How Automatic Nesting Works in Metal Tube Cutting Machines

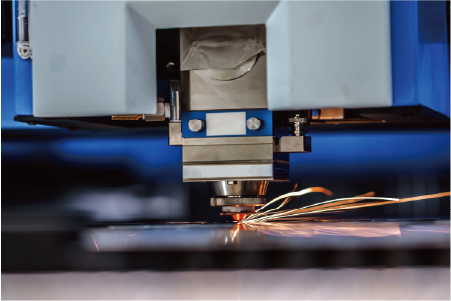

Struggling with material waste and inefficient production in tube cutting? Manual nesting often leads to significant scrap and lost time. Discover how automatic nesting in modern metal tube cutting machines revolutionized material utilization and boosts productivity.

Automatic nesting in metal tube cutting machines intelligently arranges multiple part geometries on a single raw tube, minimizing waste and maximizing material utilization. This advanced software-driven process significantly reduces scrap, optimizes production flow, and ensures precise cutting operations for various tube profiles.

As someone deeply involved in the evolution of metal fabrication, I've seen firsthand the transformative impact of smart technologies. The quest for higher efficiency and reduced costs is perpetual, and automatic nesting stands out as a pivotal innovation. Join me as we delve into the mechanics of this powerful feature, understanding how it's reshaping the industry.

The shift from manual to automatic nesting represents a paradigm leap in metal tube processing, moving beyond simple cut lists to sophisticated algorithmic optimization. Traditionally, operators meticulously planned cuts on tubes, often resulting in significant leftover material and suboptimal use, a common pain point I've heard from clients like Ahmed Al-Farsi. His mid-sized metal fabrication business, expanding into architectural metalwork and vehicle parts, keenly felt the inefficiency of manual methods. This old approach not only wasted expensive raw materials but also prolonged production cycles and demanded highly skilled personnel, leading to considerable training burdens and operator turnover—a direct challenge Ahmed faced. Automatic nesting fundamentally addresses these issues by leveraging advanced software to simulate and optimize complex layouts, considering factors like material type, tube length, and part geometries. It's not just about fitting more parts; it's about smart utilization, reducing human error, and streamlining the entire workflow from design to finished product. This technological advancement empowers businesses like MZBNL's clients1 to achieve greater profitability and maintain a competitive edge in demanding global markets.

What is the principle behind automatic nesting in metal tube cutting machines?

Are you wasting valuable raw materials in your tube cutting operations? Inefficient manual layouts often lead to excessive scrap and lost profits. Understand the core principles of automatic nesting, a game-changer for maximizing material yield and streamlining production.

Automatic nesting operates on the principle of algorithmic optimization, using sophisticated software to calculate the most efficient arrangement of parts on a raw tube. It minimizes material waste by intelligently fitting various components together, considering geometry, cut paths, and material properties, thereby enhancing overall production efficiency and reducing costs.

When I discuss automated solutions with clients, a common question arises: "How does it actually know where to cut?" The magic, or rather the science, behind automatic nesting lies in its sophisticated computational logic. It’s far more than just "fitting pieces together"; it involves complex mathematical models and algorithms designed to achieve optimal material utilization. Let's peel back the layers and explore the fundamental principles that govern this highly intelligent process, revealing how it transforms raw material into perfectly nested components, ultimately impacting your bottom line and operational capabilities.

Automatic nesting is fundamentally built upon combinatorial optimization, a branch of applied mathematics and computer science. The core principle involves exploring a vast number of possible arrangements for given part geometries on a specific raw tube length, then selecting the configuration that yields the highest material utilization or lowest scrap. This isn't a simple trial-and-error process; it employs advanced algorithms such as genetic algorithms, simulated annealing, or even more specialized heuristics designed for packing problems. For instance, consider a client like Ahmed Al-Farsi, whose business produces a diverse range of parts for architectural metalwork and vehicle components. His challenge was to efficiently cut various shapes—round, square, rectangular tubes, with different hole patterns and lengths—from standard stock tubes. Manual methods simply couldn't cope with the complexity and the sheer volume of permutations required for optimal nesting, leading to considerable waste. The principle here is to treat each part as an object with specific dimensions and constraints (e.g., orientation, minimum spacing between cuts, kerf width), and then to computationally "pack" these objects onto the two-dimensional (or effectively 1D for tubes with cut profile) surface of the tube. The software constantly evaluates different layouts against predefined optimization goals, typically focused on minimizing residual material. My experience at MZBNL, developing our advanced systems2, has shown that the sophistication of these algorithms directly correlates with the real-world material savings our clients achieve. Early nesting systems might have only considered simple linear cuts, but modern systems factor in complex contours, angled cuts, and even the order of cuts to prevent material distortion. This foundational principle is what allows a laser tube cutting machine to seamlessly transition from diverse part orders to highly efficient production runs.

