Why More Factories Are Investing in Tube Laser Cutting Machines

The landscape of manufacturing is constantly evolving, pushing factories to seek innovative solutions. Are you struggling with outdated production methods? The answer to boosting efficiency and output might lie in a critical investment: tube laser cutting machines.

Factories are increasingly investing in tube laser cutting machines due to their unparalleled precision, speed, and automation capabilities, which significantly enhance productivity and streamline complex fabrication processes. This shift reflects a growing demand for higher efficiency and advanced manufacturing solutions.

For 25 years, I’ve seen firsthand how crucial staying ahead of the curve is in metal fabrication. The global market demands precision, speed, and adaptability like never before. As factories look to optimize their operations and meet these new challenges, the strategic investment in tube laser cutting technology is no longer an option—it’s a necessity. This shift is driven by a clear understanding of its transformative power.

At MZBNL, we've witnessed a dramatic acceleration in factories embracing advanced automation. Our journey, marked by 30+ patents and over 4000 global enterprise clients, reveals a critical trend: the move away from traditional, labor-intensive methods toward smart, digitalized systems1. Consider the architectural metalwork sector, a key area for clients like Ahmed Al-Farsi in the UAE. He's actively expanding his business and recognizes that manual workflows are a bottleneck. The industry demands intricate designs and rapid turnarounds, which conventional methods simply cannot deliver. Our no-CAD system, for instance, directly addresses his pain point of needing skilled CAD operators, significantly reducing training burdens and lead times. This isn't just about cutting faster; it’s about rethinking the entire production paradigm to achieve superior quality, reduce waste, and build a more resilient supply chain.

What recent trends show increased factory investment in tube laser cutting machines?

The manufacturing sector is witnessing a significant shift towards advanced automation. Are you observing how traditional methods are struggling to keep pace? Factories are actively seeking more efficient and precise solutions for their production lines.

Recent trends indicate a strong surge in factory investments in tube laser cutting machines, driven by the need for higher automation, increased production speeds, and enhanced material utilization. This reflects a global push towards smart manufacturing and Industry 4.0 standards across various industries.

The global manufacturing landscape is undergoing a profound transformation. From our vantage point at MZBNL, working with clients across Southeast Asia, the Middle East, Europe, and North America, we've seen a decisive pivot towards integrated, high-tech solutions. This isn't merely about adopting new machinery; it's about fundamentally reshaping production processes to meet escalating demands for precision, speed, and cost-efficiency. Factories are no longer just replacing old equipment; they are strategically investing in technologies that offer a competitive edge, fostering innovation and resilience in their supply chains. The drive to automate, digitalize, and optimize is stronger than ever, signaling a new era for metal fabrication.

The Rise of Automation and Smart Manufacturing

The most prominent trend driving investment in tube laser cutting machines is the accelerating adoption of automation and smart manufacturing principles. Factories are recognizing that manual processes are not only labor-intensive but also prone to human error, leading to inefficiencies and increased waste. According to a report by Grand View Research, the global laser cutting machine market size was valued at USD 4.1 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.9% from 2024 to 2030, with tube laser cutting leading this growth. This growth is largely fueled by the integration of IoT, AI, and robotics, enabling machines to operate autonomously, monitor performance in real-time, and even predict maintenance needs. For instance, our automatic punching and cutting integrated machine exemplifies this trend, offering seamless multi-process integration that significantly reduces manual intervention. Companies, much like Ahmed Al-Farsi's, are moving towards turnkey solutions that minimize setup and operational complexity, allowing them to focus on expanding their core business. The shift towards automated front-feeding mechanisms, like our innovation that boosts efficiency by 40%, directly addresses the desire for reduced labor intensity and higher throughput.

This embrace of automation is evident across diverse sectors. In the automotive industry, manufacturers are leveraging automated tube laser cutting for chassis components and exhaust systems, where precision and repeatability are paramount. A recent industry survey indicated that over 60% of automotive suppliers plan to increase their investment in automated fabrication equipment within the next three years. This isn't just about large enterprises; even mid-sized fabrication businesses, like Ahmed's, are finding significant ROI. By automating workflows that previously relied on skilled labor, they can reallocate their workforce to higher-value tasks, thereby optimizing overall operational costs. Furthermore, the push for smart factories, where data from machines is analyzed to optimize production schedules and identify bottlenecks, is making tube laser cutting machines with integrated digital systems a crucial component of modern manufacturing infrastructure.

The impact of this trend is multifaceted. Beyond immediate gains in speed and accuracy, automation allows for greater flexibility in production. Factories can switch between different product lines more rapidly, respond to market demands with agility, and customize solutions more effectively. This adaptability is critical in today's dynamic global market. Our No-CAD system, for example, directly addresses this need by simplifying complex design processes, enabling faster prototyping and production of customized parts. Instead of weeks of CAD training, operators are proficient in a single day, dramatically shortening lead times for new product introductions or design modifications. This capability positions factories to take on more varied and intricate projects, expanding their market reach and revenue streams.

