Metal Tube Cutting Machine Buying Guide: 5 Key Factors to Consider

Searching for the right metal tube cutting machine can feel overwhelming, leading to costly mistakes if not approached carefully. As someone deeply involved in this industry, I understand these challenges. This guide will walk you through the essential factors to ensure you make an informed decision for your business.

Key factors for choosing a metal tube cutting machine include cutting specifications, budget, technology type, operational efficiency, and after-sales support. Prioritizing these aspects ensures you select a system that aligns with your production needs, maximizes return on investment, and ensures long-term operational success.

My 25 years of experience in metal fabrication, working with over 4000 global enterprise clients at MZBNL, has taught me that the right machine can revolutionize production. Choosing wisely isn't just about the initial purchase; it’s about securing future profitability and operational excellence. Let's delve into what truly matters.

In an increasingly automated world, selecting a metal tube cutting machine isn't just about raw power; it's about strategic investment. Many overlook the nuanced interplay between upfront costs, long-term operational savings, and the transformative impact of integrated solutions. For instance, in Southeast Asia and the Middle East, markets where MZBNL has a strong presence, businesses like Ahmed Al-Farsi's1 often seek to automate existing manual workflows. Ahmed, the owner of a mid-sized metal fabrication business in the UAE, consistently looks for turnkey solutions that offer not only high performance but also ease of operation and robust support. This critical perspective moves beyond mere technical specs to consider the holistic value proposition, including the machine's intelligence, integration capabilities, and the supplier's commitment to post-sales excellence. It’s this comprehensive evaluation that truly unlocks a machine's potential as a strategic asset.

What are the critical specifications to look for in a metal tube cutting machine?

Navigating the technical landscape of metal tube cutting machines can be complex, often leading to choices that don't quite fit your operational reality. I've seen businesses struggle with underpowered or oversized equipment, hindering productivity. Understanding core specifications is key to avoiding these pitfalls and ensuring optimal performance.

Critical specifications for metal tube cutting machines encompass maximum tube diameter, wall thickness, material compatibility, cutting speed, and precision. These technical parameters directly dictate the machine's capability to meet specific production demands and the quality of the finished products.

When Ahmed, a client from the UAE, first approached us, his primary concern was to find a machine that could handle a diverse range of tube types for architectural metalwork and vehicle parts. He needed a solution that offered both high speed and exceptional accuracy. This kind of real-world demand highlights why simply looking at a brochure isn't enough; you need to dig deep into how each specification impacts your daily operations. From my perspective at MZBNL, a high-tech enterprise with 30+ patents2, we've learned that tailoring solutions based on these precise needs is paramount. It ensures the machine integrates seamlessly into existing workflows, delivering the precise cuts and throughput required without compromise, truly setting the foundation for efficient and profitable production.

Cutting Capacity and Material Versatility

When evaluating a metal tube cutting machine, the first technical pillars to scrutinize are its cutting capacity and material versatility. These determine the physical dimensions and types of materials the machine can effectively process, directly impacting your production capabilities. For example, a machine specified for a maximum tube diameter of 220mm and a wall thickness of 12mm for mild steel will offer different application ranges than one designed for 300mm diameter and 20mm wall thickness.

It's not just about maximums; the machine's ability to handle various material types—such as carbon steel, stainless steel, aluminum, brass, and copper—is equally crucial. Each material has unique properties that demand specific laser parameters and cutting techniques. A truly versatile machine, like those developed by MZBNL3, is equipped with robust laser sources and intelligent control systems that can adapt to different material compositions, ensuring optimal cut quality and minimal material waste across your product portfolio. Without this adaptability, your machine might become a bottleneck for certain projects, limiting your business's growth potential.

A real-world illustration of this is Ahmed's business, which manufactures both architectural railings and intricate vehicle parts. This requires handling various tube shapes, from rounds and squares to channels and angles, across different metal types and thicknesses. His initial pain point was that some of his existing machines struggled with certain materials or complex geometries, leading to outsourcing or manual, time-consuming processes. This situation underscores the importance of a machine that provides comprehensive material and shape versatility, rather than just excelling in one narrow application.

Precision and Speed Metrics

Beyond capacity, the precision and speed of cutting are fundamental performance indicators that directly translate into product quality and production efficiency. Precision refers to the accuracy of the cut and the repeatability of operations, typically measured in millimeters or micrometers for positioning and contouring. High precision ensures that parts fit together perfectly in subsequent assembly, minimizing rework and scrap.