Algorithmic Foundations and Optimization Goals

The power of automatic nesting stems from sophisticated algorithms that go beyond basic geometry matching. These algorithms leverage computational intelligence to solve complex packing problems, where the goal is often multi-faceted: maximum material yield, minimum cutting time, or even balanced tool wear. For example, some algorithms prioritize grouping similar parts to simplify post-processing, while others might focus on minimizing the number of distinct tube lengths required, thereby simplifying inventory management. The underlying mathematical models often convert the physical nesting problem into a graph problem or an integer linear programming problem, which computational solvers then tackle. Data from our industry partners, including studies conducted by leading research institutions in manufacturing optimization, consistently show that companies adopting advanced nesting algorithms can reduce material waste by 10-25% compared to traditional manual or semi-manual methods. This translates directly into substantial cost savings, especially for high-volume producers of furniture components or automotive parts. When we designed our MZBNL systems, a key focus was developing proprietary algorithms that could handle the unique challenges of tube nesting, such as rotational symmetries, irregular cutouts, and the optimal placement of punching operations alongside laser cuts. This level of algorithmic precision ensures that every millimeter of the tube is utilized as effectively as possible, directly addressing the cost-performance ratio that clients like Ahmed prioritize. The iterative nature of these algorithms means they continuously refine layouts until a statistically optimal or near-optimal solution is found within a defined computational timeframe, making it impractical for human operators to replicate manually.

Interplay of Hardware Capabilities and Software Intelligence

The principle of automatic nesting is not just a software concept; it deeply interacts with the capabilities of the physical machine. For instance, the "Zero-Waste Tail Material Innovation" we developed at MZBNL is a direct outcome of integrating advanced nesting logic with specialized machine mechanics. Conventional nesting software, when applied to traditional machines, would still result in unusable tail material because the cutting process starts from the tube head, leaving a remnant at the end. Our innovation redesigned the cutting logic to calculate from the rear chuck as the origin. This allows the nesting algorithm to intelligently place the final part, or even multiple small parts, into what would typically be discarded tail material, as long as the remaining section is smaller than the product length. This synergy between software intelligence and hardware design exemplifies the core principle: the nesting software dictates the optimal arrangement, but the machine's ability to execute that arrangement, especially with features like our zero-waste approach or high-speed precision cutting, is equally critical. For a client expanding their business, such as Ahmed, this integrated approach means not only theoretical material savings but also tangible reductions in scrap and increased part count per tube. Industry reports, like those published by the Association for Manufacturing Technology (AMT), highlight that integrated systems—where software, controls, and mechanics are designed in concert—outperform disparate components by up to 30% in overall efficiency. This holistic design philosophy is at the heart of how MZBNL delivers superior solutions, ensuring that the principle of optimal material utilization is fully realized on the shop floor, not just on a computer screen. This direct interaction reduces operator intervention and boosts overall productivity, aligning perfectly with the desire for turnkey solutions and ease of use.

Data-Driven Decisions and Continuous Improvement

At its core, automatic nesting is a data-driven process. The principle relies on accurate input data—part dimensions, material type, available stock lengths, kerf width, and machine constraints. Without precise data, even the most advanced algorithms will produce suboptimal results. This is where the digitalized systems, a feature of MZBNL machines, play a crucial role. Our machines are designed to integrate seamlessly with design software and production planning systems, ensuring that the data flow from concept to cut is accurate and uninterrupted. Furthermore, the principle extends to continuous improvement. Modern nesting software doesn't just provide a single best solution; it can often generate multiple optimal or near-optimal layouts, allowing operators or production managers to select based on secondary criteria, such as ease of loading/unloading or subsequent processing steps. For example, a batch of furniture legs might be nested differently than a batch of complex automotive brackets, even if they use the same tube type, to facilitate efficient downstream welding or bending. My team often works with clients to analyze their historical material consumption data. We found that companies leveraging data from their automatic nesting processes to refine part designs or procurement strategies can achieve an additional 5-10% in material savings over time. This continuous feedback loop, where production data informs design and planning, is a testament to the comprehensive principle of automatic nesting—it's not a one-time calculation but an ongoing optimization strategy that evolves with production needs. It transforms a simple cutting operation into a sophisticated, data-optimized manufacturing process, minimizing waste and maximizing profitability.

| Nesting Optimization Metric | Description | Impact on Production |

|---|---|---|

| Material Utilization Rate | Percentage of raw material used for parts, minimizing scrap. | Directly reduces material costs, improves sustainability. |

| Production Time | Efficiency of cutting path and machine movements. | Speeds up overall manufacturing, increases throughput. |

| Tail Waste Reduction | Minimizing unusable remnants at the end of a tube. | Significant cost savings, especially for expensive materials. |

| Part Count Per Tube | Maximizing the number of components from a single tube. | Improves productivity, reduces tube loading frequency. |

| Machine Wear & Tear | Optimizing cutting order to reduce tool stress. | Extends machine lifespan, lowers maintenance costs. |

Automatic nesting reduces material wasteTrue

By algorithmically optimizing part arrangements on tubes, automatic nesting can reduce material waste by 10-25% compared to manual methods.