Pursuit of High Precision and Complex Geometry Cutting

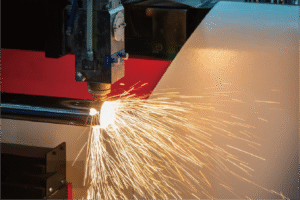

Another significant trend is the increasing demand for high-precision and complex geometry cutting capabilities. Modern product designs often feature intricate patterns, tight tolerances, and non-standard tube shapes that are challenging, if not impossible, to achieve with traditional cutting methods like sawing or drilling. The medical equipment industry, for example, requires extremely precise cuts for implants and surgical instruments, where even microscopic deviations can have critical consequences. Similarly, in architectural decoration, elaborate railings and structural elements demand highly accurate and aesthetically pleasing finishes. Tube laser cutting machines excel in these areas, offering unparalleled precision down to micrometers. For instance, our machines are designed for high-speed and high-precision cutting, ensuring that even the most complex designs are executed flawlessly.

The ability to cut complex geometries with ease has opened up new design possibilities and product innovations. Manufacturers are no longer limited by the constraints of conventional fabrication techniques. This translates into more lightweight, structurally robust, and aesthetically appealing products. Consider the furniture and sanitary ware manufacturers; they are increasingly adopting laser-cut components to create sleek, modern designs with seamless joints, which are highly sought after by consumers. A case study from a leading European furniture manufacturer showed a 30% reduction in assembly time and a 15% improvement in material utilization after implementing tube laser cutting technology for their metal frames. This is a direct testament to the efficiency and precision offered by these machines.

This trend is also driven by the adoption of advanced materials. As industries explore new alloys and composite materials for improved performance, traditional cutting methods often prove inadequate. Laser cutting, with its non-contact process and concentrated energy, is ideal for a wide range of materials, including stainless steel, aluminum, and even some composites, without causing material deformation or heat-affected zones. This versatility makes tube laser cutting machines a future-proof investment for factories looking to diversify their product offerings and work with cutting-edge materials. Our zero-waste tail material innovation also plays a critical role here, maximizing material utilization for these often expensive advanced materials, directly impacting profitability.

Supply Chain Resilience and Localized Production

The recent global disruptions, including pandemics and geopolitical tensions, have highlighted the vulnerabilities of extended supply chains. This has led to a renewed focus on supply chain resilience and, in many cases, a push towards localized production. Factories are investing in tube laser cutting machines to bring key manufacturing processes in-house or to regionalize their supply chains, reducing reliance on distant suppliers and mitigating risks associated with shipping delays and cost fluctuations. For instance, many North American and European companies that previously outsourced tube cutting to Asian markets are now re-evaluating their strategies to ensure faster lead times and greater control over quality.

This trend is supported by data from industry reports. A survey by the Reshoring Initiative indicated that over 70% of U.S. manufacturers are actively considering or implementing reshoring strategies, with investment in advanced manufacturing technologies being a key enabler. By having their own tube laser cutting capabilities, factories can respond more quickly to demand fluctuations, reduce inventory holding costs, and offer faster delivery times to their customers. This is particularly appealing to clients like Ahmed, who seeks a turnkey solution and values robust post-sales support and spare parts availability, factors that are easier to manage with localized or in-house capabilities.

| Factor | Traditional Methods | Tube Laser Cutting |

|---|---|---|

| Precision | Variable, human-dependent | High, consistent |

| Speed | Slower, multiple steps | Faster, single pass |

| Material Waste | Significant tail material | Minimal to zero waste (BNL innovation) |

| Operator Skill | High skill needed (CAD) | Lower skill needed (No-CAD) |

| Customization | Limited, time-consuming | High, rapid prototyping |

| Process Integration | Disconnected steps | Multi-process (punching, cutting) |

Furthermore, localized production enables greater customization and responsiveness to regional market needs. Factories can develop and produce bespoke solutions tailored to specific client requirements, rather than relying on mass-produced components from overseas. This agility fosters stronger customer relationships and opens up new market opportunities. Our focus on cost-effective customized solutions directly aligns with this trend, providing factories with the flexibility to adapt their production to meet diverse customer demands, whether for architectural metalwork or automotive parts.

Tube laser cutting boosts precisionTrue

Modern tube laser machines achieve micrometer-level accuracy, enabling complex geometries that traditional methods cannot replicate.

Manual cutting reduces material wasteFalse

Laser cutting's optimized nesting software minimizes waste to near-zero, while manual methods generate significant tail material.

