Why More Factories Are Investing in Tube Laser Cutting Machines

Are you finding that traditional metal tube processing methods are holding your factory back, leading to slower production and higher waste? Many manufacturers face this daily struggle, watching competitors with advanced technology surge ahead. Investing in a tube laser cutting machine can revolutionize your operations, offering unprecedented precision and speed.

Factories are increasingly investing in tube laser cutting machines due to their ability to significantly enhance production speed, improve material utilization, reduce labor costs, and achieve higher precision in complex cutting tasks, ultimately boosting overall manufacturing competitiveness and product quality.

This shift towards advanced laser technology isn't just a fleeting trend; it's a strategic move essential for staying competitive in today's demanding market. If you're wondering how this technology can specifically benefit your factory, streamlining processes from design to final product, then you're in the right place. Let's explore the compelling reasons behind this growing investment.

As someone who has been immersed in the metal fabrication industry for 25 years with MZBNL, I've witnessed firsthand the transformative power of technological innovation. We've seen over 4000 global enterprises, including clients like Ahmed Al-Farsi from the UAE, upgrade their capabilities by adopting advanced solutions. The move towards tube laser cutting machines is driven by a clear need for greater efficiency, precision, and automation. This isn't just about cutting metal; it's about reshaping how businesses approach manufacturing, reducing reliance on outdated, labor-intensive processes and embracing smart, digitalized systems that deliver superior results and a stronger bottom line. Our own journey, marked by over 30 patents, reflects this commitment to pushing boundaries.

What trends are driving increased investment in tube laser cutting machines?

Are you noticing a surge in demand for customized metal components and faster turnaround times? Traditional methods often struggle to keep pace, leading to missed opportunities. The global manufacturing landscape is rapidly evolving, pushing factories to adopt more agile and efficient technologies like tube laser cutting.

Key trends driving investment include the rising demand for complex geometries and customization, the need for increased automation to combat labor shortages and costs, a push for higher material efficiency, and the overall digitalization of manufacturing processes (Industry 4.0).

The manufacturing world is undergoing a significant transformation, and at the heart of this change is the quest for greater precision, speed, and flexibility. Factories are no longer just competing on price; they're competing on their ability to deliver intricate designs quickly and cost-effectively. This is where technologies like advanced tube laser cutting machines become indispensable. As we delve deeper, we'll see how these trends are not isolated phenomena but interconnected drivers compelling businesses, much like Ahmed's mid-sized fabrication company in the UAE, to re-evaluate their production strategies and invest in future-proofing their operations.

The imperative to modernize is palpable across the globe, from Southeast Asia to North America. My experience at MZBNL has shown me that businesses are actively seeking solutions that offer more than just incremental improvements. They are looking for game-changers. The trends we're observing are a direct response to market pressures and opportunities. For instance, the architectural decoration and automotive parts sectors, major clients for businesses like Ahmed's, are constantly pushing the envelope in design complexity. This necessitates tools that can translate sophisticated CAD designs into tangible products without compromising on quality or speed. Furthermore, the rising cost of skilled labor in many regions, coupled with the desire for consistent output, makes automation a highly attractive proposition. Tube laser cutting machines, especially those with advanced features, directly address these evolving needs, offering a pathway to enhanced competitiveness.

The Rise of Mass Customization and Complex Geometries

The modern consumer, whether in B2B or B2C markets, increasingly demands products tailored to specific needs or aesthetic preferences. This trend towards mass customization1 is particularly evident in industries like furniture manufacturing, medical equipment, and architectural design. Factories are challenged to produce a high variety of parts in smaller batch sizes without incurring prohibitive setup costs or extended lead times. Tube laser cutting machines excel in this environment. Their ability to be quickly reprogrammed to cut different profiles, hole patterns, and intricate designs on various tube shapes (round, square, rectangular, oval) makes them ideal for flexible manufacturing. For example, a furniture manufacturer can seamlessly switch from producing components for standard chair frames to bespoke display rack elements with minimal downtime. At MZBNL, our No-CAD system innovation directly supports this, allowing operators to input parameters for standard tube types and hole patterns without needing to create or modify complex 3D drawings for every minor variation, drastically reducing setup time.

This capability is a far cry from traditional methods like sawing, drilling, and manual milling, which often require dedicated tooling and fixtures for each new design, making small-batch production economically unviable. I recall Ahmed Al-Farsi mentioning how his previous machinery struggled with rapid design changes for architectural metalwork projects, leading to bottlenecks. The shift to laser cutting allowed his UAE-based company to take on more diverse and complex projects, significantly expanding his market reach. Data from industry reports, such as those by Grand View Research, consistently show a growing market for laser cutting technology, driven in part by its adaptability to custom fabrication demands. The precision of laser cutting also means that complex joints, like miters and copes, can be cut perfectly, simplifying downstream assembly processes and improving the structural integrity and aesthetics of the final product.