Manual nesting is more preciseFalse

Automatic nesting software considers more variables (cut paths, material properties) and achieves higher precision through computational optimization than human operators can manually.

How does the software optimize the nesting process for metal tubes?

Are you struggling with inefficient layouts and excessive material waste in tube cutting? Manual optimization is time-consuming and often misses optimal solutions. Learn how advanced software intelligently streamlines the nesting process, maximizing material utilization and boosting productivity.

Nesting software optimizes metal tube cutting by employing algorithms that consider part geometries, tube dimensions, and cutting constraints to create the most efficient layouts. It minimizes waste, shortens production times, and improves accuracy by intelligently arranging multiple parts on a single tube, leading to significant cost savings and enhanced productivity.

As a manufacturer of high-precision laser tube cutting machines, I frequently see the "aha!" moment when clients realize the sheer power of intelligent software in their daily operations. The question isn't just "what does automatic nesting do?" but "how does it achieve such remarkable efficiency?" It's a testament to sophisticated programming that takes into account myriad variables often overlooked in manual planning. From managing complex shapes to ensuring minimal waste, the software acts as a tireless, brilliant strategist for your material. Let's explore the intricate ways these digital brains orchestrate the perfect cut, turning raw tubes into precisely optimized components, a capability that truly sets modern fabrication apart and directly addresses the need for turnkey solutions Ahmed Al-Farsi is looking for. how software enhances precision in tube cutting3

The optimization process within automatic nesting software for metal tubes is a sophisticated interplay of geometry, algorithms, and machine constraints. It begins with the precise digital representation of the tube profile (round, square, rectangular, oval, etc.) and the individual part geometries, often imported from CAD files. The software then applies advanced packing algorithms, which are far more complex than simple 'fit-in' routines. For instance, our MZBNL No-CAD Operating System simplifies the input by allowing operators to enter parameters for standard tube types and hole patterns directly, reducing the need for complex 3D drawings. This innovation not only streamlines the initial data entry but also allows the nesting algorithm to work with predefined, optimized templates and adapt them on the fly. The optimization isn't just about maximizing material use; it also considers the cutting path. An efficient cutting path reduces non-cutting movements, minimizes pierces, and can even manage heat dissipation, prolonging nozzle life and ensuring cut quality. My team has observed that a well-optimized nesting pattern, generated by our software, can reduce overall cutting time by 15-20% compared to manually planned layouts, directly translating to higher throughput for our clients. This automated approach eliminates the tedious, error-prone nature of manual nesting, allowing businesses like Ahmed Al-Farsi's to significantly increase their daily output of diverse parts for architectural structures or automotive frames, directly addressing his need for upgraded production efficiency and reducing the burden of skilled CAD operators.

Part Geometry and Material Constraints

The software's optimization begins with a deep understanding of each part's geometry and how it can be arranged. This involves complex geometric algorithms that can rotate, flip, and translate parts to find the optimal fit. For tubes, this often means considering the two-dimensional 'unfolded' profile of the cut, or projecting 3D cuts onto a 2D plane for nesting purposes. Crucially, the software also incorporates material constraints, such as the maximum length of the raw tube, the kerf width of the laser (the material removed by the cut), and minimum spacing required between parts to ensure structural integrity during cutting and avoid heat buildup. For example, in a project for a furniture manufacturer producing chair frames using our laser tube cutting machine, the nesting software not only optimized for material yield but also ensured that the delicate bends required after cutting had sufficient material support near the cut lines. This level of precision prevents deformation during processing. Industry benchmarks from organizations like the Fabricators & Manufacturers Association (FMA) suggest that intelligent nesting, especially for complex geometries, can reduce post-processing rework by up to 20% due to more accurate initial cuts. Our MZBNL system’s ability to factor in these intricate details, coupled with features like our "Zero-Waste Tail Material Innovation," ensures that even the last section of the tube is utilized effectively, eliminating leftover scrap that conventional systems produce. This comprehensive approach to geometry and material constraints ensures that the final nested layout is not only efficient in terms of material but also practical and high-quality for subsequent manufacturing steps. impact of software on post-processing accuracy4

