Real Success Stories with MZBNL

From pipe processors to automotive manufacturers — see how MZBNL solutions transform efficiency, cut costs, and unlock new growth.

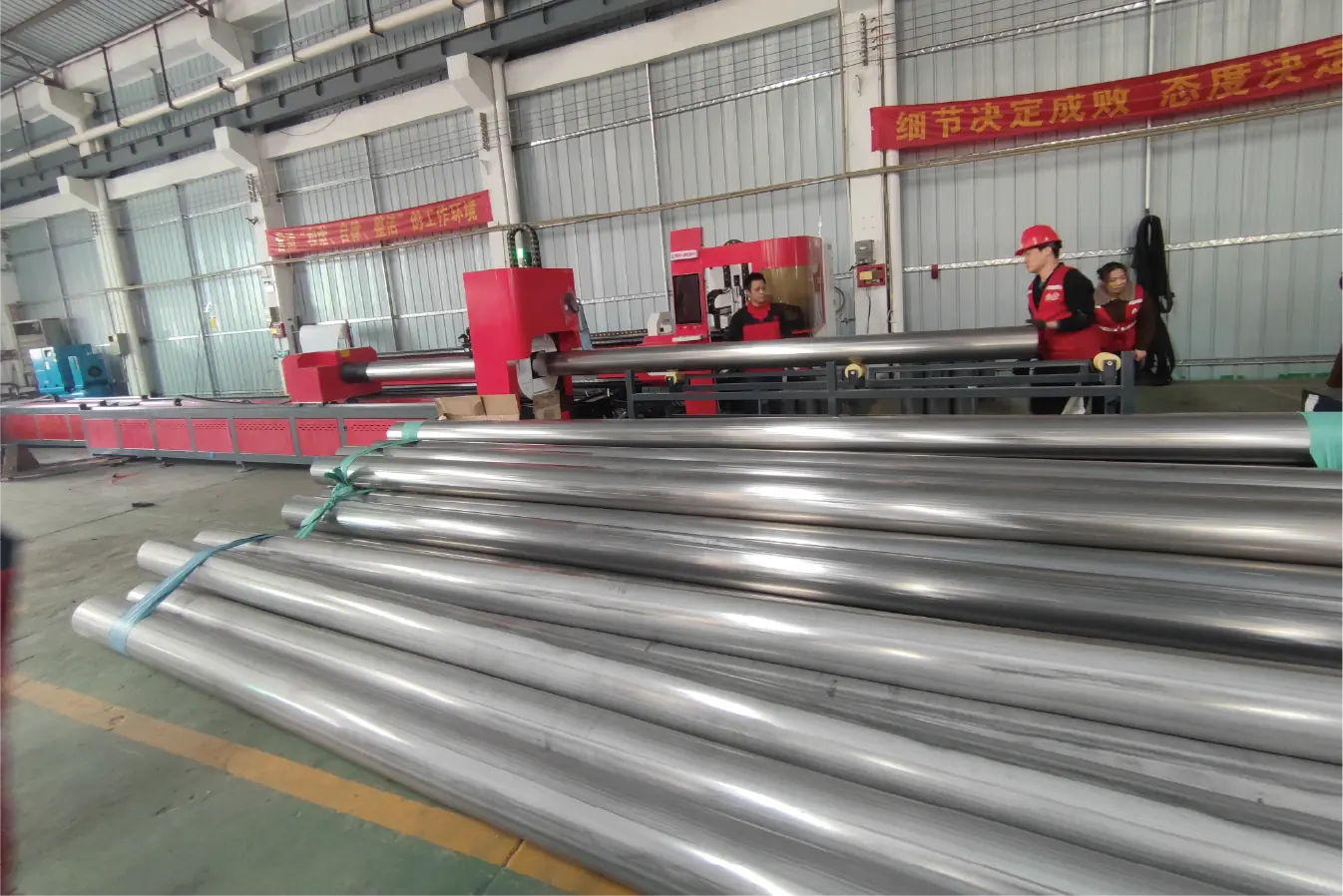

🏭 Stainless Steel Pipe Factory in Jiangsu

