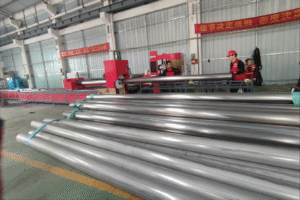

Analyzing the Current Production Processes Using Traditional Cutting Techniques

Your factory floor is busy, but are your cutting methods costing you more than you think? It's a hidden drag on efficiency that quietly eats into profits every single day.

Yes, traditional cutting techniques are increasingly holding back modern production. Methods like sawing and manual plasma cutting create bottlenecks due to high labor dependency, significant material waste, and slow operational speeds, making it difficult for manufacturers to remain competitive in a high-demand, precision-focused market.

Machine Laser tube cutting machine processing a metal pipe with precision, emitting bright sparks during operation.](https://mzbnl.com/wp-content/uploads/2025/08/advanced-laser-tube-cutting-machine-5.webp)

Over the years, I've walked through hundreds of production facilities, from automotive parts suppliers to furniture makers. I’ve seen firsthand how reliance on outdated cutting processes can cap a company's growth potential. The challenges are universal, but the solutions are more accessible than ever. Let's break down the current state of traditional cutting and explore a more efficient path forward.

What are the traditional cutting techniques used in current production processes?

Struggling with inconsistent cuts and slow turnarounds? These issues often stem from the very tools you use. Let's identify the common culprits in today's workshops.

The most common traditional cutting techniques are abrasive sawing, band sawing, and manual plasma cutting. These methods rely on mechanical friction or thermal energy to sever metal, forming the foundation of metal fabrication for decades but now showing their age in modern, fast-paced environments.

Close-up of a laser cutting machine precisely cutting metal sheet](https://mzbnl.com/wp-content/uploads/2025/08/precision-laser-cutting-machine.webp)

When I talk about traditional cutting, I'm referring to a set of established, often manually-intensive methods that have been the workhorses of the industry for a long time. It's crucial to understand what they are and how they function to see where the inefficiencies lie.

Abrasive and Band Sawing

This is perhaps the most familiar method. Whether it's a chop saw with an abrasive disc or a large band saw, the principle is the same: a blade with hardened teeth or an abrasive edge physically grinds its way through the metal. It's a straightforward process, but it's also slow, noisy, and generates a lot of heat and burrs. The blades wear out, requiring constant replacement, and the final cut often needs significant secondary processing, like deburring, to be usable.

Manual Plasma and Torch Cutting

For thicker materials or less precise cuts, manual plasma or oxy-fuel torches are common. These use a high-temperature jet to melt and blow away the metal. While faster than sawing for certain applications, they are heavily dependent on the operator's skill. A steady hand is required to follow a line, and the results can be rough, with a large heat-affected zone[^1] that can alter the metal's properties. This method is simply not suitable for the high-precision needs of industries like medical equipment or modern architectural design.

How are these traditional cutting techniques currently being implemented?

Does your production flow feel disjointed and slow? The problem often lies in the multi-step, labor-intensive implementation of traditional cutting, which creates countless opportunities for delays and errors.

Traditional cutting is implemented through a sequence of manual steps: interpreting a drawing, measuring and marking the workpiece, setting up the machine, performing the cut, and then moving the piece to another station for secondary finishing like deburring. This entire workflow hinges on operator skill.

The day-to-day reality of using these traditional methods is a complex dance of manual labor and fragmented processes. I remember visiting a display rack manufacturer where a single project required a dedicated team just for measuring, marking, and cutting tubes. The workflow looked something like this:

- Design to Paper: An engineer creates a CAD drawing, which is then printed out. This drawing becomes the blueprint for the operator on the floor.

- Manual Measurement: The operator takes a raw tube, uses a tape measure and marker to manually transfer the dimensions from the drawing onto the material. This step is slow and highly prone to human error.

- Machine Setup: The operator then secures the tube in the saw or cutting station, carefully aligning it with the blade. Each new cut length or angle requires a complete reset.

- The Cut: The operator manually guides the machine to perform the cut, a process that requires focus and physical effort.

- Post-Processing: The cut piece is rarely ready for the next stage. It typically has rough edges (burrs) that must be ground down by hand at a separate station before it can be welded or assembled.

This entire sequence is a classic example of a process with too many touchpoints, each one a potential source of delay, error, and cost.

What challenges do traditional cutting techniques face in modern production environments?

Are rising material costs and a shortage of skilled workers impacting your bottom line? These modern pressures expose the fundamental flaws of traditional cutting, turning them from tools into liabilities.

The primary challenges are staggering material waste from inefficient cuts and tail material, low productivity due to slow, multi-step processes, and a critical dependency on a shrinking pool of skilled, experienced operators. These factors make it nearly impossible to scale production flexibly and cost-effectively.

Close-up of high-tech laser cutting machine processing metal tube with precision](https://mzbnl.com/wp-content/uploads/2025/08/innovative-laser-tube-cutting-machine-1.webp)

In today's competitive market, efficiency isn't a luxury; it's a requirement for survival. Manufacturers in the automotive, furniture, and architectural sectors are being squeezed by demands for higher quality, faster delivery, and lower prices. Traditional cutting methods are fundamentally at odds with these demands.