How do tube laser cutting machines enhance productivity and efficiency within factories?

Modern factories are continuously seeking ways to optimize output and streamline operations. Are you facing bottlenecks in your current production methods? Tube laser cutting machines offer a revolutionary approach to boosting productivity and efficiency.

Tube laser cutting machines significantly enhance factory productivity and efficiency by offering high-speed, precise, and automated cutting, reducing material waste, and minimizing setup times. Their ability to integrate multiple processes further streamlines production workflows, leading to substantial cost savings and increased output.

At MZBNL, our 25 years of experience in metal fabrication2 has consistently shown us that the core drivers for any factory are productivity and efficiency. These aren't just buzzwords; they are the bedrock of profitability and competitiveness. We’ve seen countless clients, from furniture manufacturers to automotive parts producers, struggle with the limitations of traditional methods. The shift to tube laser cutting isn't merely an upgrade in machinery; it's a fundamental transformation of the production ecosystem. It empowers factories to achieve unprecedented levels of output and precision, all while minimizing operational costs and maximizing resource utilization. This leap forward is driven by several key factors that directly impact a factory’s bottom line, fundamentally changing how they approach complex fabrication tasks.

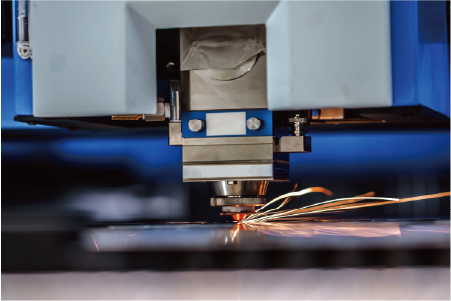

Significant Improvement in Cutting Speed and Precision

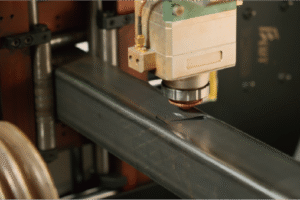

One of the most direct ways tube laser cutting machines enhance productivity and efficiency is through their superior cutting speed and precision compared to conventional methods. Traditional processes often involve multiple steps such as sawing, drilling, punching, and deburring, each requiring separate setups and potentially different machines. This fragmented workflow is inherently time-consuming and prone to cumulative errors. Laser cutting, on the other hand, performs these operations in a single pass, at speeds far exceeding manual or mechanical methods. For example, a typical tube laser cutting machine can cut complex hole patterns and intricate shapes in mere seconds, tasks that might take minutes or even hours with traditional drilling and milling. This drastic reduction in processing time directly translates to higher throughput and increased production capacity.

Moreover, the precision offered by tube laser cutting is unparalleled. Laser technology allows for extremely tight tolerances and intricate cuts, which are crucial for components requiring perfect fit and finish, such as those in medical devices or architectural structures. This high precision reduces the need for secondary finishing operations, minimizing rework and scrap rates. In a study conducted by the American Society of Manufacturing Engineers, factories utilizing laser cutting for tube fabrication reported a 25-30% reduction in post-processing time compared to those using conventional methods. Our machines, designed for high-speed and high-precision cutting, ensure that factories can meet stringent quality standards while maintaining rapid production cycles. This capability is particularly beneficial for high-volume production, where even minor gains in speed and accuracy can lead to substantial overall efficiency improvements and cost savings.

The impact of this speed and precision extends beyond mere production numbers. It also influences the overall quality of the finished product, leading to stronger customer satisfaction and fewer warranty claims. For instance, in the automotive sector, precisely cut tube components ensure better vehicle assembly and performance, directly contributing to brand reputation. The consistent quality delivered by laser cutting machines also means that parts are interchangeable, simplifying inventory management and spare parts availability. This level of reliability and consistency is a significant advantage in competitive markets, making tube laser cutting a strategic asset for any modern factory.

Optimized Material Utilization and Waste Reduction

Material costs often represent a significant portion of a factory’s operational expenses. Tube laser cutting machines dramatically improve material utilization and reduce waste, thereby contributing substantially to efficiency and profitability. Traditional cutting methods frequently leave behind unusable tail material or require larger material allowances due to cutting inaccuracies or machine limitations. Our zero-waste tail material innovation3 directly addresses this pain point. While conventional systems generate leftover material at the end of the process, our redesigned cutting logic calculates from the rear chuck as the origin, effectively eliminating unusable tail material as long as the remaining section is smaller than the product length. This design alone can save factories thousands of dollars annually, especially when working with expensive alloys or specialty tubes.