The demand for intricate designs is not just about aesthetics; it's often driven by functional requirements. In the automotive and aerospace industries, for instance, components must be lightweight yet strong, often involving complex tubular structures with precise cutouts and bevels for welding. Tube laser cutters can achieve these complex geometries with a level of accuracy and repeatability that is difficult and costly to match with conventional methods. Consider the production of roll cages for racing vehicles or intricate support frames for medical imaging equipment. These applications demand tolerances often in the sub-millimeter range. The non-contact nature of laser cutting eliminates tool wear and mechanical stress on the material, further contributing to the precision of the cut parts. This capability opens up new design possibilities for engineers, allowing them to optimize parts for performance rather than being constrained by manufacturing limitations.

Automation and the Smart Factory (Industry 4.0)

The drive towards Industry 4.0, characterized by interconnected and automated manufacturing systems, is a major catalyst for investment in advanced tube laser cutting machines. Factories are looking to reduce manual intervention, minimize human error, and improve overall operational visibility. Modern tube laser cutters often come equipped with features like automatic bundle loading, part unloading, and integration with factory-wide ERP/MES systems2. This level of automation not

only reduces the need for constant operator oversight but also enables lights-out manufacturing for certain applications, significantly boosting productivity. Ahmed's interest in automated solutions to upgrade production efficiency is a common sentiment among progressive factory owners. He specifically sought a machine with automatic feeding to reduce labor intensity and was impressed by our Front-Feeding Innovation, which increases feeding efficiency by about 40%.

The integration capabilities extend beyond simple loading and unloading. Advanced sensors and software allow for real-time monitoring of the cutting process, predictive maintenance alerts, and remote diagnostics. This data-driven approach helps to minimize downtime and optimize machine performance. For example, if the machine detects a potential issue with the laser source or a cutting nozzle, it can alert maintenance personnel before a critical failure occurs. This proactive approach is crucial for maintaining production schedules, especially in high-volume environments or when dealing with just-in-time delivery requirements. Our MZBNL machines are designed with smart, digitalized systems that align with these Industry 4.0 principles, providing clients with better control and insight into their operations. The reduction in operator skill threshold, particularly with our No-CAD system where operators need only one day of training, also addresses the challenge of skilled labor shortages.

Furthermore, the connectivity of these machines allows for seamless integration into a larger digital workflow. Designs created in CAD software can be directly transferred to the machine, with cutting parameters often automatically optimized by the machine's control system. This digital thread, from design to production, reduces the chances of errors associated with manual data entry and interpretation. For businesses like Ahmed's, which supply parts to various OEMs, this streamlined process ensures consistency and traceability. The ability to collect and analyze production data also supports continuous improvement initiatives. By understanding cycle times, material usage, and machine uptime, factories can identify areas for further optimization, leading to sustained gains in efficiency and profitability. The adoption of such smart technologies is no longer a luxury but a necessity for factories aiming to compete on a global scale.

Enhanced Material Utilization and Sustainability

In an era of fluctuating raw material prices and increasing environmental awareness, maximizing material utilization is a critical concern for manufacturers. Tube laser cutting machines offer significant advantages in this regard. The precision of the laser beam allows for very narrow kerf widths (the width of material removed by the cutting process) and enables tight nesting of parts on the tube. This means more components can be cut from a single length of tube, drastically reducing scrap. Traditional cutting methods, often with wider kerfs and less sophisticated nesting capabilities, can result in substantial material waste. This not only impacts direct material costs but also has implications for waste disposal and environmental footprint.

One of the standout innovations we've pioneered at MZBNL is the Zero-Waste Tail Material system. Conventional laser cutting typically leaves an unusable tail end because the chuck needs a certain length to grip the tube. Our redesigned cutting logic calculates from the rear chuck as the origin, allowing the system to eliminate leftover tail material as long as the remaining section is smaller than the product length. For Ahmed, who processes significant volumes of tube for railings and shelving, this feature translates directly into cost savings and improved sustainability. Imagine the cumulative savings over thousands of tubes processed annually; it's a substantial benefit. This focus on minimizing waste aligns with the growing corporate social responsibility (CSR) agendas of many companies and their clients.

Beyond just minimizing tail waste, the accuracy of laser cutting reduces the need for secondary finishing operations. Clean, dross-free edges often mean that parts can go directly to assembly or welding without requiring deburring or grinding. This not only saves time and labor but also reduces the consumption of energy and consumables associated with these secondary processes. The ability to cut complex features like weld preps (bevels and chamfers) directly on the machine further streamlines the manufacturing workflow and reduces the material handling and potential for error associated with moving parts between different workstations. This holistic approach to material and resource efficiency is a powerful driver for the adoption of tube laser cutting technology, contributing to both economic and environmental sustainability in manufacturing.

