is larger than the required product length. This significantly "boosts cutting efficiency" and maximizes material utilization, directly reducing raw material costs and minimizing scrap.

Beyond material savings, front-feeding significantly simplifies machine operations, making advanced tube cutting accessible to a wider range of operators. Our "No-CAD Operating System" is a testament to this, allowing users to simply enter parameters for standard tube types and hole patterns, circumventing the need for complex CAD drawings. This "easy to operate" functionality directly addresses Ahmed Al-Farsi's primary "sourcing key point" of "Ease of use (preferably No-CAD system)" and his preference for "turnkey solutions that are easy to install and operate." The reduced skill threshold and simplified setup means quicker project initiation and less reliance on highly specialized personnel.

The synergy of zero-waste material utilization and simplified operations provides a dual benefit: it enhances environmental sustainability by reducing waste and lowers operational barriers. This combination contributes to the "cost-effective customized solutions" that MZBNL offers, making our laser tube cutting machines incredibly attractive. For a buyer like Ahmed, this holistic approach means a machine that not only performs exceptionally but also contributes directly to his bottom line by saving material and streamlining his entire fabrication process, ultimately strengthening his position in the competitive market.

Front-feeding boosts efficiency by 40%True

The text explicitly states that front-feeding increases feeding efficiency by about 40%, reducing idle time between operations.

Front-feeding requires CAD expertiseFalse

The No-CAD Operating System mentioned eliminates the need for CAD drawings, making it accessible without specialized skills.

How does the adoption of front-feeding systems impact productivity and ergonomics in the industry?

The impact of front-feeding systems8 extends far beyond the immediate improvements in loading speed; it fundamentally reshapes productivity metrics and elevates workplace ergonomics across the entire metal fabrication industry. This isn't merely an upgrade; it's a transformative shift towards smarter, safer, and more efficient manufacturing paradigms.

The adoption of front-feeding systems significantly impacts industry productivity by enabling higher throughput and faster project completion, reducing machine lead times. Ergonomically, it minimizes labor intensity and operator turnover, fostering safer and more appealing work environments, while also driving sustainable practices through optimized material utilization.

Having delved into the specific advantages of front-feeding, it's crucial to step back and appreciate its broader, systemic impact on the metal fabrication industry. From my vantage point at MZBNL, as a high-tech enterprise with 25 years of experience and over 4000 global enterprise clients, I’ve observed firsthand how this innovation contributes to a profound shift in operational efficiency and workforce well-being. This isn't just about selling a machine; it's about providing a comprehensive solution that empowers businesses to thrive in an increasingly competitive global market. For clients like Ahmed Al-Farsi, this means a tangible improvement in their ability to meet growing demands, attract and retain skilled labor, and operate more sustainably, ultimately enhancing their market position and potentially even opening doors to new business models like regional distributorship.

Transforming Productivity Metrics Across Fabrication Shops

The integration of front-feeding systems directly translates into a significant transformation of productivity metrics within metal fabrication shops. The "approximately 40%" increase in feeding efficiency means that machines spend more time actively cutting and less time waiting for material, leading to a substantial boost in overall output. For a contract-based fabrication service like Ahmed Al-Farsi's, where revenue is directly tied to the volume of finished parts delivered, this means a greater capacity to take on more orders and complete existing projects faster. This directly addresses his "pain points" regarding "long machine lead times" and allows him to better manage his project pipeline.

This enhanced throughput means that fabrication shops can achieve higher production volumes with fewer machines or in less time, directly improving their return on investment. The faster processing times also contribute to improved customer satisfaction, as products can be delivered more quickly, enhancing a company's reputation for reliability and efficiency. This competitive edge is crucial in industries like architectural metalwork and vehicle parts supply, where timely delivery can make or break a contract.

Moreover, the seamless integration of front-feeding with "smart and digitalized systems" like MZBNL's No-CAD operating system reduces setup times, further contributing to overall productivity. When operators can quickly switch between jobs or material types without extensive reprogramming or manual adjustments, the daily output of the shop sees a marked increase. This operational agility is invaluable for businesses like Ahmed's that handle diverse projects for builders, decorators, and OEMs, allowing them to remain highly flexible and efficient.