Beyond tail material reduction, the nesting capabilities of advanced laser cutting software play a crucial role in optimizing material usage. This software intelligently arranges multiple parts on a single tube to minimize the gaps between cuts, ensuring maximum material utilization. This is particularly beneficial for factories producing a variety of components from the same tube stock. For example, a furniture manufacturer producing different lengths and shapes of tubular frames can nest these parts efficiently on a single length of tube, reducing scrap by as much as 10-15% compared to manual cutting methods. This optimized nesting not only saves on material costs but also reduces the environmental footprint of the factory, aligning with growing corporate sustainability goals.

The precise, clean cuts produced by laser technology also mean less material is lost to kerf (the width of the cut) and fewer defects requiring rework. This directly translates to a higher yield of usable parts from raw materials. Consider a factory producing components for medical or fitness equipment; the cost of specialized tubing can be substantial. Minimizing waste in such scenarios directly impacts the profit margin for each product. The cumulative effect of reduced material waste across a factory’s entire production volume can be immense, making tube laser cutting machines a highly attractive investment for businesses focused on cost-efficiency and sustainable manufacturing practices.

Simplified Operation and Reduced Labor Costs

One of the most compelling aspects of investing in tube laser cutting machines is the simplification of operation and the subsequent reduction in labor costs. Traditional metal fabrication often requires highly skilled operators with extensive training in CAD software and machine operation. This creates a reliance on a limited pool of talent, making factories vulnerable to high operator turnover and the associated retraining burdens. Our pioneering No-CAD Operating System4 for laser tube cutting machines directly addresses this challenge. Traditionally, operators had to return to the design office to create or modify complex 3D drawings before production could start—an inefficient and time-consuming process that often required 15 days of factory training.

With BNL’s system, standard tube types and hole patterns can now be processed simply by entering parameters—no drawing required. This innovation dramatically improves ease of use, shortens setup time, and significantly lowers the skill threshold for machine operation. Operators now only need 1 day of on-site training instead of spending 15 days at the equipment factory, a monumental saving in training time and cost. This ease of use means factories can quickly onboard new staff, reducing the impact of employee churn and ensuring continuous production. For clients like Ahmed Al-Farsi, whose pain point included previous machines requiring skilled CAD operators and high operator turnover, this feature is a game-changer, directly solving a major operational headache.

Furthermore, the automation capabilities inherent in tube laser cutting machines reduce the need for constant human supervision and manual handling. Features like automatic front-feeding mechanisms, which we innovated to increase feeding efficiency by about 40% and reduce operator labor intensity by approximately 40%, free up operators to manage multiple machines or focus on other value-added tasks. This optimization of labor resources not only reduces overall labor costs but also enhances workplace ergonomics and safety. By automating repetitive and physically demanding tasks, factories can create a more efficient and safer working environment, attracting and retaining talent more effectively. This strategic shift towards less labor-intensive, more automated processes positions factories for sustainable growth and increased competitiveness in the global market.

Laser cutting reduces post-processing timeTrue

Studies show 25-30% reduction in post-processing compared to conventional methods due to laser precision.

Traditional cutting is faster than laserFalse

Laser cutting performs complex operations in seconds that take minutes/hours with traditional methods.

What factors are driving factories to prioritize investments in tube laser cutting technology?

In a rapidly evolving manufacturing landscape, strategic investments are key. What compels factories to choose tube laser cutting technology over traditional methods? The answer lies in a combination of pressing industry demands and tangible benefits.

Factories are prioritizing investments in tube laser cutting technology primarily due to increasing demands for customized products, shorter lead times, and higher quality standards. The technology's ability to offer multi-process integration, reduce operational costs, and adapt to diverse production needs makes it a critical competitive advantage.

Having spent 25 years at the forefront of metal fabrication with MZBNL, I’ve seen firsthand how market dynamics dictate technological adoption. Factories today face a confluence of pressures: global competition, rising material costs, and an ever-increasing demand for bespoke solutions. Traditional manufacturing methods, once the backbone of production, are now proving to be bottlenecks, unable to keep pace with these complex requirements. This pivotal moment is driving a strategic shift, compelling decision-makers to rethink their investment priorities5. The focus is no longer just on incremental improvements but on transformative technologies that offer a definitive competitive edge. It's about building a future-ready factory capable of agility, precision, and unparalleled efficiency.

Growing Market Demand for Customization and Complex Products

One of the primary drivers for factories investing in tube laser cutting technology is the surging market demand for customized and complex products. Modern consumers and industrial clients alike are moving away from standardized, mass-produced goods, opting instead for unique, tailored solutions. This trend is evident across various sectors, from bespoke architectural elements and customized furniture designs to specialized components for electric vehicles and medical devices. Traditional fabrication methods often struggle with the intricacies of these demands, requiring extensive manual intervention, multiple setups, and significant lead times for each unique design. Tube laser cutting machines, with their advanced software and precise control, are perfectly suited to handle complex geometries and rapid design changes.