Laser cutting improves material utilizationTrue

The precision of laser cutting allows for tight nesting of parts and narrow kerf widths, significantly reducing material waste compared to traditional methods.

Tube lasers require constant operator oversightFalse

Modern tube laser cutters feature automation like automatic loading/unloading and can operate with minimal supervision, enabling lights-out manufacturing in some cases.

How do tube laser cutting machines enhance factory efficiency and productivity?

Is your factory struggling with production bottlenecks and long lead times due to outdated tube processing methods? Manual cutting, drilling, and notching are time-consuming and labor-intensive. Tube laser cutting machines offer a powerful solution by automating and streamlining these complex tasks.

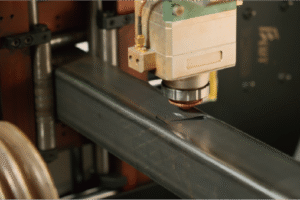

Tube laser cutters enhance efficiency by combining multiple operations (cutting, drilling, slotting, beveling) into a single setup, drastically reducing material handling and processing time, enabling faster production cycles and higher throughput with unparalleled accuracy.

This consolidation of processes, coupled with high cutting speeds and automation capabilities, is transforming how quickly and effectively factories can turn raw tubing into finished components. For businesses like Ahmed's in the UAE, which supplies parts for architectural metalwork and automotive components, these efficiency gains are crucial for meeting tight deadlines and scaling operations. Let's explore the specific mechanisms through which these machines drive such significant improvements in factory output and operational smoothness, moving far beyond simply replacing older tools to fundamentally optimizing workflow.

The impact of tube laser cutting machines on factory efficiency is multi-faceted, touching nearly every aspect of the production cycle. From the moment a design is conceived to the final part coming off the line, these machines introduce speed, precision, and automation that were previously unattainable with traditional methods. At MZBNL, we've seen clients achieve remarkable turnarounds. For instance, our No-CAD system dramatically shortens setup time, as operators can bypass the lengthy process of creating or modifying 3D drawings for standard jobs. Ahmed specifically mentioned how this feature was a key factor in his decision, as it addressed his pain point of high operator turnover and the associated retraining burdens. Furthermore, our Front-Feeding Innovation, which boosts feeding efficiency by approximately 40%, directly tackles another common bottleneck – material loading. These innovations are not just about isolated improvements; they contribute to a holistic enhancement of the entire manufacturing ecosystem within a factory.

Consolidation of Multiple Machining Processes

Traditionally, processing a metal tube into a finished component might involve several distinct steps: cutting to length on a saw, drilling holes on a drill press, creating slots or notches on a milling machine, and perhaps manually deburring the edges. Each step requires material handling, setup time, and the potential for error accumulation. Tube laser cutting machines revolutionize this by consolidating many of these operations into a single, automated process. A laser can cut intricate profiles, drill holes of various sizes and shapes, create complex slots, mark parts, and even bevel edges for weld preparation, all in one continuous operation without needing to move the tube to different machines. This drastically reduces work-in-progress (WIP) inventory, minimizes material handling, and frees up valuable floor space.

I remember Ahmed Al-Farsi explaining how his team used to spend hours moving tubes between different workstations for a single project. This not only added to labor costs but also increased the risk of damage to the tubes and inconsistencies between parts. By investing in one of our MZBNL laser tube cutting machines with multi-process integration, he was able to streamline his workflow significantly. The machine could take a raw tube and produce a finished component ready for assembly, often in a fraction of the time previously required. This consolidation is particularly beneficial for complex parts used in automotive chassis, fitness equipment frames, or custom architectural structures where multiple features are required on a single tube. The ability to perform these operations in one setup ensures higher dimensional accuracy and consistency across all parts, as the tube remains fixtured throughout the process.

The economic benefits of process consolidation are substantial. Reducing the number of machines and manual operations directly translates to lower labor costs per part. It also means fewer specialized operators are needed for different machines, simplifying workforce management and training. Maintenance costs can also be reduced as there are fewer individual machines to service. For a business like Ahmed's, aiming to automate existing manual workflows and improve overall efficiency, this consolidation is a key enabler. Industry studies, such as those focusing on lean manufacturing principles3, highlight process consolidation as a critical strategy for waste reduction and productivity improvement. The tube laser cutter embodies this principle perfectly.

High-Speed Cutting and Automation

One of the most immediate impacts of adopting tube laser cutting technology is the sheer speed at which parts can be produced. Modern fiber lasers4, commonly used in these machines, offer exceptionally fast cutting speeds, especially on thinner gauge materials. When combined with advanced CNC controls and high-speed motion systems, these machines can process tubes at rates far exceeding traditional methods. For example, cutting a series of holes and slots on a tube might take minutes with a laser, whereas manually setting up and performing these operations on conventional machinery could take significantly longer. This speed advantage is crucial for factories dealing with high-volume production or those needing to respond quickly to customer orders.