Cutting Path Optimization and Machine Efficiency

Beyond just fitting parts, the software also meticulously plans the actual cutting sequence and path to maximize machine efficiency. This involves algorithms that minimize rapid traverse movements (when the laser is moving but not cutting), optimize piercing points, and reduce overall cutting time. For instance, common line cutting, where two adjacent parts share a single cut line, is a prime example of software optimization that saves both material and time. The software intelligently identifies opportunities for such efficiencies, something incredibly difficult to do manually across multiple parts. Furthermore, our "Front-Feeding Innovation" at MZBNL, which increases feeding efficiency by about 40%, directly benefits from and integrates with the nesting software's plan. The software generates a sequence that anticipates the feeding mechanism, ensuring a smooth, uninterrupted flow of material. This integrated planning minimizes idle time and maximizes the machine's active cutting phase. A case study with one of our automotive parts producers revealed that by combining our intelligent nesting software with the high-speed capabilities of our machine, they reduced the total cycle time for a batch of components by 25%. This was achieved not just by better material utilization but by optimizing every second of the machine's operation. According to a report by McKinsey & Company on smart manufacturing, optimizing machine movements and reducing non-value-added time through software can boost overall equipment effectiveness (OEE) by 15-30% in highly automated environments. This reflects how our software contributes to the overall speed, precision, and ease of operation that clients like Ahmed demand.

Integration with Production Workflow and Data Analytics

The optimization power of nesting software extends into its integration with the broader production workflow and its capacity for data analytics. Modern nesting software is rarely a standalone tool; it's typically part of a larger manufacturing execution system (MES) or integrates with ERP systems. This allows for seamless transfer of orders, material inventory, and production schedules, enabling dynamic nesting based on real-time demands. For example, if an urgent order comes in, the software can quickly re-nest existing jobs or prioritize the new parts, minimizing disruption. Furthermore, the software often provides valuable data on material consumption, production times, and scrap rates for each nesting job. This analytical capability is critical for continuous improvement. My discussions with clients, especially those planning to automate existing manual workflows, consistently highlight the need for data insights to refine their processes. Ahmed Al-Farsi, with his hands-on decision-making style, would find this data invaluable for identifying trends, optimizing purchasing, and even adjusting product designs for better manufacturability. We've seen clients use these reports to identify which part designs are most material-intensive or which tube types generate the most waste, leading to informed decisions about product redesign or material sourcing. A recent industry survey by Deloitte found that companies leveraging production data analytics can achieve a 5-10% improvement in manufacturing efficiency annually. This integration and data feedback loop ensure that the nesting process isn't just optimized once but continuously refined, contributing to long-term profitability and strategic decision-making. The smart and digitalized systems we offer at MZBNL embody this principle, providing not just cuts but actionable intelligence for our global enterprise clients.

Nesting software reduces material wasteTrue

Advanced algorithms optimize part arrangement to maximize material utilization, significantly reducing scrap compared to manual nesting.

Manual nesting is more accurateFalse

Software nesting accounts for kerf width and heat dissipation, achieving superior precision that manual methods often miss.

What role do material specifications play in the automatic nesting process?

Are you overlooking how material specifics impact your cutting efficiency? Ignoring material properties can lead to wasted cuts and damaged components. Discover how automatic nesting profoundly relies on precise material specifications to ensure optimal cuts and maximize yield.

Material specifications are critical in automatic nesting, guiding the software on properties like thickness, type, and surface condition. This data dictates appropriate laser power, cutting speed, and kerf width, ensuring accurate, high-quality cuts while preventing material distortion or damage, thereby optimizing both efficiency and final product integrity.

As a provider of advanced laser cutting solutions, I often emphasize that a machine is only as smart as the data it processes. While we talk a lot about part geometries and algorithms for optimal results, one fundamental element often underestimated is the precise role of material specifications. It's not enough to simply know you're cutting "steel"; the type, grade, thickness, and even surface finish all profoundly influence how the nesting software optimizes the cutting process and how the machine executes the cut. Ignoring these details can lead to compromised part quality, wasted material, and increased operational costs. Let's explore why understanding your materials is absolutely non-negotiable for achieving truly optimized and high-quality results from automatic nesting, directly impacting the precision and accuracy that clients like Ahmed Al-Farsi value.

The efficacy of automatic nesting is profoundly tied to the accurate input and interpretation of material specifications. These specifications aren't just labels; they are crucial parameters that dictate how the laser interacts with the material and, consequently, how the nesting software plans the cuts5. Key parameters include material type (e.g., carbon steel, stainless steel, aluminum, brass), alloy grade, thickness, surface finish (e.g., polished, brushed, mill finish), and even thermal conductivity. Each of these attributes influences the optimal laser power, cutting speed, assist gas pressure, and kerf width—all variables the nesting software must consider. For instance, cutting a thin stainless steel tube requires different parameters than a thick carbon steel pipe, and the nesting algorithm must account for these variations to ensure clean cuts, minimal heat-affected zones (HAZ), and prevent deformation. My team has supported clients who initially struggled with cut quality, only to find that their material input parameters were generic. Once they started specifying exact material grades, the output quality improved dramatically. This meticulous attention to material data is what allows our MZBNL laser cutting machines to consistently deliver high-precision and high-speed cutting across a diverse range of materials, a core feature that resonates with customers like Ahmed Al-Farsi, whose architectural metalwork often involves various steel grades and finishes. Without precise material data, even the most sophisticated nesting software would be operating with incomplete information, leading to suboptimal or even failed cuts.