How MZBNL's No-CAD technology transformed manufacturing efficiency

The Challenge

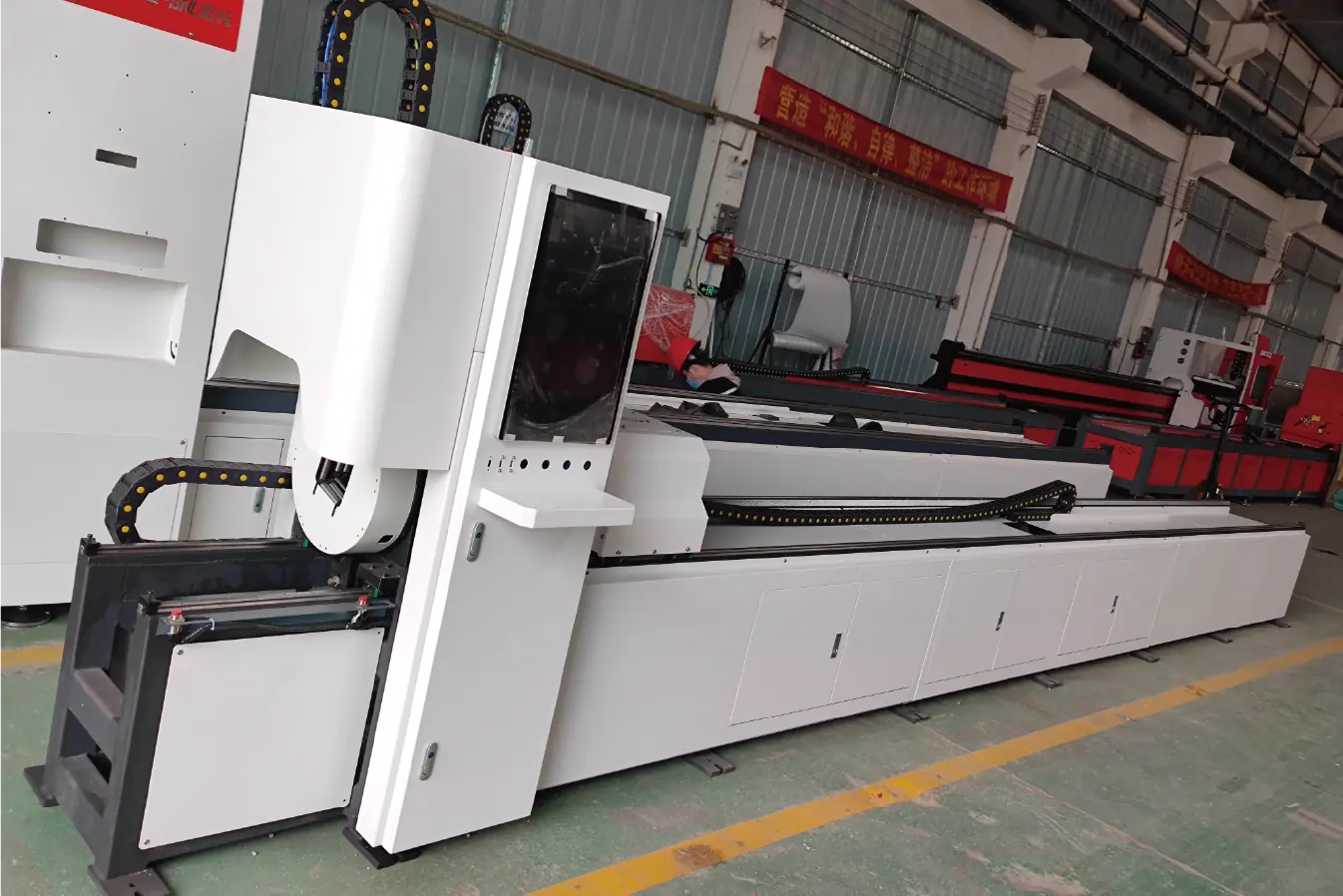

A major stainless steel pipe manufacturer faced critical bottlenecks: 15-day training cycles, heavy dependence on CAD engineers, and limited production flexibility.