Automation features further amplify this productivity. Automatic bundle loaders can feed raw tubes into the machine continuously, allowing for extended periods of unmanned or minimally supervised operation. Once cutting is complete, automated unloading systems can sort and stack finished parts, ready for the next stage of production. Our MZBNL Front-Feeding Innovation is a prime example, increasing feeding efficiency by about 40% and reducing operator labor intensity. Ahmed, like many factory owners, was looking for turnkey solutions that are easy to install and operate, and automation plays a huge role in this. The ability to run the machine for longer periods, even during off-shifts with minimal supervision, maximizes asset utilization and significantly increases overall output.

Consider a typical scenario in a factory producing components for display racks. A large order might require thousands of identical or similar tubes, each with multiple cuts and holes. With an automated tube laser cutter, the entire batch can be processed with high consistency and speed. The machine's software can optimize the cutting path and parameters for maximum efficiency, while the automation handles the material flow. This level of productivity is simply unattainable with manual or semi-automatic processes. Data from our clients consistently shows a reduction in cycle times by 50-70% or even more for complex parts after switching to laser tube cutting. This allows factories to take on more orders, reduce lead times, and improve their competitiveness in the market.

Reduced Setup Times and Increased Flexibility

A significant bottleneck in many manufacturing operations is the time it takes to set up machines for different jobs. Traditional tube processing often requires changing tools, adjusting fixtures, and performing test cuts, all of which contribute to non-productive downtime. Tube laser cutting machines offer a dramatic improvement in this area. Because the "tool" is a focused beam of light, there are no physical cutting tools to change when switching between different hole sizes, shapes, or cut profiles. Job changeovers can often be accomplished simply by loading a new program into the CNC controller, a process that can take just a few minutes. This agility is invaluable for factories that produce a high mix of parts or need to accommodate frequent design changes.

Our MZBNL No-CAD System Innovation is a perfect illustration of this. Ahmed was particularly drawn to this because it meant his operators wouldn't need to constantly go back to the design office for 3D drawings or spend extensive time on complex programming for standard tube types and hole patterns. By simply entering parameters, production can start quickly. This lowers the skill threshold for machine operation and reduces setup time from potentially hours to mere minutes. This capability is crucial for businesses like Ahmed's that cater to diverse industries like architectural metalwork and vehicle parts, where job requirements can vary significantly. The ability to quickly switch between cutting round, square, rectangular, or even custom-profiled tubes without major mechanical adjustments adds another layer of flexibility.

This reduction in setup time, combined with the inherent versatility of laser cutting, allows factories to efficiently produce small batches or even single custom pieces. This opens up opportunities for on-demand manufacturing and mass customization5, trends that are increasingly important in today's market. For example, a company manufacturing medical or fitness equipment might need to produce a wide variety of frame components, each with unique specifications. A tube laser cutter can handle this variability with ease, making it economically feasible to offer a broader range of products or customized solutions. The result is a more agile and responsive manufacturing operation that can better meet the diverse and evolving needs of its customers.

Laser cutters consolidate multiple operationsTrue

Tube laser cutting machines combine cutting, drilling, slotting and beveling into one automated process, eliminating multiple machine setups.

Physical tools need changing for different cutsFalse

Laser cutting uses a light beam rather than physical tools, enabling instant change between different cut profiles without mechanical adjustments.

What cost benefits do factories gain from adopting tube laser cutting technology?

Are high operational costs, excessive material waste, and lengthy production cycles eating into your factory's profits? Traditional tube fabrication methods can be expensive. Tube laser cutting technology presents a compelling alternative, promising significant savings across various aspects of your operation.

Factories gain substantial cost benefits through reduced labor expenses due to automation and consolidated processes, minimized material waste thanks to precision cutting and features like zero-tail systems, and lower tooling and maintenance costs compared to multiple conventional machines.

These financial advantages are not just marginal; they can fundamentally improve a factory's bottom line and overall competitiveness. For a business owner like Ahmed Al-Farsi, who values a high cost-performance ratio, understanding these tangible savings is key to justifying the investment. Let's delve into the specific areas where tube laser cutting machines deliver these crucial economic advantages, helping businesses like yours thrive.

The decision to invest in new capital equipment always hinges on the anticipated return, and tube laser cutting machines offer a strong case. My years at MZBNL, working with clients across diverse sectors like furniture, automotive, and medical equipment, have repeatedly demonstrated the profound economic impact of this technology. It's not just about cutting faster; it's about cutting smarter and more economically. Ahmed, for instance, was keen on solutions that were easy to install and operate, which inherently reduces training costs and operator error, both of which have financial implications. Our innovations, such as the Zero-Waste Tail Material system and the No-CAD operating system, were specifically designed to maximize material utilization and minimize time-consuming, costly programming, directly contributing to a better ROI for our clients.