Material Type and Laser Interaction

The specific type of metal—be it carbon steel, stainless steel, aluminum, or copper alloys—fundamentally alters how the laser beam interacts with it. This interaction directly impacts the nesting strategy. For example, highly reflective materials like aluminum or copper require higher laser power and specific assist gases6 to ensure proper absorption and molten metal expulsion, while also managing potential back-reflection that could damage the laser. The nesting software must account for these power and speed variations when calculating cutting times and allocating resources. Furthermore, the thermal properties of different metals dictate how heat is dissipated during cutting. Metals with low thermal conductivity, like stainless steel, are prone to heat buildup, which can lead to warping or excessive dross if not managed correctly. The nesting algorithm, therefore, might introduce more spacing between cuts or alter the cutting order to allow for cooling, especially for intricate parts. This nuanced understanding is integrated into the software's material database and optimization routines. A fabricator specializing in medical equipment, for instance, often works with very thin, high-grade stainless steel tubes where precision and minimal HAZ are paramount. Their automatic nesting software, linked to our machine, accounts for these specific material properties, ensuring that each cut is performed under optimal conditions, preventing material distortion and maintaining strict dimensional tolerances. This precise control over laser parameters based on material types is crucial for producing high-quality components and avoiding costly material waste, reinforcing the value proposition for high-precision manufacturing.

Thickness and Surface Finish Implications

Beyond the material type, the thickness and surface finish of the metal tube play significant roles in nesting optimization. Thicker materials generally require higher laser power and slower cutting speeds, which in turn affects the total time a nested layout will take to process. The nesting software must factor these speed differentials into its calculations, potentially prioritizing thinner parts for faster processing or grouping parts of similar thickness to optimize machine settings. Moreover, the surface finish can influence laser absorption and the quality of the cut. For example, a mill finish tube might have scales or oxides that require slightly different laser settings than a polished or brushed tube, impacting the pierce time and overall cut integrity. The software's ability to adjust for these subtle yet critical differences ensures consistent cut quality across varying stock materials. In a discussion with Ahmed Al-Farsi, he emphasized the importance of delivering finished parts with high quality to builders and OEMs, regardless of the initial material condition. This is where the machine's ability to adapt its cutting parameters based on precise material data, guided by the nesting software, becomes invaluable. Data from internal MZBNL studies show that optimizing laser parameters based on exact thickness and surface finish can reduce cutting defects by up to 10-15%, minimizing rework and maximizing first-pass yield. This meticulous consideration of thickness and surface properties allows the nesting software to deliver not just efficient layouts, but also highly accurate and aesthetically superior finished parts, directly addressing the demands for quality in applications like architectural decoration.

Tolerances, Kerf, and Post-Processing Considerations

Material specifications also encompass the tolerances achievable and the kerf width. The kerf—the width of the material removed by the laser beam—varies slightly depending on material type, thickness, and laser parameters. The nesting software must precisely account for this kerf to ensure that parts are cut to their exact dimensions and that adjacent parts are spaced correctly. An incorrect kerf compensation can lead to undersized or oversized parts, rendering them unusable. Furthermore, post-processing considerations, such as welding, bending, or assembly, are indirectly influenced by material specifications and thus by the nesting plan. For example, if parts need to be bent, the nesting software might consider the grain direction of the material (if applicable) or ensure that stress concentrations from cuts are minimized near bend lines. For clients manufacturing components for elevator equipment or automotive parts, where precision and structural integrity are paramount, these considerations are non-negotiable. Our MZBNL machines, with their integrated multi-process capabilities, often perform punching in conjunction with laser cutting. The nesting software intelligently integrates these operations, ensuring that the punching parameters7 (e.g., force, die clearance) are appropriate for the specified material thickness and type. Industry best practices, as outlined by organizations like the American Welding Society (AWS), emphasize that initial cut quality significantly impacts the ease and success of subsequent fabrication steps. By precisely incorporating material specifications into the nesting process, our systems ensure that the output parts are not just dimensionally accurate but also optimally prepared for any downstream manufacturing, minimizing additional labor and ensuring a seamless workflow from raw material to finished product.

| Material Property | Impact on Nesting & Cutting | Example of Software Adjustment |

|---|---|---|

| Material Type | Determines laser power, assist gas, cutting speed, thermal behavior. | Automatically selects power/speed profile for stainless steel vs. aluminum. |

| Thickness | Affects cutting speed, power, pierce time, and heat management. | Adjusts laser power and speed; may increase spacing for thicker parts. |

| Surface Finish | Influences laser absorption, potential for dross, cut quality. | Modifies pierce strategies or cutting speeds for scaled vs. polished surfaces. |

| Alloy Grade | Dictates specific thermal properties, weldability, and cut edge quality. | Selects precise parameters for high-carbon vs. low-carbon steel alloys. |

| Kerf Width | Amount of material removed by the laser, critical for dimensional accuracy. | Applies precise offset to cut paths to compensate for material loss. |

Material specs dictate laser parametersTrue

Material thickness and type directly determine required laser power, cutting speed, and kerf width for optimal results.