For example, in the architectural decoration sector, clients often request intricate railings, unique structural supports, and custom-designed metal partitions. A factory relying on sawing and drilling would find it prohibitively expensive and time-consuming to produce these low-volume, high-complexity parts. A tube laser cutting machine, however, can swiftly transition between different designs simply by loading new digital files. This agility allows factories to accept diverse orders, cater to niche markets, and offer value-added customization services, thereby expanding their client base and revenue streams. Our No-CAD system further amplifies this capability, allowing for parameter-driven processing of standard tube types and hole patterns, eliminating the need for complex 3D drawings and drastically shortening setup times for customized jobs.

This shift towards customization isn't just about aesthetics; it's also about functionality. In the automotive industry, for instance, there's a growing need for lightweight, structurally optimized components that can only be achieved through precise and complex cuts. Tube laser cutting enables manufacturers to create hollow structural components with integrated features, reducing overall weight while maintaining strength. This capability directly supports the development of more fuel-efficient and high-performance vehicles. Factories that embrace this technology are better positioned to meet these evolving industry demands, staying competitive and at the forefront of innovation.

Rising Labor Costs and Skill Shortages

Another critical factor influencing investment in tube laser cutting technology is the global challenge of rising labor costs and a persistent shortage of skilled workers in the manufacturing sector. Many traditional fabrication processes are labor-intensive, requiring specialized manual skills for tasks such as welding, grinding, and assembly. As wages increase and the pool of experienced fabricators dwindles due to an aging workforce and a lack of new entrants, factories face significant operational challenges and escalating expenses. This reality pushes manufacturers to seek automated solutions that reduce reliance on extensive manual labor and specialized human expertise.

Tube laser cutting machines offer a compelling solution by automating a significant portion of the fabrication process. Tasks that once required multiple skilled operators can now be performed by a single, less specialized operator overseeing an automated machine. Our innovative front-feeding mechanism, for example, increases feeding efficiency by 40% and reduces operator labor intensity by approximately 40%, directly addressing the issue of manual handling and the associated labor costs. Furthermore, the simplified operation of our No-CAD system, which reduces operator training from 15 days to just 1 day, means that factories can rapidly train new employees, mitigating the impact of staff turnover and skill gaps. This not only cuts down on training expenses but also ensures a more stable and continuous production flow.

The long-term impact of automating with tube laser cutting machines is a significant reduction in overall labor expenditures. While the initial investment in the machinery might be substantial, the recurring savings in wages, benefits, and training costs can lead to a rapid return on investment. This is particularly attractive for businesses in countries with high labor costs, making them more competitive on a global scale. By mitigating the risks associated with labor shortages and rising wages, factories can secure their long-term operational viability and dedicate human resources to more strategic, value-added activities like quality control and innovation.

Pursuit of Higher Product Quality and Reliability

The modern market places an unprecedented emphasis on product quality and reliability. Consumers and industrial clients expect components that are consistently accurate, durable, and free from defects. Traditional cutting methods, often involving mechanical tools that wear down or require frequent calibration, can lead to inconsistencies in cut quality, rough edges, and dimensional inaccuracies. These imperfections often necessitate time-consuming and costly secondary finishing processes like deburring, grinding, or sanding, which add to production time and expense while potentially introducing further inconsistencies.

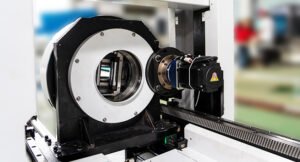

Tube laser cutting technology inherently delivers superior product quality. The non-contact nature of laser cutting eliminates tool wear, ensuring consistent, precise cuts throughout the entire production run. The focused laser beam produces clean edges with minimal burr, often eliminating the need for secondary operations altogether. This results in components that fit together perfectly, reducing assembly time and improving the overall structural integrity and aesthetic appeal of the final product. For industries like medical and fitness equipment manufacturing, where precision and smooth finishes are critical for both performance and hygiene, this level of quality is indispensable.

Furthermore, the digital control of tube laser cutting machines allows for extreme repeatability. Once a design is programmed, the machine will reproduce it identically every time, ensuring uniformity across large production batches. This consistency is vital for certifications and compliance in regulated industries and for maintaining brand reputation. The ability to achieve high-quality, reliable components efficiently gives factories a distinct competitive advantage, leading to fewer product returns, higher customer satisfaction, and a stronger market position. Our commitment to high-speed and high-precision cutting ensures that MZBNL machines consistently deliver the exceptional quality that modern industries demand.

Tube lasers enable complex customizationTrue

Tube laser cutting machines can handle intricate designs through digital file changes, unlike traditional methods requiring manual setups.

Labor costs don't affect automation adoptionFalse

Rising labor costs and skill shortages are primary drivers for factories to invest in automated tube laser cutting solutions.

