How a Tube Steel Laser Cutter Improves Fabrication Quality

Inconsistent cuts and material waste are killing your projects. This constant rework costs you time, money, and your reputation. A tube steel laser cutter delivers perfect quality, every single time.

A tube steel laser cutter improves fabrication quality by using a focused, non-contact beam for unmatched precision, clean edges, and complex geometries. This eliminates thermal distortion, tool wear, and human error common in traditional methods, ensuring consistently superior parts and assemblies with minimal material waste.

I've walked through countless fabrication shops over the years, and I see the same struggles everywhere. The drive for perfection is universal, but the tools often fall short. If you're tired of compromising on quality and want to understand how modern technology can fundamentally change your output, you've come to the right place. Let's dive into the specific ways a laser cutter can elevate your work from good to exceptional.

What are the common challenges in tube steel fabrication?

Inconsistent cuts and material waste are common. These issues delay production and increase costs. Understanding these challenges is the first step toward finding a real solution for your workshop.

Common challenges in tube steel fabrication include dimensional inaccuracies, rough edges requiring secondary finishing, material deformation from heat or mechanical stress, high material waste, and slow production speeds. These issues directly impact the final product's quality, cost, and structural integrity.

When I visit a potential client, I don't just look at their equipment; I look at their scrap bin. That bin tells a story of the daily battles they face. The biggest challenges I see consistently boil down to a few key areas that directly impact quality. First is precision. Even a millimeter of deviation can compromise the fit and function of a final assembly, especially in high-stakes industries like automotive parts or medical equipment. Second is the finish. Burrs and rough edges aren't just cosmetic flaws; they are weak points and require costly, time-consuming secondary processes like grinding and deburring. Third is material integrity. Many traditional methods introduce immense stress or heat into the tube, causing warping or micro-fractures that weaken the final product. Finally, there's waste. Every off-cut and rejected part is pure loss. These aren't just minor inconveniences; they are fundamental obstacles to profitability and growth, creating bottlenecks that ripple through the entire production line.

Why does traditional cutting often lead to quality issues in fabrication?

Old cutting methods are unreliable. Mechanical stress and tool wear lead to frequent errors and rework. This constant firefighting with quality control is a major drain on your resources.

Traditional cutting methods like sawing or plasma cutting often cause quality issues due to mechanical force, heat-induced warping, and tool degradation. This results in burrs, inaccurate dimensions, and inconsistent finishes that require extensive secondary processing, compromising the final product's integrity.

The root of the problem with traditional methods lies in their physical nature. They rely on brute force and friction to separate material, which is inherently imprecise and damaging. I remember one client in the furniture industry who was constantly dealing with rejected batches because the joints cut by their band saw were never perfectly square. This is a classic example of the limitations of these older technologies.

The Drawbacks of Mechanical and Thermal Cutting

Let's break down why these methods fall short:

- Abrasive & Saw Cutting: These methods involve a blade making physical contact with the tube. This creates significant friction and vibration, leading to burrs, rough edges, and a wide kerf[^1] (the width of the cut). Furthermore, the blade wears down over time, so the first cut of the day is never the same quality as the last. This inconsistency is a nightmare for quality control.

- Plasma Cutting: While faster than sawing for some applications, plasma cutting uses a superheated jet of ionized gas. This introduces a massive amount of heat into the material, creating a large heat-affected zone (HAZ)[^2]. This zone can alter the metallurgical properties of the steel, making it brittle and prone to failure. It also causes warping and produces dross that must be cleaned off later.

In both cases, the process itself introduces flaws that must be corrected downstream, adding labor, time, and cost to every single part.

How does a tube steel laser cutter address and resolve these quality problems?

Quality problems are hurting your bottom line. Rework and waste are constant headaches. A laser cutter offers a definitive solution by delivering precision, consistency, and efficiency in a single process.