Cutting speed, measured in meters per minute, determines the throughput of your operations. A faster machine can process more parts in less time, leading to higher productivity and lower labor costs per unit. However, it's crucial to balance speed with quality. An overly fast cut might compromise edge quality, leading to dross or burrs that require additional post-processing. Modern laser tube cutting machines, like MZBNL's, are engineered to optimize this balance, achieving high speeds without sacrificing cut integrity, thanks to advanced motion control systems and powerful laser sources.

For example, data from industry reports often indicates that a high-power fiber laser (e.g., 6kW-12kW) can cut 6mm mild steel at speeds exceeding 15 meters per minute with a positioning accuracy of ±0.03mm. This level of performance is critical for companies like Ahmed's, where tight tolerances are essential for vehicle parts, and high throughput is needed for large architectural projects. My experience shows that investing in superior precision and speed capabilities upfront pays dividends in reduced waste, faster project completion, and enhanced customer satisfaction.

| Feature | Standard Machine (Example) | MZBNL Laser Tube Cutting Machine | Impact on Business (Ahmed's Perspective) |

|---|---|---|---|

| Max. Tube Diameter | 180mm | 240mm | Broader project scope; handles larger parts. |

| Max. Wall Thickness | 8mm (Mild Steel) | 12mm (Mild Steel) | Processes heavier-duty materials; more robust products. |

| Positioning Accuracy | ±0.05mm | ±0.03mm | Higher quality finished parts; less rework for critical applications. |

| Cutting Speed (6mm MS) | 10 m/min | 18 m/min | Significantly increased throughput; faster project delivery. |

| Material Types | Limited to common metals | Versatile for various metals and alloys | Greater flexibility in production; takes on diverse orders. |

Automation and Software Integration

In today's manufacturing landscape, the level of automation and software integration in a metal tube cutting machine is as important as its physical capabilities. Automation features, such as automatic feeding, unloading, and part sorting, drastically reduce manual labor and improve overall efficiency. For instance, MZBNL's Front-Feeding Innovation4 automatically pulls the tube in from the front, increasing feeding efficiency by about 40% and reducing operator labor intensity by approximately 40%. This directly addresses common industry pain points like high operator turnover and the associated retraining burdens.

Beyond hardware automation, the intelligence embedded in the machine's software is revolutionary. Traditional machines often require skilled CAD operators to create or modify complex 3D drawings before production, a time-consuming bottleneck. MZBNL's pioneering No-CAD Operating System eliminates this. Operators can now process standard tube types and hole patterns simply by entering parameters, no drawing required. This innovation dramatically improves ease of use, shortens setup time, and lowers the skill threshold for machine operation, enabling operators to be fully proficient after just 1 day of on-site training instead of 15 days at the factory.

Furthermore, advanced software allows for sophisticated nesting algorithms to maximize material utilization and minimize waste. My personal experience at MZBNL developing our Zero-Waste Tail Material Innovation exemplifies this. By redesigning the cutting logic to calculate from the rear chuck as the origin, our system virtually eliminates leftover tail material, boosting cutting efficiency. This kind of intelligent integration not only optimizes material consumption but also simplifies complex operations, making the machine accessible to a broader range of operators and significantly improving the overall profitability of fabrication services.

Material versatility is crucialTrue

A machine's ability to handle various metals (steel, aluminum, brass) directly impacts production flexibility and business growth potential.

Faster cutting always means betterFalse

Excessive speed can compromise cut quality, requiring additional post-processing that negates time savings.

How does your budget influence your choice of metal tube cutting machine?

When I discuss new machinery with clients, budget is always a central point, and for good reason. It's easy to focus solely on the sticker price, but that’s a narrow view that can lead to long-term financial strain. Understanding how your budget truly shapes your options is crucial for a sound investment.

Your budget significantly impacts your metal tube cutting machine choice by determining the available technology, automation level, and included features. It's crucial to balance initial investment with long-term operational costs, potential productivity gains, and the machine's overall return on investment.