Significant Reduction in Labor Costs

One of the most immediate and impactful cost benefits of tube laser cutting machines is the reduction in direct and indirect labor costs. Traditional tube processing often requires multiple skilled operators for different machines – one for sawing, another for drilling, perhaps another for milling or deburring. Each of these operations involves manual labor for setup, operation, and material handling. A tube laser cutting machine, particularly one with automation features like automatic loading and unloading6, can perform all these tasks with minimal human intervention. This means a single operator can often oversee the entire process, or even manage multiple machines, drastically reducing the number of labor hours required per part.

For instance, Ahmed's concern about high operator turnover and the subsequent retraining burdens is a common issue. By investing in our MZBNL machine with its user-friendly No-CAD system, which requires only one day of on-site training instead of the traditional 15 days, he could significantly lower training expenses and reduce reliance on highly specialized (and often more expensive) CAD operators. This ease of use also means that existing staff can be cross-trained more easily, providing greater workforce flexibility. The automation aspect, like our Front-Feeding Innovation which reduces operator labor intensity by about 40%, further diminishes the physical demands on workers, potentially leading to a safer work environment and reduced costs associated with workplace injuries.

The reduction in labor isn't just about fewer operators. It's also about the type of labor. While skilled laser machine operators are valuable, the reduction in manual handling, complex setups, and multiple machine operations means that the overall labor input per unit of output decreases significantly. This is particularly beneficial in regions with high labor costs or shortages of skilled manufacturing personnel. By automating repetitive and physically demanding tasks, factories can reallocate their human resources to more value-added activities such as quality control, design, or customer service, further enhancing overall business efficiency.

Maximized Material Utilization and Reduced Scrap

Raw material costs often represent a significant portion of the total manufacturing cost for tube-based products. Tube laser cutting machines excel at maximizing material utilization, thereby reducing scrap and saving money. The precision of the laser allows for very narrow kerf widths (the material removed during cutting) compared to saws or milling tools. More importantly, advanced nesting software, often integrated with the machine's control system, can optimally arrange parts on a length of tube to minimize waste. This means more finished components can be produced from the same amount of raw material.

A standout feature we've developed at MZBNL, and one that directly addresses this, is our Zero-Waste Tail Material innovation. Conventional machines typically leave an unusable stub at the end of each tube because the chuck requires a minimum gripping length. Our system redesigns the cutting logic to virtually eliminate this tail waste, as long as the remaining section is smaller than the product length. For Ahmed, who processes large volumes of tubing for railings, shelving, and auto parts, this feature translates into direct and substantial material savings. If a factory processes thousands of tubes a month, even a small percentage reduction in waste per tube accumulates into significant annual savings.

The table below illustrates a simplified cost-saving comparison for material utilization:

| Feature | Traditional Cutting (e.g., Saw + Drill) | Tube Laser Cutter (Standard) | Tube Laser Cutter (with Zero-Tail) |

|---|---|---|---|

| Avg. Tail Waste per Tube | 150-200 mm | 80-120 mm | < 10-20 mm (or near zero) |

| Nesting Efficiency | Moderate | High | Very High |

| Usable Parts per 6m Tube | X | X + 5-10% | X + 10-15% |

| Estimated Material Savings | Baseline | 5-10% | 10-15%+ |

Note: Actual savings vary based on part complexity, tube diameter, and nesting strategies.

Furthermore, the high accuracy of laser cutting reduces the likelihood of producing out-of-spec parts, which would otherwise need to be scrapped or reworked, incurring additional material and labor costs. The clean, precise cuts often eliminate the need for secondary deburring operations, saving not only labor but also the material that might be lost during aggressive manual deburring.

Lower Tooling, Maintenance, and Consumable Costs

When comparing tube laser cutting machines to a collection of traditional machines (saws, drills, mills), the savings in tooling and maintenance become apparent. Traditional methods require a variety of physical tools – saw blades, drill bits, milling cutters, punches, and dies. These tools wear out, need sharpening or replacement, and require inventory management. A laser cutter, on the other hand, uses a focused beam of light as its "tool." While components like nozzles and lenses are consumables, their replacement cost and frequency are often lower and more predictable than managing a wide array of mechanical tooling. There's no need to stock different sizes of drill bits or specialized cutters for different jobs.

Maintenance is another area of significant cost savings. Instead of maintaining multiple distinct machines, each with its own mechanical systems, motors, and potential points of failure, a factory maintains a single, integrated tube laser cutting system. Modern laser machines are designed for reliability, and many, like ours at MZBNL, incorporate features for remote diagnostics and predictive maintenance7, helping to minimize unscheduled downtime and streamline service. Ahmed valued the prospect of reliable after-sales service and spare parts availability, understanding that uptime is critical to profitability. The reduced mechanical complexity compared to a series of conventional machines generally translates to lower overall maintenance expenditure.