Elevating Workplace Ergonomics and Attracting Skilled Labor

Beyond the pure numbers of productivity, the adoption of front-feeding systems profoundly elevates workplace ergonomics, creating safer and more appealing environments for skilled labor. By significantly "reducing operator labor intensity by approximately 40%," the physical demands on the workforce are drastically lessened. This means fewer instances of strain-related injuries, less fatigue over long shifts, and a generally healthier work environment. For me, seeing our innovations contribute to the well-being of operators is as rewarding as seeing production numbers soar.

This improved ergonomic profile has a direct impact on the challenge of "high operator turnover," which Ahmed Al-Farsi identified as a major "retraining burden." When jobs are less physically arduous and safer, employees are more likely to stay, reducing the need for constant recruitment and training of new staff. This stability in the workforce not only saves on training costs but also builds institutional knowledge and expertise within the fabrication shop, leading to higher quality work and fewer errors.

Furthermore, a modern, automated, and ergonomically sound workplace becomes more attractive to the next generation of skilled labor. As manual trades face a declining workforce, adopting advanced technologies like front-feeding positions companies as forward-thinking employers. This helps them recruit and retain talent, ensuring a stable and competent workforce for sustained growth. For Ahmed, this means being able to build a reliable team capable of handling his expansion into new business segments.

Driving Sustainable Practices and Competitive Edge

The adoption of front-feeding systems, especially those incorporating innovations like MZBNL's "Zero-Waste Tail Material Innovation," plays a crucial role in driving sustainable manufacturing practices. By nearly eliminating leftover tail material, these systems significantly reduce scrap metal waste, which translates into lower raw material consumption and reduced environmental impact. This commitment to sustainability is increasingly important for businesses, not only for corporate social responsibility but also for attracting eco-conscious clients and potentially benefiting from green manufacturing incentives.

From a competitive standpoint, the combined benefits of enhanced efficiency, reduced labor costs, maximized material utilization, and simplified operations create a powerful competitive edge. Companies that invest in such advanced systems can offer more competitive pricing due to lower operational costs, deliver projects faster, and maintain a higher standard of quality. This allows them to outpace competitors still relying on older, less efficient methods.

For a strategic buyer like Ahmed Al-Farsi, these advantages resonate deeply. His preference for "proven technology and global references," coupled with his consideration of becoming a "regional distributor" for MZBNL, underscores the market recognition of these transformative capabilities. The ability to provide "cost-effective customized solutions" with "high-speed and high-precision cutting" ensures that MZBNL machines are not just purchases but strategic investments that enable clients to expand their market reach and solidify their position as leaders in the metal fabrication industry, capable of delivering finished parts to diverse sectors with unparalleled efficiency and quality.

Front-feeding increases productivity by 40%True

The article states front-feeding systems improve feeding efficiency by approximately 40%, leading to higher throughput.

Front-feeding requires more operator trainingFalse

The text explains front-feeding reduces retraining burden by lowering operator turnover, not increasing training needs.

Conclusion

Front-feeding technology in metal tube cutting machines offers unparalleled advantages, boosting efficiency by up to 40% while significantly reducing labor intensity and material waste. This innovation simplifies operations with No-CAD systems, elevates workplace ergonomics, and drives sustainable practices. It’s a transformative solution for modern metal fabrication, embodying a crucial leap forward for businesses aiming for higher productivity and profitability.

-

Discover the benefits of smart systems in metal cutting machines ↩

-

Understand how No-CAD systems simplify machine operation ↩

-

Find out about innovations reducing waste in metal cutting ↩

-

Discover advantages of automation in improving production efficiency and reducing manual labor ↩

-

Learn how zero-waste technology reduces material waste and enhances sustainability in manufacturing ↩

-

Explore user-friendly and maintenance benefits of modern CNC machines ↩

-

Understand the zero-waste advantage for cost-saving in metal tube cutting ↩

-

Understand the comprehensive benefits of front-feeding systems in improving industrial productivity ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.