My experience, particularly with clients like Ahmed who value a high cost-performance ratio, has taught me that a budget isn't just a limit; it's a strategic tool. Ahmed seeks turnkey solutions and values long-term value over the lowest initial price, understanding that a cheaper machine might incur higher operational costs or require more skilled labor down the line. It's about finding the sweet spot where your investment delivers maximum productivity and efficiency without breaking the bank. From MZBNL's perspective, this means offering cost-effective customized solutions5 that don't compromise on technology or reliability. It's about looking beyond the purchase price to the total cost of ownership, encompassing everything from energy consumption and maintenance to the potential for increased output and reduced waste that a more advanced machine, such as one with our Zero-Waste Tail Material Innovation, can provide. This holistic view ensures that your budget empowers you to achieve your business goals efficiently.

Initial Investment vs. Total Cost of Ownership (TCO)

The initial purchase price of a metal tube cutting machine is merely the tip of the iceberg. A comprehensive financial evaluation must include the Total Cost of Ownership (TCO), which encompasses a broader range of expenses over the machine's lifespan. Beyond the upfront cost, TCO includes installation, training, power consumption, consumables (like laser gases or nozzles), spare parts, maintenance, and potential downtime losses. For example, a machine with a lower initial price might have higher energy consumption, require more frequent part replacements, or demand more specialized and costly maintenance. Conversely, a higher-priced machine, particularly one from a high-tech enterprise like MZBNL, might feature advanced energy-saving components, durable parts, and intelligent diagnostics that reduce long-term operational costs significantly.

Consider a scenario where a cheaper machine requires weekly nozzle replacements versus a premium machine where they last a month, or where the less expensive option consumes 30% more electricity per hour. Over several years, these seemingly small differences accumulate into substantial savings or unforeseen expenses. My discussions with clients like Ahmed often revolve around this precise point. He prioritizes cost-performance, understanding that a machine that optimizes material utilization, like MZBNL's Zero-Waste Tail Material system, directly impacts his profit margin on every contract. Calculating the TCO provides a more accurate financial picture, allowing businesses to make decisions that lead to sustainable profitability rather than just immediate savings.

Furthermore, factors like operator skill requirements also feed into TCO. If a machine demands highly specialized CAD operators6, as was one of Ahmed’s pain points with previous machines, labor costs and the burden of retraining due to high turnover can be substantial. MZBNL's No-CAD Operating System, which requires only 1 day of on-site training instead of 15 days, directly reduces this TCO component by lowering the skill threshold and associated labor expenditures, making the machine more accessible and cost-effective to operate in the long run.

Financing Options and ROI Calculation

Understanding various financing options is crucial for aligning your purchase with your cash flow and strategic financial goals. Options range from outright purchase with company capital, which might be suitable for businesses with strong reserves, to various forms of leasing or bank loans. Each option has implications for interest rates, tax benefits, and capital expenditure versus operational expenditure reporting. For small to mid-sized businesses looking to expand, like Ahmed's, leasing can preserve capital for other investments while providing access to high-end machinery.

Equally important is the Return on Investment (ROI) calculation. This involves quantifying the tangible benefits a new machine brings, such as increased production capacity, reduced labor costs, improved part quality leading to fewer rejections, and the ability to take on new, more profitable projects. For instance, if a new MZBNL laser tube cutting machine can increase cutting efficiency by 40% and reduce material waste by a significant margin, these efficiencies can be translated into monetary savings and increased revenue.

To calculate ROI, one might compare the total investment (including TCO elements) against the annual projected savings and revenue increases. For example, a machine costing $200,000 might generate $80,000 in annual savings and increased revenue. This indicates a payback period of 2.5 years, a compelling argument for investment. I've often guided clients through these calculations, illustrating how features like MZBNL's Front-Feeding Innovation, which boosts efficiency by 40%, directly contribute to a faster ROI by accelerating production cycles and reducing labor intensity. This data-driven approach helps businesses like Ahmed’s justify the investment to stakeholders and ensure that the machine is not just an expense but a profitable asset.

Customization vs. Standard Models

The choice between a highly customized machine and a standard, off-the-shelf model often hinges on unique business requirements and budget constraints. Standard models are typically more affordable and readily available, making them suitable for businesses with common cutting needs. However, they might not offer the specialized features or capacities required for niche applications or high-volume, specific production demands.

Customization, on the other hand, allows for a machine precisely tailored to your operational needs, optimizing performance for specific tube types, material handling, or integration with existing factory automation. MZBNL, with its integrated R&D, manufacturing, sales, and service model, specializes in providing cost-effective customized solutions. This means we can configure machines to meet unique specifications, ensuring that every feature contributes directly to the client's productivity and profitability. For Ahmed, who requires automatic feeding and punching capabilities for diverse applications, customization is not a luxury but a necessity to achieve his desired level of automation and efficiency.