How can factories ensure maximum ROI when investing in tube laser cutting machines?

Investing in new technology is a significant decision for any factory. How can you ensure that your tube laser cutting machine purchase delivers the highest possible return on investment? Strategic planning is absolutely crucial.

Factories can maximize ROI on tube laser cutting machine investments by conducting thorough needs assessments, prioritizing features like automation and material optimization, ensuring comprehensive operator training, and establishing robust maintenance protocols. Strategic supplier partnerships and ongoing performance monitoring are also key to long-term profitability.

For over two decades, I’ve advised countless factories on navigating the complexities of capital equipment investments. The decision to integrate a tube laser cutting machine is not just about purchasing a piece of hardware; it’s about strategically deploying a transformative tool. To truly unlock its potential and realize maximum return on investment, factories must look beyond the initial purchase price. It’s about meticulous planning, comprehensive training, and selecting a partner who understands your long-term vision. The path to profitability with this advanced technology requires a holistic approach, ensuring that every aspect, from implementation to ongoing support, is optimized for success.

Comprehensive Assessment and Needs Matching

Ensuring maximum ROI begins long before the purchase, with a comprehensive assessment of a factory’s specific needs6 and a meticulous matching of those needs to the capabilities of the tube laser cutting machine. Simply buying the most expensive or feature-rich machine without a clear understanding of its application to current and future production requirements can lead to underutilization and a poor return. Factories should conduct a detailed audit of their current production bottlenecks, typical material types and sizes, desired output volumes, and the complexity of parts they aim to produce. For instance, a factory focusing on large-volume, standardized parts might prioritize speed and automation, while one specializing in low-volume, highly customized components might place more emphasis on programming flexibility and rapid changeover capabilities.

Part of this assessment should involve a thorough cost-benefit analysis, considering not just the upfront machine cost but also ongoing operational expenses such as electricity consumption, gas usage, spare parts, and maintenance. Factories should also factor in the potential for reduced labor costs, increased material yield, and the ability to take on new, higher-margin projects that were previously impossible. For a client like Ahmed Al-Farsi, a mid-sized metal fabrication business owner, his primary purchase consideration is a Laser Tube Cutting Machine with automatic feeding and punching capabilities, reflecting his specific need to automate existing manual workflows. He values a high cost-performance ratio over a low price, indicating a focus on long-term value rather than just initial outlay. Matching his need for ease of use (preferably a No-CAD system) with our machine's features is critical for his ROI.

Furthermore, engaging with potential suppliers early in this assessment phase can provide invaluable insights. Reputable suppliers, like MZBNL, often offer consulting services to help factories identify the most suitable machine configuration based on their unique production profile. This collaborative approach ensures that the chosen machine is not just a technological upgrade but a strategic investment perfectly aligned with the factory's operational goals and growth trajectory, ultimately maximizing its ROI potential. This detailed pre-purchase analysis prevents mismatched investments and sets the stage for a successful integration.

Comprehensive Operator Training and Maintenance System

The performance of any advanced machinery, including tube laser cutting machines, is highly dependent on the skill of its operators and the robustness of its maintenance program. To maximize ROI, factories must invest significantly in comprehensive training for their staff and establish a proactive, well-defined maintenance system. Without proper training, even the most advanced machine will not be utilized to its full potential, leading to inefficiencies, increased error rates, and potential damage. Training should cover not only basic operation but also advanced programming, troubleshooting, and routine maintenance procedures. Our No-CAD system, which requires only one day of on-site training instead of 15 days at the equipment factory, significantly reduces this barrier, making it easier for clients like Ahmed to upskill their workforce quickly and effectively.

Beyond initial training, continuous education and access to updated technical knowledge are crucial. Factories should ensure that their operators are familiar with the latest software updates and operational best practices. This ongoing learning helps to maintain peak machine performance and adapt to evolving production demands. The availability of post-sales training and support, a key preference for Ahmed, is something MZBNL prioritizes to ensure our clients can fully leverage their investment. This support can be provided through online resources, dedicated support hotlines, and periodic on-site training refreshers.

Equally important is the implementation of a rigorous preventive maintenance schedule. Regular checks, cleaning, lubrication, and timely replacement of wear parts can prevent costly breakdowns, extend the machine's lifespan, and maintain its precision and speed. Neglecting maintenance can lead to unexpected downtime, lost production, and expensive emergency repairs, all of which severely erode ROI. Factories should also ensure they have access to readily available spare parts and effective remote diagnostics, as preferred by Ahmed. Partnering with suppliers who offer comprehensive service contracts and local agent presence can provide peace of mind and minimize disruption, ensuring the machine operates at its maximum efficiency for years to come.