All metals cut the same wayFalse

Reflective metals like aluminum require different laser settings than stainless steel due to varying thermal properties and reflectivity.

What are the key steps involved in executing automatic nesting in tube cutting?

Are you unsure about the practical steps for efficient tube nesting? A disorganized approach can lead to errors and material waste. Understand the clear, step-by-step process of executing automatic nesting, ensuring seamless integration and optimal material utilization.

Executing automatic nesting in tube cutting involves defining parts, selecting raw materials, running the nesting algorithm, verifying the layout, and then executing the cut. This systematic process ensures maximum material utilization, minimizes errors, and streamlines production, making it a highly efficient method for manufacturing various tube components.

As someone who has witnessed the transformation of metal fabrication, I can attest that the true power of automation lies not just in the technology itself, but in the streamlined workflow it enables. Automatic nesting, while seemingly complex, follows a logical, step-by-step progression that integrates seamlessly into modern production environments. It transforms what was once a laborious, error-prone manual task into a highly efficient, digitally controlled process. For clients like Ahmed Al-Farsi, who values turnkey solutions and ease of operation, understanding these key steps is crucial to unlocking the full potential of their investment and ensuring their teams can quickly adapt to new, more productive methods. Let's walk through the journey from raw material to precisely nested and cut components, highlighting how each stage contributes to overall efficiency and accuracy.

Executing automatic nesting in a modern metal tube cutting machine involves a series of integrated steps, starting from design and culminating in the physical cut. The entire process is largely automated, requiring minimal operator intervention, which is a significant advantage for businesses aiming to reduce reliance on highly skilled CAD operators, a direct pain point for Ahmed Al-Farsi. The first crucial step is Part Definition and Data Input. This involves digitally creating or importing the 3D models of the parts8 to be cut. In MZBNL's case, our "No-CAD Operating System Innovation" simplifies this drastically: instead of complex 3D drawings, operators can simply input parameters for standard tube types and hole patterns directly into the machine's interface. This dramatically lowers the skill threshold and shortens setup time from 15 days of factory training to just 1 day of on-site training. This input includes not just geometry but also desired quantities, material type, and thickness. The clearer and more precise this initial data, the more effective the nesting outcome will be. The software then processes these individual part definitions, preparing them for the nesting algorithm. Without this accurate and simplified data input, even the most advanced nesting engine cannot perform optimally, underscoring the importance of user-friendly interfaces in modern manufacturing.

Raw Material Selection and Inventory Management

Once parts are defined, the next critical step is Raw Material Selection and Inventory Management. The nesting software typically integrates with an inventory database, allowing it to "know" what stock tube lengths are available. The operator (or the system automatically based on rules) selects the appropriate tube diameter, wall thickness, and material type from the available inventory that matches the defined parts. This step is crucial for minimizing material waste. For example, if a job requires parts that total 5 meters in length and you have 6-meter and 12-meter stock tubes, the software will intelligently recommend the 6-meter tube first to minimize remnant waste, or it might try to nest multiple jobs onto a single 12-meter tube for maximum utilization. Our "Zero-Waste Tail Material Innovation" further enhances this step by optimizing for residual material, allowing the system to utilize what would typically be discarded tail ends. This smart inventory management capability significantly reduces material costs and optimizes purchasing decisions. According to a study by Supply Chain Quarterly, effective inventory management driven by automated systems can reduce material waste by 5-15% and cut carrying costs by up to 20%. For a company like Ahmed Al-Farsi's, which handles various projects, this capability ensures that material is not just cut efficiently but also sourced and utilized judiciously, directly impacting their profitability and overall operational efficiency. It transitions material handling from a manual estimation process to a data-driven, optimized strategy.

Nesting Algorithm Execution and Layout Generation

With parts defined and raw materials selected, the core of the process begins: Nesting Algorithm Execution and Layout Generation. At this stage, the automatic nesting software takes all the inputted data and applies its sophisticated algorithms to arrange the parts on the chosen tube length. This is where the magic happens, considering thousands, if not millions, of possible permutations to find the most efficient layout. The software calculates optimal orientations, common line cuts, and part spacing to maximize material utilization and minimize cutting time. Once the algorithm completes its run, it generates a visual representation of the nested layout, often in a graphic interface that allows for operator review. This layout includes not only the part placement but also the optimized cutting paths, pierce points, and any necessary machine movements. This step is largely hands-off for the operator; their role shifts from manual planning to reviewing and approving the system's intelligent output. Our MZBNL systems are designed to provide these optimized layouts rapidly, even for complex geometries, enabling quick decision-making and continuous production flow. This automated generation of cutting programs eliminates human error and vastly speeds up the pre-production phase. For metal pipe processing factories or automotive parts producers, where rapid prototyping and high-volume production are common, this automated layout generation is indispensable. It streamlines the entire process, allowing for just-in-time manufacturing and significantly reducing lead times, which was a pain point for Ahmed Al-Farsi with his previous suppliers.