Finally, consider the reduction in consumables beyond just cutting tools. The elimination of cutting fluids, often required in traditional machining to cool tools and flush chips, not only saves on the cost of these fluids but also on their disposal and the associated environmental compliance costs. The cleaner working environment is an added benefit. While laser cutting does consume assist gases (like nitrogen or oxygen)8 and electricity, the overall operational cost profile, when considering the elimination of multiple other processes and their associated consumables, often proves to be more economical in the long run, especially for medium to high-volume production.

Laser cutting reduces labor costsTrue

Automation features allow one operator to oversee multiple tasks that previously required several skilled workers.

Traditional methods waste less materialFalse

Laser cutting's precision and nesting software actually minimize material waste compared to saws and drills.

How does the integration of tube laser cutting machines impact product quality?

Are inconsistencies, inaccuracies, and post-processing issues compromising the quality of your factory's tube components? Traditional fabrication methods often struggle with repeatability and precision. Integrating tube laser cutting machines can fundamentally elevate the standard of your finished products.

Tube laser cutting machines significantly enhance product quality through superior cutting accuracy, consistent repeatability, cleaner edges requiring less finishing, and the ability to produce complex, precise geometries that are difficult or impossible with conventional methods.

This improvement in quality is not just about aesthetics; it translates into better fit-up for welding and assembly, stronger joints, and overall improved performance and reliability of the final product. For discerning clients like Ahmed, whose business depends on delivering high-quality architectural metalwork and vehicle parts, this aspect is paramount. Let's explore how this technology ensures a higher caliber of output.

At MZBNL, we've consistently seen that the quest for higher product quality is a primary motivator for factories investing in new technology. It's one thing to produce parts quickly; it's another to produce them consistently to exacting standards. Tube laser cutting machines address this by inherently offering a level of precision and control that older methods can't match. When Ahmed decided to upgrade, his focus wasn't just on speed but also on achieving the accuracy needed for sophisticated architectural designs and critical automotive components. The non-contact nature of laser cutting, combined with advanced CNC controls, minimizes many variables that can lead to quality issues in traditional fabrication. Our commitment to high-speed and high-precision cutting is central to our product philosophy, ensuring our clients can meet the stringent quality demands of their respective markets.

Unmatched Precision and Accuracy in Cutting

One of the hallmark advantages of tube laser cutting is its exceptional precision. Laser beams can be focused to very small spot sizes, allowing for extremely fine and accurate cuts. Tolerances achievable with modern tube laser cutters are typically in the range of ±0.1mm to ±0.3mm9, depending on the material thickness and machine capabilities. This level of accuracy is vastly superior to what can be consistently achieved with manual sawing, drilling, or torch cutting. Such precision is critical in many applications, such as automotive components where exact fitment is necessary for performance and safety, or in medical equipment where precise alignment of parts is crucial for functionality.

This accuracy extends to all features cut by the laser, including holes, slots, copes, and complex contours. Because the entire cutting process is CNC-controlled, human error associated with manual marking, positioning, or operation of multiple machines is virtually eliminated. For Ahmed's business, supplying parts for architectural decoration and vehicle components, this means that every piece produced is dimensionally consistent with the design specifications. This is particularly important when producing interlocking parts or components that need to align perfectly during assembly. The ability to precisely cut bevels and chamfers for weld preparation directly on the machine also ensures better weld quality and joint strength, as the fit-up between tubes is optimized.

The non-contact nature of laser cutting also plays a crucial role in maintaining accuracy. There are no cutting forces exerted on the tube, which eliminates the risk of material distortion or deflection that can occur with mechanical cutting methods, especially on thin-walled or delicate tubing. This ensures that even complex or fragile parts can be processed without compromising their dimensional integrity. The consistency from the first part to the last part in a production run is a key benefit, reducing inspection time and rework costs associated with out-of-tolerance components.

Consistent Repeatability for High-Volume Production

Beyond single-part accuracy, tube laser cutting machines offer outstanding repeatability. Once a program is set up and validated, the machine can produce hundreds or thousands of identical parts with minimal variation. This consistency is vital for mass production and for ensuring interchangeability of components. In industries like furniture manufacturing or display rack production, where large batches of identical frames or supports are needed, this repeatability ensures that all parts will assemble correctly and that the final products will be uniform in quality.

Contrast this with manual or semi-automated processes where operator skill, fatigue, and tool wear can introduce variability between parts. With a laser cutter, the process parameters are digitally controlled and maintained throughout the production run. This eliminates the \"human element\" as a source of inconsistency. For a business like Ahmed's, which aims for stable, long-term operations and supplies parts to OEMs, this reliability is a significant asset. OEMs often have stringent quality control standards and expect consistent part quality from their suppliers. Tube laser cutting helps manufacturers meet these expectations reliably.

This repeatability also simplifies quality control processes. If the first-off part is inspected and approved, there is a high degree of confidence that subsequent parts produced using the same program and material will also meet specifications. This can reduce the need for 100% inspection of all features on all parts, saving time and resources. The digital nature of the process also allows for better traceability; production data, including machine settings and batch numbers, can be logged, which is increasingly important for quality assurance and compliance in many industries.