While customized solutions may initially appear more expensive, their long-term value often outweighs the higher upfront cost. A tailor-made machine can achieve significantly higher efficiencies, reduce waste, and streamline production processes in ways a standard model cannot. This leads to greater output, lower operational costs, and the ability to take on more specialized, higher-margin projects. From a strategic perspective, investing in a customized solution ensures that your machine is not just a tool, but a competitive advantage perfectly aligned with your business model and future growth aspirations.

Budget determines machine featuresTrue

Your budget directly influences the technology level, automation features, and capabilities of the metal tube cutting machine you can purchase.

Cheaper machines always save moneyFalse

Lower initial cost machines often have higher long-term operational costs due to maintenance, energy consumption, and lower efficiency.

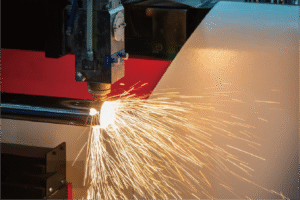

What are the pros and cons of different types of cutting technologies available?

Deciphering the various cutting technologies available can be daunting, each promising unique advantages yet harboring distinct limitations. From my perspective at MZBNL, with 25 years in metal fabrication, understanding these nuances is critical. The right technology choice directly impacts your product quality, speed, and overall operational costs.

Various cutting technologies exist, including fiber laser, CO2 laser, plasma, and saw cutting, each with distinct pros and cons regarding material compatibility, cut quality, speed, and operational costs. Fiber lasers are often preferred for their precision and efficiency on metals.

When I consult with clients, particularly those expanding into demanding sectors like automotive parts or architectural metalwork, the choice of cutting technology is a frequent discussion point. Ahmed, for example, needs high-precision cuts for vehicle components and rapid processing for large architectural projects. This scenario immediately brings fiber laser technology to the forefront due to its blend of speed and accuracy on various metals. However, it's not a one-size-fits-all solution; other technologies like plasma cutting7 or saw cutting still hold relevance for specific applications or budget constraints. My role, drawing on MZBNL’s extensive experience and R&D capabilities, is to help businesses navigate these choices by providing clear, data-backed comparisons that highlight the long-term implications of each technology on their production efficiency, material usage, and ultimately, their profitability, ensuring they select the most suitable and forward-looking solution.

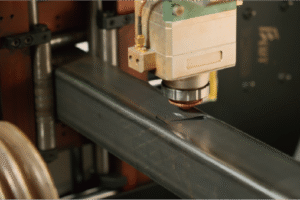

Fiber Laser Technology: Advantages and Applications

Fiber laser technology has rapidly become the dominant choice for metal tube cutting due to its superior efficiency, precision, and versatility. Unlike traditional CO2 lasers that rely on gas mixtures and mirrors, fiber lasers generate a laser beam through optical fibers, delivering it directly to the cutting head with minimal energy loss. This results in significantly lower power consumption and maintenance requirements. A major advantage is its ability to cut reflective metals like copper and brass with high efficiency, which are challenging for CO2 lasers. The concentrated beam also produces a very narrow kerf and excellent edge quality, making it ideal for precision components and intricate designs.

The speed of fiber laser cutting, particularly on thinner to medium-gauge metals (up to 20mm), is unparalleled. For instance, a 6kW fiber laser can cut 6mm mild steel at speeds of 18 meters per minute, far surpassing other methods. This high-speed capability is crucial for businesses with high production volumes, such as those supplying automotive parts or large-scale architectural elements, where throughput directly impacts project deadlines and profitability. From my work at MZBNL, we've seen how this technology allows clients to meet tight delivery schedules and produce high-quality parts consistently, aligning perfectly with Ahmed's need for both speed and accuracy for his diverse product lines. The minimal heat affected zone (HAZ) also reduces material distortion, ensuring dimensional accuracy for complex assemblies.

Furthermore, fiber lasers offer robust reliability and a long lifespan, often exceeding 100,000 hours of operation, with fewer consumables and simplified maintenance compared to CO2 systems. This contributes to a lower total cost of ownership over the machine's life. The integration with smart systems, such as MZBNL's No-CAD and Zero-Waste Tail Material innovations, further enhances their appeal by simplifying operation and maximizing material utilization. These advancements make fiber laser systems a strategic investment for businesses aiming for high efficiency, precision, and future-proof production capabilities.