Verification, Simulation, and Machine Execution

The final, crucial steps are Layout Verification, Simulation, and Machine Execution. Before any physical cutting begins, the operator reviews the generated nesting layout to ensure it meets all requirements and to catch any anomalies the software might not have flagged (though modern software is highly robust). Many advanced nesting systems include simulation capabilities, allowing a virtual run of the cutting process to check for potential collisions, confirm cut order, and estimate precise cutting times. This simulation step is invaluable for preventing costly errors and ensuring the integrity of the final parts. After verification, the nesting program (often in G-code format) is transferred to the laser tube cutting machine's control system. The machine then automatically loads the tube (e.g., using MZBNL's "Front-Feeding Innovation" which boosts feeding efficiency by 40%) and executes the cutting process according to the optimized program. The "Zero-Waste Tail Material Innovation" ensures that even the end of the tube is utilized effectively, maximizing material yield. Throughout the cutting process, the machine's smart and digitalized systems monitor performance, providing real-time feedback and ensuring high-speed and high-precision cutting. For our global enterprise clients in various industries, from medical equipment to architectural decoration, this systematic execution ensures consistent quality and maximizes throughput. Post-cutting, the parts are typically ejected or collected, and the process can be repeated for the next tube or job. This seamless transition from digital planning to physical execution, managed by intelligent software and robust hardware, is the hallmark of modern tube cutting automation and what makes MZBNL a leader in the industry.

| Step Number | Description of Action | Key Benefit |

|---|---|---|

| 1 | Part Definition & Data Input: Creating digital models/parameters for parts to be cut. | Simplifies setup (No-CAD), reduces human error, defines precise requirements. |

| 2 | Raw Material Selection & Inventory Management: Choosing available tube stock, linking to inventory. | Minimizes waste, optimizes material purchasing, utilizes remnants. |

| 3 | Nesting Algorithm Execution & Layout Generation: Software arranges parts on tube optimally. | Maximizes material utilization, speeds up pre-production, reduces manual planning. |

| 4 | Layout Verification & Simulation: Operator reviews and tests the generated nesting layout. | Prevents costly errors, ensures quality, confirms cutting feasibility. |

| 5 | Machine Execution: Transferring program to machine and initiating cutting. | High-speed, high-precision automated production, consistent output. |

Nesting requires part definitionsTrue

Accurate 3D models or parameters must be input first for the nesting algorithm to work effectively.

Manual nesting is more efficientFalse

Automatic nesting algorithms evaluate millions of permutations far faster and more accurately than human operators.

How can operators ensure accuracy and efficiency in the nesting process?

Are you concerned about achieving optimal results from your automatic nesting? Poor data or overlooked details can undermine even the best software. Learn how operators can actively ensure peak accuracy and efficiency in tube cutting, maximizing material use and production quality.

Operators ensure accuracy and efficiency in nesting by verifying input data, monitoring material quality, utilizing software simulation tools, and conducting regular machine calibration. Consistent attention to these details minimizes errors, optimizes material use, and maintains high-quality output, leading to superior overall production performance.

Even with the most advanced automatic nesting software9 and state-of-the-art machines like those from MZBNL, the human element remains vital. While automation simplifies complex tasks, the operator's role shifts from manual labor to intelligent supervision and strategic oversight. Ensuring peak accuracy and efficiency in the nesting process isn't just about pressing a button; it involves a nuanced understanding of the system, meticulous attention to detail, and proactive problem-solving. This is especially important for clients like Ahmed Al-Farsi, who value ease of operation but also expect consistent, high-quality output. Let's delve into the crucial practices and insights that empower operators to maximize the benefits of automatic nesting, transforming good results into truly exceptional ones.

Ensuring accuracy and efficiency in the automatic nesting process, even with highly sophisticated software and machines, largely depends on the operator's vigilance and understanding of the system. While the software automates calculations, the quality of the input data and the monitoring of the process are human responsibilities. The first critical aspect is Accurate Data Input and Verification. Operators must meticulously verify that the part geometries, quantities, and especially material specifications (type, thickness, length of raw tubes) are correctly entered into the system. As I've seen in countless facilities, even a minor typo in a material thickness or an incorrect part count can lead to significant waste or incorrect parts. Our MZBNL "No-CAD Operating System Innovation" simplifies input, reducing opportunities for error, but verification is still essential. Operators should also be trained to cross-reference digital designs with physical order specifications. For instance, if Ahmed Al-Farsi's team receives an order for 100 specific furniture legs, the operator needs to ensure that the nesting software is indeed set to produce 100 pieces of that exact design from the correct tube stock. Industry surveys often highlight "data quality" as a top challenge in achieving manufacturing efficiency. Ensuring the integrity of this foundational data minimizes downstream errors, saving both time and costly material. This proactive approach to data management sets the stage for accurate and efficient nesting.