MZBNL Solution

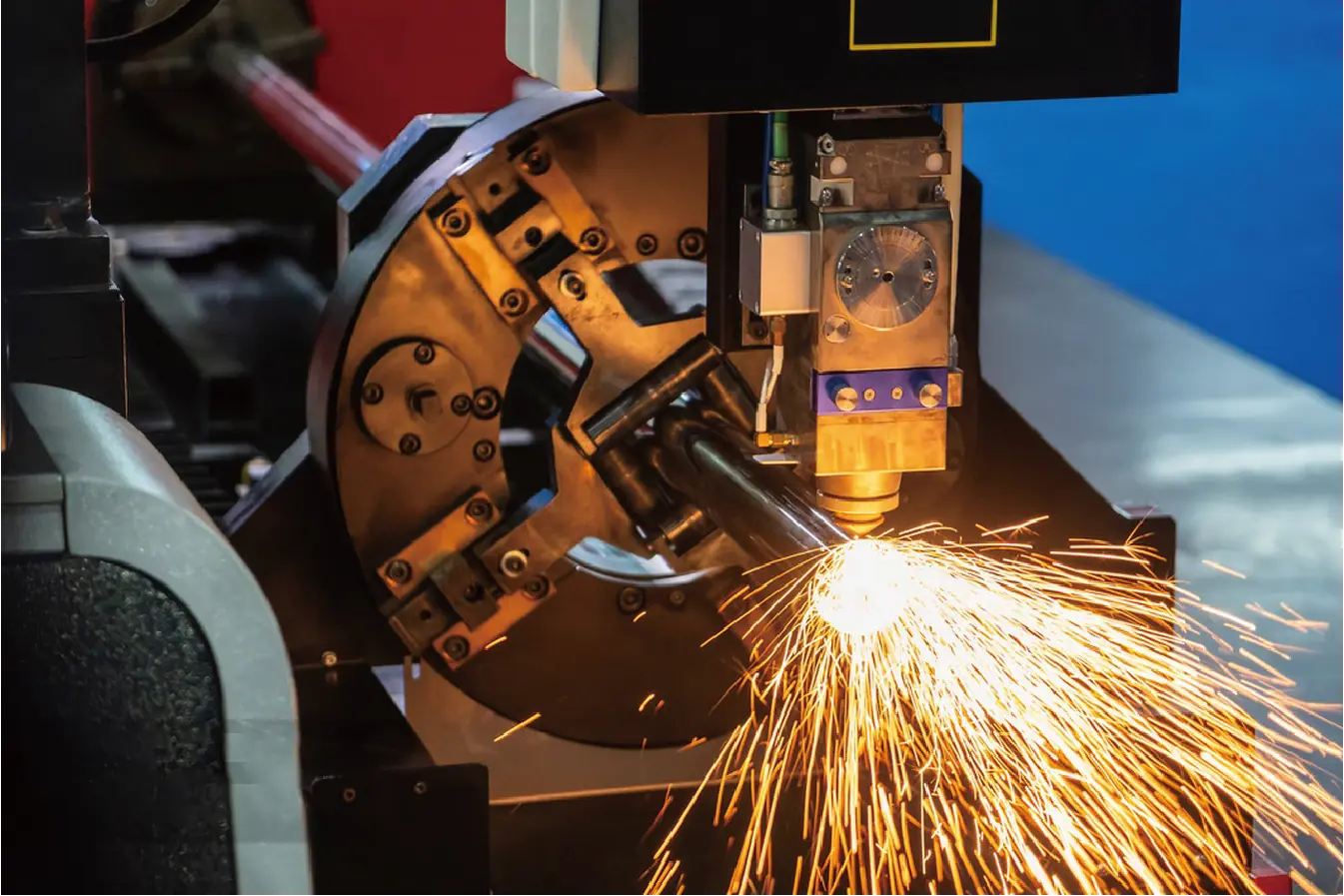

Our No-CAD laser tube cutting machine with intuitive parameter-based controls eliminated all dependencies.

"Now operators can learn in just one day. We no longer rely on CAD engineers, and production efficiency has clearly improved."

Factory Director

Jiangsu Pipe Manufacturing

Furniture & Sanitary Ware Manufacturer

Vietnam-based manufacturer transforms production efficiency and quality with MZBNL's high-precision laser cutting technology

Client Background

A furniture and sanitary ware manufacturer in Vietnam with a large export business. The company faced low efficiency, poor cutting precision, and a defect rate of over 20%, which often caused delivery delays.

Defect Rate

Over 20%

Delivery Issues

Frequent Delays

Solution & Results

By adopting MZBNL's high-speed, high-precision laser tube cutting machine, the manufacturer achieved single-hole cutting in just 0.5 seconds, improved efficiency by 40%, and reduced defect rates by 25%. On-time delivery rate increased, helping the company regain customer trust.

"The cutting precision and speed have helped us win back trust from European and U.S. clients."

CEO

Vietnam Furniture Factory

🚗 Automotive Parts Manufacturer in Monterrey, Mexico

Client Background

An automotive parts manufacturer in Monterrey, Mexico, supplying pipe components to North American carmakers. Frequent equipment downtime and long maintenance times disrupted production and delayed deliveries.

Solution & Results

MZBNL provided equipment with easy-maintenance design + intelligent digital system, enabling remote diagnostics and real-time monitoring.

Result: Year-round stable production with secured delivery schedules.

Want to explore more success stories?

Contact the MZBNL team today and discover your tailored solution.