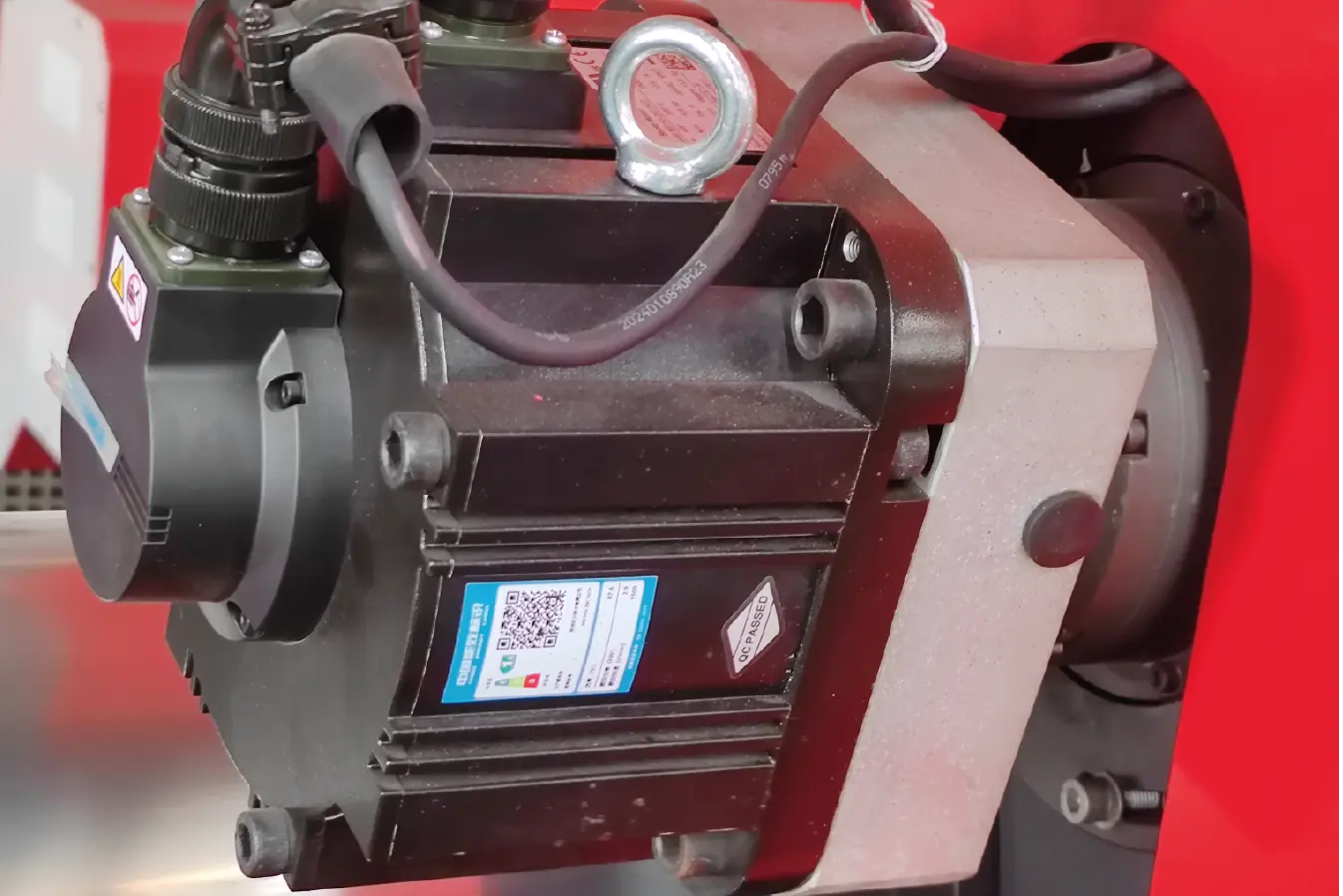

A tube steel laser cutter resolves quality problems by using a non-contact, highly focused energy beam. This eliminates mechanical stress, minimizes the heat-affected zone, and ensures precise, clean cuts every time. The process is automated and repeatable, removing human error.