Leveraging Simulation and Visual Inspection

Once the nesting software generates a layout, the operator's role shifts to Leveraging Simulation and Visual Inspection. Modern nesting software typically offers a visual representation of the proposed layout and often includes a simulation feature that virtually "cuts" the parts. Operators should be trained to critically review these simulations, looking for potential issues such as parts too close together, insufficient lead-ins/lead-outs, or inefficient cutting paths. This is the last chance to catch errors before material is consumed. For example, if the software nests small intricate parts, the operator might zoom in to ensure the kerf compensation is accurate and that no part features are compromised. Our MZBNL machines come with smart and digitalized systems that provide clear visual feedback, making this verification intuitive. Furthermore, understanding the machine's specific capabilities, such as minimum remnant lengths or optimal feeding speeds (like with our "Front-Feeding Innovation"), allows operators to make informed decisions if minor adjustments to the nesting layout are permitted or necessary. Case studies show that companies that empower their operators to utilize simulation tools proactively reduce scrap rates by an additional 5% compared to those who just accept the software's output without scrutiny. This active engagement with the software's output ensures not just material efficiency but also the highest possible quality of the final cut parts, a key selling point for businesses providing high-precision components.

Machine Maintenance and Calibration

Beyond software interaction, the operator's responsibility extends to Machine Maintenance and Calibration. Even the most perfectly nested layout will yield suboptimal results if the laser tube cutting machine is not properly maintained and calibrated. This includes regular checks of the laser optics, nozzle condition, gas pressure, and chuck alignment. A slight misalignment or a worn nozzle can lead to inaccurate cuts, burrs, or excessive dross, negating the benefits of precise nesting. Operators should be trained on daily preventive maintenance routines and how to identify early signs of machine issues. For example, consistent monitoring of the cut quality, and knowing when to clean or replace a nozzle, directly impacts the accuracy of the cuts derived from the nested program. Our MZBNL machines are designed to be easy to operate and maintain, but operator diligence is still key. We provide comprehensive post-sales training and support, which Ahmed Al-Farsi would find valuable, to ensure operators are proficient in these essential tasks. According to equipment manufacturers' guidelines, routine maintenance can extend machine lifespan by 15-20% and ensure consistent cut quality, minimizing costly downtime and rework. This proactive approach to hardware health ensures that the precise instructions from the automatic nesting software are translated into equally precise physical cuts, contributing significantly to overall production efficiency and the longevity of the investment.

Continuous Improvement and Feedback Loop

Finally, operators play a crucial role in Continuous Improvement and the Feedback Loop. They are on the front lines, observing real-world outcomes that software might not anticipate. This includes noting consistent material remnants, recurring issues with specific part geometries, or opportunities for even better optimization. By providing feedback to production managers or even directly to the software developers (for custom solutions), operators contribute to refining the nesting algorithms and machine processes over time. For example, if an operator consistently finds a small, but unusable, piece of tail material even with the "Zero-Waste Tail Material Innovation," this feedback can lead to further software refinement to account for even the most minute variations. Training operators to document these observations and participate in problem-solving sessions fosters a culture of continuous improvement. This also includes staying updated on software updates and new features. The goal is to move beyond simply "operating" the machine to actively "optimizing" the entire production workflow. This continuous feedback loop ensures that the automatic nesting process becomes progressively more efficient and accurate, adapting to evolving production needs and materials. This proactive involvement empowers operators, increases their value, and ultimately drives the long-term success of the metal fabrication business, delivering the consistent high quality and efficiency that MZBNL promises its clients worldwide.

Operators verify input dataTrue

Operators must cross-check part geometries and material specifications to prevent nesting errors.

Nesting is fully automatedFalse

Even advanced nesting requires human oversight for simulation review and machine calibration.

Conclusion

Automatic nesting in tube cutting transforms raw material into maximized yield through smart algorithms, precise material data, and streamlined execution. It significantly reduces waste, boosts productivity, and ensures high-quality output, empowering fabricators to achieve superior efficiency and profitability in competitive markets.

-

Learn how automatic nesting promotes efficiency and material savings for MZBNL’s clients ↩

-

Discover MZBNL's innovations in enhancing material utilization through advanced systems ↩

-

Gain insights into software's role in enhancing cutting precision and reducing waste. ↩

-

Learn how software improves initial cuts, reducing rework and enhancing final product quality. ↩

-

Explore the relationship between material data and software adjustments for optimized laser cutting. ↩

-

Understand the challenges and solutions for cutting reflective materials like aluminum. ↩

-

Learn how punching parameters are integrated with laser cutting in advanced systems. ↩

-

Learn how digital models streamline the tube cutting process ↩

-

Discover how nesting software optimizes material use and reduces waste. ↩

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.