Superior Edge Quality and Reduced Finishing Work

Tube laser cutting typically produces a much cleaner and smoother edge finish compared to traditional methods like sawing, plasma cutting, or manual torch cutting. The narrow kerf and high energy density of the laser result in minimal heat-affected zone (HAZ)10 and little to no dross (molten material adhering to the cut edge), especially when using appropriate assist gases like nitrogen for stainless steel or aluminum. This superior edge quality has several important implications for overall product quality and manufacturing efficiency.

Firstly, cleaner edges often mean that secondary finishing operations, such as deburring, grinding, or sanding, can be significantly reduced or eliminated entirely. These manual finishing processes are time-consuming, labor-intensive, and can be a source of inconsistency. By producing parts with smooth, clean edges directly off the machine, factories can save considerable time and labor costs. For Ahmed's fabrication business, this would mean parts are ready for welding or powder coating much faster, streamlining the overall production flow. Our MZBNL machines are engineered for high-precision cutting, which inherently leads to better edge quality.

Secondly, a high-quality edge finish improves the aesthetic appeal of the final product, which is particularly important for consumer goods like furniture, fitness equipment, or architectural elements where visual appearance is a key selling point. Rough or uneven edges can make a product look unfinished or low-quality. Furthermore, for parts that require welding, clean and precise edges contribute to stronger, more consistent welds11. Contaminants or irregularities on the cut surface can interfere with the welding process and compromise the integrity of the joint. The ability of tube laser cutters to produce weld-ready edges, including accurate bevels, directly enhances the structural quality of assembled products.

Laser cutting improves weld qualityTrue

Clean edges and precise bevels from laser cutting create optimal conditions for strong welds.

Manual cutting is more preciseFalse

Laser cutting achieves ±0.1mm accuracy, far surpassing manual methods' consistency.

What recommendations can be made for factories considering this investment?

Are you contemplating an investment in a tube laser cutting machine but feeling unsure about how to proceed? Making such a significant capital expenditure requires careful consideration. The key is to align the machine's capabilities with your specific production needs and long-term business goals.

Factories should thoroughly assess their current and future production needs, evaluate machine specifications against these needs, consider the total cost of ownership including service and support, and prioritize suppliers with proven technology and comprehensive training like MZBNL.

Choosing the right tube laser cutting machine is more than just comparing prices; it's about finding a solution that will deliver sustained value and a competitive edge. For factory owners like Ahmed, who look for turnkey solutions and reliable post-sales support, a strategic approach to selection is vital. Let's explore key considerations to guide your investment decision.

Embarking on the journey to acquire a tube laser cutting machine is a significant step towards modernizing your factory. From my experience at MZBNL, helping countless businesses, including those like Ahmed's in the UAE, make this transition, I've learned that a well-informed decision process is crucial for maximizing the return on investment. It's not just about the machine itself, but the entire ecosystem around it – from ease of use and maintenance to the support and training provided by the supplier. Ahmed's preference for suppliers with proven technology and global references underscores the importance of partnering with an experienced and reputable manufacturer. Our focus on innovations like the No-CAD system and robust after-sales service stems from understanding these exact customer needs and ensuring a smooth integration and operation of our machines.

Thoroughly Assess Production Requirements and Future Growth

Before diving into machine specifications, the first critical step is a comprehensive analysis of your factory's current tube processing needs and anticipated future demands. What types of materials (steel, stainless steel, aluminum, copper, brass) and tube profiles (round, square, rectangular, oval, special shapes) do you predominantly work with? What are the typical diameters, wall thicknesses, and lengths of tubes you process? Understanding your current workload will help define baseline requirements for machine capacity, power, and features. For example, if you primarily process thick-walled tubes, a higher-power laser source will be necessary. If your work involves a lot of small, intricate parts, precision and cutting speed on thinner materials might be more critical.

Beyond current needs, project your future growth and potential diversification. Are you planning to expand into new markets or offer new types of products that might require different processing capabilities? For instance, Ahmed was actively expanding his business in architectural metalwork and vehicle parts supply. This foresight influenced his need for a versatile machine capable of handling diverse requirements. Investing in a machine that can accommodate future needs, perhaps with options for larger tube diameters, longer processing lengths, or advanced features like bevel cutting, can prevent the need for another costly upgrade in a few years. Consider the scalability of the solution – can it be integrated with further automation down the line, such as robotic part handling or storage systems?

This assessment should also include an honest look at your current pain points. Are long setup times, high material waste, or inconsistent quality the primary issues you're trying to solve? Identifying these specific challenges will help you prioritize features when evaluating different machines. For Ahmed, the previous requirement for skilled CAD operators and high operator turnover were significant pain points, making our MZBNL No-CAD system a highly attractive solution. Documenting these requirements will create a clear benchmark against which potential machines can be evaluated.