The magic of laser cutting is that it vaporizes the material rather than shearing or melting it away with brute force. It's a non-contact process, which immediately eliminates a host of problems. There's no tool wear, no mechanical stress on the tube, and no vibration. This means every cut is as perfect as the last, from the first piece of the day to the thousandth. The beam itself is incredibly fine, resulting in a tiny heat-affected zone and a narrow kerf. This precision allows for complex shapes and patterns that are simply impossible with traditional methods. But at MZBNL, we've taken this a step further. We saw that even with a perfect cut, material waste was still a major issue for our clients. That's why we developed our Zero-Waste Tail Material innovation. By re-engineering the cutting process to utilize the entire length of the tube right up to the rear chuck, we've effectively eliminated the tailing material that other machines leave behind. This isn't just a cost-saving measure; it's a commitment to quality and sustainability, ensuring every inch of raw material is used to its full potential.

What are the specific features of laser cutters that enhance fabrication precision?

You need more than just a clean cut. Achieving true precision requires advanced features. Without them, you're just making the same old mistakes, only faster and with a more expensive machine.

Features enhancing laser cutter precision include CNC (Computer Numerical Control) for exact path execution, a small kerf width for intricate cuts, and non-contact processing to prevent material distortion. Advanced systems also offer automatic focus control and smart, simplified software.

True fabrication quality comes from a synergy of hardware and software working in perfect harmony. It’s not just about the laser beam itself; it’s about the entire system that controls and delivers that beam. A key component is the Computer Numerical Control (CNC)[^3] system, which translates a digital design into precise physical movements with micron-level accuracy. This guarantees perfect repeatability. However, we noticed that the biggest bottleneck for many shops wasn't the machine's capability, but the complexity of programming it. The need for skilled CAD engineers to create 3D drawings for every single job was slowing down production. This is precisely why we pioneered our No-CAD System. This feature allows an operator to process standard tubes simply by inputting parameters like length and hole position directly into the machine's interface. It reduces on-site training from 15 days to just one day and eliminates a major source of potential human error. Furthermore, we integrated a Front-Feeding Mechanism to automate material loading. This system increases feeding efficiency by about 40% and ensures each tube is positioned perfectly, eliminating inconsistencies that can arise from manual loading. It’s these smart, integrated features that truly elevate a machine from a simple cutter to a comprehensive quality solution.

What are the best practices for using laser cutters to achieve optimal fabrication quality?

Owning a laser cutter isn't enough. Without the right processes, you won't get the quality you paid for. Implementing best practices ensures you maximize your machine's potential and ROI.

Best practices for optimal fabrication quality include regular machine calibration, using correct assist gas types and pressures, optimizing cutting parameters for the specific material, and ensuring clean raw materials. Crucially, simplifying the operation with user-friendly systems empowers operators to focus on quality.

Investing in a high-quality laser cutter is the first step. The next is building a process around it that guarantees success. I always advise my clients to focus on three core areas: preparation, execution, and maintenance. Preparation involves ensuring your raw materials are clean and free from rust or oil, which can interfere with the laser. Execution is about dialing in the right parameters—power, speed, and assist gas pressure—for the specific material type and thickness. This is where operator skill traditionally comes in. However, a key "best practice" we've built into our philosophy at MZBNL is to simplify this step. Our No-CAD System removes the complex programming burden, allowing operators to focus on monitoring the cut and ensuring quality output rather than struggling with software. This drastically reduces the learning curve and makes it easier to maintain high standards across different shifts and operators. Finally, maintenance is non-negotiable. Regular cleaning of lenses, checking nozzle alignment, and performing scheduled calibrations will keep your machine running at peak performance. By combining a technologically advanced, user-friendly machine with these disciplined practices, you create a powerful system for consistently achieving the highest possible fabrication quality.

Conclusion

A tube steel laser cutter is more than just a piece of equipment; it's a strategic investment in quality. By eliminating the inaccuracies, waste, and secondary processes of traditional methods, it provides a direct path to superior products, higher efficiency, and a stronger competitive advantage in the market.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.