Crippling Labor Dependency

The biggest challenge I see is the reliance on skilled labor. Finding an operator who can read complex drawings, accurately measure, and execute a clean cut is becoming harder and more expensive. Training new staff is a long and costly process, often taking weeks or months before they are fully productive. This "skill barrier" creates a major bottleneck and puts businesses at risk if a key employee leaves.

Unacceptable Material Waste

Material costs are always rising. Yet, traditional methods are inherently wasteful. Saws create kerf[^2] (the material lost to the blade's width), but the biggest issue is tail material. Because of how tubes are clamped, there's always an unusable piece left at the end of every stock length. Over thousands of tubes, this waste adds up to a significant financial loss. It's like throwing money directly into the scrap bin.

A Lack of Agility

Modern manufacturing is all about customization and small-batch production. Traditional cutting struggles here. The long setup time for each new design makes it unprofitable to produce small quantities. This lack of agility prevents businesses from taking on lucrative custom jobs or quickly adapting to changes in market demand.

What strategies can be employed to overcome the limitations of traditional cutting methods?

Tired of fighting the same production battles every day? Overcoming these limitations requires more than just working harder; it demands a smarter, more strategic approach to your entire production workflow.

Strategies range from implementing lean manufacturing principles to reduce handling time and optimizing operator training for better efficiency. However, the most effective long-term strategy is to embrace automation, which directly tackles the core issues of manual labor, waste, and slow setup times.

Technology High-tech laser tube cutting machine processing metal pipe with precision and sparks](https://mzbnl.com/wp-content/uploads/2025/08/advanced-laser-tube-cutting-technology-3.webp)

Improving your cutting process is a journey, not a single leap. There are immediate steps you can take, but true transformation comes from rethinking the technology at the heart of your operation.

| Strategy Type | Traditional Approach | Optimized Strategy |

|---|---|---|

| Workflow | Multi-station process (measure, cut, deburr) | Integrated single-step processing |

| Labor | High reliance on skilled manual operators | Simplified, system-driven operation |

| Material Use | High scrap rate and tail material waste | Maximized material utilization |

| Setup | Long, manual setup for each new job | Instant, parameter-based digital setup |

Initially, you can focus on operational excellence. This means mapping out your current process, identifying wasted movement, and training your team on best practices to minimize errors and setup times. These are valuable improvements. But to truly get ahead, you have to look at the technology itself. The goal should be to move towards a system where the machine does the complex work, freeing your team to focus on higher-value tasks. This is where investing in advanced, automated solutions becomes not just an option, but a strategic necessity for long-term growth and profitability.

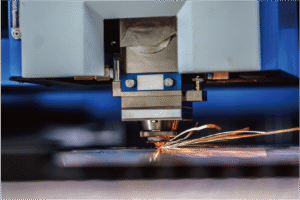

How can advanced technologies improve upon traditional cutting techniques?

What if you could eliminate drawing interpretation, automate material handling, and reduce waste to zero? This isn't a future fantasy; it's what advanced technology makes possible for your production floor today.

Advanced laser tube cutting technology revolutionizes production by integrating multiple steps into one automated process. It delivers unmatched speed and precision, eliminates human error, and introduces innovations that directly solve the core problems of labor dependency, material waste, and inefficiency.

High-tech laser cutting machine slicing metal tube with precision sparks](https://mzbnl.com/wp-content/uploads/2025/08/advanced-laser-cutting-machine-6.webp)

This is where I get truly excited, because at MZBNL, we've spent years developing solutions engineered specifically to solve the challenges I've just outlined. We saw the waste, the labor struggles, and the inefficiencies, and we built technology to eliminate them.

The No-CAD Revolution

The biggest hurdle for many is the complexity of going from a design to a finished part. Our No-CAD System completely removes this barrier. Instead of requiring a skilled operator to interpret a 3D drawing, anyone can simply input the desired parameters—length, hole position, angle—directly into the machine's interface. This innovation reduces on-site training from 15 days to just one day. It democratizes the cutting process, making your operation more resilient and flexible.

The Efficiency of Front-Feeding

Material handling is another major time sink. Traditional side-loading systems are slow and physically demanding. Our patented Front-Feeding Mechanism is an automated front-loading system that increases feeding efficiency by approximately 40%. More importantly, it reduces the operator's labor intensity by a similar margin, creating a safer and more productive work environment.

The Promise of Zero-Waste

I mentioned the costly problem of tail material waste. We solved it. By redesigning the machine's logic, our Zero-Waste Tail Material innovation allows the cutting to start from the rear chuck. This simple but brilliant change means the entire length of the tube can be used, eliminating the unusable tail piece. This maximizes material utilization and provides a direct, measurable boost to your bottom line.

Conclusion

Analyzing traditional cutting processes reveals critical weaknesses in efficiency, cost, and agility. Embracing advanced, automated laser cutting technology is no longer just an upgrade—it's a foundational business strategy for any manufacturer looking to thrive in the modern industrial landscape by reducing waste and boosting productivity.

Have Questions or Need More Information?

Get in touch with us for personalized assistance and expert advice.