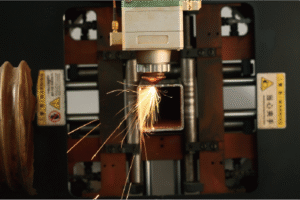

Alternative Cutting Methods: Plasma and Saw

While fiber lasers dominate the high-precision metal cutting market, plasma cutting and saw cutting technologies still hold specific niches due to their unique characteristics, cost profiles, and application suitability. Plasma cutting 8utilizes an ionized gas (plasma) at high temperatures to cut through electrically conductive materials. It offers faster cutting speeds than traditional oxy-fuel cutting and can handle thicker materials than most lasers, making it a viable option for heavy-duty fabrication or larger diameter pipes. However, plasma cuts typically result in a wider kerf and a rougher edge quality compared to laser cutting, often requiring secondary finishing operations. The heat input is also higher, which can lead to more material distortion, particularly in thinner tubes.

Saw cutting, on the other hand, is a mechanical process using a rotating blade to cut through material. It is a highly cost-effective method for simple, straight cuts on various tube profiles and is excellent for thick-walled pipes or solid bars where precision isn't paramount. Saws are generally robust and have lower operating costs per cut than thermal methods. However, they are inherently slower, produce chips and burrs, and cannot perform complex geometries like holes, slots, or intricate patterns. This limitation makes them unsuitable for applications requiring complex designs or high aesthetic quality, such as many of Ahmed’s architectural or vehicle part projects.

The choice between these technologies often comes down to a trade-off between cut quality, speed, material thickness, and budget. For businesses with limited budgets or those focusing on high-volume, less intricate cutting of thick materials, plasma or saw cutting might be a viable entry point. However, for companies seeking to upgrade their production efficiency, achieve high precision, and offer diversified products requiring complex cuts, the limitations of these alternative methods quickly become apparent. My insights from working with clients across various industries confirm that while these technologies have their place, they cannot match the versatility, precision, and efficiency offered by advanced fiber laser tube cutting machines for modern metal fabrication needs.

Technological Advancements and Future Trends

The field of metal tube cutting technology is continually evolving, driven by advancements in laser sources, control systems, and automation. One significant trend is the increasing power of fiber lasers, allowing for faster cutting of thicker materials and expanding their application range. We're seeing laser powers reaching 20kW and beyond, pushing the boundaries of what's possible in terms of speed and material processing capabilities. This means future machines will be even more efficient, reducing production times and costs further.

Another critical advancement is the integration of artificial intelligence (AI) and machine learning (ML) into cutting systems. These smart technologies enable predictive maintenance, optimizing machine performance and minimizing downtime by anticipating potential issues before they occur. They also enhance cut quality through real-time adjustments based on material variations or environmental factors. At MZBNL, our focus on smart and digitalized systems, combined with multi-process integration, aims to equip our machines with these future-forward capabilities, ensuring our clients benefit from the most advanced and efficient technologies available. This level of intelligence is essential for automated factories where seamless operation and minimal human intervention are key.

Furthermore, the emphasis on user-friendliness and simplified operation, as exemplified by MZBNL's No-CAD Operating System, is a major trend. Manufacturers are recognizing the global shortage of highly skilled operators and are designing machines that are easier to learn and operate, reducing training burdens and increasing accessibility. This shift ensures that even smaller fabrication shops can leverage advanced technology. The continuous development of automated material handling systems, including robotics and vision systems, will further enhance operational efficiency and safety, moving towards fully automated production lines. These trends collectively point towards a future where metal tube cutting machines are not just faster and more powerful, but also smarter, more autonomous, and easier to integrate into diverse manufacturing environments.

Fiber lasers cut reflective metals wellTrue

Fiber lasers excel at cutting reflective metals like copper and brass, unlike CO2 lasers which struggle with these materials.

Saw cutting is best for complex designsFalse

Saw cutting is limited to simple straight cuts and cannot perform complex geometries like laser cutting can.

How can operational efficiency and ease of maintenance impact your decision?

In the bustling world of metal fabrication, a machine’s true value extends far beyond its initial cutting prowess. As I've seen countless times, neglecting operational efficiency and ease of maintenance can transform a promising investment into a persistent drain on resources. These factors are absolutely crucial for long-term profitability.

Operational efficiency and ease of maintenance are paramount, influencing daily productivity, labor costs, and machine uptime. Factors like user-friendliness, automation features, maintenance frequency, and spare parts availability directly contribute to the overall profitability and smooth running of operations.