Evaluate Machine Specifications, Software, and Automation Options

Once you have a clear understanding of your needs, you can start evaluating specific machine models. Key specifications to consider include laser power (kW), maximum tube diameter and length, wall thickness capacity, cutting speed, and positioning accuracy. Don't just look at the maximum values; consider the machine's performance across the range of materials and thicknesses you typically process. For instance, a machine that excels at cutting thin stainless steel might not be the most efficient for thick carbon steel. Request cutting samples on your specific materials and parts to get a realistic idea of performance and quality.

Software is another crucial component. How user-friendly is the machine's control interface and programming software? Does it offer advanced nesting capabilities12 to maximize material utilization? Our MZBNL No-CAD system, which allows operators to process standard tube types simply by entering parameters, is a significant advantage in terms of ease of use and reduced reliance on specialized CAD skills. This was a major draw for Ahmed. Also, consider integration capabilities: can the machine software easily import common CAD file formats (e.g., STEP, IGES, DXF)? Can it integrate with your existing ERP or MES systems13 for production planning and tracking?

Automation options should also be high on your checklist, especially if you're looking to improve efficiency and reduce labor costs. Evaluate the sophistication and reliability of automatic bundle loading systems, part unloading and sorting mechanisms, and features like our Front-Feeding Innovation, which increases feeding efficiency by about 40%. Consider the level of automation that is appropriate for your production volume and part complexity. For Ahmed, who was looking for turnkey solutions, a high degree of automation for feeding and potentially punching capabilities was a priority. Remember that more automation often means a higher initial investment, so balance the benefits against the cost.

Consider Total Cost of Ownership (TCO) and Supplier Support

The initial purchase price is only one part of the equation. It's essential to consider the Total Cost of Ownership (TCO) over the machine's lifespan. This includes not only the upfront cost but also installation, training, consumables (nozzles, lenses, assist gases), energy consumption, maintenance, spare parts, and potential downtime costs. A cheaper machine might end up costing more in the long run if it's less reliable, consumes more energy, or requires more frequent and expensive maintenance. Ask potential suppliers for detailed information on these operational costs.

Supplier support is arguably one of the most critical factors in ensuring a successful investment. What level of after-sales service, technical support, and training does the supplier offer? Do they have a local presence or a reliable network of service technicians in your region? Ahmed prioritized suppliers with proven technology and global references, and specifically looked for after-sales service, training support, spare parts availability, and remote diagnostics. He also valued the potential for a local agent or distributor. At MZBNL, we understand this, which is why we focus on providing comprehensive support, including on-site training (just 1 day for our No-CAD system) and robust service infrastructure in our main export countries across Southeast Asia, the Middle East, Europe, and North America.

Don't hesitate to ask for references from other customers, especially those in similar industries or with similar applications. Inquire about their experience with the machine's reliability, the supplier's responsiveness to service requests, and the effectiveness of the training provided. A strong partnership with your supplier is key to maximizing the uptime and performance of your tube laser cutting machine. Consider the supplier's experience and reputation in the industry. With 25 years of experience and over 4000 global enterprise clients, MZBNL has a proven track record of delivering reliable solutions and support. For someone like Ahmed, who is even considering becoming a regional distributor, this supplier reliability is paramount.

Assessing future growth is crucialTrue

The article emphasizes projecting future needs to avoid costly upgrades later.

Purchase price is the main cost factorFalse

Total Cost of Ownership (TCO) includes many factors beyond just purchase price.

Conclusion

Investing in tube laser cutting machines offers factories a pathway to enhanced efficiency, superior product quality, and significant cost savings through automation and precision, future-proofing their operations in an increasingly competitive global market, ultimately boosting profitability and manufacturing agility.

-

Understand the concept of mass customization and its relevance in modern production. ↩

-

Discover the roles of ERP/MES systems in factory automation and data management. ↩

-

Learn how lean principles reduce waste and boost factory efficiency and productivity. ↩

-

Understand fiber laser technology and its benefits for high-speed, precise metal cutting. ↩

-

Discover how laser cutting supports flexible on-demand production and product customization trends. ↩

-

Learn how automation in tube laser cutting reduces labor and boosts efficiency. ↩

-

Discover how these smart features minimize downtime and cut maintenance costs for machinery. ↩

-

Understand the function and impact of different assist gases in laser tube cutting processes. ↩

-

Learn about tube laser cutting tolerances and factors influencing precision. ↩

-

Understand HAZ in laser cutting and how minimizing it improves material integrity. ↩

-

Discover how superior edge quality from laser cutting enhances weld integrity. ↩

-

Discover how nesting software minimizes material waste and significantly reduces cutting costs. ↩

-

Learn how ERP/MES integration boosts factory efficiency and streamlines production management. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.