Strategic Supplier Selection and Ongoing Support

The choice of supplier is a critical factor in maximizing the ROI of a tube laser cutting machine. It goes beyond the initial purchase and extends to the long-term partnership, support, and technological innovation provided by the vendor. Factories should look for suppliers with a proven track record7, extensive industry experience, and a strong commitment to post-sales service. A supplier’s reputation for reliability, product quality, and customer support is often as important as the machine's technical specifications. MZBNL, with 25 years of experience, 30+ patents, and 4000+ global enterprise clients, exemplifies the type of established and reliable partner factories should seek. Our integrated R&D, manufacturing, sales, and service model ensures a holistic approach to customer satisfaction.

A key aspect of supplier selection is the availability of robust after-sales service and training support, which is a major sourcing key point for Ahmed. This includes not only technical assistance for troubleshooting but also access to spare parts, remote diagnostics capabilities, and potentially local agent or distributor presence. A supplier with a strong global network can provide timely support, minimizing downtime and ensuring continuous operation. Ahmed's interest in becoming a regional distributor himself if the machine performs well and support is reliable further underscores the importance of a strong, symbiotic supplier relationship. This kind of partnership can unlock additional revenue streams and collaborative opportunities beyond the initial equipment sale.

ly, factories should consider a supplier's commitment to continuous innovation. The manufacturing industry is constantly evolving, and a supplier that invests in R&D and regularly introduces new features or upgrades can help factories stay competitive. This future-proofing aspect ensures that the initial investment remains relevant and productive over time. Our three major innovations—No-CAD System Innovation, Front-Feeding Innovation, and Zero-Waste Tail Material Innovation—demonstrate MZBNL's commitment to pushing the boundaries of tube laser cutting technology, ensuring that our clients are always equipped with cutting-edge solutions that maximize their ROI.

Needs assessment maximizes ROITrue

Conducting a thorough production audit before purchase ensures the machine matches actual operational requirements.

Training is optional for ROIFalse

Comprehensive operator training is essential - untrained staff can reduce machine efficiency by up to 40%.

What recommendations can help factories successfully integrate tube laser cutting machines into their production processes?

Integrating new machinery into an existing production line can be complex. What steps can factories take to ensure a seamless transition and maximize the benefits of their new tube laser cutting machines?

To successfully integrate tube laser cutting machines, factories should conduct a thorough pre-installation assessment, ensure comprehensive operator training and change management, establish robust data integration, and implement a proactive maintenance strategy. Phased implementation and leveraging supplier expertise are also crucial for a smooth transition.

As a company with 25 years of experience in metal fabrication, MZBNL has guided countless factories through the intricate process8 of integrating advanced machinery. It’s not simply about dropping a new machine onto the factory floor; it’s about orchestrating a strategic transformation. Successful integration hinges on meticulous planning, effective communication, and a forward-thinking approach that anticipates challenges before they arise. From optimizing your layout to fostering a culture of continuous improvement, every step plays a vital role in unlocking the full potential of your investment. It’s a journey we’ve mastered, ensuring our clients achieve seamless operational synergy and sustained competitive advantage.

Develop a Detailed Implementation Plan and Production Line Optimization

Successful integration of a tube laser cutting machine hinges on a meticulously detailed implementation plan and a strategic optimization of the existing production line. This is not merely a plug-and-play scenario; it requires careful consideration of the machine's placement, material flow, and connectivity with upstream and downstream processes. Factories should begin by assessing their current factory layout to identify the most efficient location for the new machine, minimizing material handling and transport distances. This might involve reconfiguring existing workstations or even a minor factory redesign. The goal is to create a seamless workflow9 where raw materials feed smoothly into the laser cutter and finished parts move efficiently to the next stage, whether it's welding, assembly, or shipping.

The implementation plan should also include a clear timeline for installation, testing, and commissioning, ensuring minimal disruption to ongoing production. This includes preparing the necessary infrastructure, such as power supply, compressed air, and ventilation systems. For instance, a factory specializing in display racks and shelves might need to reconsider their storage solutions for raw tubes and cut parts to accommodate the laser machine's faster throughput. Our automatic front-feeding mechanism, which increases feeding efficiency by 40%, exemplifies how proper machine selection combined with thoughtful layout can optimize material flow, reducing manual labor and bottlenecks. This comprehensive planning ensures that the machine becomes an integral part of an optimized production system rather than an isolated addition.

Furthermore, factories should analyze how the tube laser cutting machine will impact the entire production chain. If the laser cutter significantly increases output, are the subsequent processes (e.g., welding, bending, assembly) capable of handling the increased volume? Bottlenecks upstream or downstream can negate the efficiency gains of the new machine. Therefore, the implementation plan must consider the entire value stream, identifying potential new bottlenecks and developing strategies to address them, perhaps through additional automation or process improvements in other areas.This holistic approach ensures10 that the investment in a tube laser cutting machine translates into overall factory efficiency, not just isolated improvements.