For a business owner like Ahmed, whose primary goal is to automate existing manual workflows and expand his operations, the daily grind of machine operation and maintenance is critical. He understands that high operator turnover due to complex machinery leads to retraining burdens—a significant pain point. This is precisely why MZBNL's commitment to user-friendly design and robust, easily maintainable systems becomes a game-changer. My personal experience has shown that a machine, no matter how powerful, becomes a liability if it’s difficult to use or constantly breaks down. It's not just about the cutting; it's about seamless operation, minimal downtime, and reducing the need for highly specialized skills. Our innovations, like the No-CAD system9 that simplifies operation to a single day of training, directly address these efficiency and maintenance concerns, turning potential headaches into productivity gains and ensuring a smooth, profitable production flow for years to come.

User Interface and Automation

The user interface (UI) and the level of automation significantly influence a machine’s daily operational efficiency. A complex, unintuitive UI can lead to longer setup times, increased human error, and a steeper learning curve for operators, which contributes to higher labor costs and productivity bottlenecks. Conversely, a simple, logical interface empowers operators to quickly become proficient, minimizing training time and maximizing machine uptime. This is a crucial factor for companies like Ahmed’s, which face challenges with operator turnover and the need for constant retraining. MZBNL recognized this challenge early on, leading to our groundbreaking No-CAD Operating System10. This innovation means operators can process standard tube types and hole patterns by simply entering parameters, eliminating the need for complex 3D drawings and reducing training from 15 days to just 1 day.

Beyond the UI, integrated automation features dramatically boost efficiency. Manual loading and unloading are time-consuming and labor-intensive processes. Automated feeding systems, such as MZBNL's Front-Feeding Innovation11, can increase feeding efficiency by approximately 40% and reduce operator labor intensity by a similar margin. This directly translates to higher throughput and lower labor costs per unit. Similarly, automatic part sorting and scrap removal systems further streamline operations, allowing the machine to run continuously with minimal human intervention. For a business like Ahmed's that processes large volumes of metal tubes for architectural and automotive applications, these automation features are not merely conveniences; they are essential for achieving the scale and efficiency required to stay competitive in contract-based fabrication services. The ability to run shifts with fewer, less specialized operators fundamentally transforms the profit model.

Moreover, the integration of smart systems allows for remote diagnostics and real-time monitoring of machine performance. This enables proactive maintenance, reducing the likelihood of unexpected breakdowns and ensuring maximum uptime. A machine that is smart, digitalized, and easy to operate is a core tenet of MZBNL's product development, reflecting our understanding that true efficiency stems from a harmonious blend of advanced hardware and intelligent, user-friendly software.

Maintenance Protocols and Downtime Reduction

Effective maintenance protocols and a machine's inherent ease of maintenance are paramount for minimizing costly downtime and ensuring long-term operational reliability. A machine that is difficult to access for routine checks, requires specialized tools for common tasks, or has complex troubleshooting procedures will inevitably lead to longer repair times and higher maintenance costs. Conversely, machines designed with accessibility and modularity in mind simplify maintenance, allowing operators or technicians to quickly diagnose and resolve issues, often minimizing the need for expensive external service calls.

Preventive maintenance schedules, coupled with built-in diagnostic tools, play a critical role in proactive problem-solving. Modern machines often include sensors that monitor key components, alerting operators to potential issues before they escalate into major breakdowns. This predictive capability allows businesses to schedule maintenance during off-peak hours, avoiding disruption to production. For instance, MZBNL designs its machines for easy operation and maintenance, providing digitalized systems that aid in quick diagnostics. This approach aligns with industry best practices, where a focus on reliability and quick recovery from minor faults is prioritized to sustain high production rates.

The impact of downtime can be catastrophic for contract manufacturers like Ahmed. Every hour a machine is not running translates directly into lost revenue, delayed project deliveries, and potentially damaged client relationships. Industry data suggests that unscheduled downtime can cost manufacturers thousands of dollars per hour, depending on the scale of operations. Therefore, investing in a machine with a proven track record of reliability, simple maintenance requirements, and readily available technical support is not just a preference; it’s an economic imperative. A machine that can be quickly brought back online ensures project continuity and protects a business's reputation for timely delivery.

Training and Skill Requirements

The level of training required for operators is a significant factor in both initial investment and ongoing operational costs, particularly for businesses facing challenges with skilled labor availability and turnover. Traditional metal tube cutting machines often demand highly skilled operators proficient in CAD software and complex machine programming, necessitating extensive training periods—sometimes weeks or even months—and commanding higher wages. This creates a bottleneck in staffing and increases the cost of onboarding new employees, a pain point Ahmed specifically highlighted regarding previous equipment.

MZBNL directly addresses this challenge with its innovative No-CAD Operating System. By allowing operators to process standard tube types and hole patterns simply by entering parameters, the system dramatically lowers the skill threshold. My experience has shown that operators now only need 1 day of on-site training to become proficient, instead of spending 15 days at the equipment factory. This reduction in training time and complexity makes the machine more accessible to a wider pool of talent, significantly reducing labor costs and mitigating the impact of high operator turnover. For businesses expanding rapidly, this simplified training means faster scaling of operations without the bottleneck of finding and training highly specialized personnel.

Moreover, a machine that is easy to operate also contributes to higher job satisfaction among employees, potentially reducing turnover rates. When operators feel competent and confident using the equipment, they are more productive and engaged. This holistic benefit—from reduced training expenses and lower labor costs to improved workforce stability—underscores why user-friendliness and simplified skill requirements are not just a convenience but a strategic advantage in the modern manufacturing landscape, making advanced technology accessible and profitable for businesses of all sizes, especially those looking to automate manual workflows as Ahmed is.

Automation reduces labor costsTrue

Automated feeding systems can increase efficiency by 40% and reduce labor intensity, directly lowering operational costs.

Complex UI improves efficiencyFalse

A complex user interface leads to longer setup times and increased errors, while simple UIs minimize training time and maximize uptime.

What role do after-sales service and warranty play in your purchasing decision?

After investing in a high-tech metal tube cutting machine, the last thing you want is to be left adrift when an issue arises. My 25 years in this industry have repeatedly shown that the quality of after-sales service and the comprehensiveness of a warranty can be the ultimate make-or-break factors.

After-sales service and warranty are crucial, providing peace of mind, ensuring machine longevity, and minimizing costly downtime. They encompass technical support, spare parts availability, training, and repair services, directly impacting the long-term reliability and success of your investment.

For discerning clients like Ahmed, who prioritizes suppliers with proven technology and global references, the discussion around after-sales support isn't an afterthought—it's a critical component of his buying preference. He explicitly expects customization and post-sales training/support, understanding that even the most advanced machine can become a liability without reliable backing. My role at MZBNL, a company with 4000+ global enterprise clients12, involves ensuring that our commitment to our machines extends far beyond the sale. This encompasses everything from remote diagnostics and spare parts availability to the potential for local agent presence, which Ahmed also values highly. We recognize that true value lies in ensuring your investment continues to operate seamlessly, preventing costly interruptions and providing the peace of mind necessary for you to focus on growing your business.

Importance of Comprehensive Support Packages

A comprehensive after-sales support package is as vital as the machine's technical specifications. It ensures that when issues inevitably arise, you have a reliable lifeline to minimize downtime and maintain production. This package typically includes access to technical support lines, on-site repair services, and remote diagnostics capabilities. For a high-tech machine like a laser tube cutter, troubleshooting can be complex, requiring specialized knowledge. A vendor offering 24/7 technical support or quick response times can drastically reduce the impact of operational glitches. My experience with clients across Southeast Asia, the Middle East, and North America13 underscores that prompt support can save thousands in lost production and prevent project delays.

Beyond immediate troubleshooting, a comprehensive support package often includes regular preventive maintenance visits and performance optimization services. These proactive measures help identify potential issues before they become critical failures, extending the machine's lifespan and ensuring it operates at peak efficiency. For a business like Ahmed's, which operates a stable, long-term business with over 100 staff and relies on contract-based fabrication, consistent machine uptime is directly tied to profitability and reputation. A supplier like MZBNL, with its integrated R&D, manufacturing, sales, and service model, is inherently positioned to offer robust support due to our deep understanding of our own equipment and commitment to client success.

Furthermore, access to ongoing training for operators and maintenance staff is a cornerstone of effective support. As technology evolves, ensuring your team is up-to-date with best practices and new features maximizes the return on your investment. Ahmed specifically values post-sales training and support, understanding that skilled personnel are key to leveraging the machine's full capabilities and minimizing costly errors or inefficiencies, particularly given his prior pain points regarding equipment that lacked local service support.