Invest in Employee Training and Change Management

The human element is paramount to the successful integration of any new technology. Investing in comprehensive employee training and effective change management is crucial for maximizing the benefits of a tube laser cutting machine and ensuring smooth operations. While machines like ours are designed for ease of use, operators still need to be proficient in their operation, programming, and basic troubleshooting. Training should not be limited to just the machine operators; maintenance staff, supervisors, and even design engineers should receive relevant training to understand the machine’s capabilities and requirements. For example, our No-CAD Operating System significantly reduces the learning curve, requiring only one day of on-site training compared to the traditional 15 days at the equipment factory, making it easier for factories to train their workforce and adapt quickly.

Beyond technical training, factories must implement a robust change management strategy. Introducing new technology can sometimes be met with resistance from employees accustomed to traditional methods. It is vital to communicate the benefits of the new machine clearly—how it will improve their work, enhance safety, and contribute to the company's long-term success. Involving employees in the planning and implementation process can foster a sense of ownership and reduce apprehension. For example, inviting operators to participate in pre-installation discussions or providing opportunities for early hands-on experience can significantly smooth the transition.

Furthermore, establishing a support system for employees during the transition period is essential. This can include dedicated mentors, open feedback channels, and regular check-ins to address any concerns or difficulties. By empowering employees with the knowledge and confidence to operate the new machine, factories can ensure its rapid adoption and sustained performance. Our commitment to providing comprehensive post-sales training and support, a key preference for clients like Ahmed, is designed to ensure that factories have the necessary resources to effectively integrate and leverage their new machinery. This focus on people ensures that the technological investment translates into tangible operational improvements driven by a skilled and engaged workforce.

Establish a Data-Driven Production and Maintenance System

To truly maximize the benefits of a tube laser cutting machine, factories should establish a data-driven production and maintenance system. Modern laser cutting machines are equipped with advanced sensors and control systems that generate a wealth of operational data—from cutting speeds and material usage to machine uptime and error codes. Leveraging this data through robust monitoring and analytics platforms can provide invaluable insights into production performance, identify bottlenecks, and optimize processes for continuous improvement. This approach moves beyond reactive problem-solving to proactive optimization, ensuring the machine operates at peak efficiency.

For example, real-time data on material consumption can help factories accurately track waste, optimize nesting algorithms, and precisely manage inventory, leading to significant cost savings. Performance data on machine uptime and throughput can identify opportunities for scheduling adjustments or reveal areas where operator training might be needed. Our smart and digitalized systems are designed to facilitate this data collection and analysis, providing factories with the insights needed to make informed decisions and fine-tune their operations. This level of transparency allows for rapid identification of deviations from optimal performance and immediate corrective action.

Furthermore, a data-driven approach is critical for effective preventive maintenance. By monitoring machine parameters like laser power, cooling system performance, and component wear, factories can predict potential failures before they occur and schedule maintenance proactively, minimizing unexpected downtime. This reduces reliance on reactive repairs, which are typically more costly and disruptive. The ability to conduct remote diagnostics, a priority for Ahmed, is also a key feature that relies on a robust data infrastructure. By embracing a data-driven mindset, factories can transform their tube laser cutting machine from a standalone piece of equipment into a smart, integrated component of a highly efficient, continuously optimized production ecosystem, leading to sustained operational excellence.

Pre-installation assessment is crucialTrue

A thorough pre-installation assessment helps identify the optimal machine placement and necessary infrastructure changes before integration begins.

Training only operators is sufficientFalse

Comprehensive training should include maintenance staff, supervisors and design engineers to fully leverage the machine's capabilities.

Conclusion

Factories are increasingly investing in tube laser cutting machines, driven by the need for high-speed, precise, and automated production. These machines significantly enhance productivity, optimize material utilization, and simplify operations, ultimately leading to substantial ROI.

-

Discover the benefits of integrating digital technologies into manufacturing processes. ↩

-

Discover why experience in metal fabrication is pivotal for operational success and efficiency. ↩

-

Understand the cost savings and material efficiency benefits of zero-waste technology. ↩

-

Explore how simplified systems lower skill requirements and training costs, enhancing efficiency. ↩

-

Discover how strategic investments affect factory competitiveness ↩

-

Discover methods for aligning machine features with factory needs. ↩

-

Understand the importance of supplier reliability and support. ↩

-

Discover MZBNL's proven track record in guiding factories through technological integration. ↩

-

Learn strategies for seamless material flow and minimized handling in laser cutting projects. ↩

-

Understand the importance of considering the entire production chain for overall efficiency boosts. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.