Global Service Networks and Local Presence

For companies operating in diverse geographical locations or those considering international expansion, the presence of a global service network and local agents or distributors is paramount. While direct factory support is crucial, having local expertise and a quick response team can dramatically reduce repair times and logistical challenges. Shipping parts internationally or waiting for technicians to travel from afar can result in significant downtime and associated costs. For instance, Ahmed, located in the UAE, actively sources from China, Germany, and Turkey, and one of his key sourcing points is the presence of a local agent or distributor.

A supplier with a strong global footprint, like MZBNL with its main export countries including Southeast Asia, the Middle East, Europe, and North America, can provide more reliable and timely support. This means having trained technicians, spare parts inventories, and a network of qualified partners strategically located around the world. In my role, I frequently emphasize to prospective clients that while remote diagnostics and support are excellent first lines of defense, nothing replaces the assurance of a local presence for urgent on-site interventions. This is particularly relevant for critical equipment like laser tube cutting machines, where precision and continuous operation are vital.

Moreover, a local presence can also facilitate better communication, cultural understanding, and personalized service tailored to regional specificities. It builds trust and ensures that clients feel fully supported, leading to stronger, long-term partnerships. Ahmed’s consideration of becoming a regional distributor if the machine performs well and support is reliable further highlights the importance of a robust local infrastructure, indicating that a strong service network can even open doors for strategic business collaborations.

Warranty Coverage and Long-Term Value

The warranty offered by a manufacturer is a direct reflection of their confidence in the machine's quality and durability. A comprehensive warranty covers critical components for a reasonable period, providing financial protection against unexpected defects or failures. It’s essential to scrutinize not only the length of the warranty but also what it specifically covers, including parts, labor, and travel expenses for technicians. A longer or more extensive warranty often indicates a higher quality product and a manufacturer willing to stand behind their engineering.

Beyond the initial warranty period, understanding the availability and cost of extended warranty options or service contracts is crucial for long-term planning. This ensures continued protection and peace of mind as the machine ages. For a significant capital investment like a metal tube cutting machine, protecting that investment over its operational lifespan is key to maximizing its long-term value. For example, some industry standards suggest a minimum of one to two years for comprehensive parts and labor warranty on such sophisticated equipment, with options for extended coverage.

Ultimately, the warranty and after-sales service contribute directly to the machine's total cost of ownership and its overall return on investment. A machine with excellent support and a robust warranty will experience less downtime, require fewer unscheduled repairs, and maintain a higher resale value. This aligns perfectly with Ahmed’s preference for suppliers with proven technology and global references, and his expectation of customization and post-sales support. Investing in a machine from a reputable company like MZBNL, which backs its products with strong warranties and dedicated support, is not just about mitigating risk but about ensuring uninterrupted productivity and sustained profitability for years to come.

After-sales service prevents costly downtimeTrue

Comprehensive after-sales support minimizes production interruptions by providing quick technical assistance and repairs.

Warranty only covers machine partsFalse

Quality warranties typically cover parts, labor, and sometimes technician travel expenses for comprehensive protection.

Conclusion

Choosing the right metal tube cutting machine hinges on five critical factors: precise specifications, a strategic budget that considers TCO, selecting the optimal cutting technology, ensuring high operational efficiency and maintainability, and securing robust after-sales service and warranty. By meticulously evaluating these elements, you can make an informed decision that drives your business forward.

-

Discover why integrated solutions are essential for efficiency and profitability in metal fabrication ↩

-

Learn about MZBNL's patented innovations in metal fabrication for advanced manufacturing solutions ↩

-

Understand the importance of material versatility in expanding production capabilities ↩

-

Explore the benefits of increased efficiency and reduced labor intensity in metal tube cutting ↩

-

Understand when customization offers long-term advantages for specific industrial needs ↩

-

Discover the typical skills needed for operating CAD-based machinery in manufacturing ↩

-

Learn about fiber laser precision, efficiency, and lower maintenance advantages over CO2 lasers ↩

-

Discover plasma cutting's speed benefits and edge quality on thicker materials ↩

-

Learn how No-CAD simplifies training and enhances production flow ↩

-

Understand how No-CAD reduces training time and complexity ↩

-

Discover how front-feeding boosts productivity by 40% ↩

-

Discover the comprehensive after-sales support services offered by MZBNL for its products. ↩

-

Learn about MZBNL's global and regional support networks for their machines. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.